Understanding the Weber DCOE Parts Diagram for Better Engine Performance

In the realm of automotive engineering, the intricacies of performance tuning play a vital role in enhancing vehicle efficiency and responsiveness. A key aspect of this tuning involves the careful examination of carburetors, which are essential for managing air and fuel mixtures. By delving into the various elements that constitute these devices, enthusiasts can unlock their full potential and achieve optimal engine performance.

Each component serves a distinct function, contributing to the overall operation and effectiveness of the system. From the throttle mechanisms to the fuel delivery systems, understanding how these individual parts interact is crucial for anyone looking to modify or repair their vehicle. Moreover, a comprehensive grasp of these mechanisms enables tuners to troubleshoot issues and make informed decisions during upgrades.

This exploration aims to provide insights into the layout and functionality of these crucial assemblies. By examining the relationships between different sections, readers can gain a clearer picture of how to optimize their performance setups and ensure longevity in their automotive investments. With the right knowledge, the path to achieving peak performance becomes not just a possibility, but a tangible reality.

Understanding Weber DCOE Carbs

The performance of an internal combustion engine can significantly hinge on the efficiency of its fuel delivery system. The particular model discussed here is renowned for its ability to enhance throttle response and provide a more engaging driving experience. This type of carburetion system is often favored in motorsport and classic car applications for its unique design and adjustable features.

Components and Functionality

At its core, this fuel management system consists of multiple key elements, each contributing to its overall effectiveness. The primary functions include regulating airflow and optimizing fuel mixture, which are crucial for achieving peak performance. Key components, such as the float chamber and jets, work together to ensure the correct amount of fuel is delivered at various engine speeds.

Tuning for Optimal Performance

To achieve the best results, precise tuning is essential. This involves adjusting various settings to match engine specifications and driving conditions. Fine-tuning these aspects can lead to improvements in power output and fuel efficiency. Enthusiasts often experiment with different configurations to find the perfect balance between performance and drivability.

