Kubota SVL 75-2 Parts Diagram Guide

When it comes to operating heavy machinery, having a clear understanding of its internal structure is essential for effective maintenance and troubleshooting. This section delves into the intricate arrangement of various elements within these powerful machines, enabling operators and technicians to enhance their knowledge and efficiency.

By examining the arrangement of components, users can gain valuable insights into the functionality of each part, ensuring optimal performance and longevity. A well-organized schematic serves as a vital tool for identifying specific elements, facilitating timely repairs and replacements.

Furthermore, mastering the layout of these crucial components not only aids in routine upkeep but also empowers users to tackle unexpected issues with confidence. Emphasizing the significance of familiarization with this detailed overview can lead to improved operational reliability and reduced downtime.

Kubota SVL 75-2 Overview

This section provides a comprehensive look at a compact track loader designed for versatility and efficiency in various applications. Known for its robust performance, it caters to both professionals and enthusiasts in the construction and agricultural sectors.

- Powerful engine ensuring high productivity.

- Compact design allowing access to tight spaces.

- Advanced hydraulic system for smooth operation.

With a focus on user comfort and operational ease, this machine incorporates several features that enhance its functionality:

- Spacious cab design for operator comfort.

- Intuitive controls for enhanced maneuverability.

- Durable tracks providing superior traction.

This machine stands out as an ultimate choice for those seeking reliability and performance in challenging environments.

Importance of Parts Diagrams

Understanding the layout of machinery components is crucial for effective maintenance and repairs. These visual representations serve as essential tools for technicians and enthusiasts, providing clarity on the arrangement and function of various elements. By referring to these illustrations, users can streamline their work processes and enhance their overall efficiency.

Enhanced Clarity

Visual aids simplify complex structures, allowing for quicker identification of parts. This clarity reduces the likelihood of errors during assembly or disassembly, ultimately saving time and resources.

Guided Maintenance

With detailed visuals, users can delve into specific areas that require attention. This targeted approach ensures that maintenance is thorough, addressing potential issues before they escalate into major problems. The ultimate goal is to prolong the lifespan of the equipment and improve performance.

Key Components of Kubota SVL 75-2

This section highlights the essential elements of a compact track loader designed for efficiency and versatility in various applications. Understanding these components is crucial for maintenance and optimal performance, ensuring that the machine operates smoothly under different conditions.

