Understanding the White Snow Blower Parts Diagram for Optimal Maintenance

In the world of outdoor machinery, grasping the intricacies of your device’s assembly can significantly enhance performance and maintenance. A thorough exploration of its elements not only facilitates effective repairs but also optimizes functionality. This knowledge empowers users to tackle issues confidently and ensures longevity for their machinery.

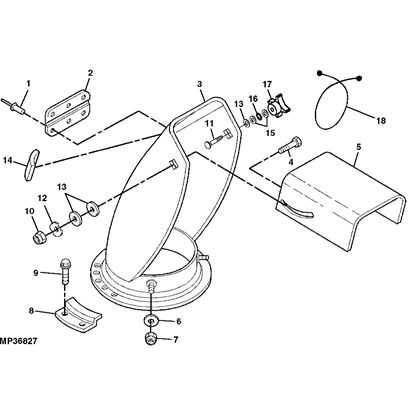

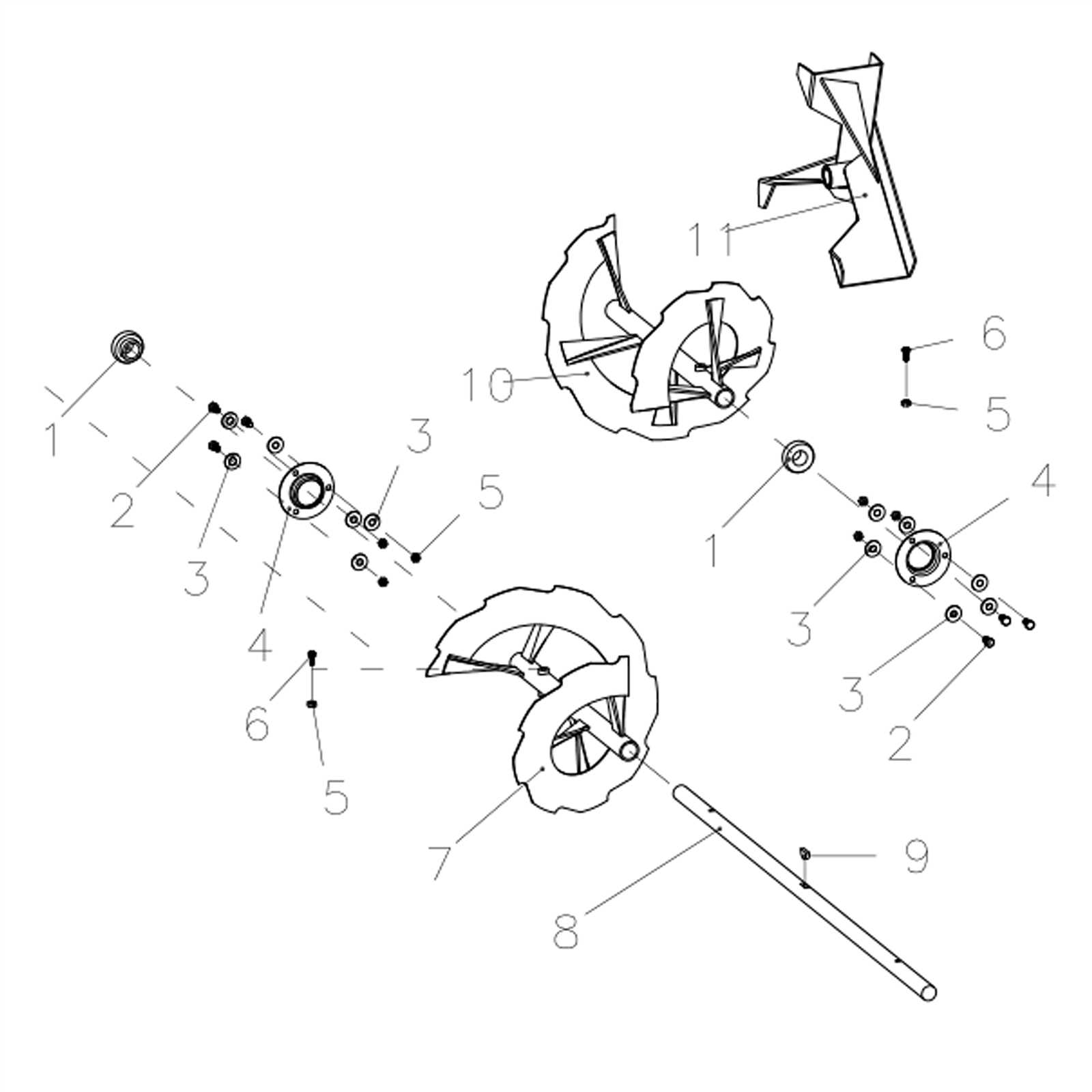

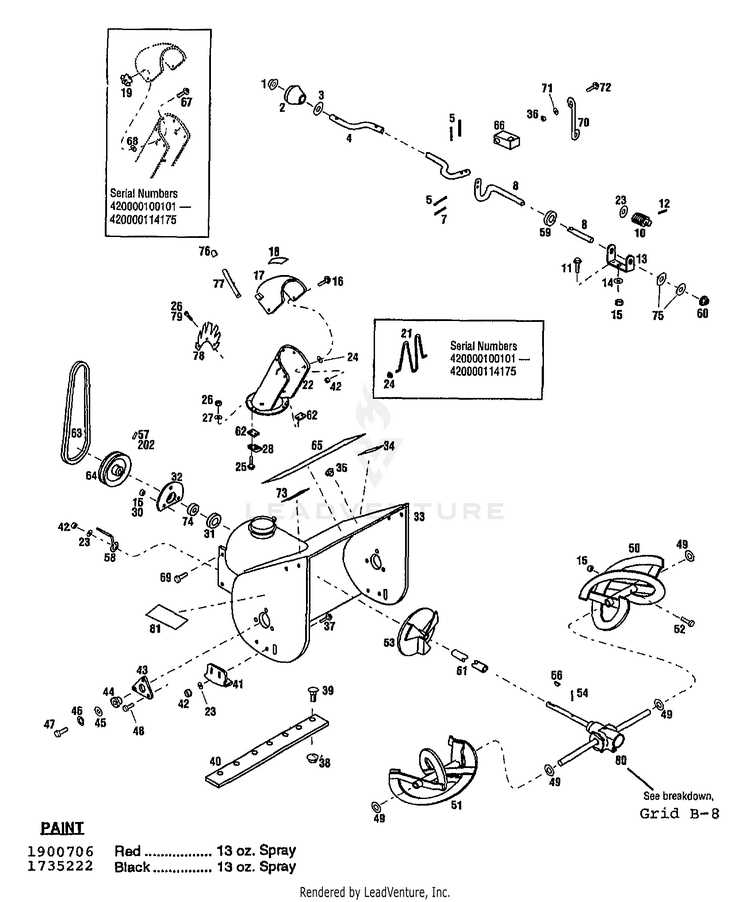

For enthusiasts and professionals alike, visual representation of each component serves as a crucial reference point. By breaking down the intricate relationships between the various segments, individuals can easily identify wear or malfunction. This structured approach allows for a seamless repair process and promotes an ultimate understanding of the equipment.

