Comprehensive Guide to Fs 90 Parts Diagram

The intricacies of machinery often lie in their individual elements, each playing a crucial role in the overall functionality. Understanding these components not only enhances operational efficiency but also aids in effective maintenance and troubleshooting. A comprehensive exploration of these units can illuminate their significance and interrelationships within the system.

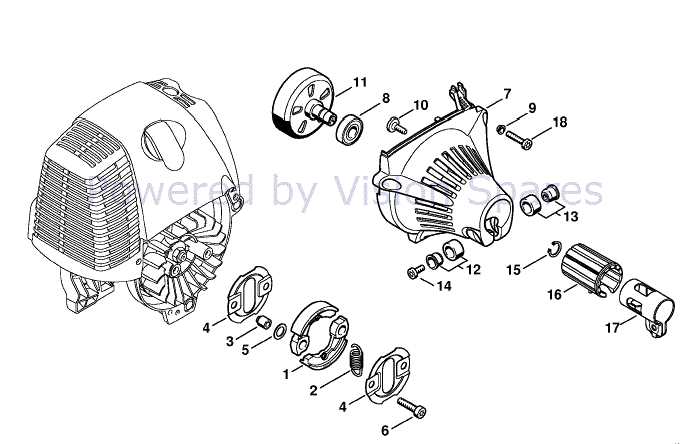

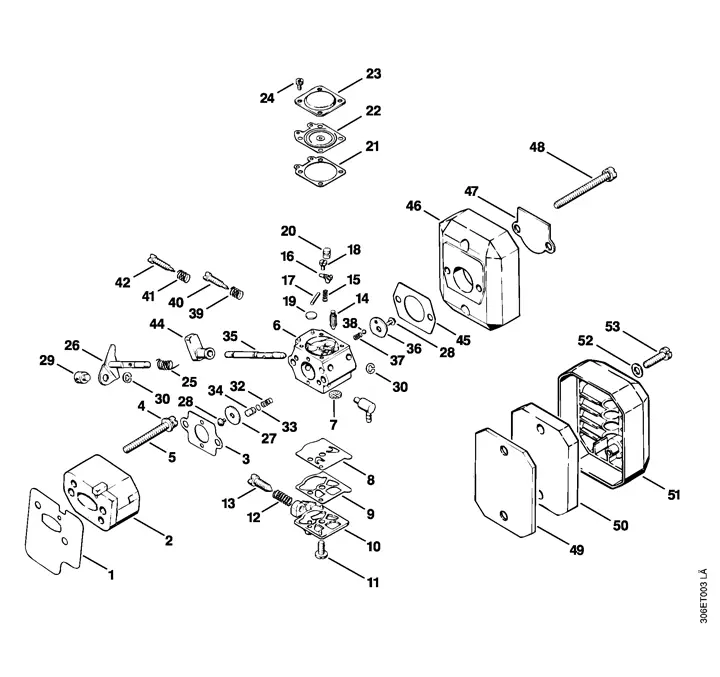

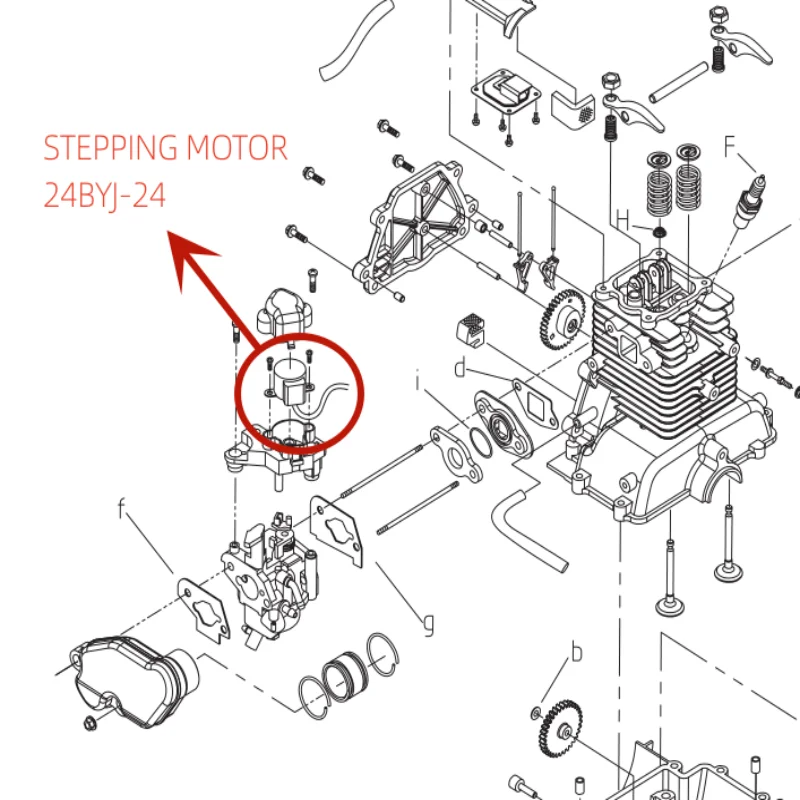

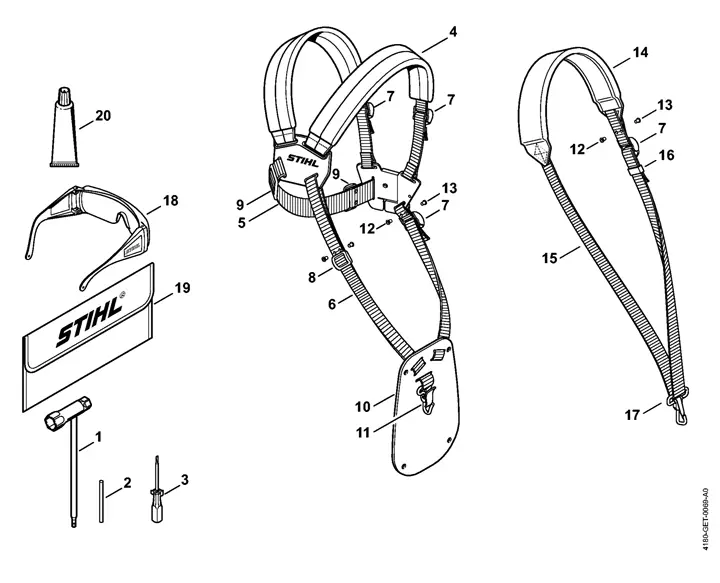

In this section, we will delve into a structured visualization of the various constituents that make up the Fs 90. By examining their arrangement and interaction, we can better appreciate the engineering that enables optimal performance. This insight is essential for anyone involved in the care and management of such equipment.

Moreover, a well-organized representation of these entities serves as a valuable reference for technicians and operators alike. Familiarity with the layout and roles of each segment allows for quicker diagnostics and informed decision-making during repairs. Understanding the underlying framework not only fosters expertise but also contributes to enhanced safety practices.

Understanding Fs 90 Parts Diagram

The Fs 90 assembly representation serves as a vital tool for comprehending the various components and their interrelations within the system. Grasping this information enhances maintenance and repair efficiency, ensuring optimal performance.

Key aspects to consider include:

- Identification of individual elements

- Relationship between components

- Maintenance requirements

- Assembly procedures

To effectively utilize this representation, follow these steps:

- Familiarize yourself with each component’s location.

- Understand how components interact with each other.

- Refer to maintenance guidelines associated with each element.

- Practice disassembly and reassembly using the representation for hands-on experience.

By delving into this essential resource, users can achieve a clearer understanding of the system’s functionality, leading to improved troubleshooting and longevity.

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations serve as crucial tools, providing clarity on how various elements interact within a system. These resources enhance communication among technicians, enabling them to work more efficiently and accurately.