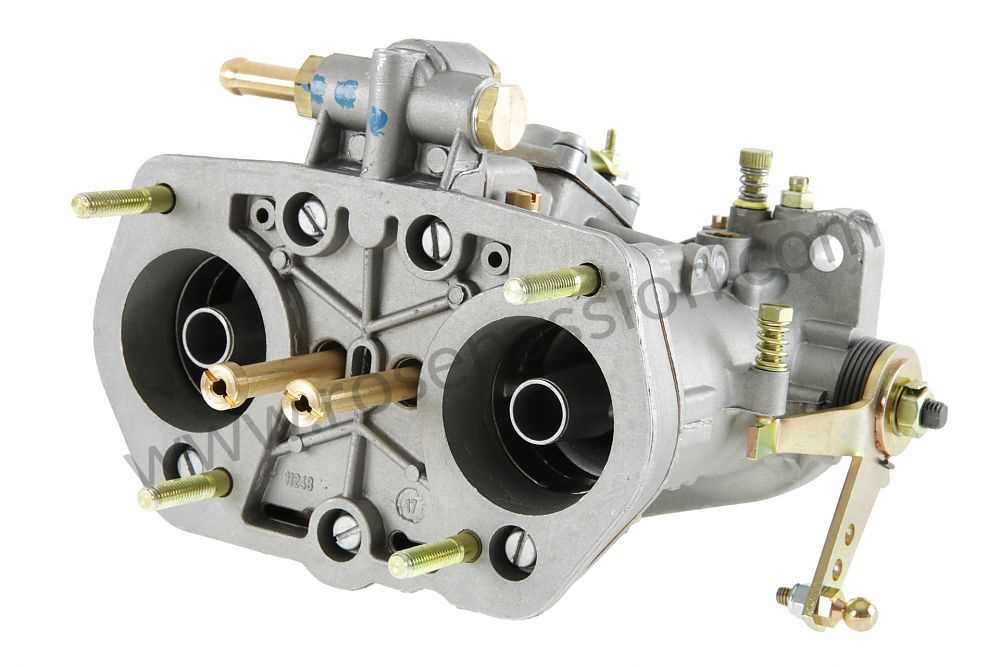

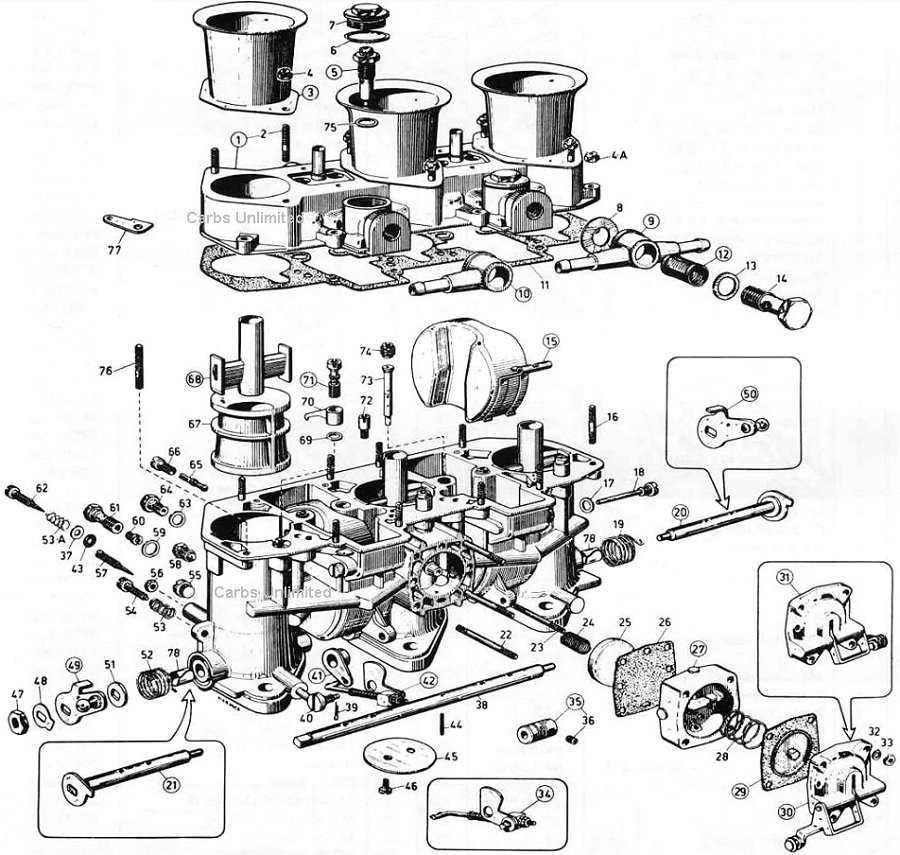

Overview of Weber DCOE Design

This section explores the intricate design and functionality of a specific type of carburetor renowned for its performance in various applications. With a focus on the engineering principles that govern its operation, we aim to shed light on how these components work together to optimize fuel-air mixtures, ensuring efficiency and responsiveness in engines.

Key Components

Understanding the essential elements of this carburetor reveals its unique characteristics. Each component, from the venturi to the throttle valves, plays a crucial role in managing airflow and fuel delivery. Precision engineering ensures that these parts are finely tuned to achieve the ultimate balance between performance and reliability.

Functionality Insights

The design facilitates an optimal combustion process, enhancing engine performance across various RPM ranges. By incorporating advanced features such as variable venturi sizes and sophisticated linkage systems, this type of carburetor provides a responsive driving experience, making it a favored choice among automotive enthusiasts.

