Understanding the Hydro-Gear ZT-3100 Parts Diagram

Understanding the intricate systems within modern machinery is crucial for ensuring optimal performance and longevity. Each element plays a vital role in the overall function of the equipment, requiring careful attention to detail when maintaining or repairing such systems.

The layout and arrangement of key mechanical units allow for smooth operation and efficient handling of tasks. Whether it’s ensuring proper movement, control, or stability, every element has its own importance and contributes to the seamless integration of the whole mechanism.

When looking at specific assemblies, it’s important to recognize how individual elements interact within the broader structure. Maintenance and replacements become more straightforward when the relationship between the core elements is clear, allowing for more efficient problem-solving and upkeep.

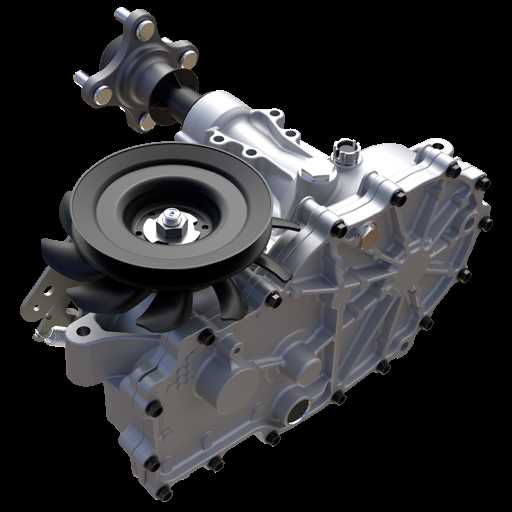

Overview of Hydro-Gear ZT-3100 Components

The intricate assembly of this transmission system consists of several key elements that work in unison to ensure smooth and efficient performance. Each element plays a crucial role in providing consistent control and power, making the overall unit reliable and durable for various applications. Understanding how these pieces interact offers valuable insights into the mechanics of the entire drive system.

Pumps and motors serve as the heart of the unit, responsible for regulating the flow of hydraulic fluid, which directly influences movement. These components are vital for translating hydraulic energy into mechanical motion, ensuring precise speed control.

Axles and gears form the structure that transfers power from the motor to the wheels, allowing seamless movement. They are essential in maintaining the correct balance between speed and torque, enabling the system to handle different loads and terrains efficiently.

The assembly also includes specialized seals and bearings that minimize friction and prevent leaks, ensuring the long-term functionality of the system. These smaller but significant parts contribute to the overall longevity and reliability of the unit, keeping it operational under various conditions.

Key Functions of the ZT-3100

The system is designed to deliver high efficiency and robust performance for various applications. Its mechanism ensures precise control and adaptability in different operational conditions, making it suitable for demanding tasks. The core functionality emphasizes smooth transitions and reliability, providing a seamless experience for users.

Control and Responsiveness

One of the standout features of this model is its ability to offer excellent responsiveness. The control mechanism allows for intuitive handling, ensuring that operators can easily maneuver in tight spaces or at high speeds. This makes the system versatile for a range of use cases.

Durability and Longevity

Built with longevity in mind, the unit incorporates materials and designs that enhance durability. Its components are optimized for wear resistance, reducing maintenance needs and ensuring consistent performance over time, even in rigorous environments.

| Function | Description |

|---|---|

| Speed Control | Provides smooth and efficient regulation of velocity in various settings. |

| Torque Output | Delivers high torque, supporting heavy-duty operations without compromising control. |

| Cooling System | Integrated cooling features ensure optimal temperature regulation during prolonged use. |

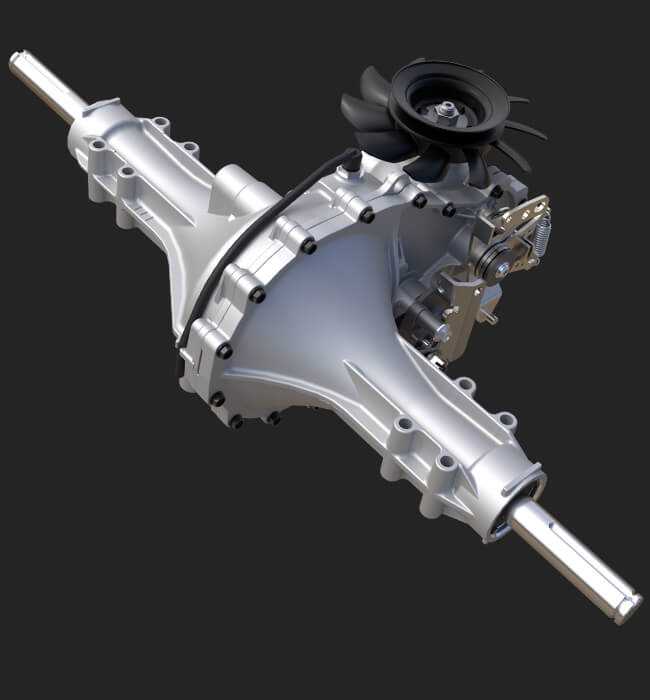

Drive System Elements and Layout

The drive system is a complex mechanism that ensures the movement and operation of various components within a vehicle. Its design involves multiple key components, each playing a specific role in delivering power efficiently. Understanding how these elements are arranged and function together is crucial for maintaining performance and reliability.

