Understanding the John Deere JS35 Parts Diagram

In the world of landscaping machinery, comprehending the arrangement of various elements is crucial for efficient maintenance and repairs. A detailed exploration of these configurations not only aids in troubleshooting but also enhances the overall performance of the equipment.

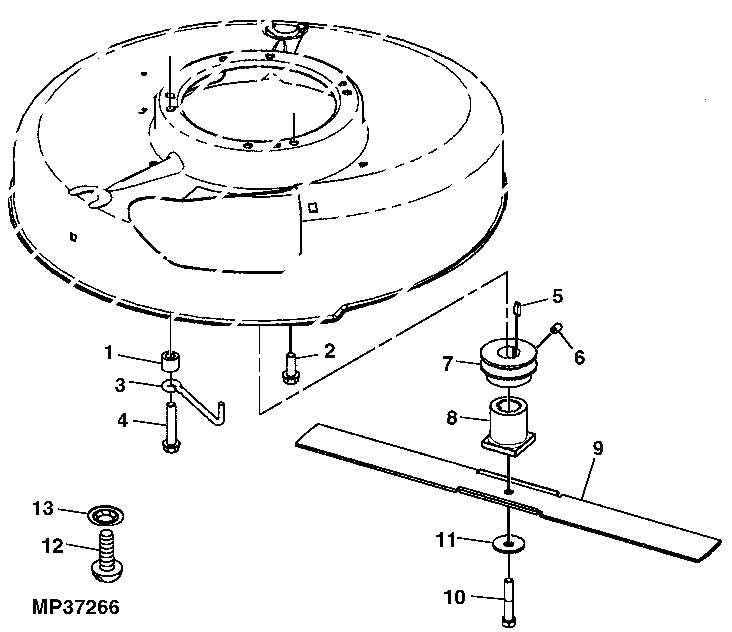

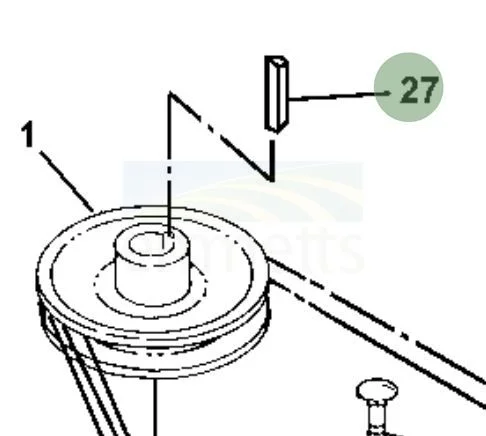

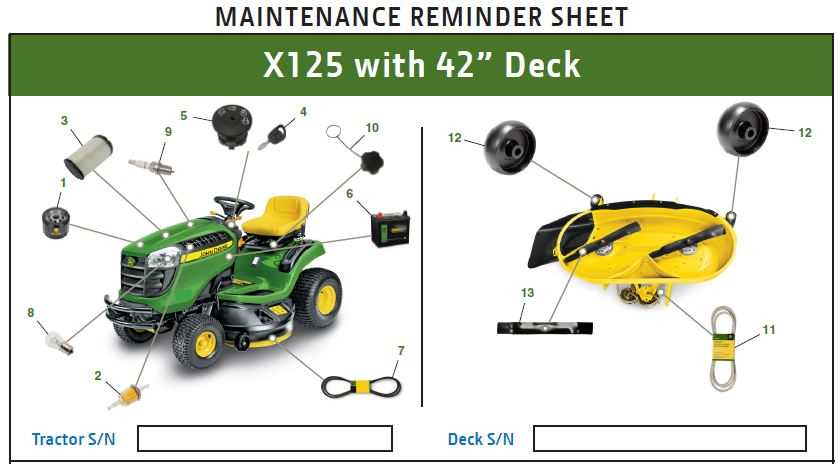

Visual representations serve as invaluable tools, providing a clear overview of each component’s location and function. By examining these illustrations, users can swiftly identify what parts require attention or replacement, streamlining their workflow.

Furthermore, delving into the intricacies of these layouts empowers operators with the ultimate knowledge needed to optimize their machinery’s lifespan. Whether you are a seasoned professional or a novice, understanding the structure of your equipment is essential for achieving outstanding results.

Understanding John Deere JS35 Components

Gaining familiarity with the various elements of a lawn care machine is essential for effective maintenance and repair. Each part plays a critical role in ensuring optimal performance, contributing to the overall efficiency and longevity of the equipment. A comprehensive grasp of these components allows users to troubleshoot issues, replace worn elements, and enhance the overall functionality of the device.

The machine is comprised of several key segments, including the engine, cutting deck, and propulsion system. Each section has specific functions that work in harmony to achieve the desired results. The engine serves as the power source, converting fuel into mechanical energy, while the cutting deck is responsible for the precision trimming of grass, ensuring a well-manicured lawn. Meanwhile, the propulsion system enables smooth movement across various terrains, providing both ease of use and control.

