Understanding the Stihl RE 90 Parts Diagram for Easy Maintenance

In the realm of outdoor tools and machinery, grasping the intricacies of their construction is essential for effective maintenance and operation. Familiarizing oneself with the various elements that contribute to functionality not only enhances performance but also extends the lifespan of the device. This knowledge serves as a foundation for troubleshooting and repairs, allowing users to tackle challenges with confidence.

By exploring the visual representations of these essential components, one can develop a clearer understanding of how each piece interconnects and contributes to overall efficiency. A comprehensive overview of these elements reveals the importance of each individual part and how they work harmoniously to achieve optimal results. Embracing this knowledge empowers users to take proactive measures in their upkeep routines.

Whether you’re a seasoned operator or a newcomer eager to learn, delving into the layout and relationship of the various sections of your machinery will prove invaluable. Armed with this insight, you will be better equipped to handle maintenance tasks, ensuring your equipment remains reliable and performs at its best, no matter the challenge.

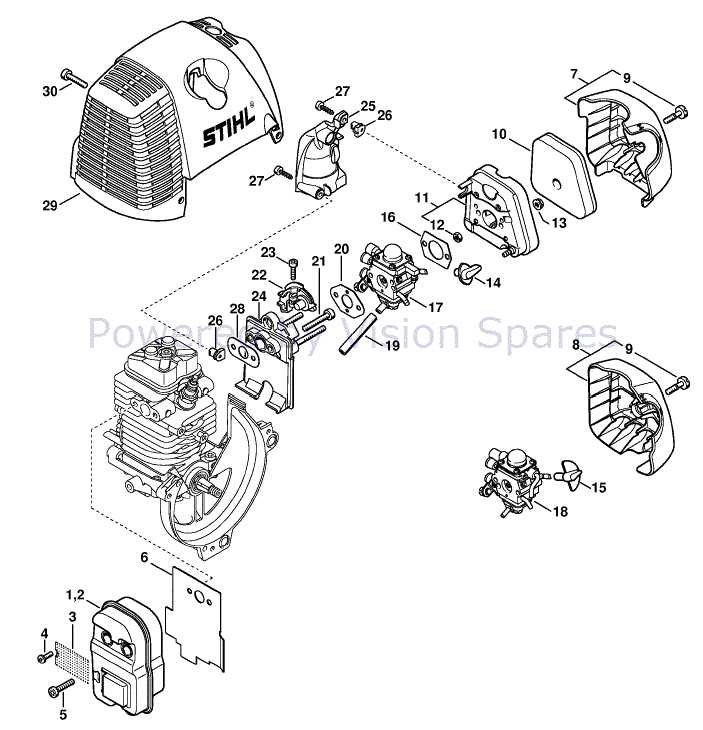

Understanding Stihl RE 90 Components

