Understanding Stihl MS391 Parts Diagram

The functionality of any cutting tool relies heavily on its internal elements. Knowing the layout and role of each component is crucial for effective maintenance and repairs. This section aims to provide a comprehensive overview of the various pieces that make up a typical cutting device, ensuring optimal performance and longevity.

By familiarizing yourself with the intricate design and arrangement of these essential parts, you can better troubleshoot issues that may arise during operation. A clear understanding of how each element interacts will not only enhance your repair skills but also promote a safer working environment.

In this guide, we will explore the specific roles of different sections within the machinery. Each part plays a vital role, contributing to the overall efficiency and reliability of the tool. Whether you’re a seasoned professional or a novice user, grasping the details of these components will empower you to maintain your equipment with confidence.

This section aims to provide a comprehensive overview of the various elements that comprise the equipment in question. Understanding these components is essential for proper maintenance and effective troubleshooting. Each part plays a critical role in ensuring optimal performance and reliability.

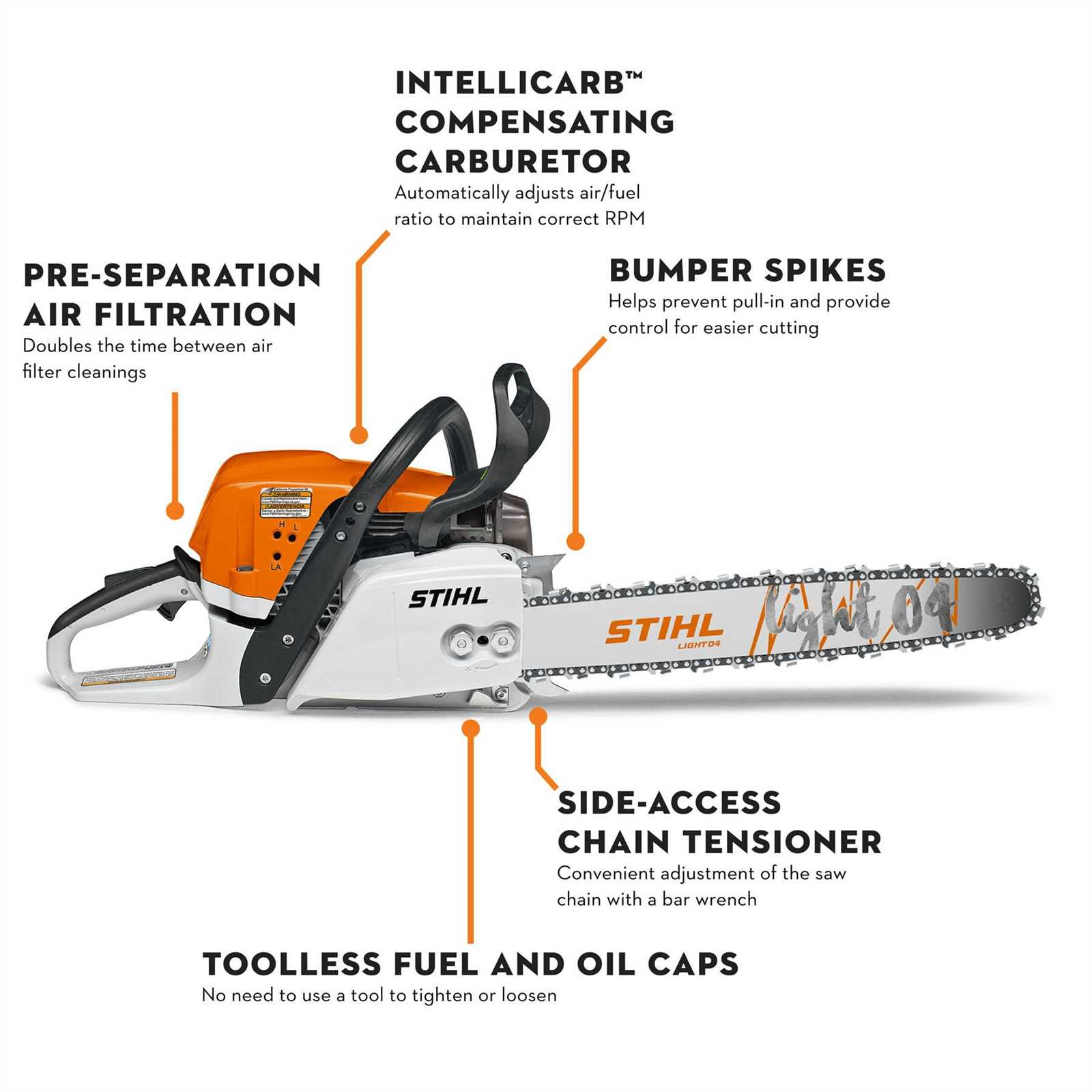

Essential Features of the Equipment

- Overview of key attributes

- Importance of durability and performance

- Impact on user experience

Common Components and Their Functions

- Engine assembly: power source and operation

- Fuel system: types of fuel and delivery mechanisms

- Bar and chain: cutting mechanisms

Maintenance and Care

- Routine inspections for longevity

- Lubrication procedures

- Replacement schedules for wear and tear

Troubleshooting Common Issues

- Identifying performance problems

- Steps for resolving starting issues

- Dealing with cutting difficulties

Safety Considerations

- Protective gear recommendations

- Proper handling techniques

- Emergency procedures

Frequently Asked Questions

- What to do when the machine won’t start?

- How to extend the life of components?

