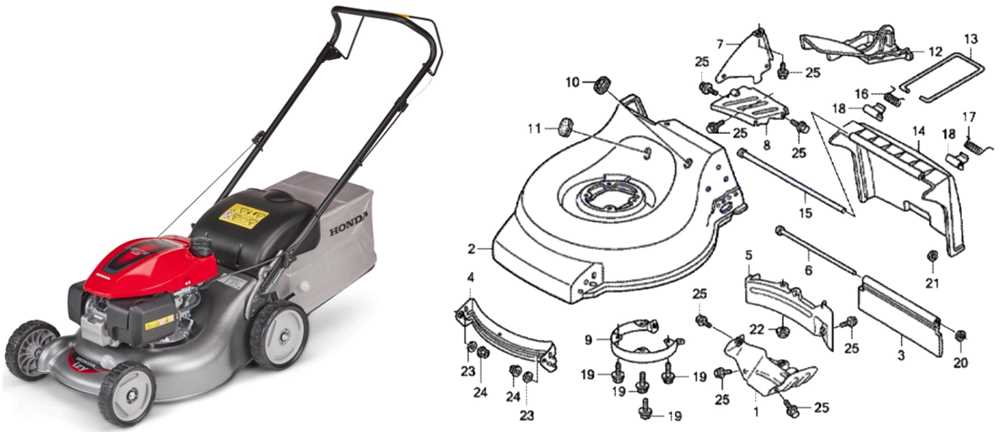

Comprehensive Guide to Honda Izy Parts Diagram

The exploration of assembly layouts is essential for anyone seeking to enhance their knowledge of machinery maintenance and repair. This section provides a comprehensive overview of the components involved in a particular model, allowing users to grasp the intricacies of its construction and functionality.

By delving into the arrangement of various elements, individuals can gain valuable insights into how each part interacts with one another. This understanding not only aids in troubleshooting issues but also facilitates more efficient servicing and upgrades. A clear illustration of these components is invaluable for both novice users and seasoned technicians alike.

Familiarity with the configuration of key elements can significantly improve the overall experience of operating and maintaining the equipment. Whether you are looking to replace a worn component or simply wish to enhance your expertise, a thorough comprehension of the assembly structure will prove beneficial in achieving your goals.

This section provides an overview of the critical elements that contribute to the overall functionality and efficiency of this equipment. Understanding these components is essential for maintenance and performance enhancement, ensuring that the machine operates smoothly and effectively.

Below is a table that outlines the key elements along with their respective functions:

| Component | Description |

|---|---|

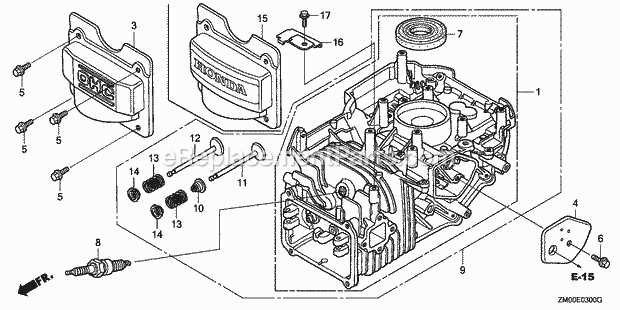

| Engine | The powerhouse responsible for generating the necessary energy for operation. |

| Blade | Sharp tool designed to cut through grass efficiently, providing a clean finish. |

| Chassis | The frame that supports the entire structure, ensuring stability during use. |