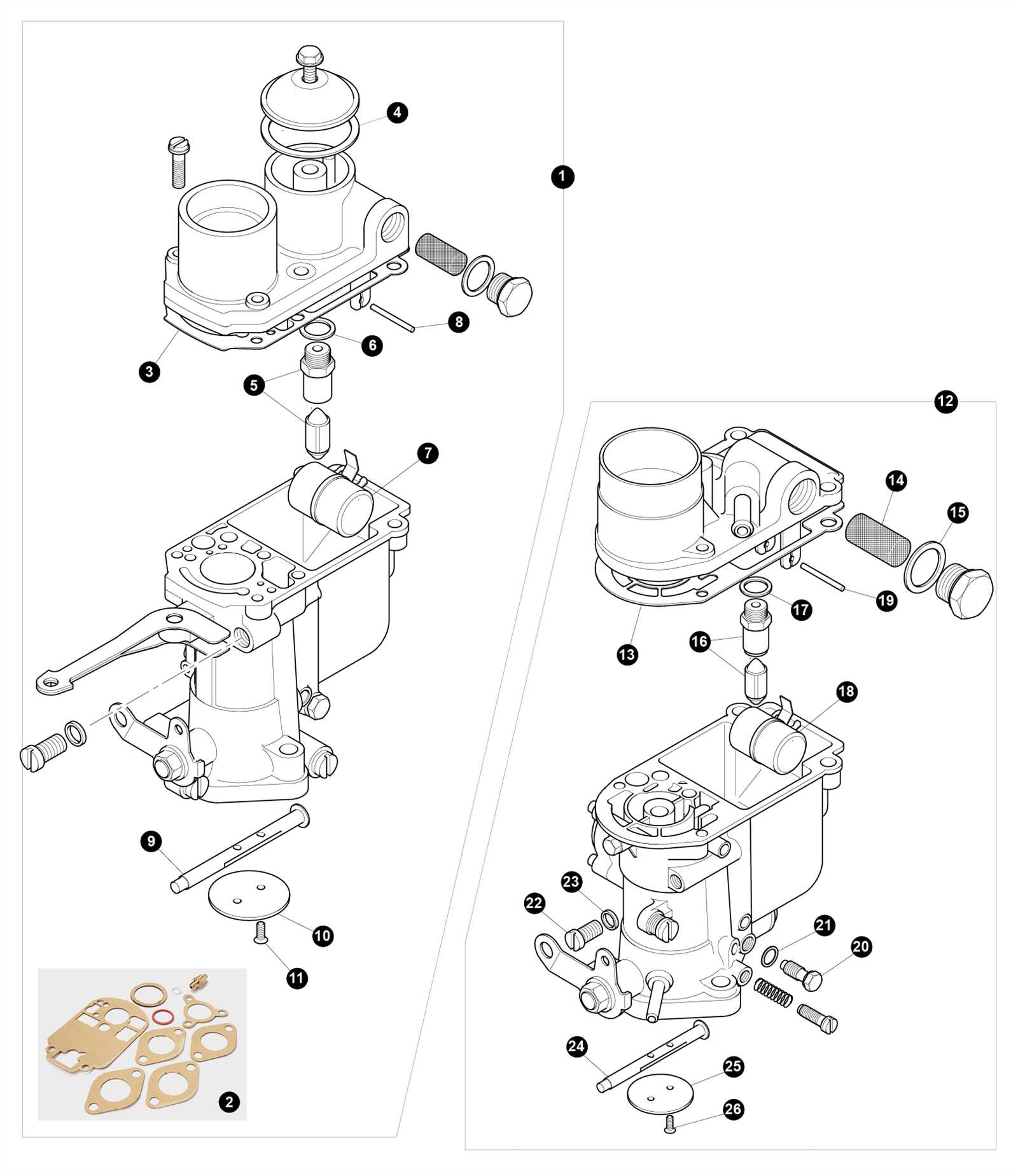

Key Components of DCOE Carbs

The intricacies of a specific type of carburetor are fundamental for optimal engine performance. Understanding its essential elements not only enhances tuning but also aids in troubleshooting potential issues. Each component plays a pivotal role in the overall functionality, affecting everything from fuel delivery to air mixture adjustments.

At the heart of this system lies the throttle body, which regulates airflow into the engine. This is complemented by the venturi, a crucial section that creates a vacuum effect, drawing fuel into the airstream. The jets, strategically positioned, control the fuel supply and are adjustable to cater to different performance needs.

Another significant part is the float chamber, which maintains a constant fuel level, ensuring consistent delivery during operation. The accelerator pump is vital for providing an additional fuel surge during rapid throttle openings, preventing flat spots in acceleration. Lastly, the mixture control screw allows fine-tuning of the air-fuel mixture, enabling precise adjustments based on driving conditions.