- Common myths about operation

Tools Required for Repairs

- Basic toolset overview

- Specialized equipment for complex tasks

- Where to source tools

Upgrades and Modifications

- Popular enhancements for performance

- Impact of upgrades on functionality

- Considerations before modifying

Choosing Quality Replacement Parts

- Factors to consider when selecting parts

- Comparison of OEM vs aftermarket options

- Where to purchase quality components

Understanding User Manuals

- Importance of referring to manuals

- How to read and interpret diagrams

- Utilizing manuals for troubleshooting

Community Resources and Support

- Online forums for advic

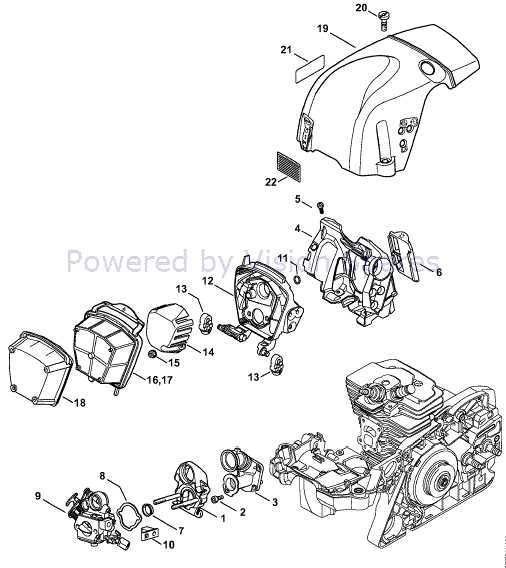

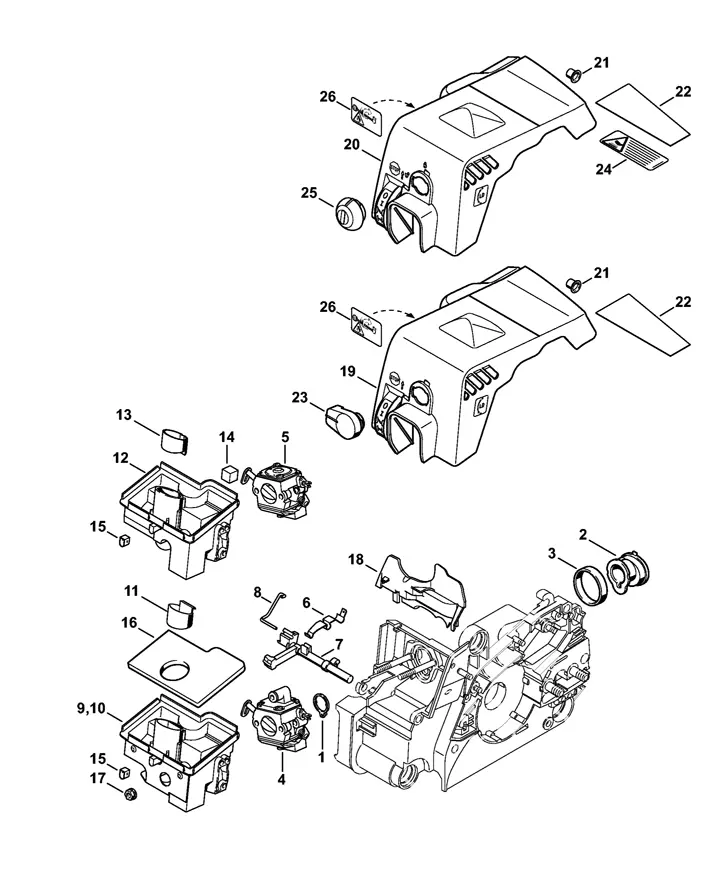

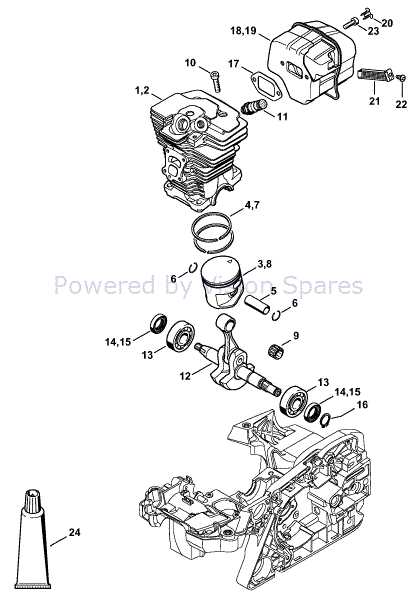

Exploring the Engine Assembly

The engine assembly is a crucial component that powers a variety of outdoor equipment. Understanding its structure and function can significantly enhance your ability to maintain and troubleshoot these machines. This section delves into the various elements that constitute the engine, highlighting their roles and interactions.

Key Components: Within the assembly, several vital parts work in harmony to generate energy. The piston, cylinder, and crankshaft are fundamental elements that facilitate the conversion of fuel into mechanical motion. Each component must function optimally to ensure efficient operation.

Maintenance Tips: Regular inspection and maintenance of the engine assembly are essential for longevity and performance. Ensure that the air filter is clean, and check for any signs of wear on the gaskets and seals. Proper lubrication of moving parts will also prevent friction and overheating, contributing to the overall efficiency of the equipment.

Conclusion: A thorough understanding of the engine assembly enhances not only performance but also safety. Familiarity with these components empowers users to make informed decisions regarding maintenance and repairs, ensuring the equipment remains in top condition.

Chain and Bar Specifications

The performance of any cutting tool heavily relies on the specifications of its chain and bar. These components are essential for achieving optimal results and ensuring the tool operates efficiently. Understanding the various measurements and characteristics of the chain and bar can significantly impact the overall functionality and longevity of the equipment.

Specification Description Bar Length Measured from the tip of the bar to the point where it attaches to the engine, determining the maximum cutting diameter. Chain Type Refers to the design of the chain links, which affects cutting speed and precision. Gauge The width of the groove in the bar where the chain fits, ensuring a proper fit and smooth operation. Pitch The distance between the drive links, which influences compatibility with the bar and overall performance. Number of Links The total count of drive links in the chain, affecting the length and cutting capability. Fuel System Breakdown