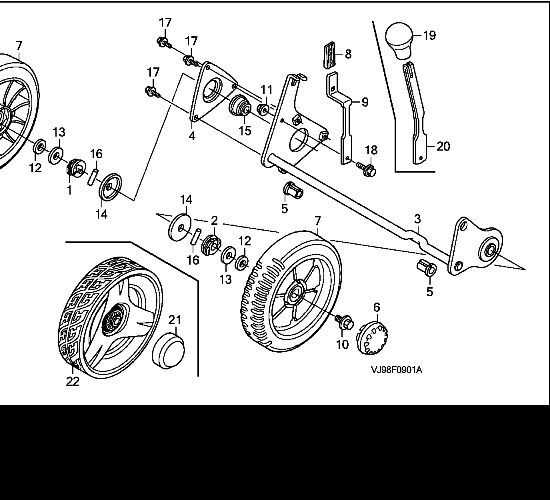

| Wheels | Components that enable mobility, allowing the equipment to traverse various terrains. |

| Handle | A control mechanism that allows the user to steer and guide the machine effectively. |

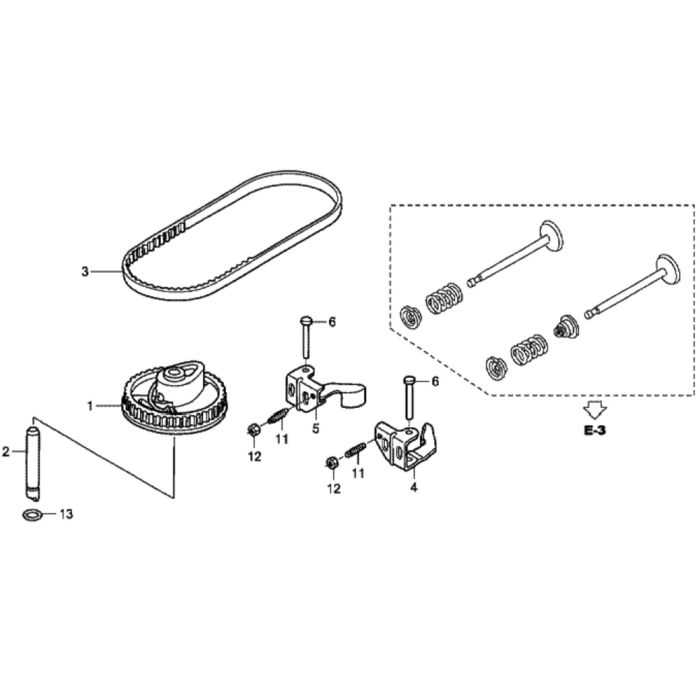

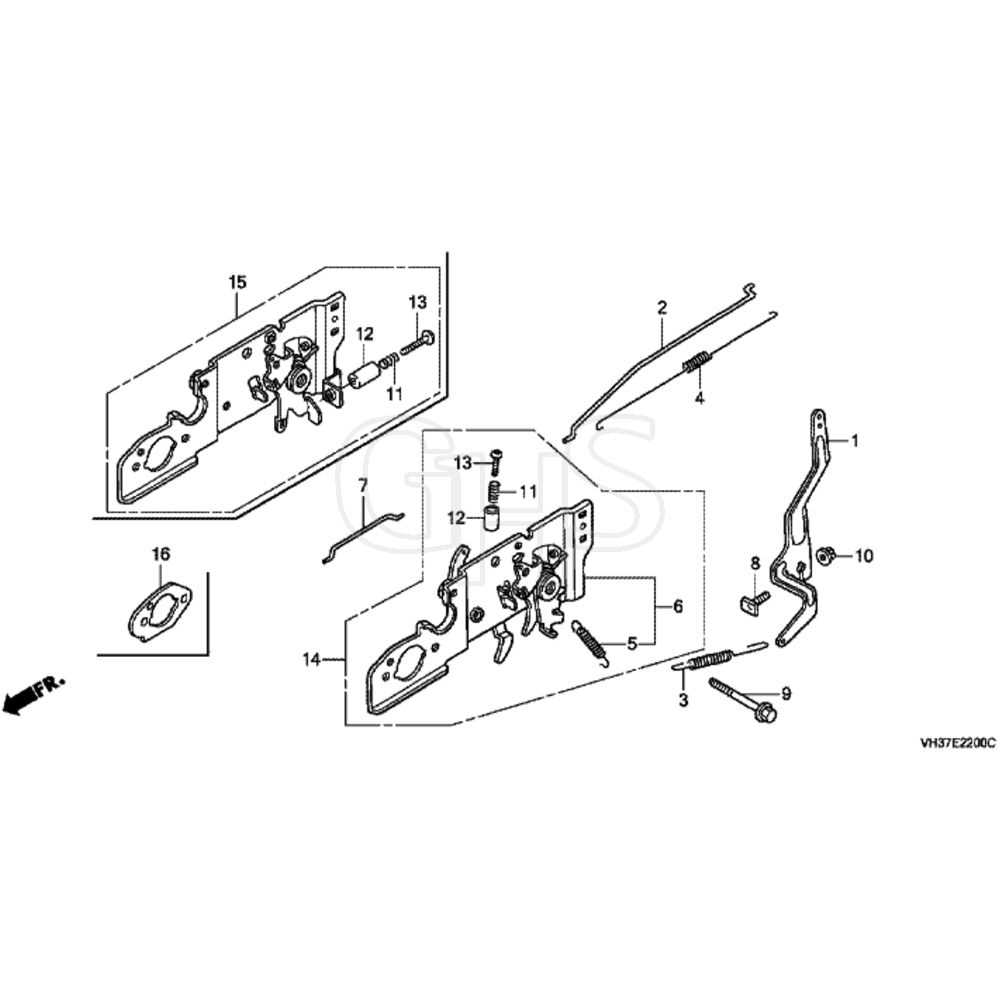

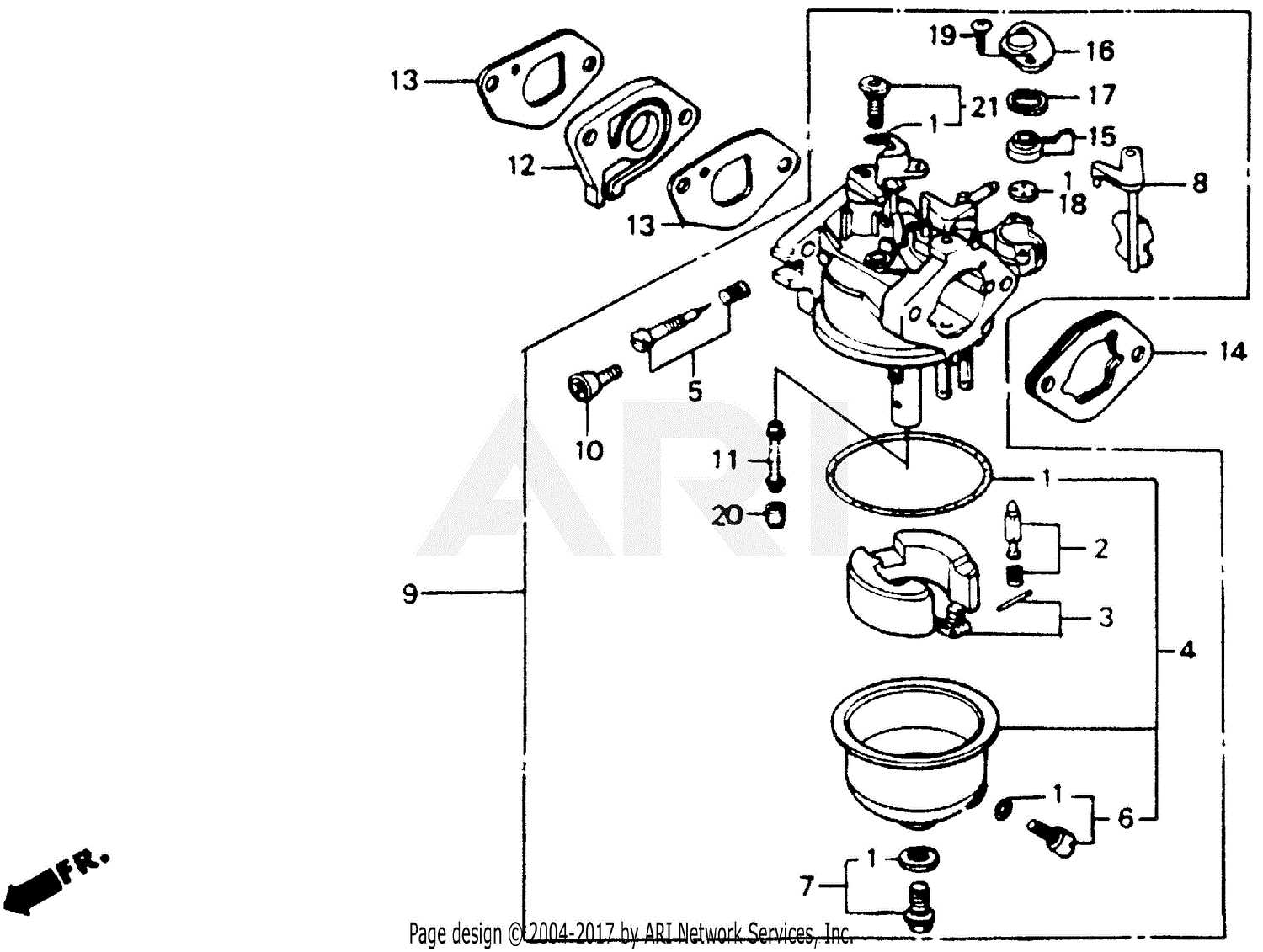

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations provide valuable insights into the components of a machine and their interconnections. By familiarizing yourself with these images, you can enhance your comprehension of assembly and disassembly processes.

When approaching these illustrations, consider the following steps:

- Identify the Key Elements: Look for labels and legends that explain various symbols and parts shown in the illustration.

- Examine the Layout: Observe how the elements are arranged, noting any groups or clusters that indicate related components.

- Follow the Connections: Trace the lines or arrows that demonstrate how different parts interact with each other, providing a clearer picture of the assembly.

