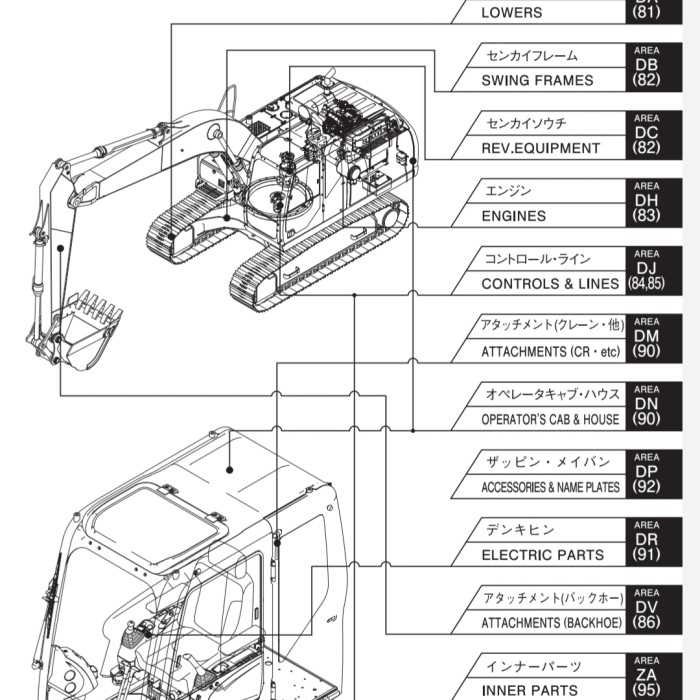

Understanding the Takeuchi TB016 Parts Diagram for Efficient Maintenance

When working with compact excavators, having a clear visual reference of the various elements is essential for effective maintenance and repairs. A well-organized layout not only aids in identifying parts but also streamlines the process of replacement and troubleshooting. Such illustrations serve as a vital resource for both professionals and enthusiasts alike, facilitating a deeper understanding of the machinery’s architecture.

These visual aids can illuminate the relationships between different sections of the equipment, ensuring that users can navigate the complexities of assembly and disassembly. Recognizing how each piece interacts with others is crucial for optimizing performance and extending the lifespan of the machinery. Moreover, familiarizing oneself with these layouts enhances the ability to perform repairs swiftly and accurately.

Whether you are a seasoned technician or a new operator, grasping the intricacies of these representations can significantly impact your workflow. Emphasizing clarity and precision, they empower users to approach maintenance tasks with confidence, ensuring that the machinery operates at its best. Thus, understanding these component layouts is not just beneficial–it is indispensable for efficient operation and upkeep.