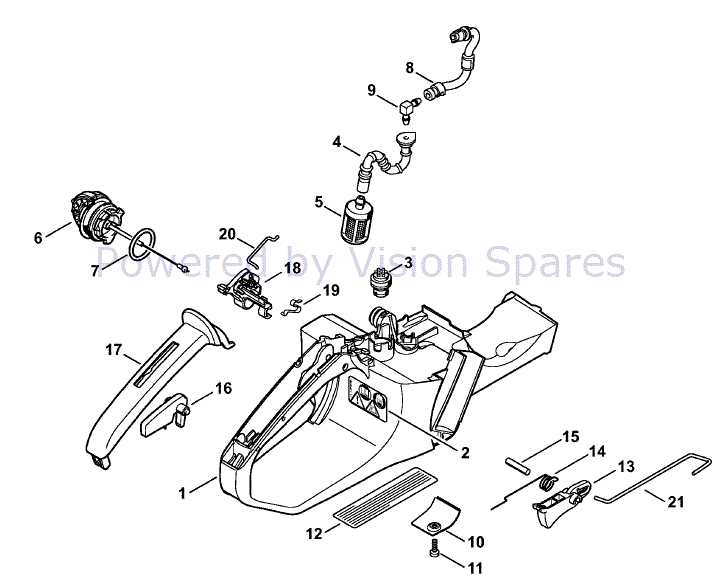

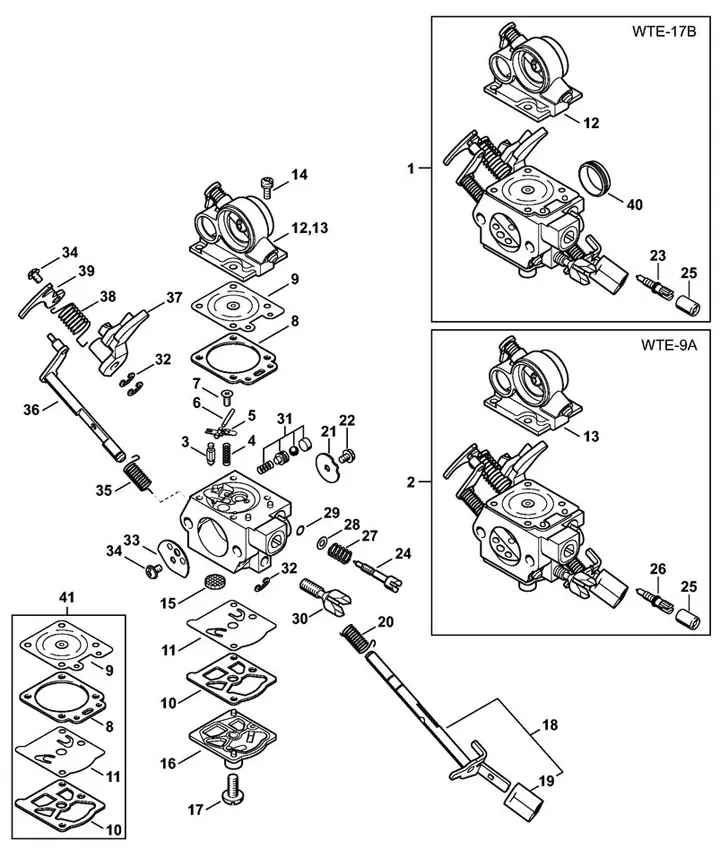

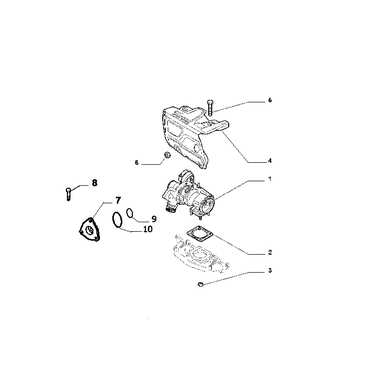

The fuel system of a chainsaw is crucial for its optimal performance, ensuring that the engine receives the necessary mixture of fuel and air. Understanding the components involved in this system can help in diagnosing issues and performing maintenance effectively.

Key Components

Essential parts of the fuel system include the fuel tank, fuel lines, filter, and carburetor. Each element plays a vital role in delivering the correct amount of fuel to the engine, maintaining efficiency, and preventing potential failures.

Maintenance Tips

Regular checks and cleaning of the fuel filter are recommended to avoid clogs that can hinder fuel flow. Additionally, inspecting fuel lines for wear and ensuring proper sealing will enhance the longevity and reliability of the chainsaw’s operation. Always use high-quality fuel to prevent deposits from forming within the system.