Delving into the specifics of each section reveals the underlying mechanics that contribute to overall efficiency. Recognizing the roles that each element plays fosters a deeper appreciation for the craftsmanship involved. Ultimately, this insight equips users with the tools needed to maintain and enhance their machinery effectively.

Understanding Snow Blower Components

When it comes to managing winter conditions, having a thorough knowledge of the machinery involved can greatly enhance efficiency and performance. Each element of the device plays a crucial role in ensuring optimal operation and effectiveness during heavy precipitation. Familiarizing oneself with these various components is essential for proper maintenance and troubleshooting.

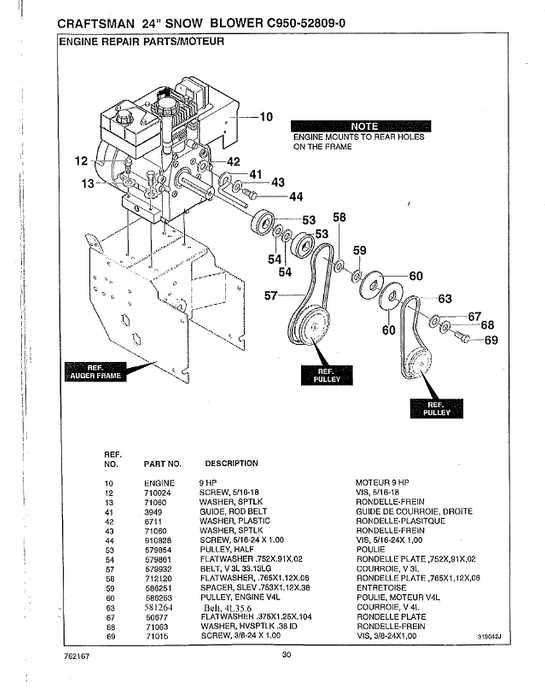

The heart of the machine is typically the engine, which provides the necessary power to drive all other functions. This unit is often paired with a transmission system that controls the speed and direction of movement. Understanding how these two parts interact can help in diagnosing issues related to performance.

