Comprehensive Guide to Yanmar 3hm35f Parts Diagram

In the realm of marine mechanics, grasping the intricacies of engine assembly is crucial for effective maintenance and repair. A detailed visual representation serves as a roadmap, guiding technicians through the complex arrangement of various components. This knowledge empowers professionals to diagnose issues swiftly and ensure optimal performance.

By exploring a specific model’s configuration, one can delve into the interconnectedness of parts, identifying each element’s role within the system. The clarity provided by such illustrations not only aids in troubleshooting but also enhances the understanding of operational dynamics.

Ultimately, a comprehensive overview of component arrangements fosters better upkeep practices, prolonging the lifespan of the machinery and enhancing reliability on the water. Embracing this information is essential for anyone involved in marine engine care.

Understanding Yanmar 3HM35F Engine Parts

Having a clear comprehension of engine components is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring optimal performance and longevity of the machinery. Familiarity with these individual pieces allows for informed decisions regarding repairs and replacements, enhancing overall efficiency.

Key components include the crankshaft, cylinder head, and fuel injectors, all of which contribute significantly to the engine’s functionality. The crankshaft transforms linear motion into rotational force, while the cylinder head seals the combustion chamber, facilitating efficient fuel combustion. Fuel injectors, on the other hand, atomize the fuel, ensuring proper mixing with air for maximum power output.

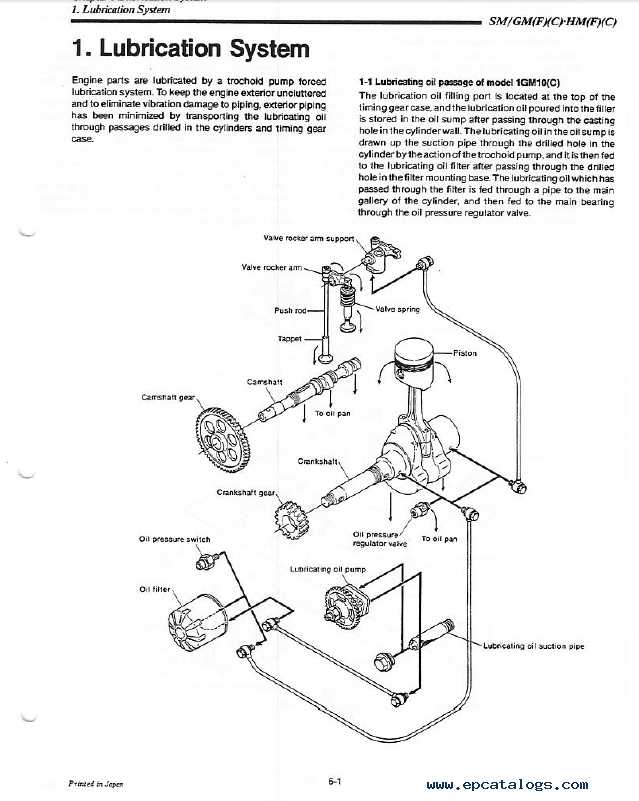

Additionally, understanding the cooling system and lubrication is vital. The cooling system prevents overheating, maintaining an ideal operating temperature, whereas proper lubrication reduces friction between moving parts, minimizing wear and tear.

By gaining insights into these components, operators can ensure their machinery runs smoothly and efficiently, ultimately extending its lifespan and enhancing performance.

Overview of the 3HM35F Engine

The engine in question is a compact and efficient marine power unit designed for reliable performance in various boating applications. Known for its robust construction and advanced engineering, this model delivers a perfect blend of power and fuel efficiency, making it a preferred choice among enthusiasts and professionals alike.

Key features of this engine include:

- Compact size suitable for tight spaces.

- Durable components designed for longevity.

- High torque output for improved acceleration.

- Low emissions, adhering to modern environmental standards.

This engine is particularly valued for its:

- Versatility: Ideal for various vessels, from small yachts to fishing boats.

- Ease of maintenance: User-friendly design facilitates straightforward servicing.

