Ditch Witch 1020 Parts Diagram Overview

In the realm of specialized machinery, comprehending the intricate layout of essential components is crucial for effective operation and maintenance. Each unit consists of various elements that work in harmony to ensure peak performance and reliability.

Visual representations play a vital role in aiding operators and technicians in identifying and troubleshooting issues. By examining these illustrations, one can gain insights into the arrangement and function of each integral piece.

Moreover, having access to detailed schematics enhances the ability to perform repairs and replacements efficiently. This knowledge ultimately contributes to the longevity and productivity of the machinery, empowering users to tackle challenges confidently.

Ditch Witch 1020 Overview

This section provides a comprehensive look at a specific model of underground construction machinery, emphasizing its design, functionality, and significance in the industry. The equipment is engineered for various tasks, showcasing reliability and efficiency in trenching and installation processes.

Key Features

Engineered for versatility, this machinery includes advanced technological components that enhance performance. Its robust structure allows for efficient operation in challenging environments, making it a preferred choice among professionals.

Specifications

| Feature | Details |

|---|---|

| Engine Type | Diesel |

| Operating Weight | 5000 lbs |

| Max Depth | 36 inches |

| Width | 36 inches |

Importance of Parts Diagrams

Visual representations of components are crucial in understanding machinery. They serve as a key resource for users to identify and locate individual elements, facilitating maintenance and repairs. By providing clarity, these illustrations enhance efficiency and accuracy during service tasks.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Illustrations simplify complex assemblies, making it easier to grasp how parts fit together. |

| Streamlined Repairs | Identifying components quickly leads to faster troubleshooting and repairs. |

| Informed Decisions | Users can make better choices regarding replacements and upgrades based on clear visuals. |

Key Components of the Ditch Witch 1020

Understanding the essential elements of this equipment is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the overall functionality and efficiency of the machine.

- Engine: The powerhouse that drives the entire unit, providing necessary energy for various operations.