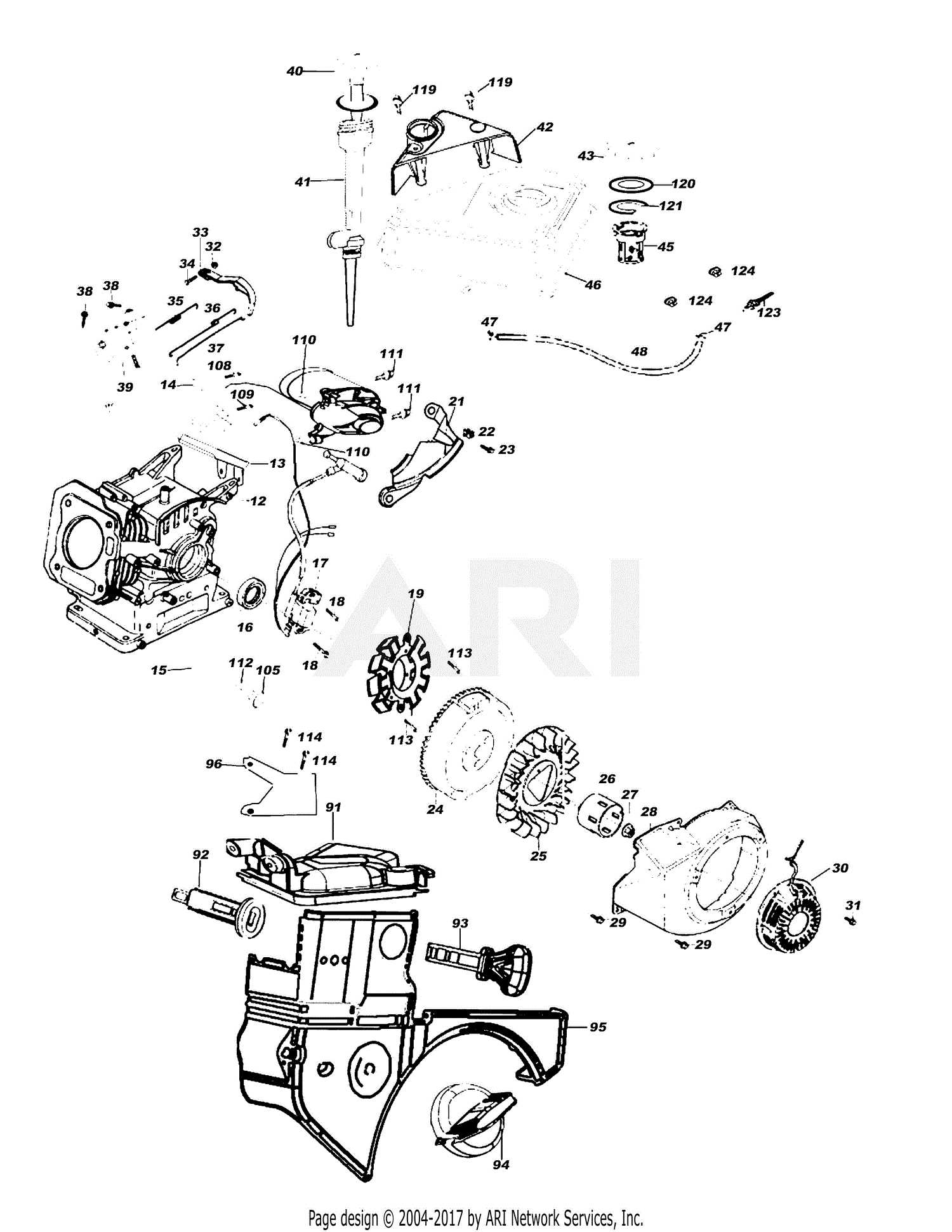

Ignition Parts Overview

The ignition system is a crucial component in ensuring the effective operation of a small engine. This system is responsible for generating the spark necessary to ignite the fuel-air mixture in the combustion chamber, ultimately leading to the engine’s performance. Understanding the various components involved in this system can help in troubleshooting and maintenance.

Key elements of the ignition assembly include:

- Ignition Coil: Converts battery voltage into a high-voltage spark.

- Spark Plug: Creates the actual spark that ignites the mixture.

- Flywheel Magnet: Provides the necessary magnetic field to generate current.

- Contact Points: Ensure the correct timing of the spark generation.