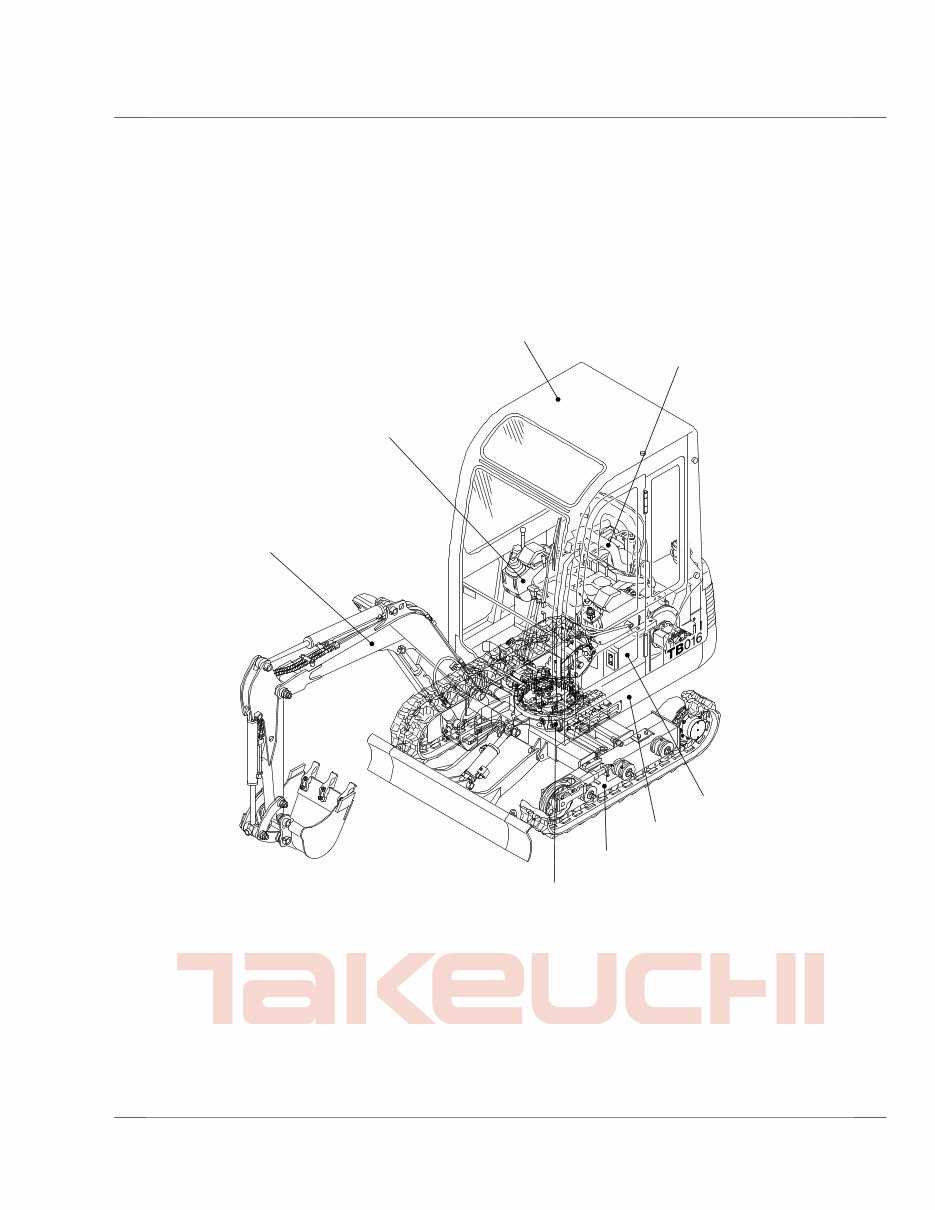

Understanding Takeuchi TB016 Overview

This section provides a comprehensive exploration of a compact and versatile construction machine designed for efficiency and maneuverability in various work environments. Its robust features and innovative design make it an ideal choice for both professionals and enthusiasts in the industry.

Key Features

Among its many attributes, this equipment boasts powerful hydraulic capabilities, allowing it to perform a wide range of tasks with ease. Durability and reliability are paramount, ensuring that operators can depend on its performance over extended periods.

Applications and Benefits

Utilized in landscaping, excavation, and other construction activities, this machine enhances productivity while minimizing the impact on the surrounding environment. Its compact size enables it to navigate tight spaces, making it an ultimate tool for various projects.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide an organized view that simplifies understanding the assembly and functionality of each element. By clearly illustrating the relationships between various pieces, these resources enable technicians to efficiently identify issues and implement solutions.

Enhanced Understanding

Clarity is key when tackling mechanical problems. Visual aids enhance comprehension, allowing users to quickly grasp the layout and purpose of individual elements. This leads to more effective troubleshooting and repair processes.

Efficient Maintenance

Utilizing these visual guides can significantly reduce downtime. By streamlining the identification of required components, users can expedite repairs and ensure that machinery operates smoothly. This ultimately contributes to better productivity and longer equipment lifespan.