- Fuel efficiency: Optimized fuel consumption enhances operational range.

Overall, this power unit stands out in the marine engine market, providing boat owners with reliability, efficiency, and performance tailored to their needs.

Importance of Accurate Parts Diagrams

Detailed visual representations of components are crucial for anyone involved in maintenance or repair tasks. These illustrations serve as vital tools that simplify the identification and organization of various elements within complex systems. A well-crafted visual guide can enhance understanding, ensuring that individuals can locate and replace parts efficiently.

Enhancing Efficiency

When tackling repairs or maintenance, time is of the essence. Clear visual references streamline the process by providing instant clarity on component placement and orientation. This efficiency reduces the likelihood of errors, minimizing downtime and costs associated with misdiagnosis or incorrect installations.

Facilitating Communication

Accurate visual aids also play a significant role in communication among technicians, suppliers, and customers. These references create a common language, allowing all parties to discuss components with precision. As a result, ordering the correct replacements or discussing repairs becomes significantly more straightforward.

| Benefit | Description |

|---|---|

| Time-Saving | Reduces the time spent on repairs by providing clear guidance. |

| Accuracy | Minimizes the risk of errors in identifying and replacing elements. |

| Improved Communication | Enhances dialogue between technicians and suppliers for effective problem-solving. |

Main Components of the Yanmar Engine

This section explores the fundamental elements that constitute a marine engine, highlighting their significance and functionality in ensuring optimal performance and reliability. Each part plays a crucial role in the overall operation, contributing to the engine’s efficiency and longevity.

Core Parts

The primary elements include the cylinder block, which houses the cylinders, and the cylinder head, where combustion occurs. Together, these components create the necessary environment for energy production.

Supporting Systems

Essential supporting systems, such as the fuel injection system and cooling mechanisms, ensure the engine operates smoothly. These systems manage fuel delivery and temperature regulation, safeguarding the engine from potential damage and enhancing performance.

Common Issues with 3HM35F Parts

In any mechanical system, certain components often encounter recurring problems that can hinder performance and reliability. Understanding these issues is crucial for effective maintenance and long-term operation.

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Excessive heat can lead to engine failure. | Check cooling systems, replace worn hoses. |

| Fuel Leaks | Leaks can cause inefficient combustion. | Inspect fuel lines, tighten connections. |

| Corrosion | Rust can weaken metal components. | Apply protective coatings, store in dry conditions. |