Transmission plays a central role in the system, guiding the flow of power from the engine to the wheels. It works in tandem with axles and gears, ensuring smooth transitions and optimal speed control.

Another important aspect is the control system, which regulates the movement and allows the operator to manage the vehicle’s direction and pace with precision. This involves both mechanical and electronic components working in harmony.

The overall layout of the drive system is designed to balance power, efficiency, and ease of control, making it a vital part of any vehicle’s performance.

Hydraulic Components and Their Roles

Hydraulic systems rely on a variety of interconnected elements to perform crucial functions in fluid transmission. These systems are designed to provide precise control over mechanical movements by converting fluid power into motion, making them indispensable in many types of machinery.

The pump serves as the heart of the system, generating the necessary flow of liquid under pressure. The control valves regulate the flow direction and ensure that the right amount of pressure reaches the desired component. Cylinders and motors then convert this hydraulic energy into useful mechanical work, driving the movement of machinery with precision. Additionally, filters and coolers protect the system from contamination and overheating, ensuring long-lasting and reliable performance.

Pump Assembly Breakdown and Functionality

The pump assembly is an essential component responsible for the movement and regulation of hydraulic fluid. It plays a key role in maintaining proper fluid circulation, ensuring the system’s smooth and efficient operation. By analyzing the structure of the assembly, we can better understand how each part contributes to the overall function.

| Component | Role |

|---|---|

| Pump Housing | Encloses and protects the internal elements, maintaining the flow of fluid. |

| Input Shaft | Transfers mechanical energy to drive the internal mechanisms of the pump. |

| Rotating Group | Converts mechanical power into fluid motion, enabling the circulation of hydraulic oil. |

| Seals and Gaskets | Prevent fluid leaks and ensure pressure retention within the system. |

Each element of the pump works together to ensure that fluid is moved efficiently through the system, providing the necessary power and control for various operations. Regular inspection of these components can help maintain optimal performance and prolong the lifespan of the assembly.

Understanding the Motor Assembly

The motor assembly is a crucial component in many mechanical systems, playing a vital role in converting energy into motion. Its design and functionality are essential for the overall performance of the system. This section will explore the various elements of the motor assembly, highlighting their significance and interconnections.

Key Components

Each motor assembly consists of several integral parts, each contributing to its efficiency and effectiveness. Understanding these components is essential for troubleshooting and maintenance.

| Component | Description |

|---|---|

| Stator | The stationary part that generates a magnetic field when electricity is applied. |

| Rotor | The rotating element that turns as a result of the magnetic field produced by the stator. |

| Bearings | Support structures that reduce friction and allow smooth rotation of the rotor. |

| End Bells | Caps that enclose the motor assembly, providing structural integrity and protection. |

Functionality and Maintenance

Regular inspection and maintenance of the motor assembly are crucial to ensure optimal performance and longevity. Understanding the role of each component aids in diagnosing issues and implementing effective solutions.

Transmission Mechanism in Detail

The transmission system plays a crucial role in converting the power generated by an engine into usable motion for vehicles. This complex assembly comprises various components that work together seamlessly to ensure efficient operation and reliable performance. Understanding the intricacies of this mechanism can significantly enhance maintenance practices and troubleshooting techniques.

Key Components and Their Functions

At the heart of the transmission system lies a series of essential elements, each with its specific role. The primary components include gears, clutches, and shafts, which collaborate to facilitate power transfer and speed regulation. Below is a summary of these crucial parts:

| Component | Function |

|---|---|

| Gears | Adjust the torque and speed by altering gear ratios. |

| Clutches | Engage and disengage power flow to the wheels, allowing for smooth transitions. |

| Shafts | Transmit power between different components of the transmission system. |

Operational Mechanics

The operational mechanics of the transmission system rely heavily on the coordinated interaction of its components. When the engine generates power, it is directed through the clutches to the gears, which then modify the power’s speed and torque according to the vehicle’s requirements. This dynamic interaction allows for smooth acceleration and deceleration, making the driving experience both efficient and enjoyable.

Seals and Gaskets: Purpose and Types

Seals and gaskets play a crucial role in ensuring the proper functioning of mechanical systems. They serve as barriers that prevent fluid leaks and contamination, thereby maintaining the integrity and efficiency of machinery. Understanding their various types and purposes is essential for effective maintenance and troubleshooting.