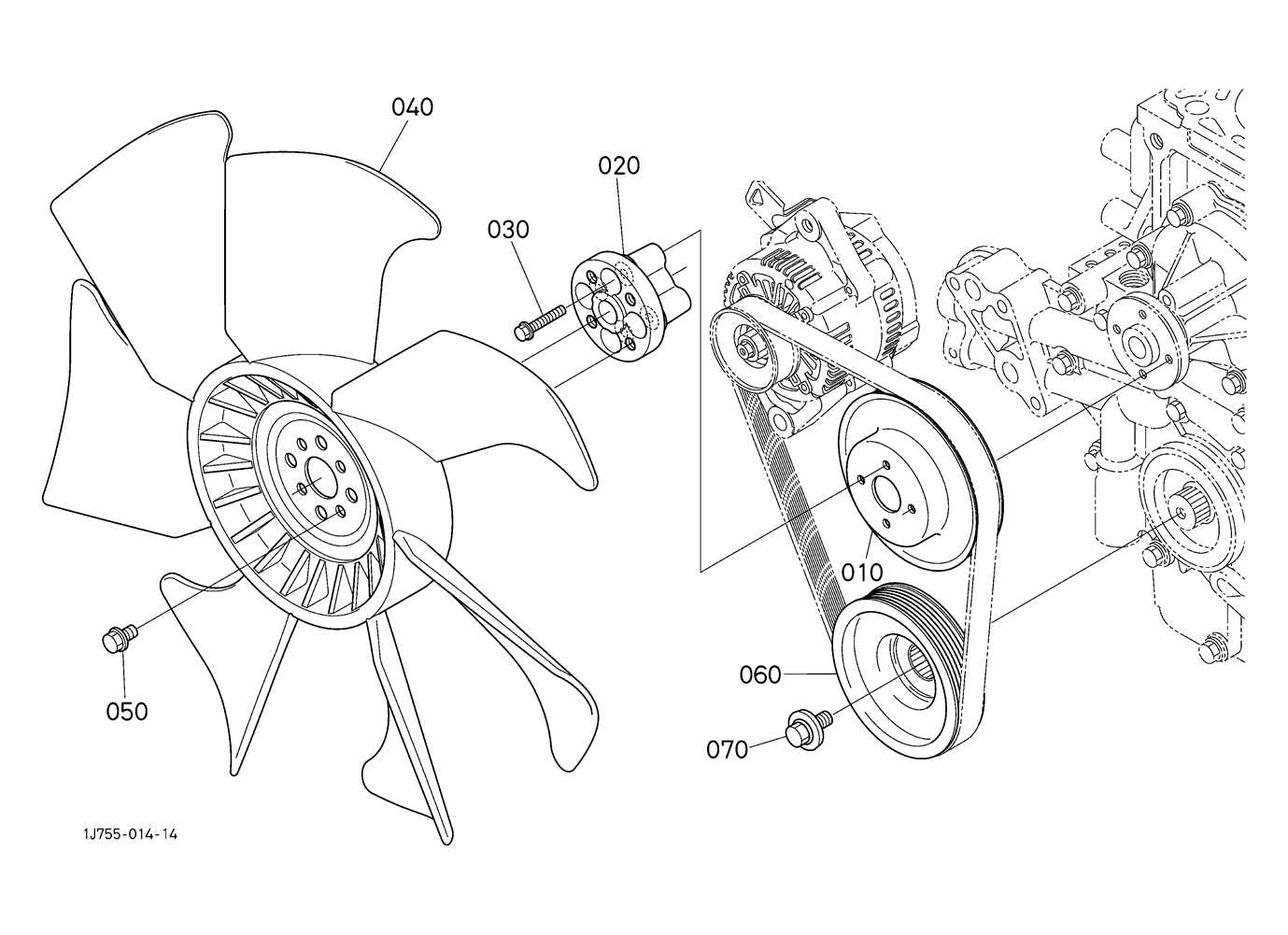

The engine serves as the powerhouse, providing the necessary torque and horsepower to handle demanding tasks. This unit is typically equipped with advanced technology to enhance fuel efficiency and reduce emissions.

The hydraulic system is vital for powering attachments and enabling smooth operation of the loader’s arms. Its design ensures precision and responsiveness, allowing for seamless execution of various functions.

The undercarriage is another significant feature, offering stability and traction on uneven terrain. It usually comprises robust tracks and rollers that facilitate maneuverability and weight distribution.

In addition, the operator’s cab is designed with ergonomics in mind, featuring controls that are easily accessible and provide comfort during prolonged use. Visibility is optimized to enhance safety and efficiency while working.

Finally, the attachment system enables users to switch between different tools quickly, making the loader adaptable for multiple tasks, from grading to excavation. This versatility is a key reason for its popularity in construction and landscaping projects.