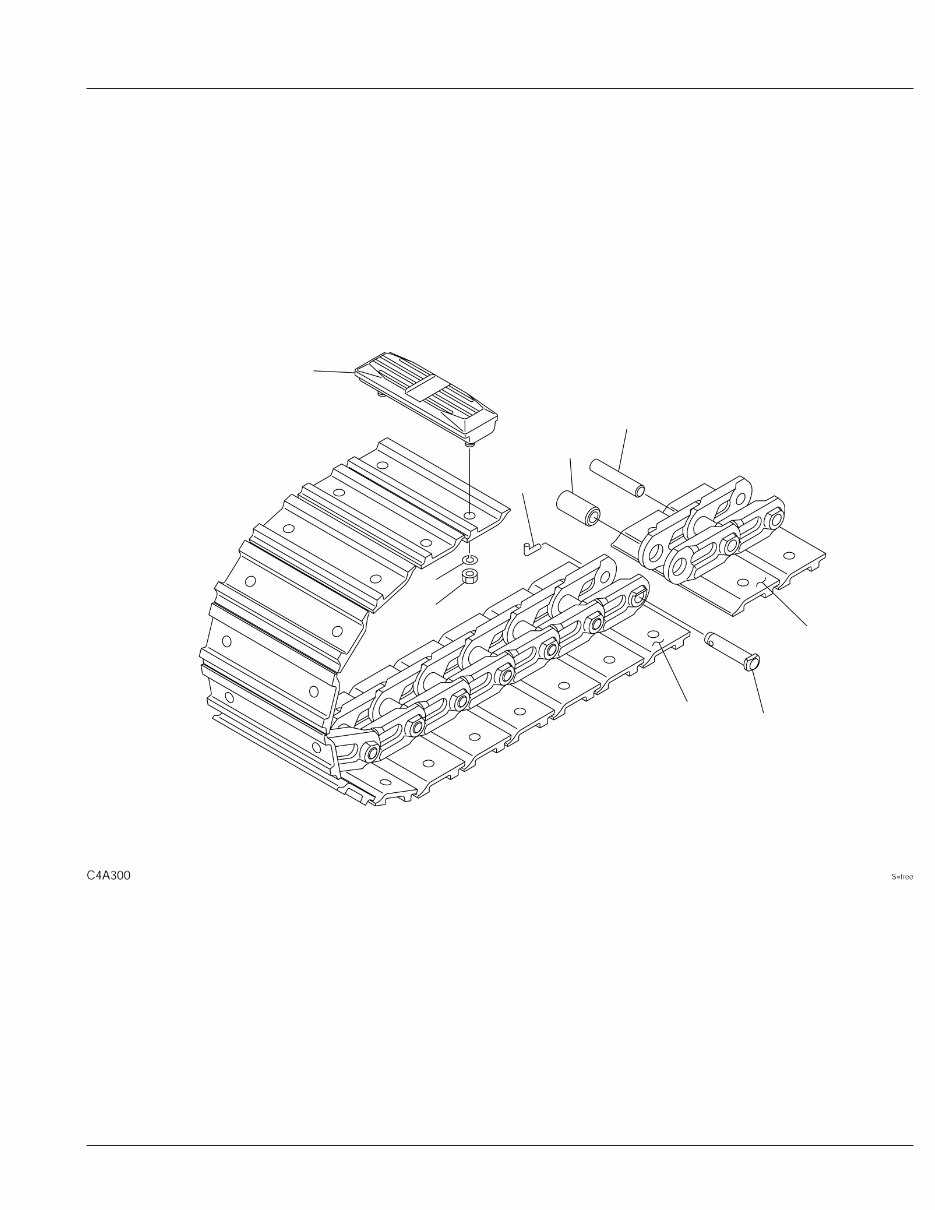

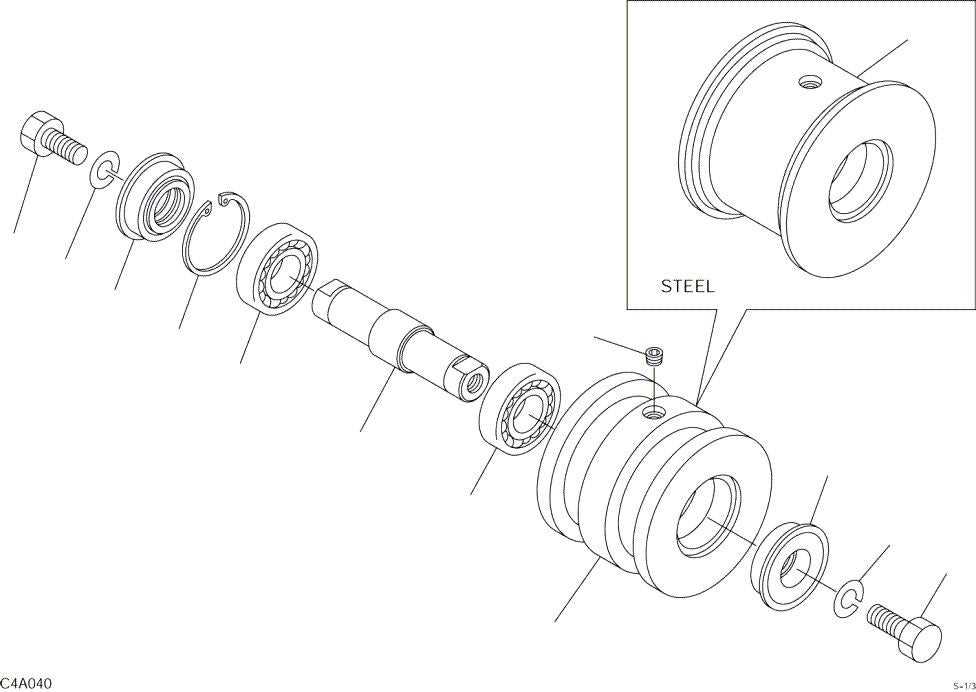

Key Components of TB016 Excavator

Understanding the essential elements of a compact digger is crucial for maintenance and optimal performance. Each component plays a significant role in ensuring efficient operation and longevity.

