Understanding the Components of a Deep Fryer

The intricate workings of cooking apparatus designed for frying are often taken for granted. Each element plays a crucial role in ensuring optimal performance and delicious outcomes. A comprehensive grasp of these components can elevate both cooking skills and culinary creativity.

From heating elements to specialized containers, every segment contributes to the overall efficiency and safety of the device. By exploring the various functionalities and interconnections of these sections, one can ultimately enhance their frying techniques and results.

In this exploration, we will delve into the essential components that make up this cooking tool. Understanding these elements not only enriches knowledge but also aids in troubleshooting and maintenance, ensuring a longer lifespan for the equipment.

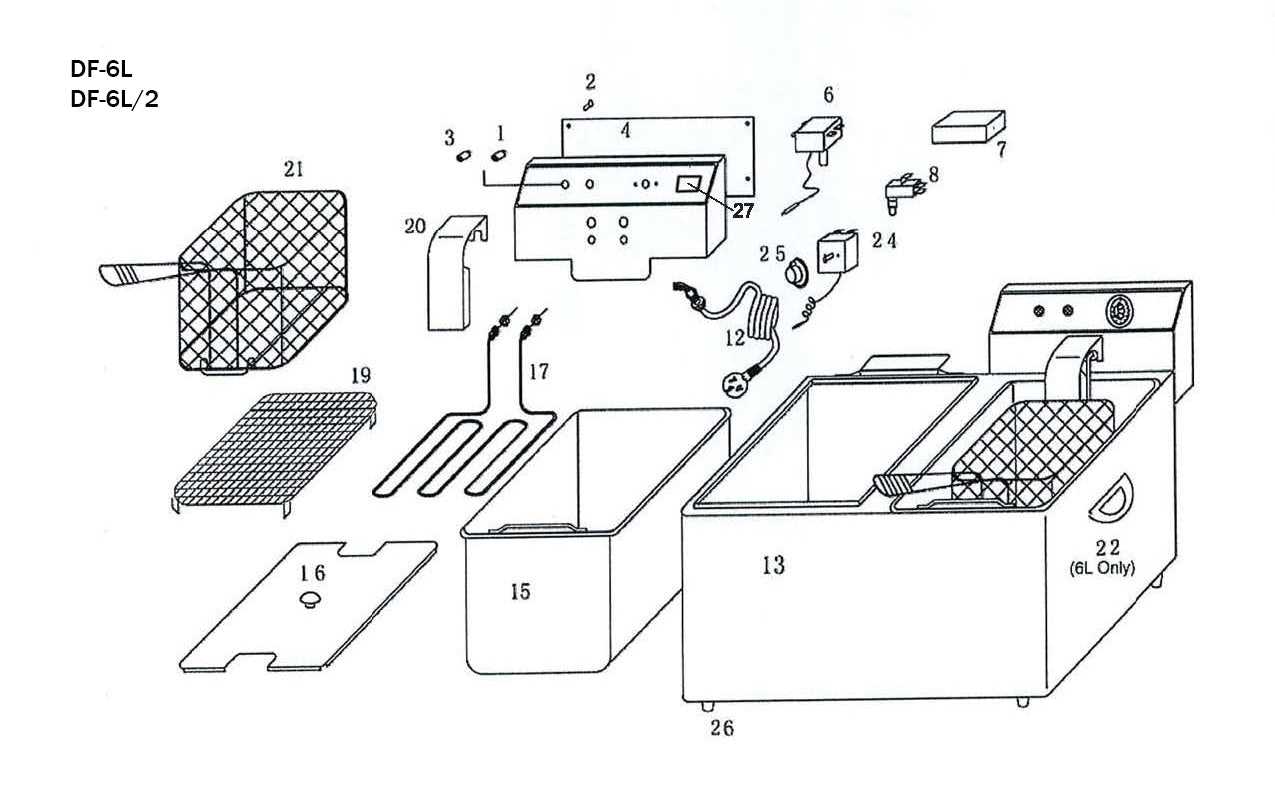

Understanding Deep Fryer Components

To create perfectly cooked, crispy dishes, it’s essential to grasp the various elements that make up a frying appliance. Each component plays a crucial role in ensuring that the cooking process is efficient, safe, and consistent. Familiarizing oneself with these elements not only enhances the user experience but also improves the overall quality of the fried food.