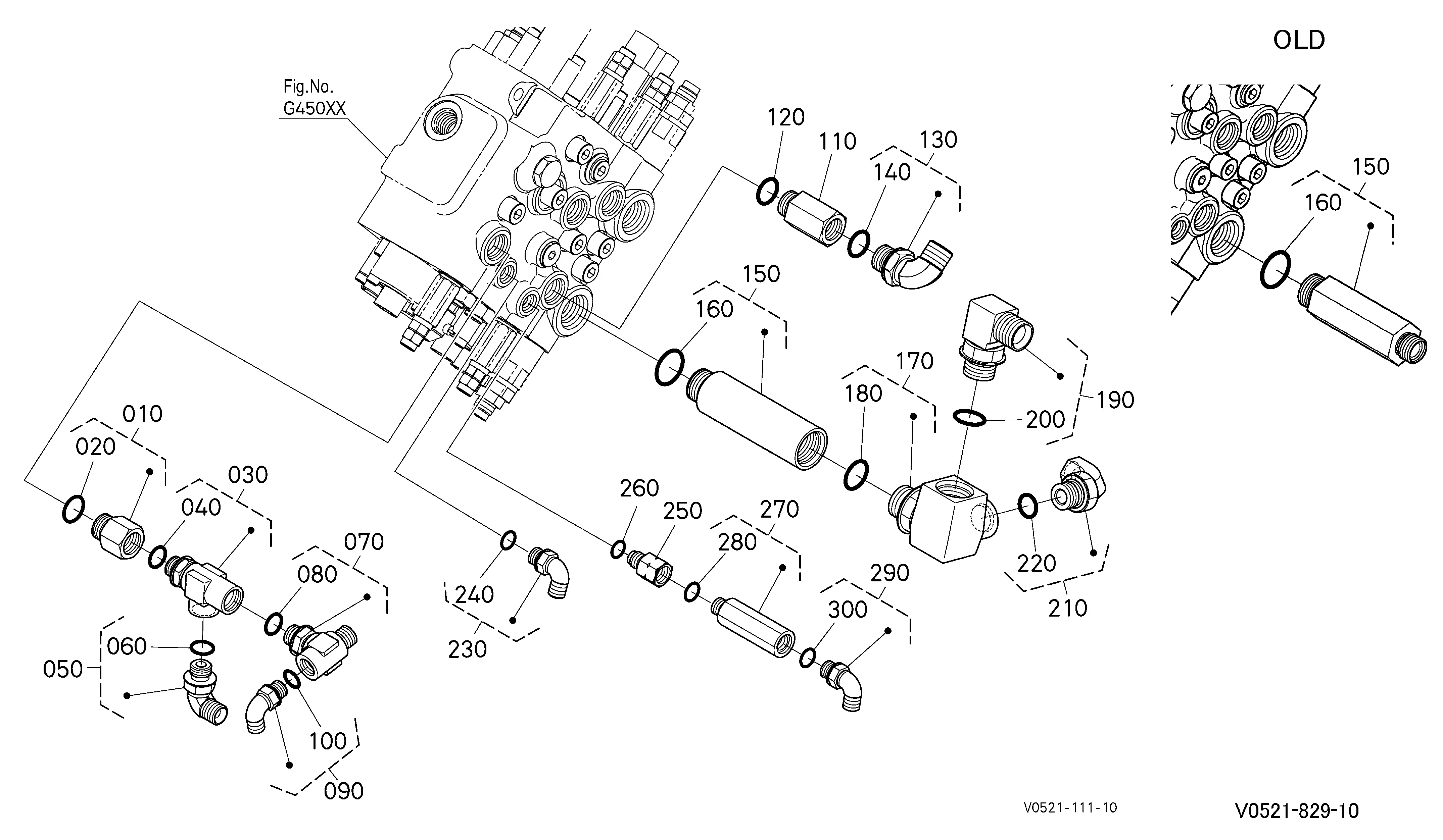

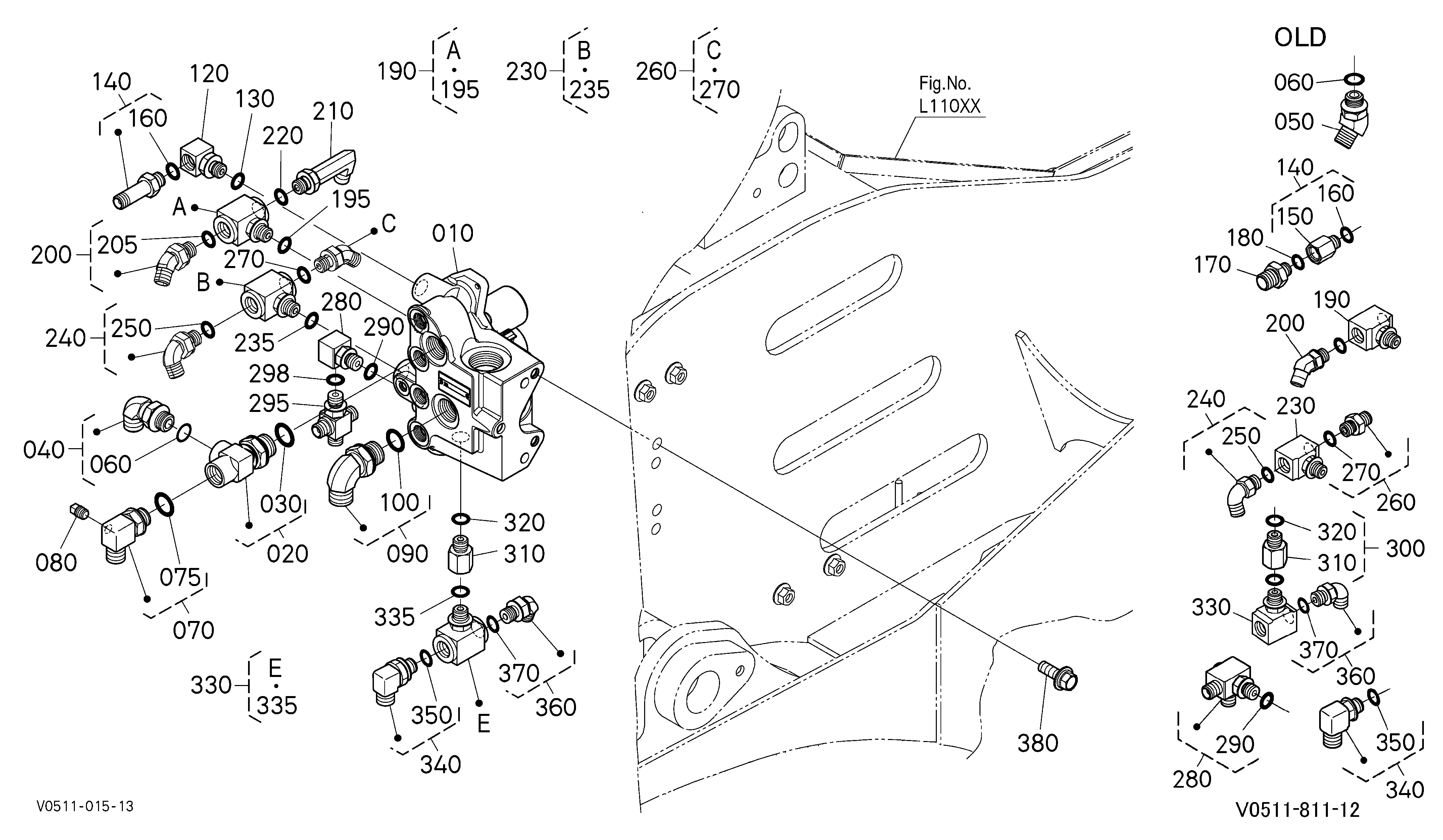

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations provide a clear view of individual components and their arrangement within a machine. By mastering the art of interpreting these visuals, you can efficiently identify necessary elements and their relationships, streamlining your repair processes.

Begin by familiarizing yourself with the legend or key, which typically explains the symbols and notations used throughout the illustration. Each item will often be numbered, corresponding to a list that details specifications and part numbers. Pay attention to the layout, as it reveals how components interact and fit together, guiding you in the assembly or disassembly processes.

When examining the image, focus on the flow of the system. Noting connections and orientations helps in understanding functionality and potential issues. Cross-referencing with the accompanying list ensures you have the right parts for your project, ultimately leading to more effective repairs and maintenance.

Common Issues and Solutions

When operating heavy machinery, users may encounter a variety of challenges that can affect performance and efficiency. Understanding these issues and their respective solutions can significantly enhance the lifespan and functionality of the equipment.

-

Hydraulic Problems:

Leaks or insufficient pressure can lead to poor performance. Regularly check hydraulic fluid levels and inspect hoses for wear and tear.

- Solution: Replace damaged hoses and ensure proper fluid levels are maintained.

- Solution: Clean or replace filters as needed to enhance hydraulic efficiency.

-

Engine Overheating:

Overheating can result from various factors, including low coolant levels or blocked radiators.

- Solution: Regularly inspect and top off coolant levels.

- Solution: Clean the radiator to ensure proper airflow.

-

Electrical Failures:

Issues with the electrical system can cause malfunctions and start-up problems.

- Solution: Inspect wiring for damage and ensure connections are secure.

- Solution: Replace blown fuses and check the battery’s condition.

-

Track Wear:

Over time, tracks can experience significant wear, affecting mobility and stability.