| Component | Description |

|---|---|

| Hydraulic System | Drives the machine’s movements and attachments through fluid power. |

| Engine | Powers the excavator and provides the necessary torque for heavy tasks. |

| Boom | Extends the reach of the machine for digging and lifting operations. |

| Bucket | Used for scooping and moving material from one location to another. |

| Tracks | Provide stability and mobility across various terrains. |

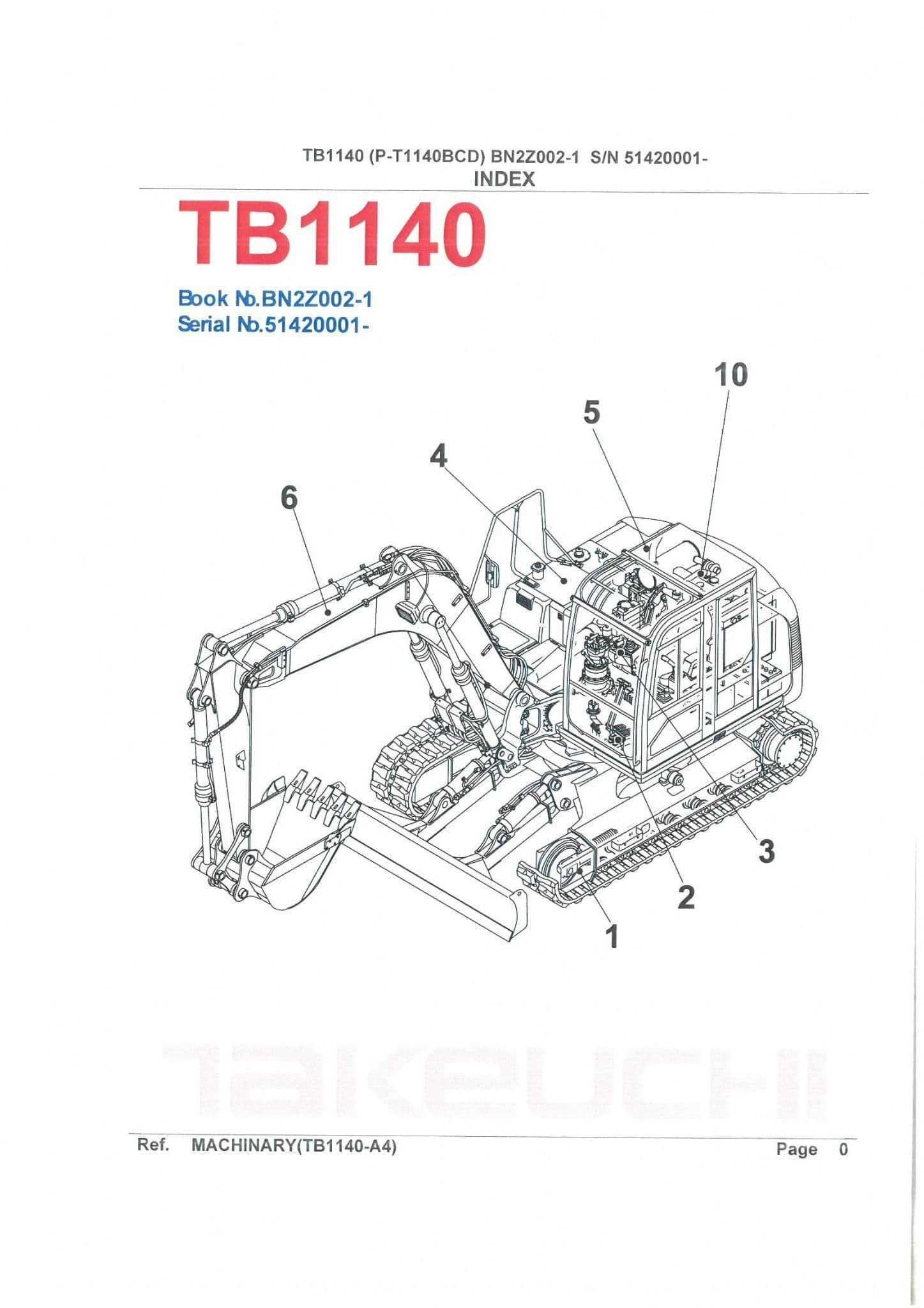

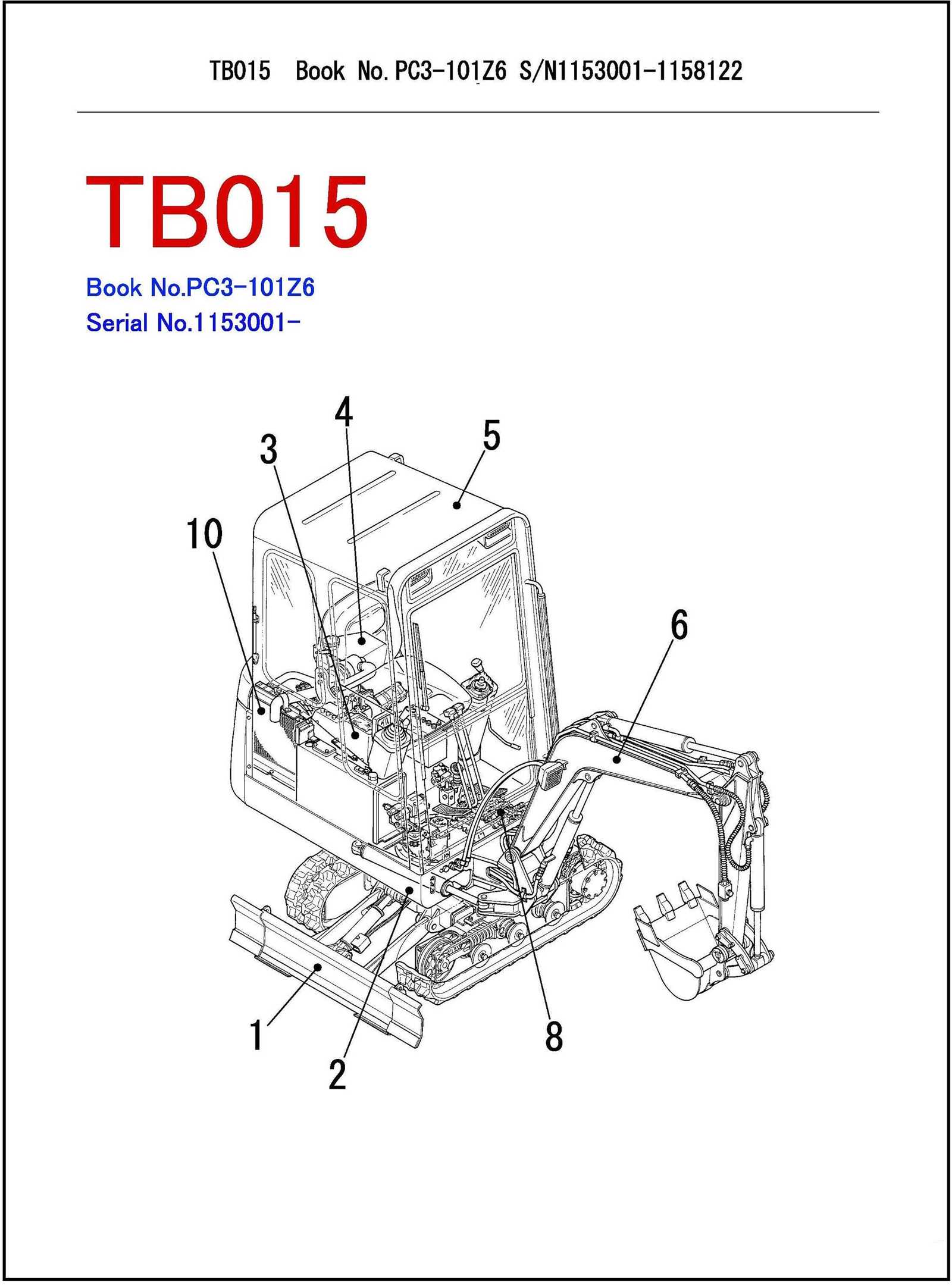

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals serve as a roadmap, providing a clear representation of components and their relationships within a system. By familiarizing yourself with these representations, you can identify what you need for repairs and replacements more efficiently.

Key Elements to Identify

- Labels: Each component is usually labeled with a number or letter that corresponds to a list.

- Connections: Lines often indicate how parts are connected, showing both assembly and disassembly paths.

- Legends: Some illustrations include a legend that explains symbols used for various components.

Steps to Decipher the Illustration

- Start with the legend, if available, to understand the symbols.

- Identify the main components that are crucial for your task.

- Follow the connections to see how components interact with each other.

- Cross-reference the labels with the accompanying list to find specific details.

By following these guidelines, you can navigate technical illustrations effectively, making your repair process smoother and more efficient.