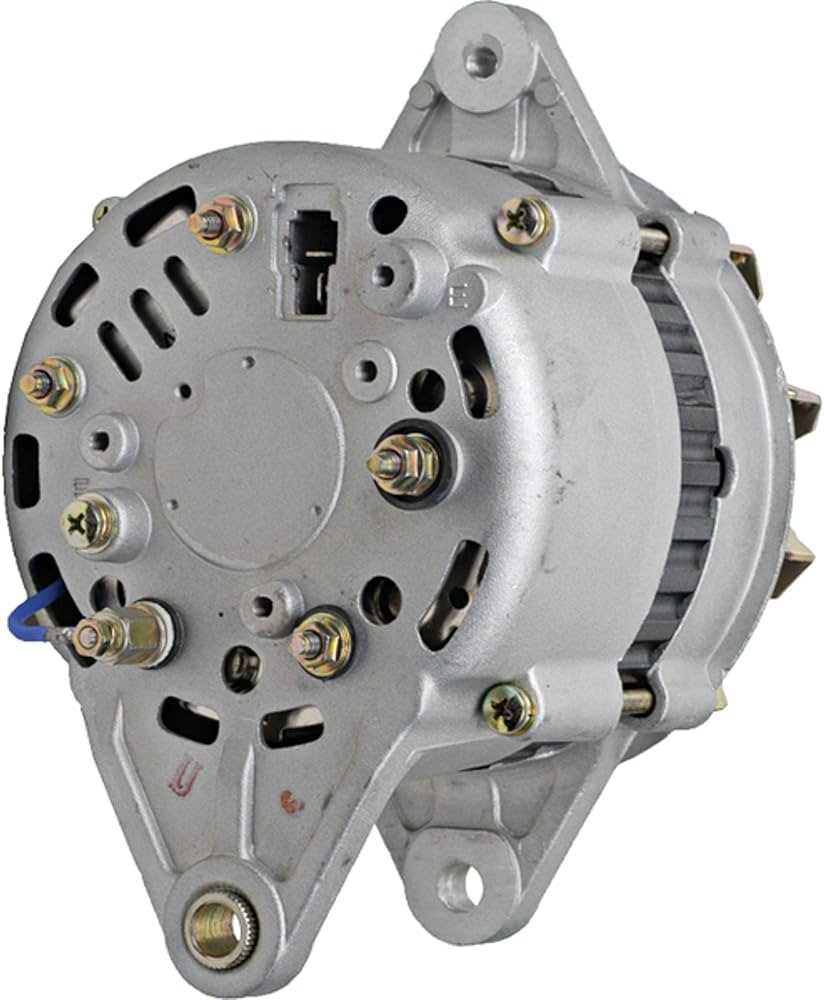

| Electrical Failures | Electrical issues can disrupt functionality. | Examine wiring, replace faulty connections. |

