Understanding the Parts Diagram for Case IH 1660

In the realm of agricultural equipment, comprehending the intricate assembly of machinery is essential for efficient operation and maintenance. Each unit consists of various elements, meticulously designed to perform specific functions that contribute to the overall performance of the vehicle. Knowledge of these components can aid in troubleshooting, repairs, and enhancing the longevity of the equipment.

Identifying individual elements within machinery not only empowers operators but also enhances their ability to make informed decisions regarding repairs and upgrades. Familiarity with the layout and interconnections of these components allows for smoother operations and reduces downtime during critical farming periods. Understanding how each piece interacts with others is crucial for maximizing productivity.

Additionally, gaining insights into the structure of these machines fosters a deeper appreciation for their engineering. Recognizing the significance of each part in the operational context can inspire confidence in utilizing and maintaining the equipment effectively. This knowledge base serves as a valuable resource for both novice users and seasoned professionals alike.

This section provides a comprehensive overview of the remarkable attributes of a renowned agricultural machine. Designed for efficiency and productivity, it combines advanced engineering with user-friendly features to enhance performance in the field. Understanding these characteristics is crucial for operators and maintenance personnel alike.

The key features include innovative design elements, robust construction, and cutting-edge technology. This machine is equipped with a powerful engine that delivers exceptional power and fuel efficiency, allowing for extended working hours without frequent refueling. Additionally, the intuitive controls and ergonomic layout ensure ease of operation, reducing operator fatigue during long hours of use.

| Feature | Description |

|---|---|

| Powerful Engine | Delivers high performance and fuel efficiency for extended operation. |

| Advanced Technology | Incorporates modern systems for enhanced productivity and ease of use. |

| User-Friendly Controls | Designed to minimize operator fatigue and improve overall efficiency. |

| Robust Construction | Engineered for durability and reliability in demanding environments. |

Importance of Accurate Parts Diagrams

Precise visual representations of components play a vital role in ensuring the efficient operation and maintenance of machinery. These illustrations serve as essential references for users, technicians, and service personnel, allowing for effective identification and understanding of each element within complex systems. Accurate visuals facilitate timely repairs and replacements, ultimately contributing to the longevity and reliability of equipment.

Enhancing Maintenance Efficiency

Detailed visuals enable quicker troubleshooting and repair processes. When users can easily locate and identify specific elements, they save valuable time and resources, reducing the potential for errors during maintenance. This efficiency is especially crucial in time-sensitive situations where operational downtime can lead to significant losses.

Ensuring Compatibility and Quality

Using reliable visual references helps guarantee that replacements are compatible with existing machinery. This minimizes the risk of malfunction due to improper parts being installed. Furthermore, high-quality representations can improve the overall understanding of the equipment’s design, fostering a greater appreciation for the engineering behind it.

Common Components of the 1660 Model

This section explores the essential elements found in the agricultural machinery model, highlighting their roles and importance in overall functionality. Each component contributes significantly to the efficiency and reliability of the equipment, ensuring optimal performance in various farming tasks.

Key Mechanisms

Among the vital mechanisms are the engine and transmission systems, which are crucial for driving the machinery. The engine provides the necessary power, while the transmission system enables smooth operation across different terrains. Proper maintenance of these components is essential for ensuring longevity and optimal performance.

Operational Features

In addition to the main mechanisms, other operational features such as the hydraulic system and control panels enhance user experience. The hydraulic system allows for effective lifting and lowering of attachments, while the control panels provide users with the necessary feedback and controls to manage the equipment efficiently.