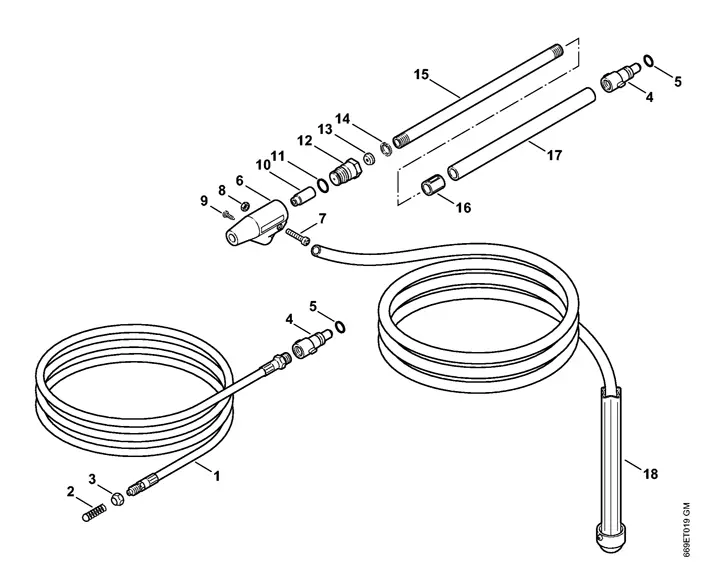

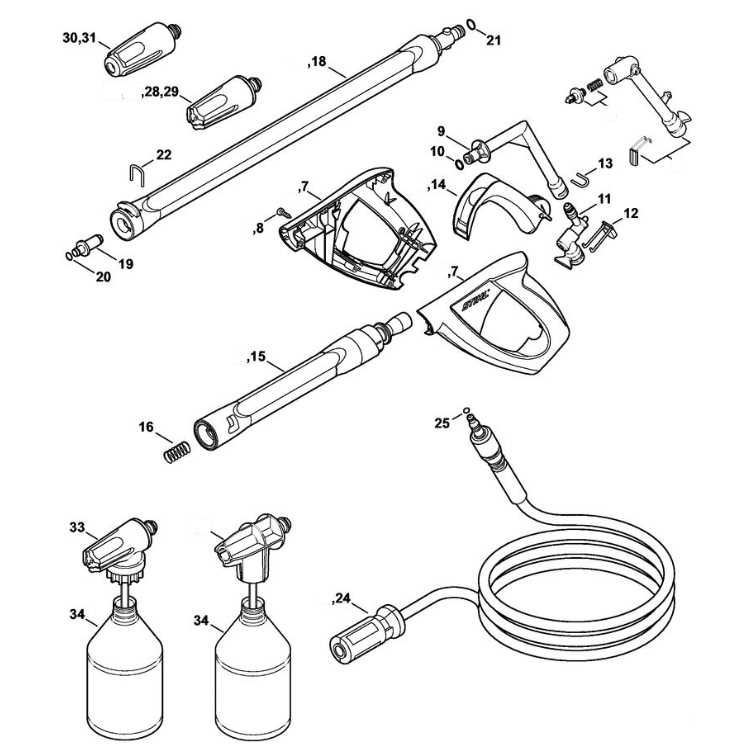

Exploring the intricacies of a pressure washer reveals a well-engineered assembly that contributes to its efficiency and effectiveness. Each element plays a crucial role in the overall functionality, ensuring that tasks are completed with precision and ease. A thorough comprehension of these components allows users to maximize performance and troubleshoot issues effectively.

Key Elements of the Pressure Washer

At the heart of this machine lies the motor, which serves as the powerhouse, converting electrical energy into mechanical force. Coupled with the pump, it generates the high-pressure water necessary for cleaning various surfaces. The nozzle system further enhances this functionality by allowing users to adjust the spray pattern according to the task at hand, making it versatile for different applications.

Maintenance and Care

Regular upkeep of these critical components is essential for longevity and optimal performance. Routine checks on the hose and connections help prevent leaks, while ensuring the filters are clean enhances the machine’s efficiency. Understanding how each part interacts within the system not only facilitates better maintenance but also empowers users to address minor issues before they escalate.