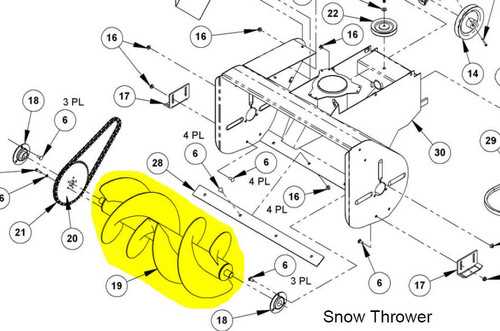

Another vital aspect includes the auger, designed to gather and propel the accumulated material. Its efficiency can be impacted by wear and tear, so recognizing signs of deterioration is important for ensuring longevity. Additionally, the housing structure protects internal elements and contributes to the overall design’s effectiveness.

Lastly, the chute system directs the expelled material away from the area being cleared. Mastering the adjustments and mechanisms involved can greatly improve maneuverability and control. Each component works in harmony to create a well-functioning apparatus, making it imperative to have a comprehensive understanding of their functions and interrelations.

Importance of a Parts Diagram

Understanding the components of any machinery is crucial for effective maintenance and repair. A visual representation serves as a valuable resource, enabling users to identify various elements and comprehend their functions. This clarity not only aids in troubleshooting but also enhances the overall efficiency of servicing processes.

Enhancing Maintenance Efficiency

When users have access to a clear schematic, they can easily locate and replace malfunctioning elements. This minimizes downtime and allows for quicker resolutions to issues, ultimately prolonging the lifespan of the equipment.

Facilitating Communication

Such illustrations promote better communication among technicians, suppliers, and users. By providing a common reference point, it ensures that all parties are on the same page regarding specific components, reducing the chances of misunderstandings during repairs.

| Component | Function |

|---|---|

| Motor | Drives the system |

| Auger | Moves material forward |

| Chassis | Houses all parts |

| Control Panel | Regulates operations |

Common White Snow Blower Models

This section explores popular models that are widely recognized for their efficiency and reliability during winter tasks. These machines vary in features and capabilities, making it essential for users to choose the right model for their specific needs.

Top Models to Consider

- Model A: Known for its powerful engine and user-friendly controls.

- Model B: Features a compact design, ideal for residential areas.

- Model C: Offers advanced technology for enhanced performance.

Key Features to Look For

- Engine Power: Higher horsepower can improve efficiency.

- Width of Clearing Path: Wider paths reduce time spent on tasks.

- Weight: Heavier models may provide better traction.