- Ignition Module: Regulates the timing and strength of the spark.

Each of these components plays a vital role in the ignition process, and any malfunction can lead to performance issues or engine failure. Regular inspection and maintenance of these parts can help prevent unexpected breakdowns.

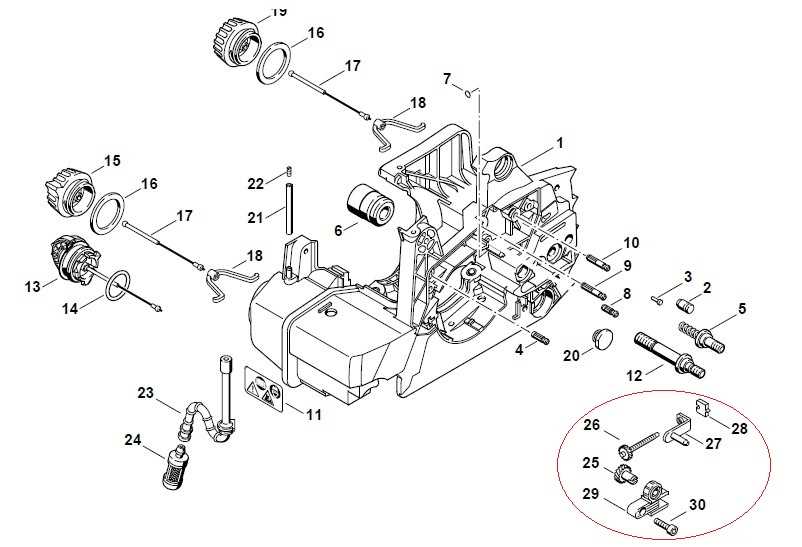

Lubrication Mechanism Details

The lubrication system plays a crucial role in ensuring the smooth operation and longevity of cutting equipment. By providing a continuous flow of lubricant, it minimizes friction between moving parts, thereby enhancing performance and reducing wear. Understanding the components and functioning of this system is essential for proper maintenance and optimal efficiency.