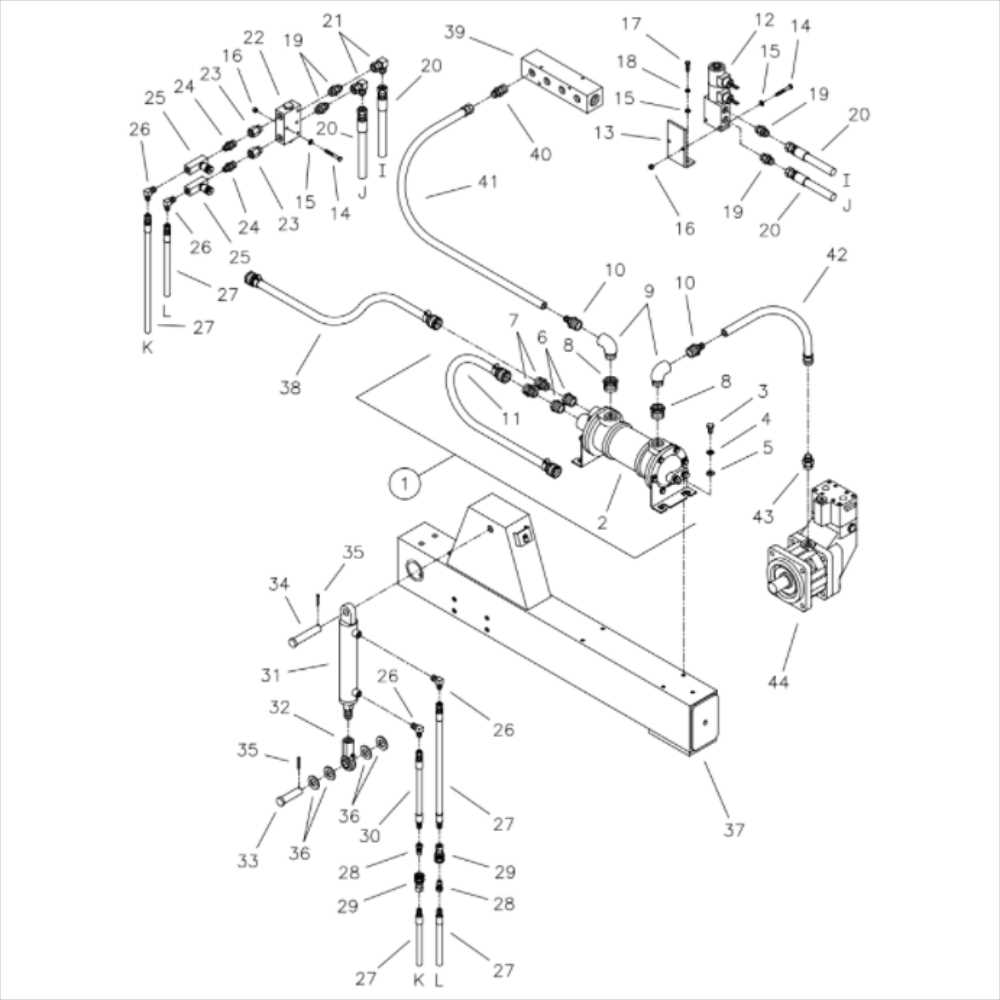

- Hydraulic System: Responsible for powering attachments and enabling various movements through fluid pressure.

- Transmission: Facilitates power transfer from the engine to the wheels, allowing for controlled movement and speed adjustments.

- Track System: Enhances stability and traction, especially on uneven terrains, ensuring better maneuverability.

- Operator Controls: Interface through which the user manages the machine, affecting precision and response during tasks.

- Frame: Provides structural support and durability, housing all other components securely.

Each of these elements contributes to the overall performance, making familiarity with them essential for effective use and upkeep.

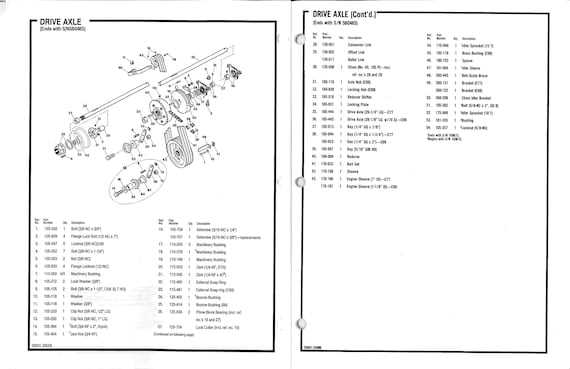

Understanding the Parts List

This section aims to provide clarity on the components essential for efficient machinery operation. Familiarity with the various elements can enhance maintenance and repair processes, ensuring optimal functionality.

| Component Name | Description |

|---|---|

| Drive System | Facilitates movement and power transfer throughout the equipment. |

| Hydraulic Assembly | Enables the operation of various attachments and enhances performance. |