Common Issues with TB016 Parts

Understanding frequent challenges encountered with components of machinery can enhance maintenance efforts and prolong equipment life. Identifying these common problems allows operators to act proactively, ensuring smooth operation and reducing downtime.

Typical Problems

- Wear and Tear: Over time, components may degrade, leading to decreased performance.

- Fluid Leaks: Seals and gaskets can fail, resulting in loss of essential fluids.

- Electrical Failures: Wiring and connections may corrode or break, causing operational issues.

Prevention Tips

- Regular Inspections: Conduct routine checks to identify wear early.

- Proper Lubrication: Ensure all moving parts are adequately lubricated.

- Use Quality Components: Opt for high-quality replacements to enhance longevity.

Ordering Replacement Parts Efficiently

Acquiring new components for machinery can be a daunting task, yet with the right approach, the process can become seamless and efficient. Understanding how to navigate the procurement of these essential elements ensures minimal downtime and optimal performance.

Research and Identify

Before placing an order, it is crucial to thoroughly research and pinpoint the specific items needed. Utilize resources like manuals or online catalogs to ensure accuracy in selection. This step significantly reduces the chances of receiving incorrect items.

Compare Suppliers

Once the desired components are identified, comparing various suppliers is vital. Look for those offering competitive pricing, reliable delivery times, and excellent customer service. Utilizing customer reviews can provide insight into their reputation, enabling informed decisions that lead to the ultimate procurement experience.

Benefits of Genuine Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These high-quality items are specifically designed to meet the exact specifications of the equipment, providing several advantages that aftermarket alternatives often lack.

- Enhanced Reliability: Genuine items undergo rigorous testing and quality control, leading to improved reliability during operation.

- Better Fit and Compatibility: Original components are engineered to fit perfectly, minimizing the risk of malfunction due to improper installation.

- Longer Lifespan: Using authentic parts often results in a longer lifespan for both the component and the machinery itself, reducing the frequency of replacements.

- Warranty Protection: Many manufacturers offer warranties on their genuine components, providing peace of mind in case of any defects.

- Optimal Performance: Authentic components are designed to work in harmony with the machinery, ensuring peak performance and efficiency.

Investing in genuine components not only promotes safety and reliability but also contributes to the overall effectiveness of the equipment, leading to greater satisfaction and reduced operational costs in the long run.

Maintenance Tips for TB016

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By adhering to a structured maintenance routine, operators can prevent issues and enhance productivity. Here are some essential guidelines to follow.

Routine Checks

- Inspect fluid levels frequently, including hydraulic and engine oils.

- Check air filters and clean or replace them as necessary.

- Examine belts and hoses for signs of wear and tear.

Cleaning and Lubrication

- Clean the exterior to prevent dirt buildup, which can cause overheating.

- Lubricate moving parts regularly to reduce friction and wear.

- Ensure that all joints and pivot points are well-greased to maintain smooth operation.

Implementing these maintenance practices can lead to better efficiency and reduced downtime, ultimately enhancing the lifespan of your machinery.

Where to Find Parts Diagrams

Finding visual guides for machinery components is essential for effective maintenance and repairs. These resources provide valuable insights into the layout and assembly of various elements, ensuring that users can identify the correct pieces needed for their tasks.

Online Resources

- Manufacturer Websites: Often, official sites provide comprehensive manuals and visuals.

- Specialized Retailers: Many parts suppliers host diagrams to aid customers in selecting the right components.

- Forums and Community Groups: Enthusiasts often share diagrams and insights on dedicated platforms.

Printed Manuals

- Service Manuals: Check for hard copies that include detailed schematics.

- Industry Publications: Trade magazines may feature articles with useful visuals.

- Local Libraries: Some libraries maintain archives of equipment manuals and diagrams.