Understanding the relationships between these parts is vital for anyone looking to optimize their lawn maintenance experience. Regular inspections and knowledge of component functionality can prevent minor issues from escalating into significant problems, ultimately saving time and resources in the long run.

Importance of Parts Diagrams

Understanding the intricate layout of components is crucial for effective maintenance and repair. These visual representations serve as essential tools for technicians and enthusiasts alike, providing clarity on how each element interacts within the larger assembly. By leveraging such illustrations, one can quickly identify specific sections and ensure that tasks are executed with precision.

Moreover, these schematics enhance the efficiency of troubleshooting processes. When issues arise, having access to detailed layouts allows for quicker diagnostics and helps pinpoint the source of malfunctions. This not only saves time but also minimizes the risk of overlooking critical aspects during repairs.

Additionally, familiarity with these visuals fosters a deeper comprehension of machinery. Understanding the relationship between various components equips users with the knowledge necessary to optimize performance and extend the lifespan of their equipment. This proactive approach to maintenance ultimately leads to improved reliability and reduced operational costs.

In summary, visual guides are indispensable for anyone working with complex systems. They provide the foundation for informed decision-making, efficient repairs, and ongoing learning, making them invaluable resources in the realm of equipment management.

Key Features of JS35 Model

This model is designed to provide exceptional performance and efficiency, catering to the needs of both professionals and homeowners. Its innovative features enhance usability and durability, making it a reliable choice for various outdoor tasks.

- Powerful Engine: Equipped with a robust engine that ensures optimal power output for demanding jobs.

- User-Friendly Controls: Intuitive control layout allows for easy operation and minimal learning curve.

- Durable Construction: Built with high-quality materials for enhanced longevity and resistance to wear.

- Versatile Design: Adaptable for multiple applications, making it suitable for different landscaping needs.

- Maintenance-Friendly: Engineered for straightforward maintenance, ensuring longevity and reliability.

Overall, this model stands out for its combination of strength, ease of use, and versatility, making it an ultimate choice for outdoor enthusiasts.

Common Issues with JS35 Parts

When maintaining outdoor power equipment, users often encounter specific challenges related to its components. These difficulties can arise from wear and tear, incorrect assembly, or even environmental factors. Understanding these common problems can significantly enhance the longevity and performance of the machinery.

Wear and Tear: Over time, certain elements may degrade due to regular usage. This deterioration can lead to decreased efficiency and functionality. Regular inspections are essential to identify parts that need replacement before they fail completely.

Improper Assembly: Many users may struggle with correctly putting together components, leading to misalignment or functionality issues. It’s crucial to follow the manufacturer’s guidelines to ensure that every piece is installed as intended.

Environmental Factors: Exposure to extreme weather conditions can impact the integrity of various elements. Moisture, heat, and dirt accumulation can lead to rust or clogging, which hampers the overall performance. Maintaining cleanliness and protecting equipment from harsh elements can mitigate these risks.

Compatibility Issues: Using non-compatible components can result in performance problems. Always verify that replacements match the specifications of the original elements to avoid further complications.

By being aware of these potential issues, users can take proactive measures to maintain their equipment effectively and ensure smooth operation for years to come.

Where to Find Parts Diagrams

Locating accurate schematics for machinery components is essential for effective maintenance and repair. These illustrations provide a visual representation of the individual elements and their arrangement, making it easier to identify necessary replacements. Several reliable resources exist to help enthusiasts and professionals access these valuable guides.

Manufacturer Websites: The official websites of manufacturers often have dedicated sections for technical documents. These resources frequently include comprehensive visuals and specifications for their products, allowing users to find the exact components they need.

Online Retailers: Various online retailers specializing in machinery and equipment often provide detailed guides alongside their product listings. These resources can be helpful when searching for specific parts or understanding how different elements fit together.

Forums and Community Groups: Engaging with online communities focused on machinery can be beneficial. Enthusiasts and experts often share resources, including schematics, tips, and advice on maintenance, which can lead to discovering useful visual references.

Service Manuals: Many service manuals include detailed illustrations of components and assembly instructions. These manuals can be purchased or accessed through libraries and are invaluable for anyone looking to gain a deeper understanding of their equipment.

Social Media Platforms: Networking on platforms such as Facebook or Reddit can yield fruitful results. Joining groups dedicated to machinery repair can connect users with others who have access to the diagrams needed for their specific models.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components offers several advantages that can enhance the performance and longevity of your machinery. These products are designed specifically for your equipment, ensuring a perfect fit and optimal functionality.

- Quality Assurance: OEM components undergo rigorous testing to meet strict standards, providing reliability and durability.

- Enhanced Performance: Designed for specific models, these components ensure that your equipment operates at its best.

- Warranty Protection: Using original parts often helps maintain the warranty of your machinery, safeguarding your investment.

- Consistent Availability: OEM components are readily available through authorized dealers, ensuring you can find what you need quickly.