- Solution: Regularly inspect tracks for signs of wear and replace them as necessary.

- Solution: Maintain proper tension to extend track life.

By proactively addressing these common issues, operators can ensure their machinery remains reliable and efficient, minimizing downtime and repair costs.

Where to Find Genuine Parts

Finding authentic components for machinery is essential for ensuring optimal performance and longevity. Sourcing high-quality replacements not only enhances functionality but also maintains the integrity of your equipment. Here are key avenues to explore for acquiring these essential elements.

Authorized Dealers

Authorized dealerships are reliable sources for obtaining original components. They offer a wide range of products specifically designed for your machinery, ensuring compatibility and quality. Furthermore, these dealers often provide professional guidance to assist you in selecting the right parts.

Online Retailers

Many reputable online platforms specialize in selling genuine replacements. These sites frequently feature comprehensive catalogs and detailed descriptions, making it easy to locate the specific items you need. Ensure that you verify the seller’s credibility to avoid counterfeit products.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your machinery. Implementing a proactive maintenance schedule can significantly reduce the likelihood of unexpected failures and costly repairs.

1. Routine Inspections: Conduct frequent checks to identify wear and tear early. Look for signs of damage or deterioration in critical components.

2. Cleanliness is Key: Keep your equipment clean to prevent dirt and debris from causing damage. Regular cleaning helps maintain optimal performance and efficiency.

3. Lubrication: Ensure all moving parts are properly lubricated. This reduces friction and prevents premature wear, contributing to smoother operation.

4. Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This will help ensure that your equipment remains in peak condition.

5. Monitor Fluid Levels: Regularly check and change fluids as needed. Maintaining proper levels of oil, coolant, and hydraulic fluids is crucial for performance.