| Component | Function |

|---|---|

| Heating Element | Provides the necessary heat to maintain the cooking temperature. |

| Oil Container | Holds the cooking medium, allowing for effective heat transfer. |

| Basket | Supports food during cooking and allows for easy removal once done. |

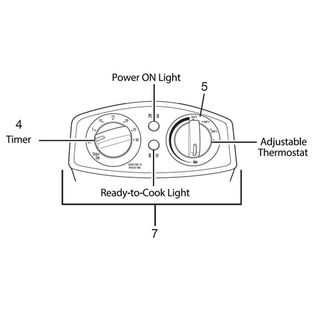

| Control Panel | Enables users to adjust temperature settings and timers for precision. |

| Safety Lid | Prevents splatter and controls the release of steam, enhancing safety. |

Understanding these components and their functions leads to better frying results and ensures that culinary creations are both delicious and well-prepared.

Key Parts of a Deep Fryer

Understanding the essential components of a frying appliance is crucial for achieving optimal cooking results. Each element plays a significant role in ensuring efficiency and safety during the frying process.

- Heating Element: This component is responsible for maintaining the desired temperature of the oil.

- Basket: Used to hold food while it cooks, allowing for easy immersion and retrieval.

- Oil Reservoir: The chamber that contains the cooking oil, designed for easy filling and cleaning.

- Temperature Control: A crucial feature for regulating heat and preventing overheating.

- Safety Lid: Protects users from splatters and helps contain aromas during frying.

Each of these components contributes to the ultimate functionality and safety of the cooking appliance, making it essential to familiarize oneself with them for an enjoyable cooking experience.