Components of the Lubrication System

Key elements of the lubrication system include the oil reservoir, pump, and delivery lines. The oil reservoir stores the lubricant, while the pump circulates it through the system. Delivery lines ensure that the lubricant reaches critical areas, promoting adequate coverage and reducing the risk of overheating.

Importance of Regular Maintenance

Regular maintenance of the lubrication system is vital for ensuring reliable operation. Checking oil levels, inspecting for leaks, and replacing worn components contribute to the system’s efficiency. Keeping the lubrication mechanism in good condition not only prolongs the life of the equipment but also enhances its performance during use.

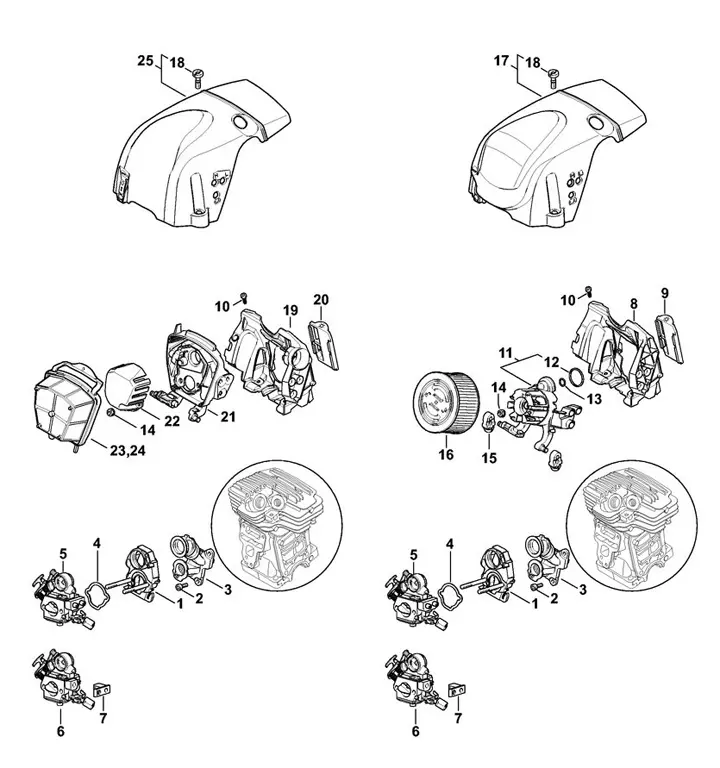

Air Filtration System Insights

The air filtration system plays a crucial role in maintaining optimal performance in various machinery. This system is designed to prevent harmful particles and debris from entering the engine, ensuring a clean airflow that supports efficient combustion. Understanding how this component functions and the importance of regular maintenance can significantly enhance the longevity and efficiency of the equipment.

Effective air filtration relies on a series of components that work together to capture contaminants. Regular checks and timely replacements of the filter elements are essential for sustaining high operational standards. Neglecting this system can lead to reduced performance and increased wear on engine parts.

Component Function Maintenance Tips Air Filter Traps dirt and debris Replace regularly; clean if reusable Pre-Filter Removes larger particles Inspect frequently; clean as needed Filter Housing Protects the filter Ensure it is sealed properly Starter Mechanism Analysis

The starter mechanism plays a crucial role in the functioning of any engine, serving as the initial system that engages the engine to begin operation. Understanding its components and their interactions is essential for effective maintenance and troubleshooting.

Components Overview

The starter assembly typically includes several key elements: the pull cord, recoil spring, and the engagement pawls. Each component works in unison to ensure a smooth and reliable start, allowing the engine to transition from an inactive to an operational state.

Common Issues and Solutions

While the starter mechanism is generally robust, it can encounter issues that hinder performance. Some frequent problems include wear on the pull cord, malfunctioning springs, or jammed pawls. Identifying these issues early can prevent more significant damage and ensure consistent engine reliability.