6. Training and Safety: Ensure that all operators are well-trained. Proper handling and operation can prevent misuse and prolong the lifespan of the equipment.

7. Store Properly: When not in use, store your machinery in a clean, dry environment to protect it from the elements and prolong its life.

Upgrades for Enhanced Performance

Improving the functionality of heavy machinery is essential for maximizing productivity and efficiency on the job site. A range of enhancements can be applied to elevate the overall performance of these powerful machines. These upgrades not only boost operational capabilities but also contribute to longevity and reliability.

Power and Efficiency Enhancements

One of the most effective ways to enhance performance is by upgrading the engine or implementing better fuel systems. Improved filtration systems can lead to cleaner combustion, which in turn increases power output. Additionally, integrating advanced throttle control technologies can result in more responsive handling and greater fuel efficiency.

Hydraulic System Improvements

Upgrading hydraulic components can significantly impact performance. High-flow hydraulic kits can enhance the lifting and digging capabilities, allowing for faster and more efficient operation. Furthermore, installing advanced hydraulic filters can help maintain optimal fluid conditions, reducing wear and extending the lifespan of critical components.

Comparing with Other Models

In the world of compact machinery, evaluating various models is essential for making informed decisions. Each machine offers unique features and performance capabilities, influencing suitability for different tasks and environments. By examining how one model stands against its competitors, users can better identify the right choice for their specific needs.

Performance and Efficiency

When analyzing different models, performance metrics such as horsepower, lifting capacity, and operational speed play a critical role. Some machines excel in power output, making them ideal for heavy-duty tasks, while others focus on fuel efficiency, providing longer operational hours with less consumption. Understanding these differences can significantly impact productivity on the job site.

Maintenance and Durability

Maintenance requirements and overall durability are crucial considerations as well. Certain models may offer easier access to components for repairs, reducing downtime and service costs. Additionally, construction materials and design elements can influence longevity and resistance to wear. Comparing these aspects helps in selecting a machine that not only performs well but also lasts over time, minimizing the total cost of ownership.

Understanding Hydraulic Systems

Hydraulic systems are essential components in various machinery, relying on fluid power to perform tasks efficiently. These systems convert mechanical energy into fluid energy, enabling movement and force transmission through liquids, typically oil or water.

The core principle behind hydraulics is Pascal’s Law, which states that pressure applied to a confined fluid is transmitted equally in all directions. This allows for the multiplication of force, making it possible to lift heavy loads with minimal effort.

Key components of hydraulic systems include pumps, cylinders, valves, and hoses. Each part plays a critical role in ensuring smooth operation, controlling flow, and maintaining pressure within the system. Understanding the interaction between these elements is crucial for optimal performance and troubleshooting.

Maintenance of hydraulic systems is vital for longevity and efficiency. Regular checks for leaks, pressure levels, and fluid quality can prevent failures and ensure the system operates at its ultimate capacity.

Safety Precautions During Repairs

When performing maintenance or repairs on heavy machinery, ensuring safety is paramount. Workers must be aware of potential hazards and adopt practices that minimize risks. Proper preparation and adherence to safety protocols not only protect individuals but also enhance the efficiency of the repair process.

Preparation and Personal Protective Equipment

Before starting any work, it is essential to gather the necessary tools and equipment. Wearing appropriate personal protective gear (PPE) such as gloves, helmets, and safety glasses significantly reduces the likelihood of injury. Ensure that clothing is suitable and does not have loose ends that could become entangled in machinery.

Working Environment and Equipment Checks

Maintaining a clean and organized workspace is crucial. Clear the area of any unnecessary items to prevent trips and falls. Additionally, conducting a thorough inspection of the equipment before starting repairs helps identify potential issues that could lead to accidents. Always follow the manufacturer’s guidelines and consult the manual for specific safety measures.

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding of machinery and their components. Whether you are a professional operator or an enthusiast, having access to various resources will provide valuable insights and knowledge. Here are some avenues to consider for expanding your expertise.

Online Resources

- YouTube Tutorials – Visual guides on maintenance and operation.

- Specialized Forums – Engage with communities to ask questions and share experiences.

- Manufacturer Manuals – Official documents for in-depth technical information.

- Industry Blogs – Articles and posts from experts covering various topics.

Books and Publications

- Technical Handbooks – Comprehensive guides on machinery operation and maintenance.

- Trade Journals – Scholarly articles focusing on innovations and best practices.

- Local Libraries – Access to resources and historical documents related to equipment.

- Professional Associations – Memberships offering exclusive resources and networking opportunities.

By utilizing these resources, you can deepen your knowledge and stay updated on the latest trends and technologies in the field.