- Refer to the Index: Use any accompanying documentation that outlines the specific components referenced in the visual to ensure you understand each part’s function.

Additionally, practicing with multiple representations will improve your ability to interpret these visuals quickly and accurately. Over time, you will develop a systematic approach that will make repairs and maintenance tasks more efficient.

Common Issues with Honda Izy Parts

When it comes to maintaining a specific brand of lawn equipment, various complications can arise. Understanding these frequent challenges can help users better prepare for troubleshooting and repairs, ensuring a smoother operation and longevity of the device. Below are some of the most commonly encountered difficulties.

Frequent Malfunctions

Users often report several recurring malfunctions that hinder performance. These issues can stem from wear and tear or inadequate maintenance practices.

| Issue | Description | Possible Solution |

|---|---|---|

| Engine Starting Problems | Difficulty in starting the engine can be caused by a clogged fuel filter or old fuel. | Check and replace the fuel filter; use fresh fuel. |

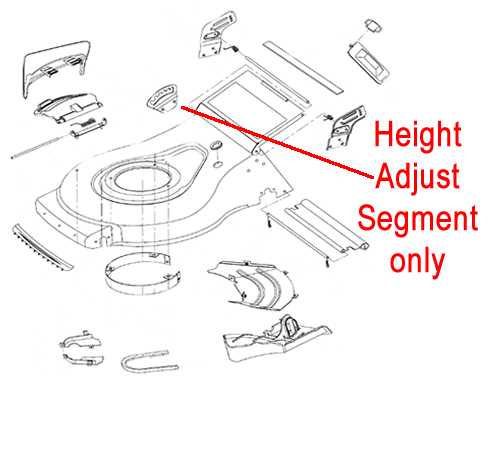

| Uneven Cutting | This can occur due to dull blades or incorrect height settings. | Sharpen the blades and adjust cutting height as needed. |

| Excessive Vibration | Vibration issues may arise from loose components or misaligned parts. | Tighten screws and ensure all parts are properly aligned. |

Preventative Measures

To minimize the likelihood of experiencing these issues, users should adhere to regular maintenance schedules. This includes checking components for wear, cleaning air filters, and ensuring all connections are secure.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires consistent upkeep and attention to detail. Implementing effective maintenance practices can significantly enhance functionality and prevent potential issues down the road.