These components can be categorized based on their materials, design, and specific applications. The choice of seal or gasket depends on factors such as temperature, pressure, and the type of fluid involved. Below is a table highlighting some common types of seals and gaskets, along with their characteristics and typical applications.

| Type | Material | Application |

|---|---|---|

| O-Ring | Rubber, Silicone | Hydraulic systems, pumps |

| Flat Gasket | Fiber, Cork, Rubber | Flanged joints, automotive engines |

| Mechanical Seal | Ceramic, Carbon, Metal | Pumps, compressors |

| V-Ring | Rubber, Plastic | Shaft sealing in rotating equipment |

By selecting the appropriate seal or gasket, one can enhance the performance and longevity of equipment while minimizing maintenance needs.

Control Mechanisms and Their Placement

The efficiency and functionality of any hydraulic system significantly depend on the arrangement and design of its control mechanisms. These components play a crucial role in regulating fluid flow, ensuring optimal performance and responsiveness. Understanding their configuration can aid in troubleshooting and maintenance, contributing to the overall longevity of the system.

Types of Control Mechanisms

- Valves: Essential for directing fluid movement, these devices can vary in type and complexity.

- Actuators: Responsible for converting energy into motion, actuators are pivotal in controlling various system functions.

- Controllers: These units manage the operation of other components, ensuring they work harmoniously.

Strategic Placement of Components

Optimal positioning of control mechanisms is vital for enhancing system performance. Consider the following aspects when assessing component layout:

- Accessibility: Components should be placed where maintenance and adjustments can be easily performed.

- Flow Efficiency: Arranging parts to minimize resistance can improve fluid dynamics.

- Safety: Proper spacing can prevent potential hazards related to fluid leakage or component failure.

Exploring the Brake System

The braking mechanism plays a vital role in the overall functionality of any vehicle. Its primary purpose is to ensure safe and controlled deceleration when required. Understanding how this system operates and its various components can enhance maintenance practices and promote longevity.

Key Components of the Braking Mechanism

Several essential elements comprise the braking mechanism, each contributing to its effectiveness. The most notable components include the brake pads, rotors, and calipers. Brake pads are responsible for generating friction against the rotors, enabling the vehicle to slow down. Rotors provide the surface for the brake pads to grip, while calipers hold the brake pads in place and apply the necessary pressure.

Importance of Regular Maintenance

Regular inspection and maintenance of the braking system are crucial for optimal performance. Over time, wear and tear can affect various parts, leading to diminished efficiency. Timely replacements and adjustments ensure that the braking system functions as intended, thereby enhancing safety and reliability on the road.

How to Maintain ZT-3100 Parts

Proper upkeep of mechanical components is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances functionality but also prevents costly repairs. Adopting a systematic approach can significantly improve the efficiency and reliability of your machinery.

Begin by routinely inspecting the key elements for signs of wear or damage. This proactive measure helps identify potential issues before they escalate. Keeping the assembly clean is crucial; accumulated dirt and debris can hinder performance. Use appropriate cleaning agents and tools to remove grime without causing harm.

Lubrication is another critical aspect. Applying the right lubricant to moving parts reduces friction and wear, enhancing the overall efficiency of the system. Follow manufacturer recommendations regarding the type and frequency of lubrication.

Monitoring fluid levels is vital for smooth operation. Regularly check hydraulic and transmission fluids, topping them off as necessary to maintain proper function. Consider implementing a replacement schedule for fluids, filters, and other consumables to ensure optimal performance.

Lastly, refer to the following table for a quick reference on maintenance tasks:

| Task | Frequency | Notes |

|---|---|---|

| Inspection | Monthly | Check for wear or damage |

| Cleaning | Every 3 months | Use appropriate cleaning agents |

| Lubrication | Every 50 hours of operation | Follow manufacturer recommendations |

| Fluid Check | Weekly | Ensure proper levels |

| Filter Replacement | Annually | Refer to guidelines for specifics |

Common Issues and Troubleshooting

When dealing with complex mechanical systems, various challenges may arise that can affect performance and efficiency. Identifying and addressing these problems promptly is crucial for ensuring the longevity and functionality of the equipment. This section delves into typical complications encountered and provides guidance on effective resolutions.

Performance Degradation

A frequent concern involves a noticeable decline in operational efficiency. This issue may stem from inadequate lubrication or the accumulation of debris in critical areas. Regular maintenance is essential to mitigate such risks. Ensure that all moving components are appropriately lubricated and free from obstructions to maintain optimal functionality.

Unusual Noises

Unanticipated sounds during operation can signal underlying problems that require immediate attention. These noises might indicate wear or misalignment of components. Inspecting the system for any loose or damaged parts can help identify the source of the issue. Promptly addressing these findings can prevent further damage and extend the lifespan of the machinery.