| Control Panel | Interface for operating machinery and monitoring systems. |

| Frame Structure | Provides stability and support for all other components. |

| Cutting Attachment | Specialized tool for digging and trenching tasks. |

How to Read the Diagram

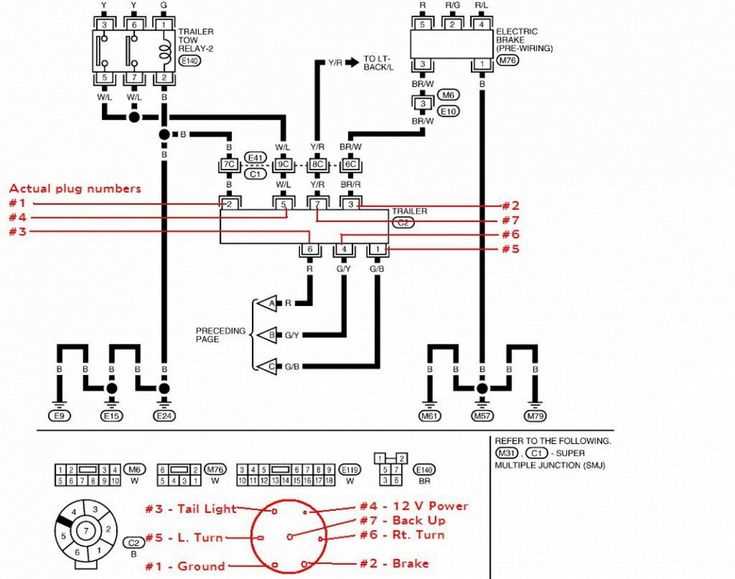

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals provide a comprehensive overview of components, their arrangements, and interconnections. Familiarizing yourself with the layout allows for easier identification of parts and enhances your ability to troubleshoot issues efficiently.

Start by identifying the legend or key, which typically explains the symbols used in the illustration. Each symbol corresponds to a specific component or function, making it essential to know what each represents. Once you have a grasp of the symbols, examine the overall layout to understand how the various elements interact with each other.

Next, pay attention to the numbering or labeling system. This often indicates the sequence of assembly or the order of operations. By following this system, you can gain insight into how to approach repairs or replacements methodically.

Finally, take note of any arrows or lines that suggest movement or connection. These graphical cues guide you through the relationships between different parts, providing clarity on how they work together to ensure the system functions properly. Mastering these aspects will significantly enhance your understanding and ability to work with the illustration effectively.

Common Issues with Ditch Witch 1020

Operating heavy machinery often presents a range of challenges that users may encounter over time. Understanding these potential problems can help in maintaining efficiency and prolonging the life of the equipment. Below are some frequently observed concerns associated with this type of equipment.

- Hydraulic Leaks: Leaks in the hydraulic system can lead to reduced performance. Regular checks are essential to identify any fluid loss.

- Starter Issues: Difficulties in starting the engine may arise from battery failures or ignition system malfunctions.

- Overheating: Engines may overheat due to insufficient coolant levels or radiator blockages, which can lead to serious damage.

- Track Wear: Continuous use can cause significant wear on the tracks, affecting traction and stability.

- Electrical Problems: Wiring issues or faulty connections can disrupt power delivery and operational functionality.

Regular maintenance and prompt attention to these issues can significantly enhance the reliability and performance of the equipment.

Replacement Parts: What You Need

When maintaining heavy machinery, understanding the components that require replacement is crucial for optimal performance. Identifying the necessary elements ensures that your equipment runs smoothly and efficiently, minimizing downtime and maximizing productivity.

First, familiarize yourself with the essential components of your machine. Regular wear and tear can affect various parts, from cutting edges to hydraulic elements. Recognizing these key sections will help you anticipate which items may need to be replaced during routine maintenance.

Documentation is your best ally. Consult manuals and technical guides to determine the specifications of the components that may require substitution. These resources provide valuable information on part numbers and compatibility, helping you make informed purchasing decisions.

Moreover, consider sourcing your replacements from reputable suppliers. Quality is paramount; using substandard items can lead to further issues down the line. Investing in reliable components can save time and resources, ensuring that your equipment continues to operate at peak efficiency.

Finally, don’t overlook the importance of expert advice. Engaging with professionals who have extensive experience in machinery can provide insights that are not readily available in documentation. They can guide you on best practices for maintenance and suggest timely replacements.

Where to Find Genuine Parts

Locating authentic components for your machinery is crucial for ensuring optimal performance and longevity. Whether you are looking for replacement items or upgrades, the source of these elements can significantly impact functionality and reliability.

Authorized Dealers are often the most reliable option. They typically offer a range of original components, ensuring that you receive high-quality and compatible options. Checking the manufacturer’s website can direct you to local distributors.

Online Retailers provide convenience and variety. Numerous e-commerce platforms specialize in equipment components, allowing you to compare prices and availability easily. Look for sellers with strong customer reviews to ensure authenticity.