Regular Inspections

- Conduct routine checks for any signs of wear or damage.

- Examine all moving parts for proper alignment and functionality.

- Assess fluid levels and replace as necessary to maintain optimal performance.

Cleaning and Care

- Keep surfaces free of debris to avoid blockages and overheating.

- Utilize appropriate cleaning agents that do not harm the materials.

- Lubricate mechanical components regularly to ensure smooth operation.

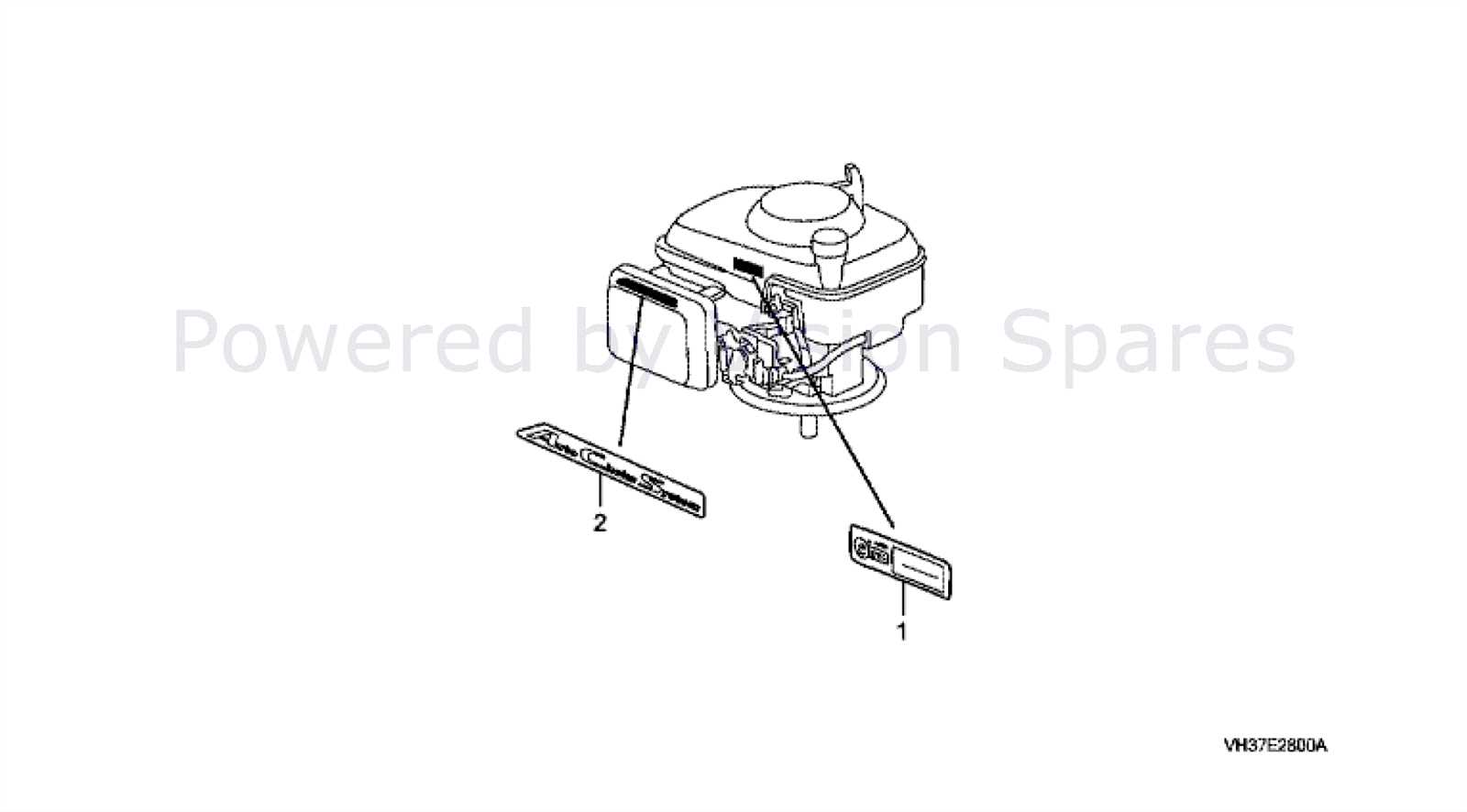

Identifying Genuine Honda Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of machinery. Genuine components are designed specifically for each model, providing reliability and a perfect fit. Understanding how to differentiate authentic items from imitations can save time and money while enhancing overall user satisfaction.

Key Characteristics of Authentic Components

Recognizing genuine items involves examining several features that distinguish them from counterfeit alternatives. Below are some notable characteristics to consider:

| Feature | Description |

|---|---|

| Quality Markings | Authentic items typically bear specific quality marks or logos that indicate their origin. |

| Packaging | Original components are usually packaged in branded, tamper-proof packaging that includes relevant product information. |

| Warranty Information | Genuine items come with a warranty that protects against defects and offers peace of mind. |

| Part Numbers | Each component has a unique part number that can be verified through authorized dealers or manufacturers. |

How to Verify Authenticity

To confirm the authenticity of components, one can take the following steps:

- Check for serial numbers or barcodes.

- Consult authorized retailers or the manufacturer’s website for verification.

- Compare pricing with standard market values to identify potential red flags.

Aftermarket vs. Original Parts

When it comes to maintaining and repairing equipment, the choice between alternative and genuine components is a crucial consideration. Each type offers distinct advantages and potential drawbacks that can significantly impact performance, longevity, and cost-effectiveness. Understanding these differences helps users make informed decisions tailored to their needs.