How to Read a Parts Diagram

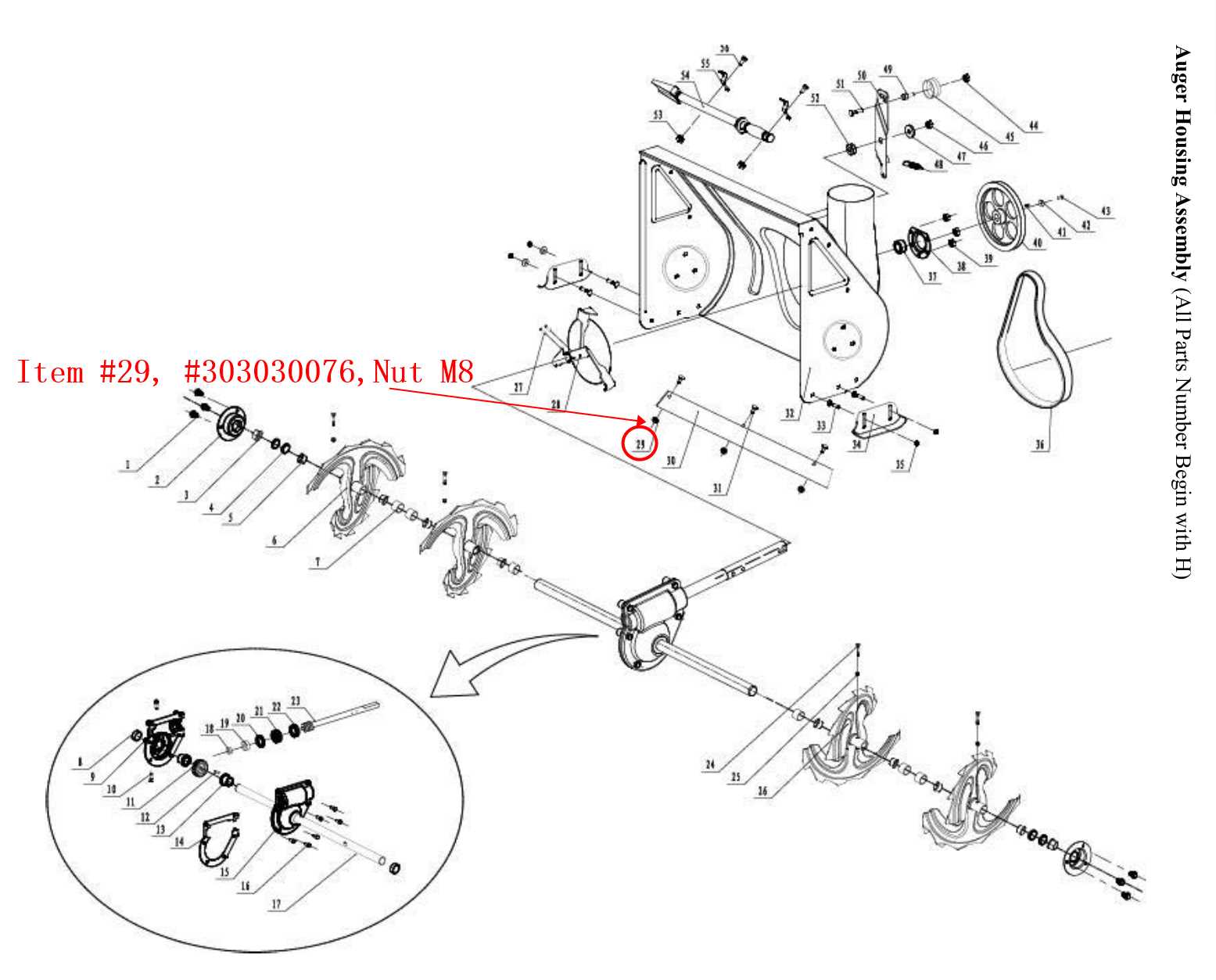

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate these illustrations with confidence, ensuring you can identify and source the necessary elements efficiently.

Key Elements to Identify

- Labels: Each component is usually marked with a specific identifier.

- Numbers: Numerical references correspond to a parts list, aiding in quick identification.

- Connections: Arrows or lines often show how parts fit together or interact.

Steps to Decipher the Visual

- Examine the overall layout to grasp the arrangement of elements.

- Locate the identifiers and match them with the provided list.

- Pay attention to connections for understanding functionality.

Identifying Key Components in Diagrams

Understanding the essential elements in schematics is crucial for effective maintenance and repair. These visual representations often encapsulate a wealth of information, helping users recognize how each component interacts within the system. By examining the layout and labeling, one can discern the roles and relationships of various parts, making troubleshooting more efficient.

When analyzing these illustrations, it is beneficial to focus on common features such as connectors, switches, and operational mechanisms. Each of these elements plays a pivotal role in the overall functionality, and grasping their placement can significantly enhance comprehension. Moreover, familiarity with standard symbols aids in quick identification, streamlining the process of understanding complex configurations.

Maintenance Tips for Snow Blowers

Regular upkeep is essential for ensuring optimal performance during harsh winter conditions. Proper care not only extends the life of the equipment but also enhances its efficiency when tackling heavy accumulations. Here are some valuable guidelines to keep in mind.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every season | Replace old oil to maintain engine health and performance. |

| Check Spark Plug | Once a season | Inspect and replace the spark plug for reliable ignition. |

| Inspect Belts | Monthly | Look for wear and tear; replace if damaged. |

| Clean Fuel System | Once a season | Ensure the fuel lines and filters are free of debris. |

| Sharpen Blades | Before use | Maintain sharp edges for effective clearing. |

Finding Replacement Parts Easily

Locating components for your equipment can be a straightforward process if you follow a few essential steps. Understanding the resources available to you will ensure that you find the right elements without unnecessary hassle.

- Utilize Online Resources: Websites specializing in machinery can provide extensive catalogs and detailed information about available components.

- Consult Manufacturer Guides: Official manuals often contain part numbers and specifications, making it easier to identify what you need.