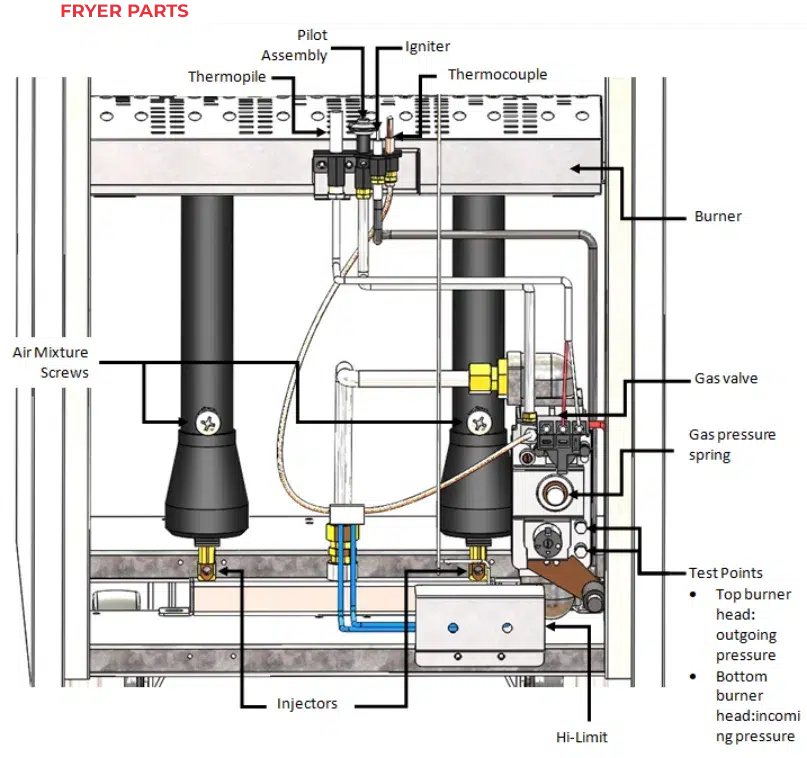

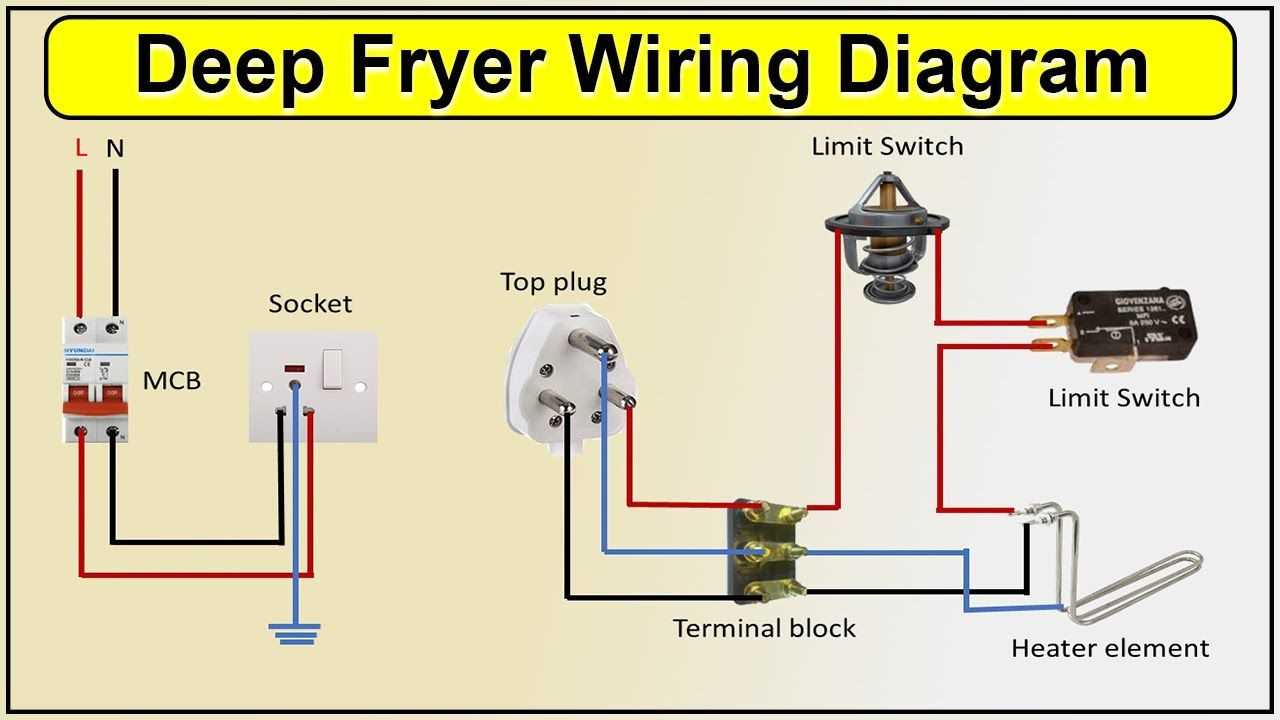

Functionality of Fryer Heating Elements

The heating components of cooking equipment play a crucial role in ensuring that food is prepared efficiently and consistently. These elements are designed to provide a reliable source of heat, which is essential for achieving the desired cooking temperatures. Understanding their operation helps in appreciating their significance in the overall cooking process.

Heating elements typically convert electrical energy into thermal energy, which then transfers to the cooking medium. The efficiency and effectiveness of these components can greatly influence the quality of the final dish. Here’s an overview of their primary functions:

| Function | Description |

|---|---|

| Heat Generation | The primary role is to produce heat through electrical resistance, allowing the cooking oil to reach optimal temperatures. |

| Temperature Control | Many heating elements come with built-in thermostats to regulate the temperature, ensuring food is cooked evenly. |

| Energy Efficiency | Modern components are designed to maximize heat retention and minimize energy consumption, which is beneficial for both cost savings and environmental impact. |

| Durability | Constructed from robust materials, these elements are built to withstand high temperatures and prolonged use, ensuring longevity. |

Overall, the functionality of heating components is integral to achieving optimal cooking results, enhancing both the taste and texture of prepared dishes.