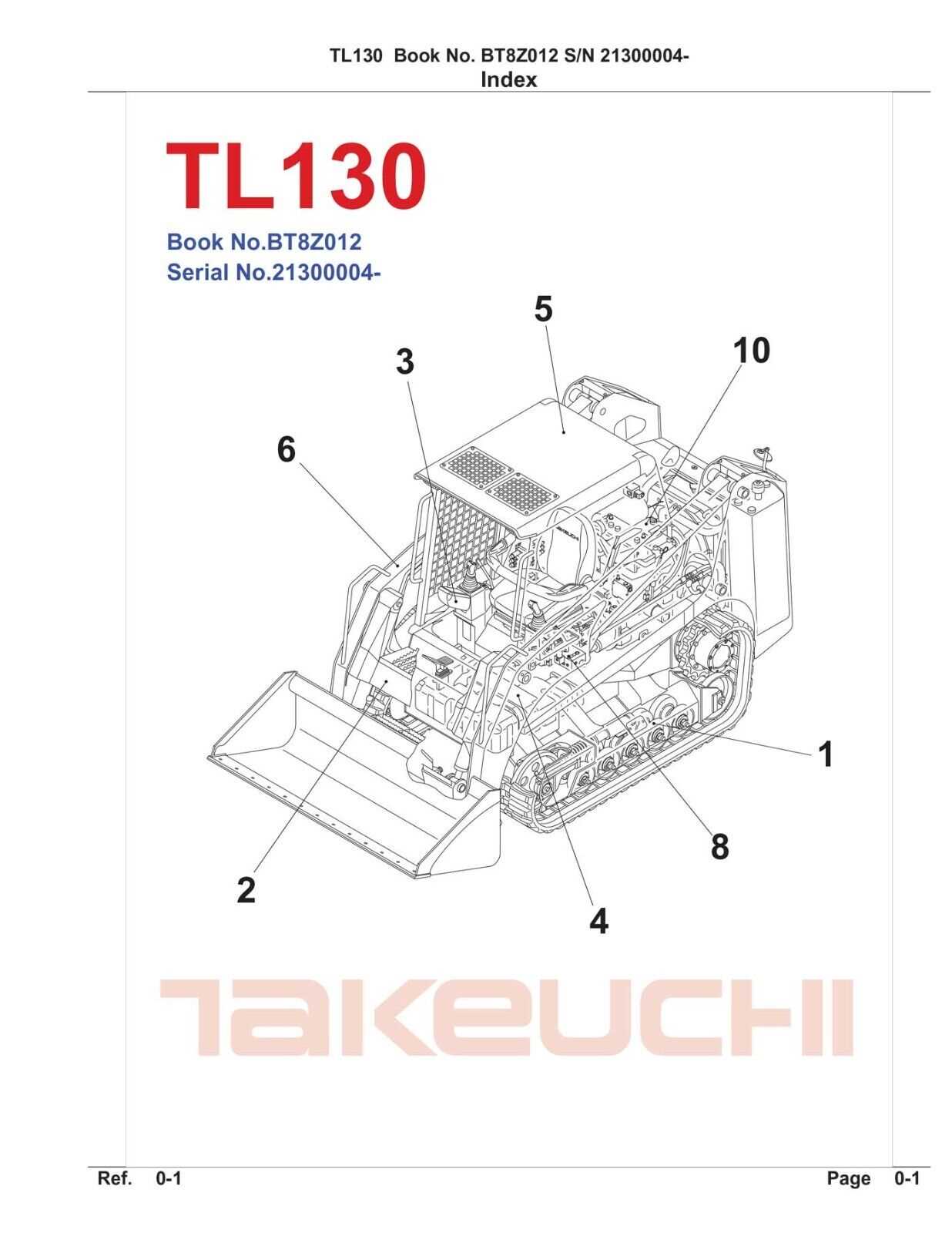

Upgrades and Modifications Available

Enhancing machinery performance through various upgrades and modifications can significantly improve efficiency and functionality. These enhancements allow users to tailor equipment to meet specific operational needs, increasing productivity and extending the lifespan of the machine.

Power Enhancements: Upgrading the engine or hydraulic systems can lead to improved power output and efficiency. This ensures that the equipment can handle heavier loads and operate more smoothly in challenging environments.

Attachment Options: Various attachments can be added to increase versatility. Options like different buckets, augers, or grapples allow operators to perform a wider range of tasks, making the equipment more adaptable to different job sites.

Control System Upgrades: Implementing advanced control systems can enhance precision and ease of use. Features like joystick controls or digital displays provide better feedback and improve overall user experience.

Safety Features: Integrating additional safety mechanisms, such as enhanced lighting, backup alarms, or rollover protection, can create a safer working environment, protecting both operators and bystanders.

Comfort Improvements: Modifications to the operator’s cabin, including upgraded seating and climate control, can significantly enhance comfort during long working hours, leading to improved focus and productivity.