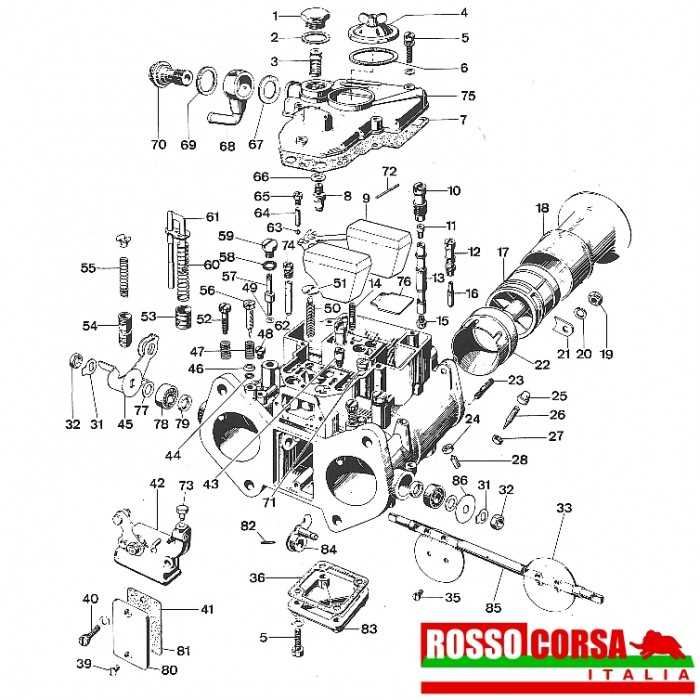

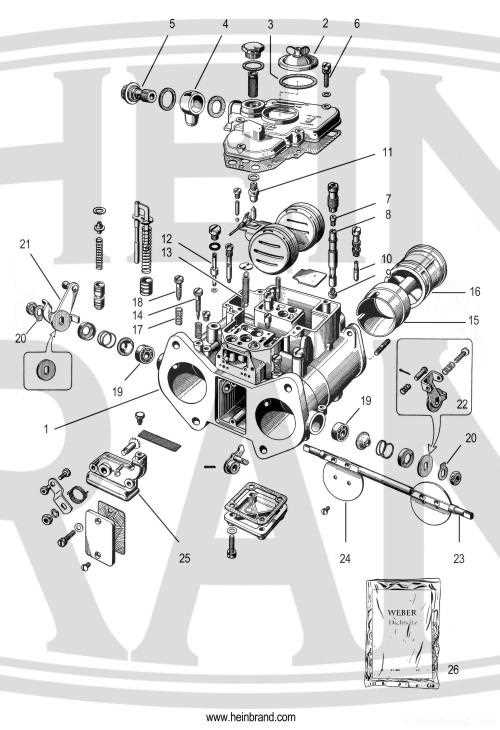

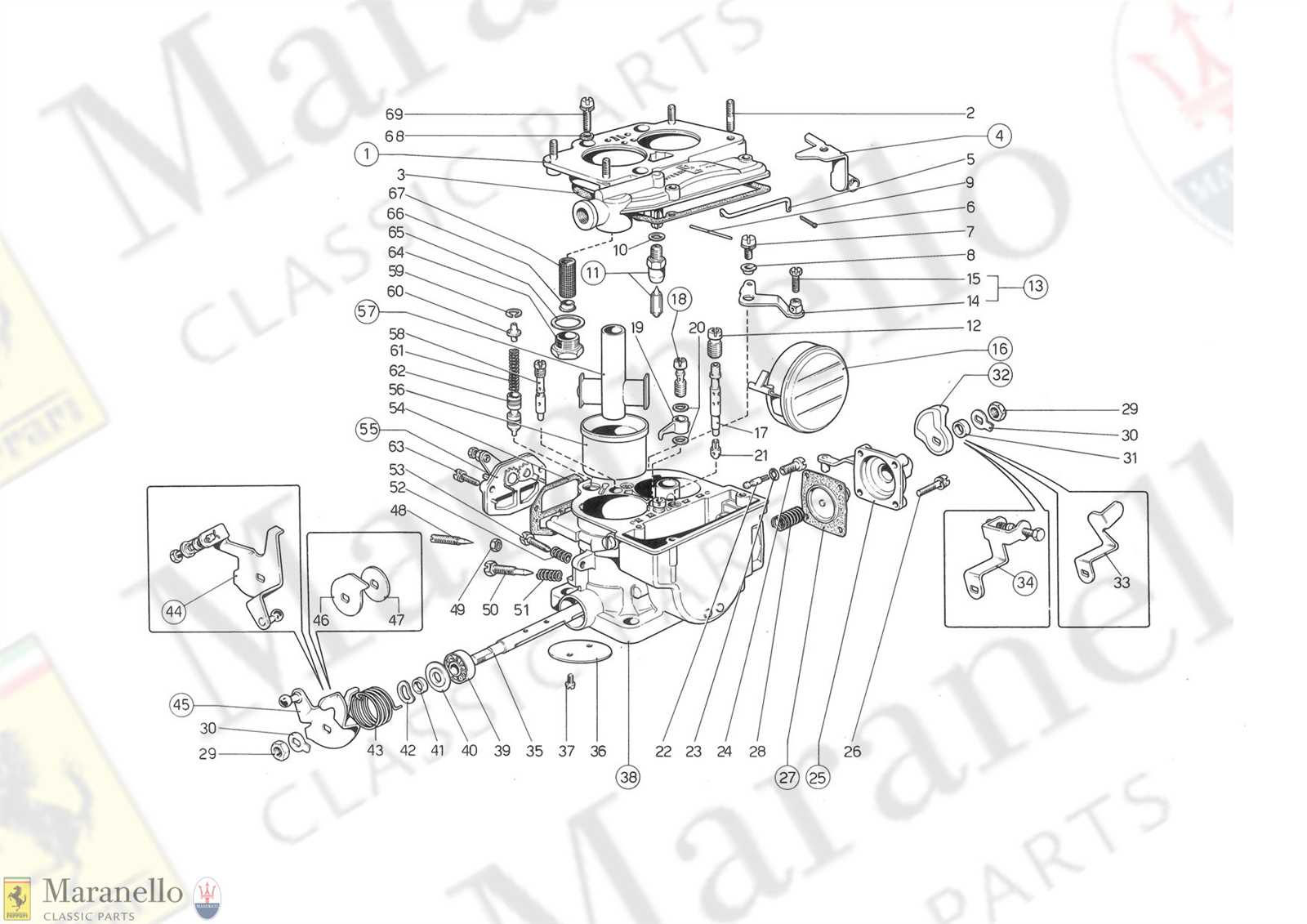

How to Read DCOE Diagrams

Understanding technical schematics can significantly enhance your ability to work with specific components in automotive applications. These illustrations provide a visual representation of various elements, allowing you to identify their functions and relationships. Mastering this skill is crucial for effective maintenance and tuning.

Start by familiarizing yourself with the key symbols and notations used in these illustrations. Each component is typically represented by a distinct symbol, and it’s essential to know what each one signifies. Take note of labels and numbers that correspond to specific functions or settings.

Next, analyze the layout to understand how components interact. Look for connections between parts and their respective roles in the system. This will give you insight into how adjustments may affect overall performance. Pay special attention to flow directions and possible adjustments indicated in the schematics.

Finally, refer to supplementary materials such as manuals or guides that can provide deeper context. Often, these resources elaborate on the functions and tuning options available, helping you delve into the intricacies of each element. With practice, interpreting these illustrations will become second nature.

Common Issues with DCOE Parts

When working with performance carburetors, various complications can arise that affect their functionality and overall efficiency. Understanding these challenges is crucial for any enthusiast looking to maintain or optimize their setup. Addressing these concerns not only enhances performance but also prolongs the lifespan of the components involved.

Fuel Delivery Problems

One frequent issue involves the delivery of fuel. Blockages in the fuel lines or improper tuning can lead to insufficient supply, causing poor engine performance. Additionally, incorrect float levels may result in flooding or starvation, leading to erratic behavior during operation. Regular checks and adjustments can help mitigate these problems.