Importance of Fryer Oil Reservoir

The oil reservoir plays a crucial role in ensuring the efficiency and effectiveness of cooking processes. It acts as a vital component that influences the quality of the final product, maintaining consistency and flavor while also impacting safety and maintenance routines.

Key Functions

- Storage of oil, allowing for optimal heat distribution.

- Facilitation of even cooking, preventing uneven textures.

- Assurance of safety by minimizing fire hazards through proper containment.

Maintenance and Quality

- Regular cleaning prevents oil degradation and enhances flavor.

- Monitoring oil levels ensures consistent cooking results.

- Filtering oil helps extend its life and maintain food quality.

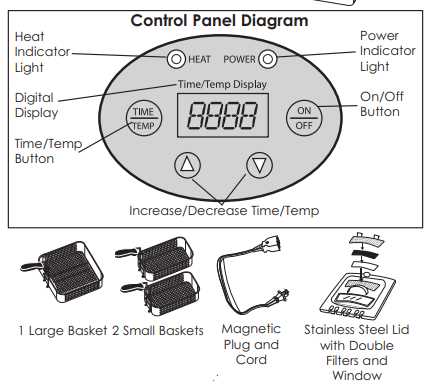

Control Mechanisms in Deep Fryers

The efficiency and safety of cooking equipment are significantly influenced by the systems that manage temperature and timing. These mechanisms are essential for ensuring optimal cooking results while preventing hazards. Understanding these components provides insights into how culinary devices operate effectively in both commercial and home settings.

Types of Control Systems

- Mechanical Controls: These are often found in simpler models and involve knobs or dials that allow users to manually adjust temperature settings.

- Digital Controls: More advanced units feature electronic interfaces that enable precise temperature regulation and timers, often with user-friendly displays.

- Programmable Controls: These allow users to set specific cooking cycles, which can enhance consistency and reduce the need for constant monitoring.

Key Features

- Temperature Sensors: These components monitor oil temperature to ensure it stays within desired ranges.

- Safety Cut-Offs: Systems designed to automatically turn off the appliance if temperatures exceed safe limits.

- Timers: Built-in timing devices that alert users when cooking is complete, helping prevent overcooking.

Effective control mechanisms not only enhance cooking performance but also promote safety and energy efficiency, making them crucial for any cooking appliance.

Safety Features of Fryer Designs

Modern cooking appliances incorporate a variety of protective mechanisms to ensure user safety and efficient operation. These innovations minimize risks associated with high temperatures and prevent accidents in the kitchen environment.

Temperature Control: Accurate heat regulation is crucial. Many models feature automatic shut-off systems that engage if the device overheats, thereby reducing fire hazards.

Non-slip Feet: Stability is essential during use. Non-slip bases help prevent accidental tipping, ensuring a secure cooking experience.

Heat-resistant Handles: Cool-touch handles are designed to minimize the risk of burns. These are crafted from materials that remain safe to touch, even when the unit is in operation.

Safety Lids: Some designs include lids that prevent splatter and control vapor release, enhancing user protection while cooking.

Automatic Safety Features: Many advanced models are equipped with sensors that detect oil levels and temperature irregularities, activating alerts or shutdowns to safeguard users.

By integrating these thoughtful enhancements, contemporary cooking devices strive to provide a secure and efficient culinary experience, allowing enthusiasts to enjoy their craft with peace of mind.