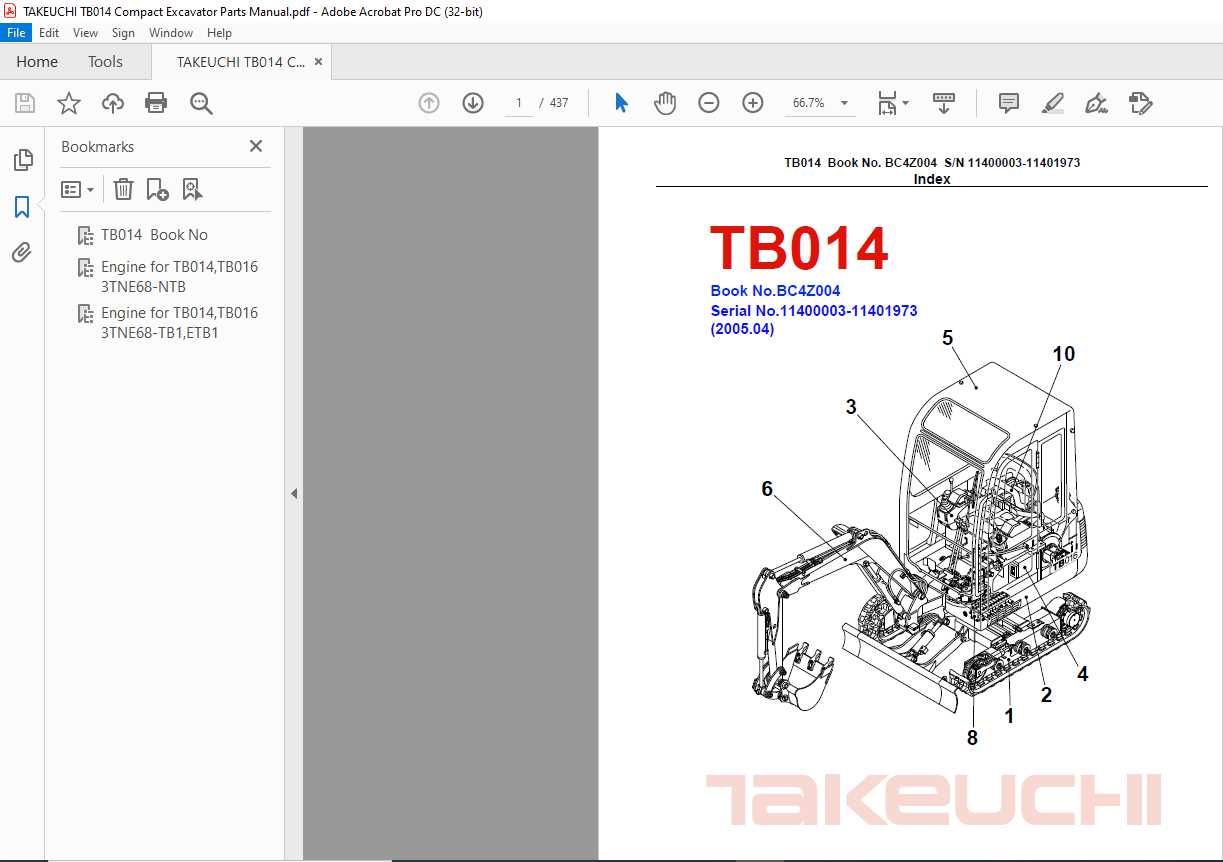

Comparing TB016 to Other Models

When evaluating compact excavators, understanding the differences between various models can significantly impact your decision-making process. Each machine offers unique features and specifications, tailored to different applications and user needs.

In this section, we will explore key aspects that differentiate one model from another, focusing on performance, size, and versatility.

- Performance:

- Engine power and torque ratings

- Hydraulic flow rates and lifting capacities

- Operating speed and efficiency

- Size and Dimensions:

- Overall weight and footprint

- Digging depth and reach

- Stability and maneuverability in tight spaces

- Versatility:

- Attachment compatibility and options

- Ease of transport and setup

- Adaptability to various job site conditions

By comparing these characteristics, potential buyers can determine which excavator model aligns best with their operational requirements and budget constraints. Each option presents distinct advantages, making it essential to assess them in the context of specific tasks and environments.

Expert Recommendations for Owners

Maintaining heavy machinery requires careful attention to detail and a proactive approach. Owners should prioritize understanding their equipment’s inner workings to ensure longevity and optimal performance. Knowledge of component arrangement and maintenance schedules can significantly enhance reliability and reduce downtime.

Routine Maintenance Tips

Implementing a regular maintenance schedule is crucial. This includes checking fluid levels, inspecting for wear, and ensuring all mechanical systems are functioning smoothly. Owners should also familiarize themselves with common issues specific to their machinery model.

Essential Resources

Utilizing available resources can empower owners to make informed decisions. Manuals, online forums, and expert consultations are invaluable for troubleshooting and part selection.

| Resource Type | Description |

|---|---|

| User Manuals | Provide detailed operational and maintenance guidance. |

| Online Forums | Offer community support and shared experiences from other owners. |

| Professional Consultations | Access expert advice tailored to specific machinery issues. |