Air Mixture Imbalances

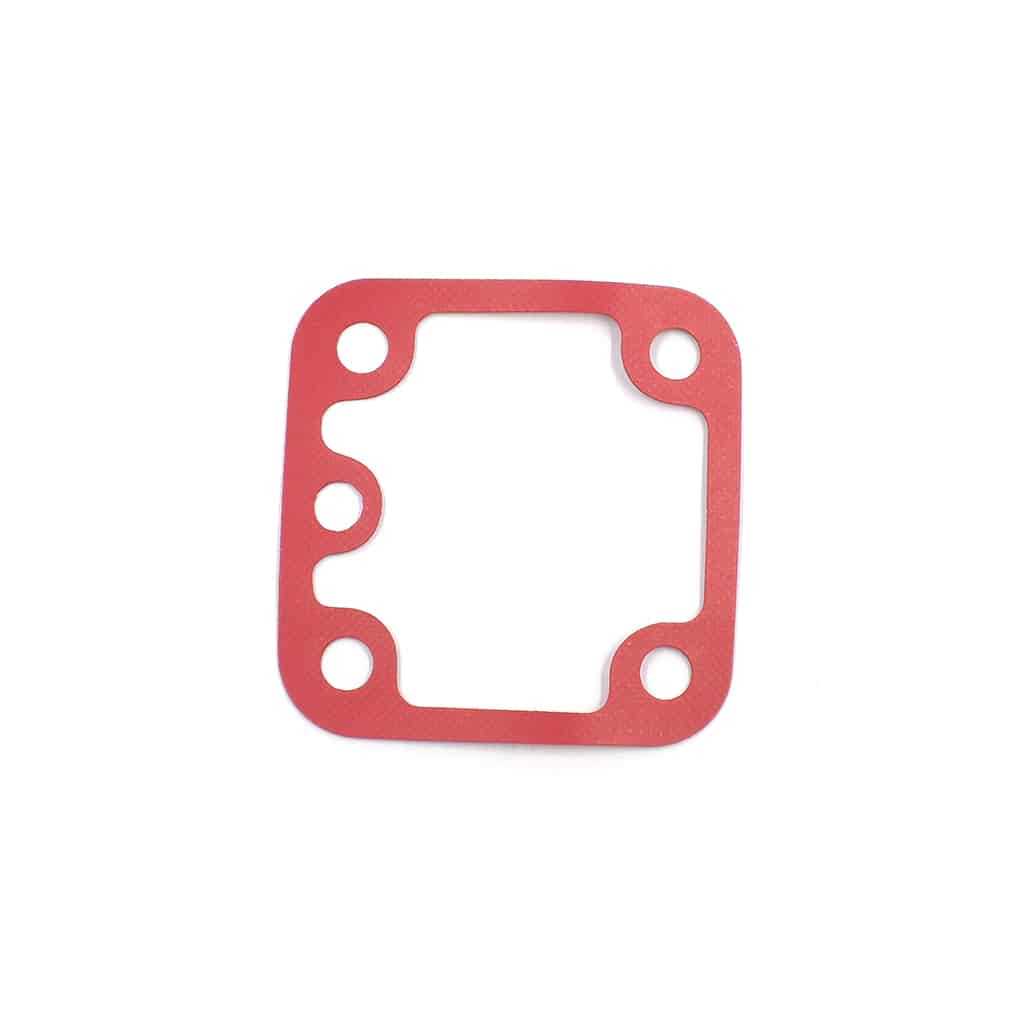

Another common concern is the imbalance in air and fuel mixture. This can occur due to worn jets or gaskets, leading to inconsistent throttle response. A thorough inspection of all sealing surfaces and a calibration of the jets can significantly improve performance and ensure a smoother driving experience.

Choosing the Right DCOE Model

Selecting the appropriate model for your specific needs is crucial for optimizing performance and enhancing the overall driving experience. Various factors come into play, such as engine specifications, intended use, and personal preferences. Understanding these aspects can significantly influence your decision-making process.

Factors to Consider

Evaluate engine displacement, power goals, and intended application, whether it’s for street driving, racing, or off-road use. Additionally, consider the compatibility with existing components and tuning options available for each model.

Performance Implications

The right choice can lead to improved throttle response, better fuel efficiency, and increased horsepower. Analyze how each model aligns with your performance aspirations to make an informed decision.

Maintenance Tips for DCOE Systems

Proper upkeep of carburetor systems is essential for optimal performance and longevity. Regular attention to these components can prevent issues that affect efficiency and drivability. Here are some essential practices to ensure your setup remains in peak condition.

Regular Cleaning: It is crucial to clean the assemblies periodically to remove dirt, fuel residue, and other contaminants. Using a dedicated cleaner will help maintain the internal components and ensure smooth operation.

Inspect Gaskets and Seals: Check all gaskets and seals for wear and tear. Replacing damaged parts promptly can prevent air leaks, which can disrupt the air-fuel mixture and lead to performance issues.

Monitor Fuel Quality: Always use high-quality fuel to minimize the risk of deposits forming within the system. Contaminated fuel can lead to clogging and operational inefficiencies.

Adjust Settings Regularly: Periodically review the tuning of the system to ensure it is optimized for your specific engine setup. Fine-tuning can enhance performance and responsiveness.

Check for Leaks: Regularly inspect the system for fuel leaks. Any signs of leaking can not only affect performance but also pose safety risks.

Professional Servicing: Consider having a professional inspect the system at least once a year. Experienced technicians can identify potential problems and provide solutions that might be overlooked during routine maintenance.

Implementing these practices will help ensure your carburetor system runs efficiently and reliably, enhancing your overall driving experience.

Performance Enhancements for DCOE

Optimizing the efficiency and responsiveness of an automotive induction system can significantly elevate a vehicle’s performance. By implementing various enhancements, enthusiasts can achieve improved throttle response, increased horsepower, and better fuel atomization, ultimately resulting in a more exhilarating driving experience. This section outlines several effective strategies to boost performance.