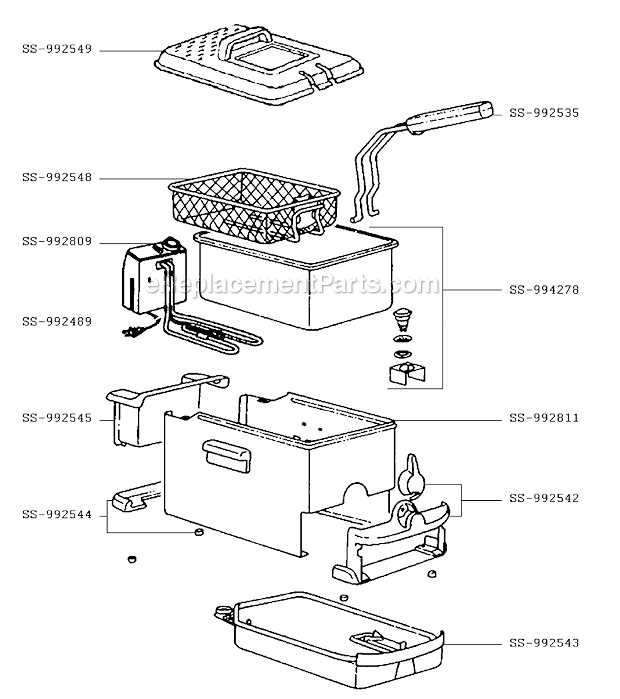

Fryer Basket: Design and Usage

The basket plays a crucial role in the cooking process, facilitating the immersion of food into hot oil while ensuring optimal results. Its thoughtful design enhances efficiency, safety, and convenience in preparing various dishes.

Construction Features

The design of the cooking receptacle typically includes a sturdy frame and mesh material, allowing for even heat distribution and easy drainage of excess oil. Features such as ergonomic handles and locking mechanisms add to user safety and comfort.

Practical Applications

These baskets are versatile, commonly used for frying vegetables, proteins, and snacks. Their ability to hold items securely while submerged makes them essential for achieving crispy textures.

| Feature | Benefit |

|---|---|

| Mesh Design | Promotes even cooking and drainage |

| Ergonomic Handle | Ensures safe handling |

| Locking Mechanism | Prevents accidental spills |

Maintenance Tips for Fryer Parts

Proper upkeep of cooking equipment is essential for ensuring optimal performance and longevity. Regular attention to key components not only enhances efficiency but also promotes safety and food quality.

Routine Cleaning

Consistent cleaning is crucial. Residue buildup can lead to malfunction and undesirable flavors in food. Use appropriate cleaning agents and follow manufacturer guidelines to maintain a pristine environment.

Regular Inspections

Conduct frequent checks on vital components. Look for wear and tear, corrosion, or any signs of damage. Early detection of issues can prevent costly repairs and ensure smooth operation.

Types of Deep Fryer Materials

When it comes to culinary equipment for frying, the choice of materials significantly influences performance, durability, and maintenance. Different substances bring unique properties to the cooking experience, affecting everything from heat retention to ease of cleaning.

Common Materials Used

Among the most prevalent materials are stainless steel, aluminum, and cast iron. Stainless steel is favored for its resistance to rust and corrosion, ensuring longevity. Aluminum, on the other hand, is lightweight and provides excellent heat conduction, allowing for quick temperature adjustments. Cast iron is renowned for its ability to maintain consistent heat, making it a popular choice for those seeking rich, flavorful results.

Specialty Materials

In addition to these common options, some units utilize ceramic coatings or non-stick surfaces. These coatings can simplify cleanup and reduce the need for excessive oils. However, they may require more careful handling to avoid scratching or damage. Each material type offers distinct advantages, catering to various cooking styles and preferences.

Common Issues with Fryer Components

When it comes to frying appliances, various elements can encounter problems that affect performance and safety. Identifying these issues early can help maintain efficiency and prolong the lifespan of the equipment.

- Heating element failures

- Clogged oil filtration systems

- Faulty thermostats leading to temperature inconsistencies

- Damaged power cords and connections

- Wear and tear on baskets and lids

Regular maintenance and timely repairs are essential to ensure optimal functionality and prevent more significant malfunctions down the line.

Upgrades for Efficient Frying

Enhancing the performance of your cooking equipment can lead to superior results and energy savings. By implementing certain modifications, you can optimize the frying process, ensuring quicker cooking times and better food quality.

- High-Quality Heating Elements: Upgrade to more efficient heating components that provide consistent temperatures.

- Thermostatic Control: Install advanced thermostats for precise temperature management.

- Insulated Frying Units: Utilize insulated designs to retain heat and reduce energy consumption.

- Filtration Systems: Incorporate effective oil filtration to extend the life of your cooking medium.

- Smart Monitoring: Employ digital sensors for real-time temperature and oil quality monitoring.

These enhancements not only improve cooking efficiency but also elevate the overall dining experience.