- Join Online Communities: Forums and social media groups dedicated to equipment enthusiasts can offer valuable insights and recommendations.

By leveraging these resources, you can efficiently source the necessary items to keep your machinery operating smoothly. Be sure to compare options and prices to make informed decisions.

- Identify the Component: Start by determining the specific item you need, using model numbers or descriptions.

- Search Multiple Vendors: Don’t settle for the first option; exploring various suppliers may lead to better prices or availability.

- Check Reviews: Look for customer feedback on the components you are considering to ensure quality and reliability.

With these strategies, acquiring the right elements becomes a more manageable task, allowing you to maintain your equipment efficiently.

Common Issues with Snow Blower Parts

Understanding frequent complications that arise with these machines can enhance performance and extend their lifespan. Identifying symptoms early can save time and reduce repair costs.

Typical Complications

Several factors contribute to malfunctions, including wear and tear, improper maintenance, and environmental conditions. Regular inspections can help pinpoint issues before they escalate.

Signs of Wear

| Issue | Symptoms |

|---|---|

| Difficulty Starting | Engine does not turn over or starts inconsistently. |

| Weak Performance | Inability to clear snow effectively or loss of power. |

| Unusual Noises | Grinding or rattling sounds during operation. |

| Fuel Leaks | Puddles of fuel under the machine or a strong smell of gasoline. |

Tools Required for Snow Blower Repair

Effective maintenance and repair of your equipment necessitate specific instruments that ensure precision and efficiency. Having the right tools at your disposal not only simplifies the process but also enhances safety and performance during any repair task.

Key tools include wrenches and screwdrivers, which are essential for loosening and tightening various components. A reliable socket set is also crucial, allowing for quick adjustments and replacements of bolts and nuts. Additionally, pliers can be indispensable for gripping and manipulating small parts, while a multimeter is useful for electrical troubleshooting.

Don’t forget about safety gear such as gloves and goggles, which are vital for protecting yourself during repairs. Furthermore, a work light can illuminate dark areas, making it easier to work effectively. Having these tools organized and readily accessible will ensure that you are well-prepared for any maintenance challenge.

Upgrading Your Snow Blower Parts

Enhancing the efficiency and performance of your winter equipment can make a significant difference during the colder months. By selecting high-quality components and modernizing your machinery, you can improve its reliability and longevity.

Identifying Key Components

Start by assessing which elements of your machinery require attention. Focus on those that show signs of wear or diminished functionality. Upgrading essential parts can enhance overall effectiveness, ensuring smoother operation when tackling the elements.

Choosing Quality Replacements

Opt for durable and reputable replacements to maximize performance. Consider materials that withstand harsh conditions, and don’t hesitate to consult user reviews or expert recommendations. Investing in superior components can lead to a noticeable improvement in your equipment’s capabilities.

DIY Repairs vs. Professional Help

When faced with equipment issues, individuals often weigh the benefits of tackling repairs independently against seeking assistance from experts. Each approach has its merits, and understanding these can lead to more informed decisions.

Do-It-Yourself solutions can offer a sense of accomplishment and can be cost-effective. With the right tools and resources, many can successfully resolve minor malfunctions without incurring labor costs. Additionally, this hands-on experience can enhance one’s skills and confidence for future tasks.

On the other hand, professional services provide the advantage of expertise and experience. Skilled technicians are equipped with specialized knowledge and tools, which can be invaluable for complex issues that may not be easily addressed by the average person. Their insights can also prevent further damage, saving time and money in the long run.

Ultimately, the choice between DIY repairs and professional intervention depends on factors such as the complexity of the problem, available resources, and personal comfort with technical tasks. Weighing these elements carefully can lead to the most effective and satisfying outcome.

Seasonal Preparations for Snow Blowers

As winter approaches, ensuring optimal performance of your equipment is essential. Proper readiness can prevent issues during the cold months and enhance efficiency.

- Inspect the fuel system for cleanliness and ensure proper fuel quality.

- Check the oil levels and consider an oil change to maintain engine health.

- Examine the belts and cables for wear, replacing any damaged components.

- Clean the exterior and remove any debris to prevent clogs.

Additionally, familiarize yourself with the operation manual to fully understand maintenance needs and troubleshooting steps.

- Test the equipment before the first snowfall to identify potential issues.

- Store extra supplies, such as fuel and oil, in a safe location.

Being proactive will ensure that you are ready to tackle winter’s challenges effectively.