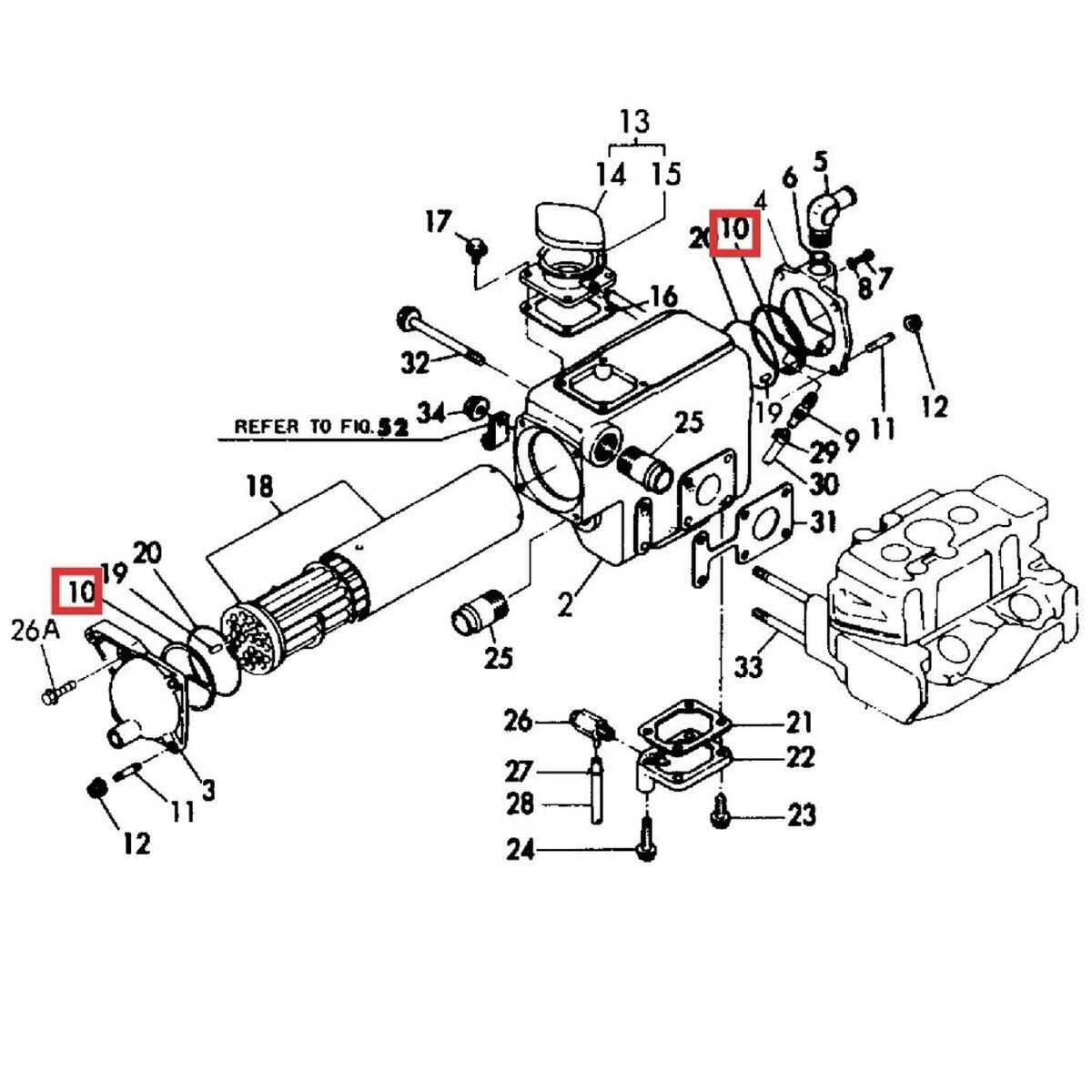

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair tasks. These illustrations provide essential insights into the structure and arrangement of various elements, making it easier to identify and source the necessary items.

To interpret these visuals effectively, follow these guidelines:

- Familiarize Yourself with Symbols: Different symbols represent various components. Knowing what each symbol signifies will aid in quick identification.

- Follow the Numbering System: Components are usually numbered in a logical sequence. This helps in tracking connections and relationships between parts.

- Refer to the Legend: Most illustrations include a legend that explains symbols and numbers. Always consult it for clarification.

- Understand Layout and Flow: Pay attention to how parts are arranged. This often reflects the order of assembly or disassembly.

- Use as a Reference: Keep the illustration handy during repairs. It can guide you in locating and replacing the right components.

By following these steps, you can navigate these essential visuals with confidence, ensuring that your tasks are completed efficiently and accurately.

Finding Genuine Yanmar Replacement Parts

Ensuring the longevity and optimal performance of your machinery requires sourcing authentic components. When it comes to maintenance or repairs, utilizing quality replacements is crucial for efficiency and reliability.

Here are some key steps to consider:

- Research Authorized Dealers

- Check Online Marketplaces for Authentic Listings

- Consult Manufacturer Websites for Recommendations

- Verify Part Numbers for Compatibility

- Read Customer Reviews and Testimonials

By following these guidelines, you can delve deeper into the process and ultimately secure the right components for your equipment.

Maintenance Tips for Yanmar Engines

Regular upkeep is essential for ensuring optimal performance and longevity of marine propulsion systems. By adhering to specific maintenance practices, operators can prevent issues and enhance reliability. Below are key recommendations for effective care and management of these engines.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours | Use high-quality oil to protect engine components. |

| Fuel Filter Replacement | Every 200 hours | Ensure clean fuel to prevent clogging and damage. |

| Coolant Level Check | Monthly | Maintain proper levels to avoid overheating. |

| Air Filter Inspection | Every 500 hours | Replace if dirty to ensure efficient airflow. |

| Belt Tension Check | Monthly | Adjust tension to prevent slippage and wear. |

In addition to these tasks, maintaining a clean environment around the engine and promptly addressing any leaks or unusual noises can significantly enhance operational reliability. Establishing a routine and keeping a detailed log of maintenance activities are also highly recommended.

Comparing 3HM35F with Other Models

When evaluating marine engines, it’s essential to consider various aspects that distinguish one model from another. Each engine brings unique features and specifications that cater to different boating needs and preferences. By analyzing performance, fuel efficiency, and maintenance requirements, one can make an informed decision about which engine suits their vessel best.

Performance: Different engines may offer varying horsepower and torque outputs, which directly affect acceleration and cruising capabilities. For instance, some models excel in high-speed applications, while others are designed for fuel efficiency during long voyages.

Fuel Efficiency: Another critical factor is how effectively each engine utilizes fuel. Models that prioritize economy can significantly reduce operating costs, making them attractive options for long-term use on the water.