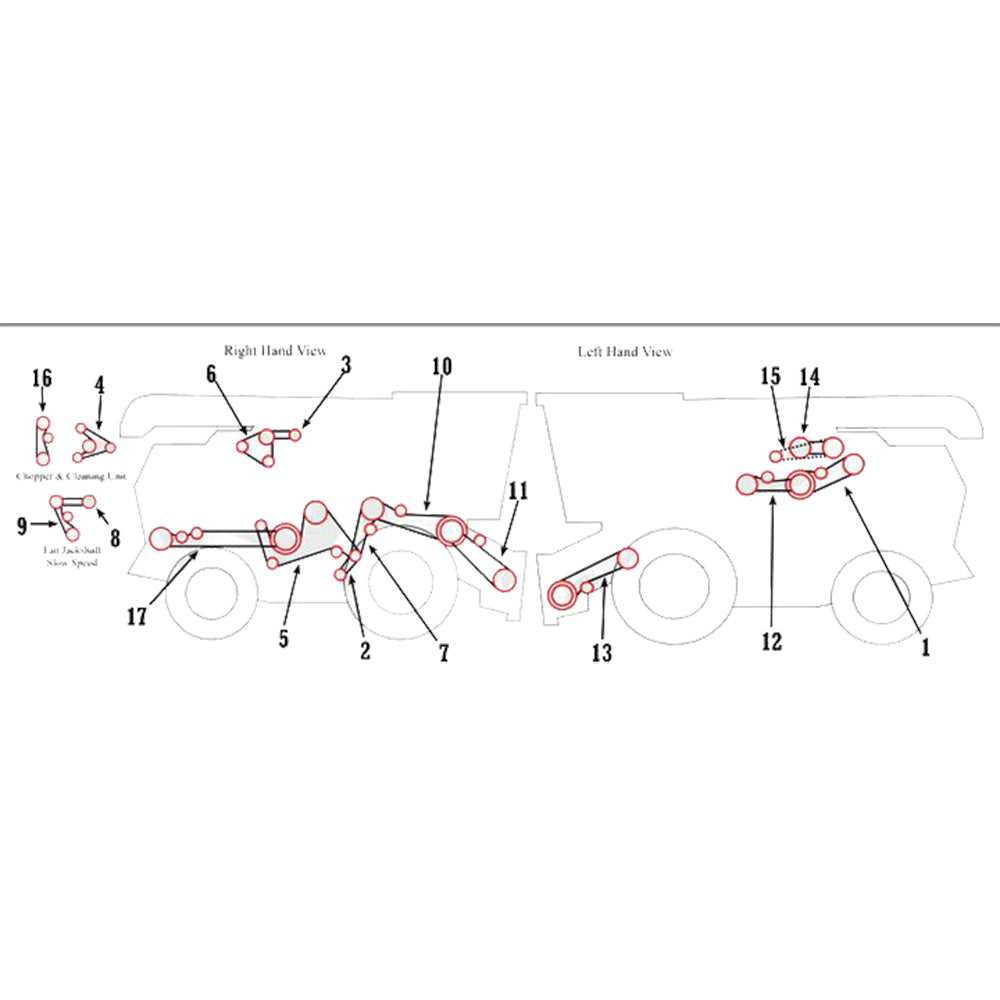

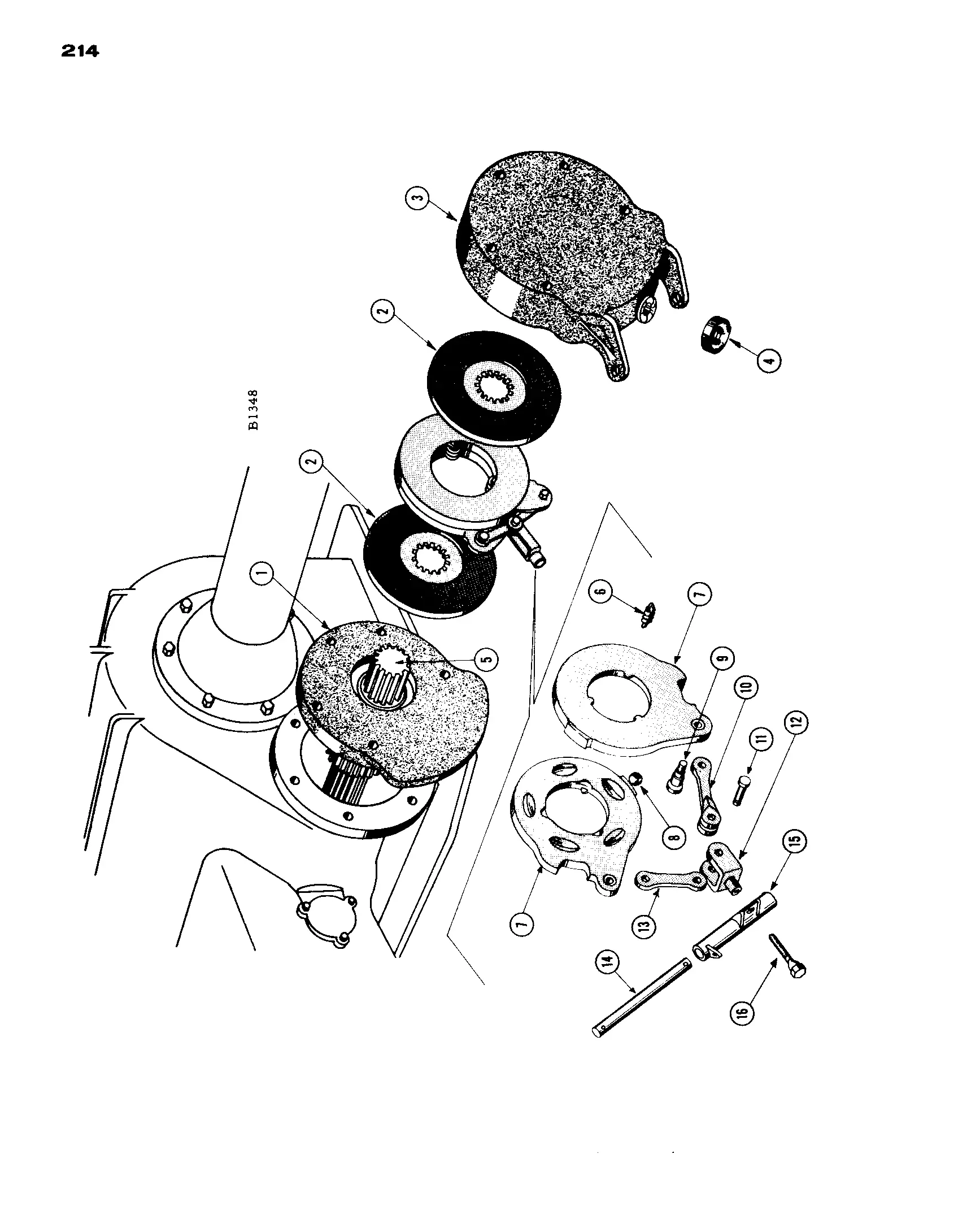

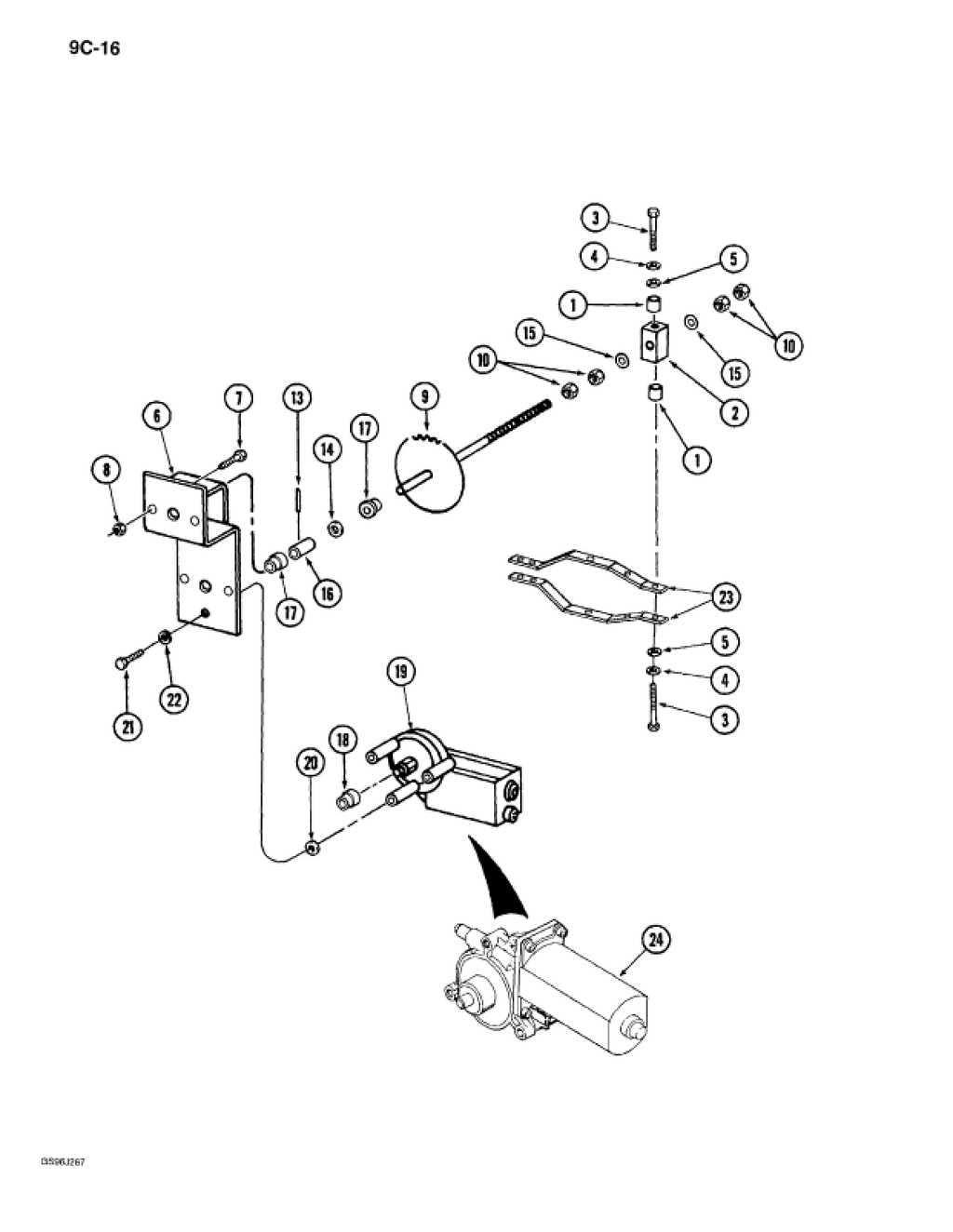

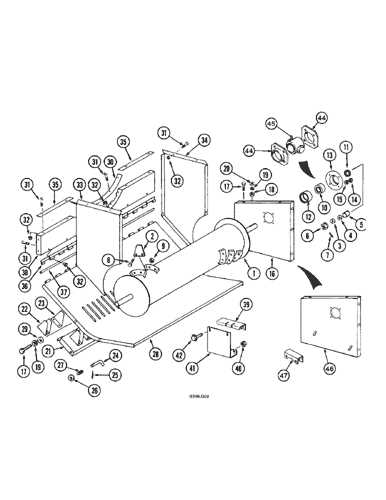

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repair. This visual guide helps identify various elements and their relationships within a mechanical system. Familiarizing yourself with the layout can streamline the troubleshooting process and enhance your ability to source replacements effectively.

Familiarize Yourself with Symbols and Notations

Each representation features unique symbols that denote different components. It is crucial to understand what these icons signify. Often, accompanying