Importance of Parts Diagrams

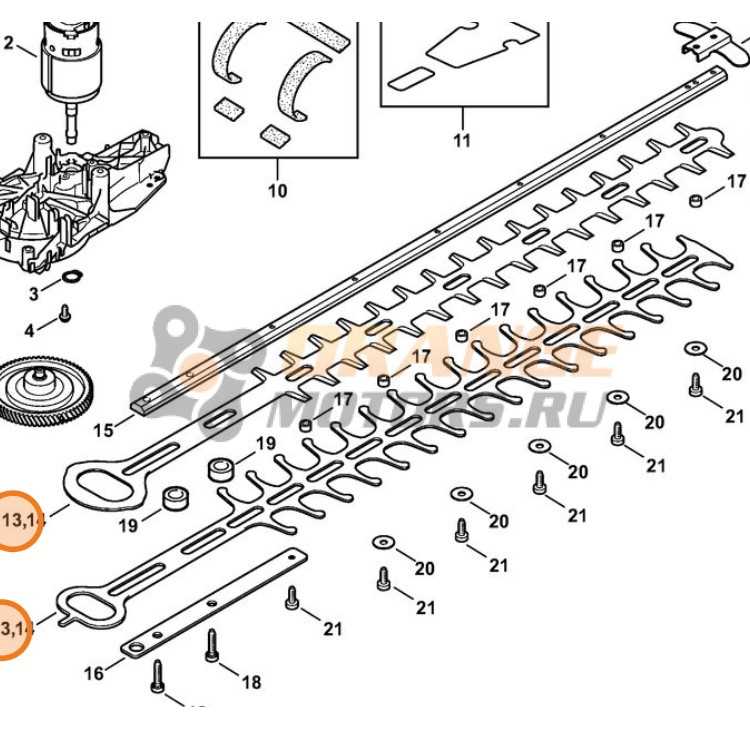

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as essential tools for both professionals and enthusiasts, allowing users to understand the intricate relationships and functions of various elements within a system. By providing a clear overview, these illustrations facilitate more efficient troubleshooting and assembly processes.

Enhancing Understanding

Having access to detailed schematics enhances comprehension of how different elements interact. Users can quickly identify individual parts, their placements, and potential issues, which streamlines the repair process. This clarity reduces the likelihood of mistakes, ensuring that each component is correctly addressed.

Streamlining Repairs

When tackling maintenance tasks, accurate visual aids can save significant time. By following step-by-step guides based on these representations, individuals can complete repairs more effectively. Additionally, these resources enable users to order the right components without guesswork, minimizing downtime and enhancing productivity.

In summary, visual guides are invaluable for anyone involved in equipment maintenance, promoting efficiency and a deeper understanding of mechanical systems. Their role in simplifying complex processes cannot be overstated.

Key Features of Stihl RE 90

The RE 90 model stands out in its category due to its exceptional performance and user-friendly design. This high-pressure cleaner combines efficiency with reliability, making it an ideal choice for various cleaning tasks around the home and garden. Its features are tailored to enhance usability and ensure thorough results, appealing to both casual users and professionals alike.

Powerful Performance

Equipped with a robust motor, this device delivers impressive water pressure and flow rate, allowing users to tackle stubborn dirt and grime with ease. Its efficient nozzle design optimizes cleaning capabilities, ensuring that every task is completed effectively.

User-Friendly Design

Convenience is at the forefront of this model’s design. Lightweight and portable, it is easy to maneuver and store. Additionally, the quick-connect system for hoses and nozzles simplifies setup and transitions between cleaning tasks.

| Feature | Description |

|---|---|

| Power Rating | High-performance motor for optimal cleaning power |

| Pressure Control | Adjustable pressure settings for various surfaces |

| Portability | Lightweight design for easy transport and storage |

| Accessory Compatibility | Compatible with a range of nozzles and attachments |

Common Issues and Solutions

When using outdoor equipment, users often encounter various challenges that can affect performance and efficiency. Understanding these common problems and their remedies can significantly enhance the overall experience and longevity of the machinery.

Frequent Problems

One of the most prevalent issues is difficulty starting the engine. This can stem from factors such as a clogged air filter, stale fuel, or spark plug malfunctions. Additionally, improper fuel mixture ratios may lead to poor combustion, resulting in reduced power and efficiency.

Effective Solutions

To resolve starting issues, first check and clean the air filter to ensure proper airflow. Replace stale fuel with fresh gasoline mixed with the correct oil ratio. Inspect and replace spark plugs if necessary to restore reliable ignition. Regular maintenance, such as cleaning and inspecting components, can prevent many of these common challenges.

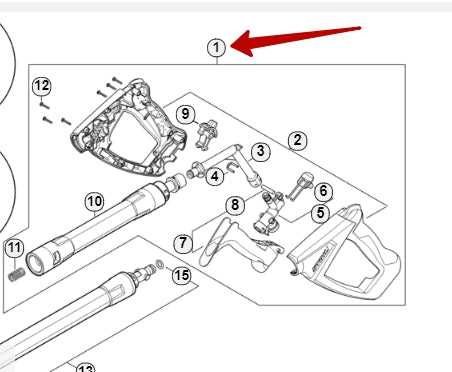

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. These visual aids provide a clear outline of individual elements, their arrangement, and how they interact within a system. By familiarizing yourself with the symbols and layout, you can easily identify the necessary components for any given project.