Maintenance: The ease of maintenance is often a deciding factor for boat owners. Some engines have simpler designs that allow for quicker and easier service, while others might require specialized knowledge or tools, impacting overall reliability and downtime.

Ultimately, understanding these comparisons helps in making a knowledgeable choice, ensuring that the selected engine aligns with specific operational needs and boating goals.

Cost Factors for Yanmar Parts

When considering the expenses associated with marine engine components, several key elements influence the overall cost. Understanding these factors can help owners make informed decisions and optimize their maintenance budgets.

Quality and Brand Reputation

The reputation of the manufacturer plays a significant role in determining prices. Well-established brands often charge a premium due to their commitment to quality and reliability. Consumers may find that investing in higher-quality items can lead to long-term savings through improved performance and reduced maintenance needs.

Supply and Demand

The availability of specific components in the market can also impact their pricing. Limited supply often leads to increased costs, especially for rare or specialized items. Additionally, economic conditions and changes in manufacturing can influence the accessibility of certain parts, affecting their market value.

Logistics and Shipping are other critical factors that can contribute to the final price. Transportation costs, import duties, and delivery times can add significant expenses, especially for international orders.

By considering these aspects, individuals can better navigate the complexities of acquiring essential engine components while managing their costs effectively.

Where to Purchase Yanmar Components

Finding quality components for marine engines can be a challenge, especially when it comes to reliability and performance. Whether you are looking for essential parts for maintenance or upgrades, knowing the right sources can make all the difference. This section aims to guide you on where to find trusted suppliers and resources for your needs.

Authorized Dealers

One of the best places to start your search is through authorized dealers. These retailers are often equipped with genuine items that meet the required specifications and standards. They provide the assurance of quality and may also offer warranties on their products.

Online Marketplaces

Another option is to explore various online platforms. Numerous e-commerce sites specialize in marine equipment and accessories, offering a wide range of components. However, it’s crucial to check customer reviews and seller ratings to ensure a positive purchasing experience.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine parts, warranty | May be pricier |

| Online Marketplaces | Convenience, variety | Quality assurance needed |

| Local Marine Supply Stores | Immediate access, expert advice | Limited stock |

Upgrades and Modifications for Performance

Enhancing the efficiency and output of marine engines can lead to significant improvements in overall performance. By implementing strategic modifications, enthusiasts can achieve better speed, fuel economy, and reliability, making for a more enjoyable boating experience. This section explores various options for optimizing engine capabilities.

Engine Tuning and Calibration

Tuning the engine can unlock its full potential. Adjusting parameters such as fuel mixture and ignition timing can lead to noticeable gains in horsepower and torque. Employing specialized software or consulting with professionals can provide tailored adjustments for specific operating conditions.

Upgraded Components

Replacing standard components with high-performance alternatives can significantly enhance efficiency. Consider options like upgraded exhaust systems, improved air intakes, and stronger fuel pumps. These changes often result in better airflow and reduced restrictions, contributing to increased overall power and responsiveness.

Resources for Yanmar Engine Owners

Maintaining a reliable engine requires access to valuable information and tools that can aid in effective management. This section aims to provide essential resources tailored for enthusiasts and operators who seek to enhance their understanding and upkeep of their machinery.

Online Forums: Engaging with online communities can be invaluable. These platforms allow owners to share experiences, seek advice, and troubleshoot issues together.

Manufacturer’s Manuals: Accessing official documentation is crucial. These guides offer detailed insights into maintenance procedures and specifications, ensuring that owners follow the correct protocols.

Parts Suppliers: Reliable vendors are essential for sourcing quality components. Establishing relationships with trusted suppliers can streamline repairs and maintenance efforts.

Video Tutorials: Visual learning resources provide step-by-step instructions for common tasks. These can be particularly helpful for those who prefer hands-on approaches.

Local Mechanics: Building rapport with skilled technicians can provide peace of mind. They often possess extensive knowledge and can assist with complex repairs or regular service.

By utilizing these resources, owners can delve deeper into the nuances of their engines, ultimately enhancing performance and longevity.