legends or keys provide explanations, enabling users to correlate symbols with specific elements in the assembly. Take time to review these notations to gain a clearer perspective of the overall structure.

Follow the Flow of Components

Components are typically arranged in a way that illustrates their interactions. Tracing lines connecting various elements will help you comprehend how they function together. This flow not only highlights how components work in unison but also aids in identifying potential issues within the system. Pay attention to any numbered sequences that might indicate assembly order or hierarchy.

By mastering the ability to interpret these visuals, you can improve your understanding of mechanical assemblies, ultimately leading to more effective repairs and enhanced operational efficiency.

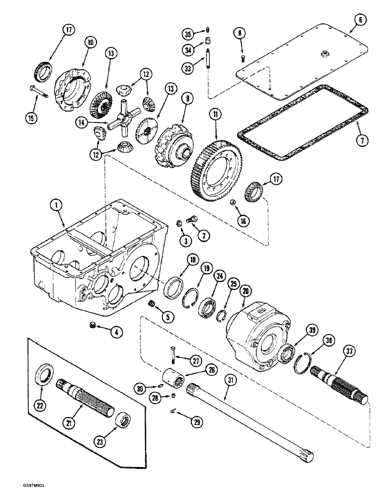

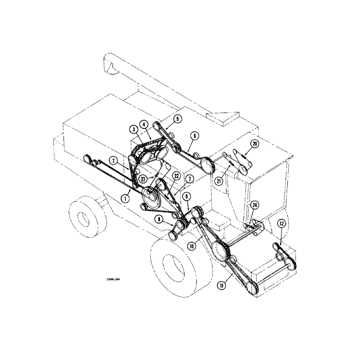

Identifying Key Mechanical Assemblies

Understanding the essential mechanical components of agricultural machinery is crucial for efficient operation and maintenance. This section highlights the major assemblies that contribute to the overall functionality and performance of these machines. By familiarizing oneself with these key elements, operators can ensure optimal performance and address potential issues promptly.