Here are some key steps to help you navigate these illustrations:

| Step | Description |

|---|---|

| 1 | Identify the overall structure. Look for the main assembly or framework that supports all components. |

| 2 | Examine the labels. Most representations include annotations that indicate part numbers or names, helping you locate specific items. |

| 3 | Trace connections. Follow lines or arrows that show how different elements link together, which is crucial for understanding functionality. |

| 4 | Consult the legend. If available, this key provides definitions for symbols used, ensuring accurate interpretation. |

| 5 | Cross-reference with a list. Often, an accompanying document provides additional details about each element, including specifications and compatibility. |

By following these guidelines, you can enhance your comprehension and confidently approach any repair or assembly task, ensuring efficient and accurate work.

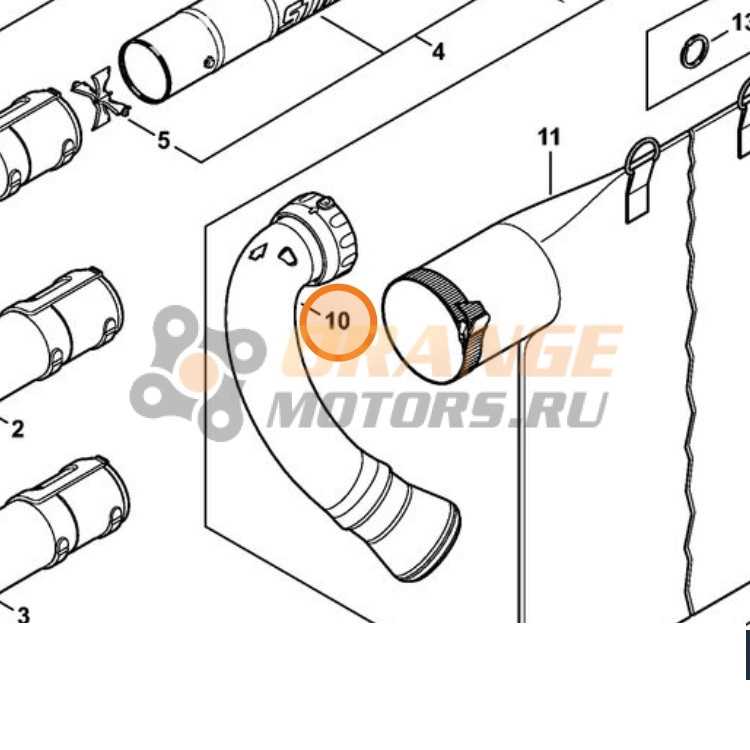

Maintenance Tips for RE 90

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. Following a few straightforward practices can prevent wear and tear, enhance efficiency, and minimize the likelihood of breakdowns. A consistent maintenance routine will not only keep your machine running smoothly but also contribute to safer operation.

Firstly, always inspect the device before each use. Look for any signs of damage, loose components, or wear that may require attention. Cleaning the exterior and removing debris will help maintain airflow and prevent overheating. Additionally, checking fluid levels and replacing them as necessary is crucial for proper functionality.

It’s important to pay attention to the filters and ensure they are clean. Clogged filters can impede performance and increase fuel consumption. Regularly changing or cleaning these components will improve efficiency. Also, lubricating moving parts according to the manufacturer’s recommendations can significantly extend their lifespan.

Finally, store the equipment in a dry, sheltered area when not in use. This protects it from environmental factors that can cause deterioration. Keeping a maintenance log can also be helpful, allowing you to track services performed and plan for future upkeep effectively.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for optimal performance and longevity. Various avenues exist for acquiring the necessary items, ensuring that your tools remain in top shape.

Consider the following options for locating suitable replacements:

- Authorized Dealers: Visiting certified retailers guarantees access to genuine components that meet manufacturer specifications.

- Online Marketplaces: Websites such as eBay or Amazon often offer a wide variety of items, making it easy to compare prices and availability.

- Local Hardware Stores: Many community hardware shops stock commonly needed items, providing convenience and immediate access.

- Specialty Stores: Look for stores dedicated to outdoor equipment; they frequently carry a diverse selection of components.

- Manufacturer’s Website: Checking the official website can yield helpful information and allow for direct purchasing.

Before making a purchase, ensure compatibility with your specific model. Reading reviews and verifying seller reliability can also help in making informed choices.