Original components are crafted by the manufacturer, ensuring compatibility and adherence to specified quality standards. They are often perceived as a safer choice, providing assurance in terms of fit and performance. Conversely, alternative components are typically produced by third-party companies and may offer a more affordable solution. However, their quality can vary widely, and compatibility may not always be guaranteed.

| Aspect | Original Components | Alternative Components |

|---|---|---|

| Quality | Generally higher; made to manufacturer’s specifications | Varies; not all meet the same standards |

| Price | Often more expensive | Typically more affordable |

| Availability | Usually readily available from authorized dealers | Can be found at various retailers and online |

| Warranty | Usually comes with a warranty from the manufacturer | Warranties vary; may not be as comprehensive |

Ultimately, the decision between alternative and genuine components depends on individual priorities, including budget constraints, performance expectations, and personal preferences. Careful consideration of these factors can lead to a more satisfying ownership experience.

Tools Required for Repairs

When undertaking maintenance or fixing tasks, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-prepared toolkit can significantly simplify the process, allowing for smoother repairs and ultimately leading to better outcomes.

Essential Instruments

- Wrenches: Necessary for loosening and tightening various components.

- Screwdrivers: Required for handling screws of different sizes and types.

- Pliers: Useful for gripping and bending materials as needed.

- Socket set: Ideal for accessing hard-to-reach fasteners.

- Measuring tape: Important for ensuring precise dimensions during assembly.

Safety Equipment

- Gloves: Protect hands from sharp edges and hazardous materials.

- Goggles: Safeguard eyes from debris and harmful substances.

- Ear protection: Essential when working in noisy environments to prevent hearing damage.