Powertrain Components: The powertrain is fundamental in transferring energy from the engine to various operational parts. It consists of several elements, including the transmission, driveshafts, and differentials. Proper maintenance of these components is vital for smooth operation and preventing mechanical failures.

Harvesting Mechanisms: The harvesting systems play a critical role in the effective collection of crops. Key components, such as the header, reel, and cutter bar, work together to ensure a clean and efficient harvest. Regular inspection of these mechanisms can enhance productivity and reduce downtime during harvesting periods.

Hydraulic Systems: Hydraulic assemblies are essential for powering various functions, such as lifting and lowering equipment. Understanding the layout and operation of hydraulic circuits can aid in troubleshooting issues and maintaining efficient hydraulic performance. Regular checks for leaks and proper fluid levels are necessary to prevent malfunctions.

Chassis and Structural Elements: The chassis serves as the backbone of the machinery, providing stability and support for all attached components. Familiarity with the structural design and reinforcements can assist in identifying wear and tear, ensuring the machine remains robust under operational stresses.

By recognizing and understanding these integral assemblies, operators can maintain their machinery more effectively and enhance overall agricultural productivity.

Maintenance Tips for Efficient Operation

Ensuring optimal functionality of agricultural machinery requires regular upkeep and attention to detail. Implementing effective maintenance practices not only prolongs the lifespan of the equipment but also enhances productivity during critical operational periods. Below are essential strategies to maintain your machinery efficiently.

Routine Inspections

Conducting regular inspections is vital for identifying potential issues before they escalate. Check for wear and tear on essential components, ensuring that all moving parts are well-lubricated and functioning correctly. Pay special attention to hydraulic systems and belts, as they are crucial for smooth operation.

Scheduled Cleaning

Keeping the equipment clean is another crucial aspect of maintenance. Dirt and debris can cause overheating and mechanical failures. Regularly clean filters, radiators, and other essential areas to prevent buildup. Additionally, using protective covers when the machinery is not in use can help shield it from environmental factors.

Incorporating these maintenance tips will contribute to the reliable performance of your machinery, ensuring it operates efficiently during demanding tasks.

Parts Replacement Procedures Explained

Ensuring optimal performance and longevity of machinery requires a thorough understanding of component exchange methods. This section delves into the essential procedures for replacing elements effectively, promoting seamless operations and minimizing downtime. Following precise guidelines is crucial for achieving successful outcomes and maintaining the efficiency of the equipment.

Preparation Steps

Before initiating the replacement process, it is vital to prepare adequately. Gather the necessary tools and replacement components to facilitate a smooth operation. Ensure that the work area is clean and organized, allowing for efficient movement and access to the equipment. Safety should be a top priority, so wearing appropriate protective gear is essential to prevent injuries.

Replacement Procedure

After preparing the work area and gathering materials, follow these systematic steps for effective component replacement:

| Step | Description |

|---|---|

| 1 | Disconnect the power supply and secure the machinery to prevent accidental start-up. |

| 2 | Carefully remove any covers or panels that obstruct access to the component needing replacement. |

| 3 | Remove the old component by unscrewing or detaching it from its position. |

| 4 | Install the new component, ensuring it is secured firmly and properly aligned. |

| 5 | Reattach any covers or panels that were removed during the process. |

| 6 | Reconnect the power supply and conduct a thorough check to confirm the functionality of the new component. |

By adhering to these guidelines, individuals can ensure that the replacement process is executed efficiently, thereby enhancing the performance and reliability of their machinery.

Essential Tools for Disassembly

Proper tools are crucial when it comes to taking apart machinery efficiently and safely. Having the right equipment not only simplifies the process but also reduces the risk of damage to components. This section outlines the fundamental tools required for successful disassembly tasks.

Hand Tools

- Wrenches: A variety of sizes is necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips types are essential for removing screws from different parts.

- Pliers: Useful for gripping, twisting, and cutting wire or small components.

- Hammer: A rubber or plastic mallet can be helpful for gently persuading parts apart without causing damage.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Pry Bar: Aids in separating components that may be stuck together.

- Parts Tray: Keeps small pieces organized and prevents loss during the disassembly process.