In conclusion, opting for original components is ultimately a wise choice that pays off in the long run through superior performance and dependability.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and restoring your equipment, ensuring it operates smoothly. Following a systematic method can help identify issues and facilitate efficient repairs.

Preparation

- Gather necessary tools and materials.

- Review the maintenance manual for specifications.

- Ensure a clean and organized workspace.

Repair Process

- Identify the problem by inspecting the machinery.

- Remove any faulty components carefully.

- Replace with high-quality replacements.

- Reassemble the unit, ensuring all parts fit correctly.

- Test the equipment to confirm proper function.

Identifying Replacement Parts Easily

Finding the right components for your machinery can be a straightforward process if you know where to look and how to approach it. Understanding the structure of your equipment and having access to reliable resources can simplify this task significantly.

Here are some effective strategies to help you locate the correct components:

- Consult the Manual: Your equipment’s manual is a valuable resource, often containing detailed information about specific components and their numbers.

- Online Databases: Utilize manufacturer websites and reputable online platforms that provide comprehensive listings and images of available components.

- Visual Identification: Take clear pictures of the components you need to replace. This can help you compare with online resources or seek assistance from experts.

- Ask for Help: Engage with community forums or local repair shops where knowledgeable individuals can provide guidance and recommendations.

By employing these methods, you can confidently navigate the replacement process, ensuring your equipment remains in optimal condition.

Tools Needed for Maintenance

Proper upkeep of machinery requires a selection of essential instruments to ensure optimal performance and longevity. Having the right tools on hand can facilitate routine checks and repairs, minimizing downtime and enhancing efficiency.

Here are some key tools that are beneficial for maintenance tasks:

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening various fasteners.

- Screwdrivers: A set of flathead and Phillips screwdrivers will cover most screws found in equipment.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping, twisting, and cutting wires or other materials.

- Grease Gun: This tool is essential for applying lubrication to moving parts to reduce friction and wear.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Oil Filter Wrench: Aids in removing and replacing oil filters during routine servicing.

Maintaining a well-stocked toolkit will help in performing regular maintenance tasks effectively, ultimately prolonging the life of the equipment.

Comparing JS35 with Other Models

This section explores the distinctions and similarities between a specific mower model and its competitors, providing insight into their performance, features, and usability. By analyzing various options, users can make informed decisions based on their specific needs and preferences.

Performance Metrics

When evaluating performance, it’s essential to consider factors such as engine power, cutting efficiency, and maneuverability. This particular model excels in providing a balance between power and precision, making it suitable for both small and medium-sized lawns. Comparatively, some rival models may offer higher power but lack in handling and agility.

User Experience

User-friendliness is a critical aspect of any mower. This model features an intuitive design that enhances ease of operation, while other alternatives might have more complex controls. The overall comfort and ergonomics play a significant role in prolonged use, with certain competitors focusing on advanced technology that may not always translate into better usability.

Frequently Asked Questions about JS35

This section addresses common inquiries regarding a specific model, providing clarity on its features, maintenance, and available components. Understanding these aspects can enhance the user experience and ensure optimal performance.

General Inquiries

- What are the main features of this model?

- How often should maintenance be performed?

- What types of fuel are recommended for optimal performance?

Maintenance and Support

- What are the common issues faced by users?

- Where can I find replacement components?

- Is there a warranty or support available?

Tips for Effective Maintenance

Regular upkeep of machinery is essential to ensure optimal performance and longevity. By adopting proactive measures, operators can significantly reduce the risk of breakdowns and enhance efficiency. This section outlines some fundamental strategies for maintaining equipment effectively.

Establish a Routine

Creating a consistent schedule for inspections and maintenance tasks can prevent minor issues from escalating. Daily checks on fluid levels, filters, and belts are crucial. Weekly and monthly maintenance should include more comprehensive evaluations, allowing for timely interventions.

Utilize Quality Components

Investing in high-quality replacements and consumables is vital for maintaining functionality. Genuine parts may offer better durability and compatibility, ensuring smoother operation. Regularly reviewing and updating the inventory of essential components can also minimize downtime during repairs.

Contacting John Deere Support

When it comes to maintaining equipment, having access to reliable assistance is essential. Whether you’re facing technical issues or need guidance on product features, reaching out to customer service can provide the necessary support for optimal operation.

For any inquiries or concerns, it’s advisable to utilize the official channels available. Customers can easily find contact information on the manufacturer’s website, where a dedicated support section typically lists various methods of communication, including phone numbers, email addresses, and live chat options.

Tips for Effective Communication:

- Be prepared with your equipment model and serial number to ensure quick assistance.

- Clearly articulate the issue you are experiencing, including any error messages or unusual behavior.

- Take notes during the conversation for future reference and follow-up steps.

In addition to direct support, many users benefit from community forums where they can share experiences and solutions with fellow equipment owners. These platforms often serve as valuable resources for troubleshooting and advice.

Timely and efficient assistance can enhance your experience and ensure your machinery operates smoothly.