Having these tools at your disposal not only enhances the repair experience but also contributes to safety and quality of work.

Step-by-Step Repair Guide

This guide provides a systematic approach to address common issues, ensuring efficient troubleshooting and maintenance. Following these steps will help you diagnose and rectify problems effectively, extending the lifespan of your equipment.

Before starting the repair process, gather all necessary tools and materials. A well-organized workspace will facilitate a smoother operation. Here’s a brief overview of the essential steps involved:

| Step | Description |

|---|---|

| 1 | Identify the issue by conducting a thorough inspection of the equipment. |

| 2 | Gather the required tools and spare parts for the repair. |

| 3 | Disassemble components as needed, taking care to remember the order of removal. |

| 4 | Replace any faulty components, ensuring compatibility with the remaining parts. |

| 5 | Reassemble the unit, following the reverse order of disassembly. |

| 6 | Test the equipment to confirm that it functions correctly after repairs. |

By adhering to this structured method, you can tackle repairs confidently, ensuring optimal performance and reliability.

Ordering Parts Online: A Guide

In today’s digital era, acquiring components for maintenance or repair tasks has become remarkably straightforward. The online marketplace offers a vast selection of items, making it easier for users to find what they need without the hassle of visiting physical stores. This guide aims to provide essential insights for navigating the process of ordering components through online platforms.

1. Identifying the Correct Components: Before placing an order, it is crucial to determine the exact items required for your equipment. Utilize model specifications or references to ensure compatibility and avoid any potential issues during installation.

2. Choosing Reputable Retailers: Opt for established online vendors known for their reliability and quality. Look for reviews and ratings from previous customers to gauge the credibility of the seller.

3. Comparing Prices: With numerous online options, take the time to compare prices across various platforms. This step can help you secure the best deal while ensuring the quality of the components.

4. Understanding Shipping Policies: Familiarize yourself with the shipping policies of the chosen retailer. Pay attention to delivery times, shipping costs, and return policies to avoid unexpected surprises.

5. Securing Payment Information: When finalizing your purchase, ensure that the website has secure payment options. Look for indicators such as HTTPS in the URL and trusted payment gateways to protect your financial information.

By following these steps, you can enhance your online shopping experience and ensure that you obtain the right items efficiently.

Warranty Information and Support

This section provides essential details regarding the guarantees and assistance available for your equipment. Understanding the terms and conditions associated with coverage ensures you can take full advantage of the benefits offered. If you encounter any issues, it’s important to know how to access support services effectively.

Customers are encouraged to review the warranty policy to familiarize themselves with the scope of protection provided. Typical coverage includes repairs and replacements for manufacturing defects under normal usage conditions. Here are some key points to keep in mind:

| Warranty Period | Coverage Details | Contact Information |

|---|---|---|

| 1 Year | Defects in materials and workmanship | Customer Service: 1-800-555-0199 |

| 2 Years | Specific components as listed | Email: [email protected] |

| Lifetime | Frame and certain key elements | Website: www.example.com/support |

For additional assistance, reach out to the customer support team, who can provide guidance on warranty claims and general inquiries. Ensure that you have your purchase receipt and product details handy to facilitate the process.

Frequently Asked Questions

This section aims to address common inquiries related to the components and assembly of lawn care equipment. By providing clear answers, we hope to enhance your understanding and assist in maintaining optimal performance.

General Queries

Here are some typical questions and their corresponding answers:

| Question | Answer |

|---|---|

| What should I do if a part breaks? | Inspect the component and consult the manual for replacement options. |

| How can I identify the correct component for my model? | Refer to the specifications and comparison charts available in the product documentation. |

Maintenance Tips

Maintaining your equipment is crucial for longevity. Here are a few tips:

| Tip | Details |

|---|---|

| Regular Cleaning | Keep the machine clean to prevent debris buildup that can affect performance. |

| Periodic Inspections | Check all components periodically for wear and tear to ensure efficient operation. |