Key Upgrades to Consider

There are numerous modifications that can be employed to enhance the overall functionality of your induction system. Below are some key upgrades that can yield substantial benefits:

| Upgrade Type | Description | Benefits |

|---|---|---|

| Jetting Adjustments | Changing the jet sizes to better match engine airflow. | Improved fuel mixture and efficiency. |

| Air Filter Upgrade | Installing high-performance air filters for better airflow. | Increased power and acceleration. |

| Choke Modifications | Adjusting or removing chokes to enhance airflow. | Smoother throttle response and higher RPM capability. |

| Venturi Sizing | Utilizing larger venturis to allow more air intake. | Greater power output and efficiency at higher speeds. |

Tuning for Maximum Performance

Beyond hardware modifications, fine-tuning the system is crucial for achieving optimal results. Adjusting ignition timing and synchronizing multiple units can ensure that the system operates harmoniously. Regular maintenance and recalibration can also prevent performance degradation over time, keeping the vehicle performing at its best.

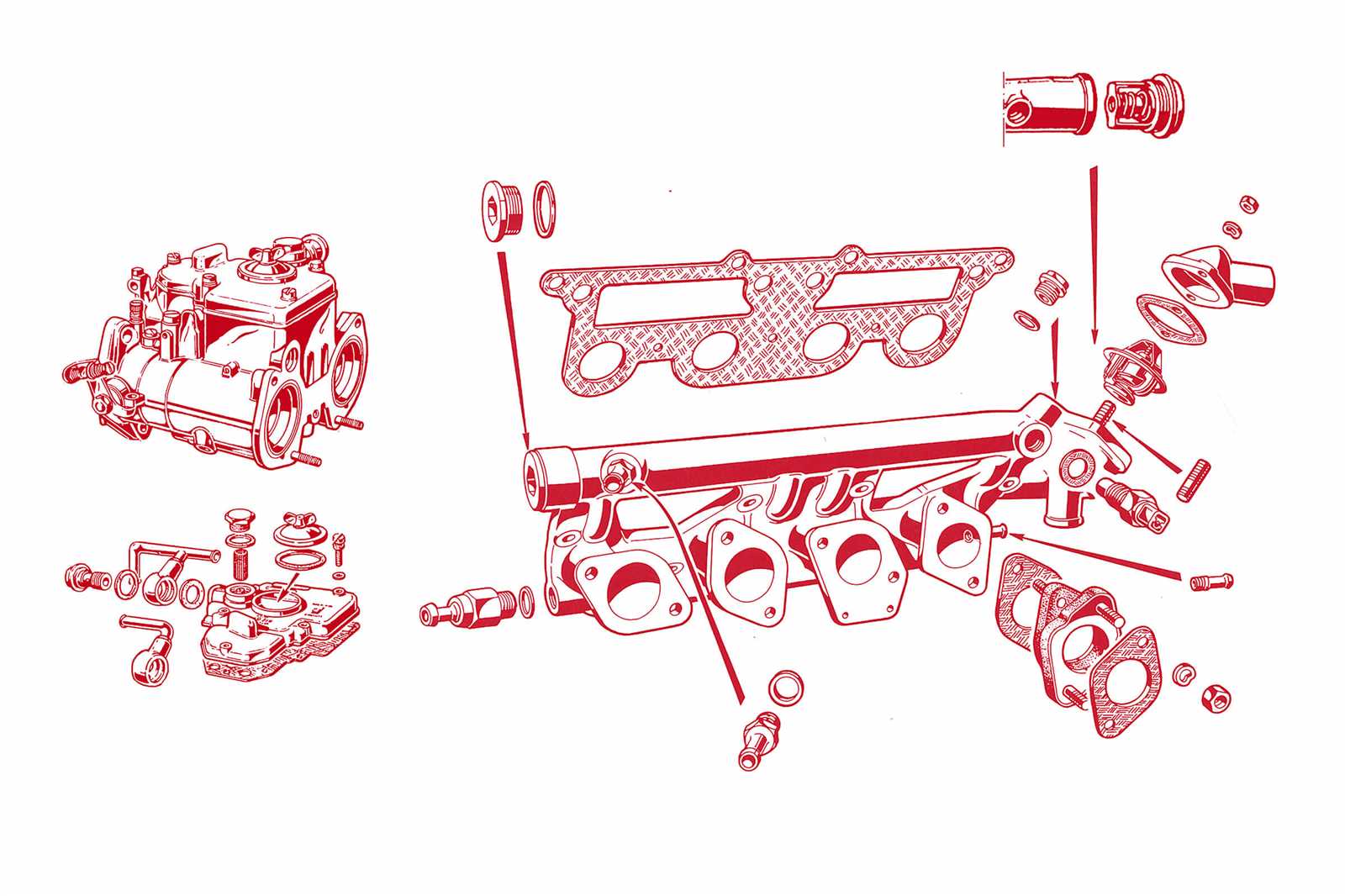

Installation Guide for DCOE Carbs

This guide provides essential steps for the proper setup of performance carburetors to enhance engine efficiency. By following the outlined instructions, you can achieve optimal performance and tuning for your vehicle.