Comparison with Other Models

When evaluating different equipment options, it’s essential to consider how each model stacks up against its competitors. Various tools within the same category can offer distinct features, performance levels, and durability, catering to diverse user needs. This section highlights the unique characteristics and functionalities of a specific model compared to others available in the market.

For instance, while some machines prioritize lightweight construction for ease of maneuverability, others may focus on enhanced power output for tackling more demanding tasks. Moreover, the design of components can vary significantly, influencing maintenance requirements and overall user experience. A thorough analysis allows potential buyers to make informed choices based on their specific applications and preferences.

Additionally, the availability of accessories and compatibility with other equipment can be a deciding factor. Some models may offer a wider range of attachments, enhancing versatility and expanding the tool’s potential. This flexibility can be particularly beneficial for users looking to invest in a multi-functional solution.

Customer Reviews and Experiences

Feedback from users offers valuable insights into the performance and reliability of a product. Understanding customer experiences can guide potential buyers in making informed decisions and highlight areas of excellence or concern. This section gathers testimonials that reflect various perspectives on usability and satisfaction.

User Insights

Many users appreciate the efficiency and ease of use of the equipment, noting how it meets their specific needs in various tasks. The reliability of the machine is often praised, contributing to overall satisfaction.

While the majority of experiences are positive, some users express concerns regarding certain aspects. Identifying these issues can help manufacturers improve future models and address customer needs more effectively.

| Rating | Comment | User |

|---|---|---|

| 5/5 | Excellent performance, highly recommend! | John D. |

| 4/5 | Very reliable but a bit heavy. | Sarah P. |

| 3/5 | Decent, but had some issues with maintenance. | Mike R. |

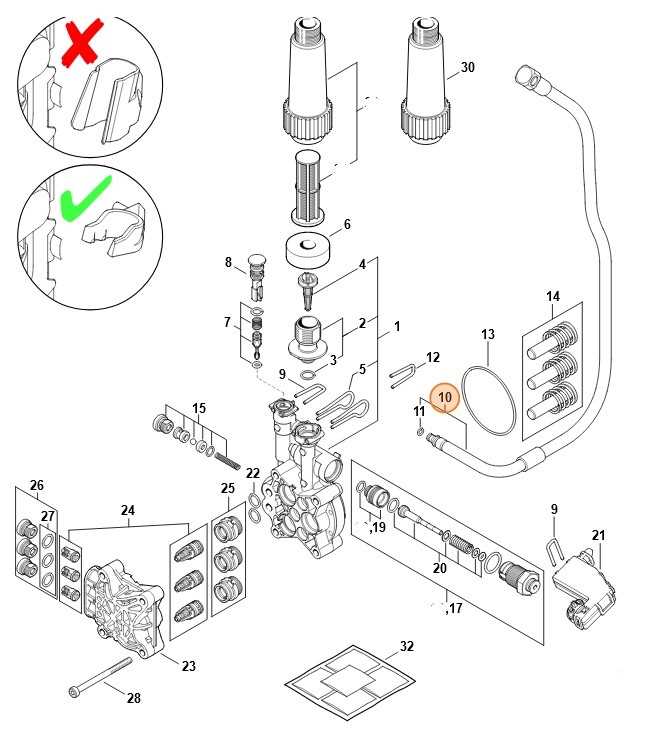

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures involved in assembling and disassembling equipment components. Understanding these processes is crucial for maintenance, troubleshooting, and ensuring optimal performance of your device.

Tools Required

- Wrenches

- Screwdrivers

- Pliers

- Torque wrench

- Cleaning cloth

Disassembly Steps

- Ensure the equipment is powered off and unplugged.

- Gather all necessary tools to avoid interruptions.

- Begin by removing any external covers or guards.

- Loosen and detach the main components, taking care to note their arrangement.

- Carefully disconnect electrical connections, if applicable.

- Store removed parts in a safe location to prevent loss.

Assembly Steps

- Inspect all components for wear or damage before reassembly.

- Reattach electrical connections, ensuring proper orientation.

- Align and secure the main components as they were originally configured.

- Replace any covers or guards, ensuring they are securely fastened.

- Test the assembly for proper function before full operation.

Following these guidelines will help maintain the longevity and functionality of your equipment, ensuring efficient operation for years to come.