Lastly, consider Specialty Shops that focus on machinery and equipment. These shops often have knowledgeable staff who can assist you in finding the exact components you need and can provide valuable advice on installation and maintenance.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires regular attention and care. Implementing a few key practices can significantly extend the lifespan of your equipment and enhance its performance.

- Regular Inspections: Schedule consistent checks to identify any wear and tear early.

- Cleaning: Keep components free from dirt and debris to prevent damage.

- Lubrication: Apply the appropriate lubricants to reduce friction and wear.

- Fluid Changes: Regularly replace oils and other fluids to maintain optimal function.

- Monitor Usage: Be mindful of operating conditions and avoid overloading the equipment.

By following these practices, you can delve deeper into the care needed for your machinery and ultimately ensure it remains reliable for years to come.

Comparison with Other Models

When evaluating various equipment models, it’s essential to consider their distinct features and capabilities. Understanding how one model stands against others can provide valuable insights for potential users looking for the most suitable option for their specific needs.

Key Differences

- Performance: Different models exhibit varying levels of efficiency and power output.

- Durability: Construction quality can greatly affect longevity and maintenance requirements.

- Versatility: Some models are designed for a wider range of applications, enhancing their usability.

Advantages of Alternatives

- Innovative Technology: Other models may incorporate advanced technology, improving operational effectiveness.

- Cost-Effectiveness: Certain alternatives might offer better pricing structures, making them more accessible.

- User-Friendly Features: Some options prioritize ease of use, appealing to less experienced operators.

Upgrades for Improved Performance

Enhancing the functionality and efficiency of machinery is crucial for optimal operation. Implementing various upgrades can significantly boost performance, reliability, and overall productivity.

- Engine Modifications

- Hydraulic System Enhancements

- Advanced Control Systems

- Improved Ground Engagement Tools

By focusing on these key areas, operators can ensure their equipment performs at its best, leading to increased output and reduced downtime.

DIY Repairs: A Guide

Engaging in home repairs can be a rewarding experience, allowing you to save money and gain valuable skills. This section will provide you with essential insights to tackle common issues effectively and confidently. By understanding the basics and preparing adequately, you can ensure that your projects are successful.

Assessing the Situation: Before starting any repair, take a moment to evaluate the problem thoroughly. Identify the necessary tools and materials, as well as potential challenges you might face during the process. A clear understanding will enhance your efficiency.

Gathering Tools: Collect the appropriate equipment for your task. Having the right tools on hand not only simplifies the job but also minimizes frustration. Make sure to familiarize yourself with each tool’s function before beginning.

Step-by-Step Approach: Break down the repair into manageable steps. Following a systematic process helps maintain focus and ensures you don’t overlook important details. Documenting each step can be beneficial for future reference.

Safety First: Always prioritize safety when undertaking repairs. Wear protective gear and ensure your workspace is organized. Being cautious can prevent accidents and injuries.

Seek Help: Don’t hesitate to consult guides, videos, or professionals if you encounter difficulties. Learning from others’ experiences can provide valuable insights and enhance your understanding of the task.

With the right mindset and preparation, DIY repairs can be an ultimate way to develop your skills and maintain your space effectively.

Resources for Further Learning

For those interested in expanding their knowledge about machinery and equipment, numerous resources are available. These materials can help you understand the intricacies of various components, improve maintenance skills, and enhance operational efficiency.

Here are some valuable resources to consider:

- Online Courses: Platforms like Coursera and Udemy offer specialized courses on machinery maintenance and operation.

- Industry Journals: Subscribe to publications focused on equipment technology to stay updated with the latest advancements.

- Manufacturer Websites: Explore the official sites of machinery manufacturers for technical documents, user manuals, and tutorials.

- Forums and Community Groups: Join online forums and local groups where enthusiasts share experiences and insights.

- YouTube Channels: Many channels provide instructional videos on equipment repair and maintenance techniques.

Utilizing these resources can significantly enhance your understanding and proficiency in working with various types of machinery.