Step 1: Preparation – Before starting the installation, ensure you have all necessary tools and components ready. Clean the mounting surface thoroughly to prevent debris from affecting the seal.

Step 2: Mounting – Position the carburetor onto the intake manifold, aligning the gasket properly. Secure it with bolts, but do not overtighten to avoid damaging the gasket.

Step 3: Fuel Connections – Connect the fuel lines, ensuring a tight fit to prevent leaks. Check for any obstructions that could hinder fuel flow.

Step 4: Linkage Setup – Attach the throttle linkage, making sure it moves smoothly without binding. Adjust as necessary for a responsive throttle response.

Step 5: Final Checks – Inspect all connections and ensure everything is secure. Start the engine and listen for any irregularities in operation, adjusting as needed for optimal performance.

Following these steps will allow you to effectively install your new carburetors, ultimately enhancing your vehicle’s performance and driving experience.

Comparing DCOE to Other Carbs

When evaluating various types of carburetors, it’s essential to understand their unique characteristics and performance attributes. Different models offer distinct advantages and disadvantages, influencing engine efficiency, throttle response, and overall driving experience.

Multi-barrel designs are often praised for their ability to deliver precise fuel-air mixtures at different engine speeds, enhancing performance. In contrast, single-barrel options might provide simplicity and ease of tuning, appealing to those seeking a more straightforward setup.

Another critical factor is the tuning flexibility. Some systems allow for more extensive modifications, making them preferable for enthusiasts looking to maximize performance. Meanwhile, other models may have limited adjustment capabilities, which could affect their adaptability to various conditions.

Ultimately, the choice between these systems depends on individual needs, vehicle type, and desired performance outcomes. Understanding these differences can help enthusiasts make informed decisions about the best option for their specific applications.

Aftermarket Parts for Weber DCOE

Enhancing performance and efficiency in carburetor systems is a key goal for many automotive enthusiasts. By exploring a range of alternative components, users can significantly improve throttle response and overall functionality. These enhancements often lead to a more engaging driving experience and can cater to specific tuning requirements.

Types of Upgraded Components

Several upgraded components are available to maximize performance. These may include high-flow venturis, specialized jets, and custom intake manifolds designed to optimize air-fuel mixture delivery.

Benefits of Upgrading

Investing in enhanced components can lead to improved power output, better fuel efficiency, and increased reliability. These modifications allow for finer tuning, catering to individual driving styles and vehicle specifications.

| Component | Benefit |

|---|---|

| High-flow Venturis | Improved airflow and throttle response |

| Custom Jets | Optimized fuel delivery for performance |

| Upgraded Linkages | Smoother operation and better control |

Resources for DCOE Enthusiasts

For those passionate about performance carburetors, a wealth of information and tools is essential for optimizing and maintaining these intricate systems. Whether you’re a seasoned expert or a newcomer to the world of tuning, access to quality resources can significantly enhance your experience and understanding.

Online Forums and Communities: Engaging with fellow aficionados can provide invaluable insights. Websites and social media groups dedicated to carburetor enthusiasts often feature discussions, troubleshooting advice, and tips from experienced tuners.

Technical Manuals: Comprehensive guides and manuals are crucial for understanding the nuances of these systems. Look for well-reviewed publications that delve into both the historical context and modern applications of these carburetors.

Video Tutorials: Visual learning can be particularly effective when dealing with complex mechanical components. Numerous channels on platforms like YouTube offer step-by-step guides for installation, tuning, and maintenance, catering to various skill levels.

Specialty Shops: Consider reaching out to stores that specialize in performance parts. These retailers often have knowledgeable staff who can provide tailored advice and may also stock rare components that are hard to find elsewhere.

Local Workshops: Participating in hands-on workshops can deepen your practical skills. Many automotive clubs and specialty shops host events where you can learn directly from experts and gain firsthand experience.

Networking Events: Attending car shows and meetups can foster connections with others who share your passion. These gatherings often feature discussions on optimization techniques and showcase innovative builds that can inspire your projects.