Issue Symptoms Possible Solutions Worn Pull Cord Difficulty in starting, frayed edges Replace the pull cord Malfunctioning Recoil Spring Inconsistent engagement, noise during operation Inspect and replace the spring Jammed Pawls Starter fails to engage Clean and lubricate the pawls Handle and Grip Design Features

The design of handles and grips plays a crucial role in the usability and comfort of power tools. Ergonomically crafted grips not only enhance user control but also reduce fatigue during extended use. Features such as shape, material, and texture contribute significantly to the overall user experience.

Ergonomic Shape

An ergonomic shape is essential for providing a natural grip, allowing users to maintain a comfortable hold without straining their hands. This design consideration ensures that the tool can be used for longer periods without discomfort.

Materials and Textures

The materials used in handles can greatly influence grip quality. Soft-touch materials often provide better friction, enhancing control even in wet conditions. Additionally, textured surfaces can prevent slipping, offering a secure hold.

- Soft rubber grips for enhanced comfort.

- Textured surfaces for improved traction.

- Shock-absorbing materials to reduce vibrations.

- Adjustable handle positions for personalized comfort.

- Evaluate the handle shape for ergonomic benefits.

- Choose materials that suit the intended usage environment.

- Test grip textures for optimal control.

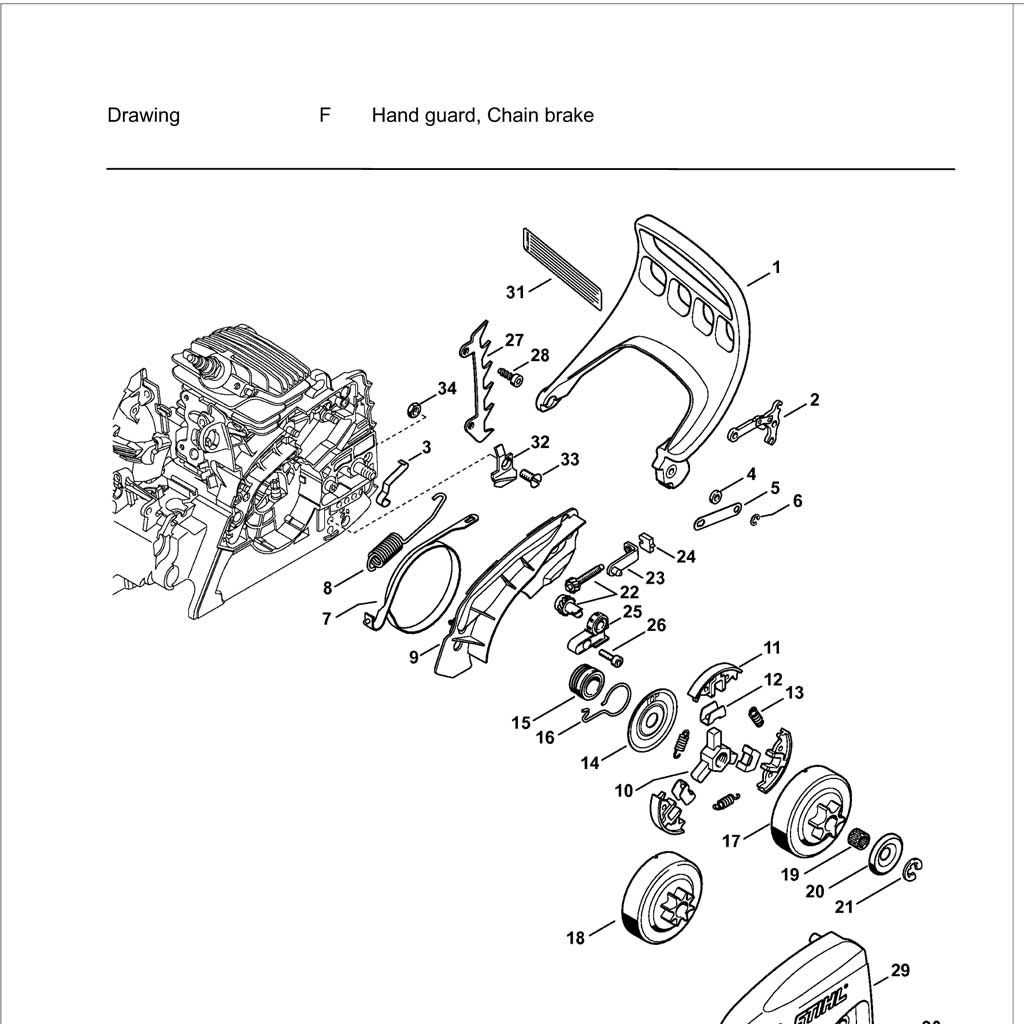

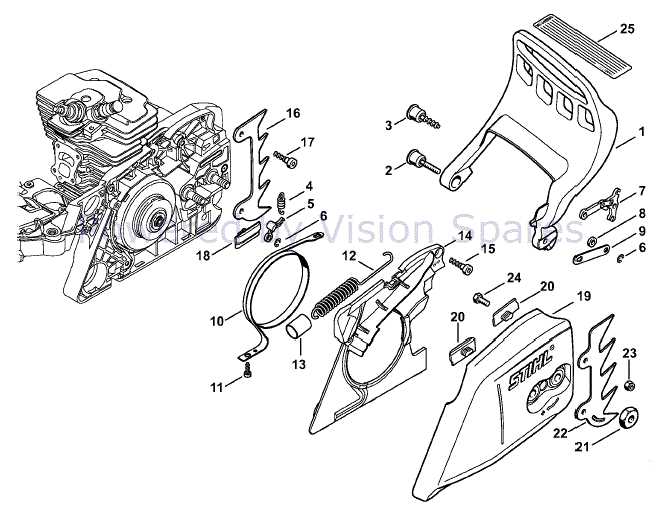

Safety Features and Additions

When operating powerful machinery, ensuring the highest level of safety is crucial. Various enhancements and features have been designed to protect users and promote secure operation. These components not only safeguard the operator but also contribute to overall equipment longevity.

Among the essential safety features found in modern machines are:

- Chain Brake: This mechanism stops the chain quickly in the event of kickback, significantly reducing the risk of injury.

- Anti-Vibration System: Reducing vibrations helps minimize operator fatigue and enhances comfort during extended use.

- Safety Throttle Lock: Prevents unintentional activation of the throttle, ensuring the machine only operates when intended.

- Felling Spike: Provides stability while cutting, allowing for better control and accuracy.

- Automatic Oilers: Ensures proper lubrication of the chain, enhancing performance and preventing overheating.

In addition to these built-in features, users can consider optional accessories to further enhance safety:

- Protective Gear: Wearing helmets, goggles, gloves, and chaps can significantly reduce injury risk.

- Safety Chains: Available for added stability during cutting operations.

- Visibility Enhancements: Reflective stickers or bright colors help ensure the operator remains visible in various conditions.

Incorporating these safety features and accessories into regular use can lead to a more secure and efficient working environment.

Maintenance Parts and Tools

Proper upkeep of equipment is essential for ensuring optimal performance and longevity. Various components and tools play a critical role in this process, allowing users to maintain their machinery efficiently. Understanding the necessary items and how to utilize them can significantly enhance the maintenance experience.

Essential Components for Upkeep

Maintaining machinery requires a selection of key components that contribute to its functionality. These may include filters, blades, and spark plugs. Each part serves a specific purpose, and regularly checking their condition can prevent larger issues from arising.

Recommended Tools for Maintenance

Alongside components, having the right tools is crucial for effective maintenance. Tools such as wrenches, screwdrivers, and cleaning brushes should be part of every user’s toolkit. Utilizing these instruments ensures that tasks can be completed swiftly and accurately, reducing downtime and enhancing productivity.

Common Replacement Parts List

When it comes to maintaining outdoor equipment, understanding the essential components that may require periodic replacement is crucial. This section outlines a selection of frequently needed items to ensure optimal performance and longevity of your device. Regularly replacing worn or damaged elements can significantly enhance efficiency and reduce the likelihood of breakdowns.

Essential Components

Among the key items that users should consider for replacement are:

- Air Filters: Vital for keeping the engine free from debris and ensuring proper airflow.

- Chains: Necessary for efficient cutting and should be inspected regularly for wear.

- Fuel Lines: Important for maintaining a steady flow of fuel; damaged lines can lead to performance issues.

- Spark Plugs: Crucial for ignition; replacing them can improve starting efficiency and engine performance.

Maintenance Tips

To prolong the lifespan of these components, it is advisable to:

- Perform regular inspections to identify signs of wear.

- Use quality replacement items to ensure compatibility and performance.

- Follow the manufacturer’s guidelines for maintenance schedules.