By equipping yourself with these essential tools, you will be better prepared to tackle any disassembly task efficiently and effectively.

Finding Genuine Replacement Parts

When maintaining machinery, ensuring the use of authentic components is crucial for optimal performance and longevity. Original items not only guarantee compatibility but also enhance the overall reliability of your equipment. Understanding where to source these genuine alternatives can save both time and money while preventing future issues.

One of the most effective ways to identify trustworthy suppliers is to connect with authorized dealers. These vendors often provide a comprehensive selection of original components and accessories, ensuring that you receive high-quality materials tailored specifically for your model. Additionally, they can offer expert advice regarding installation and maintenance.

It is also advisable to explore online marketplaces that specialize in authentic equipment. Reputable websites will typically have a clear return policy and customer reviews, helping you make informed purchasing decisions. Always verify the seller’s credentials to ensure you are acquiring genuine materials.

| Source | Benefits |

|---|---|

| Authorized Dealers | Access to a wide range of original components and expert support |

| Online Marketplaces | Convenient purchasing options with customer reviews and return policies |

| Manufacturer Websites | Direct sourcing of authentic items with specifications and compatibility details |

By prioritizing authentic components, you can enhance the functionality of your machinery while safeguarding your investment. Being diligent in sourcing genuine replacements will lead to better operational efficiency and reduce the likelihood of breakdowns.

Cost Considerations for Repairs

When addressing maintenance and restoration of agricultural machinery, it’s crucial to assess the financial implications associated with repairs. Evaluating these costs helps ensure that investments align with operational needs and longevity of equipment. A well-thought-out budgeting process can significantly impact overall efficiency and productivity.

Evaluating Repair Expenses

Understanding the different components that contribute to repair expenses is essential. Costs may vary based on the extent of damage, availability of components, and labor rates. Parts procurement can fluctuate, particularly for specialized items, while local labor charges can differ widely based on geographic location and expertise required. Therefore, conducting thorough research on suppliers and technicians can lead to better financial decisions.

Long-Term Financial Planning

Investing in preventive maintenance can minimize repair costs over time. Regular check-ups and timely replacements can help identify potential issues before they escalate into significant problems. Additionally, maintaining a reserve budget for unforeseen repairs will allow for prompt action without disrupting operations. Prioritizing repairs based on urgency and overall impact on productivity can further optimize resource allocation.

Upgrades and Modifications Available

Enhancements and alterations can significantly improve the performance and efficiency of agricultural machinery. Various options exist for those seeking to optimize their equipment, catering to different operational needs and preferences.

Key upgrades often focus on enhancing the engine’s power output, improving harvesting capabilities, or increasing overall reliability. These modifications can lead to better fuel efficiency, reduced downtime, and a more streamlined operation during critical harvesting seasons.

| Modification Type | Description | Benefits |

|---|---|---|

| Engine Upgrade | Installing a more powerful engine or enhancing the existing one. | Increased power and torque, better fuel efficiency. |

| Header Modification | Upgrading the header for improved cutting and feeding. | Enhanced crop flow, reduced crop loss. |

| Electronic Controls | Integrating advanced electronic monitoring and control systems. | Improved operational efficiency and precision. |

| Tire and Track Upgrades | Replacing standard tires with larger or more durable options. | Better traction and stability on uneven terrain. |

| Cleaning System Enhancements | Upgrading or modifying the cleaning system for better grain separation. | Higher quality output and reduced contamination. |

Resources for Further Learning

Expanding your knowledge on agricultural machinery maintenance and components can greatly enhance your operational efficiency. Numerous resources are available to assist enthusiasts and professionals alike in understanding the intricacies of these machines. Whether you seek manuals, online forums, or instructional videos, leveraging these materials can empower you to tackle repairs and upgrades effectively.

Online Communities and Forums

Participating in online platforms dedicated to agricultural equipment provides invaluable insights. Forums often feature discussions on troubleshooting, user experiences, and recommendations for replacement components. Engaging with fellow users can lead to the discovery of practical tips and innovative solutions that may not be covered in traditional manuals.

Technical Manuals and Guides

Accessing technical manuals is essential for anyone looking to gain a deeper understanding of machinery specifications and assembly details. These documents typically include detailed schematics and maintenance instructions, ensuring users can perform repairs and optimizations confidently. Consider visiting manufacturer websites or specialized publications to obtain the latest resources.