Moreover, they facilitate troubleshooting by allowing users to identify issues quickly and pinpoint the necessary replacements. By simplifying complex assemblies, these visuals empower users to grasp the configuration of each component, ultimately leading to better decision-making and problem-solving capabilities.

In educational contexts, they play a vital role in teaching the intricacies of equipment design and functionality. Students and new technicians benefit greatly from these visual aids, as they bridge the gap between theory and practical application. Overall, the value of these illustrations extends beyond mere reference, reinforcing knowledge and fostering expertise in the field.

Common Components in Fs 90

The Fs 90 model incorporates a variety of essential elements that contribute to its overall functionality and performance. Understanding these components is crucial for users seeking to optimize their experience and maintain the equipment effectively. Each element plays a specific role in ensuring the system operates smoothly, enhancing reliability and efficiency.

Key Functional Elements

Among the significant components, several are fundamental to the system’s operation. These elements work in harmony, allowing the unit to perform various tasks seamlessly. Below is a brief overview of these critical components.

| Component | Function |

|---|---|

| Engine | Provides the necessary power for operation. |

| Control System | Enables user interaction and system management. |

| Transmission | Transfers power from the engine to the wheels. |

| Suspension | Enhances stability and comfort during operation. |

Supportive Features

In addition to the core components, several supportive features enhance the usability and effectiveness of the Fs 90. These elements ensure that the primary components function optimally and provide added convenience for the user.

| Feature | Description |

|---|---|

| Safety Systems | Includes measures to protect users and equipment. |

| Diagnostic Tools | Assists in troubleshooting and maintenance. |

| Ergonomic Design | Improves user comfort and accessibility. |

How to Read a Parts Diagram

Understanding the visual representation of components is essential for efficient assembly and maintenance. This guide will provide insights into interpreting these illustrations effectively.

- Familiarize Yourself with Symbols: Different icons represent various elements. Knowing what each symbol signifies is crucial.

- Identify Key Sections: Often, illustrations are divided into sections that correspond to different assemblies. Focus on one area at a time.

- Follow the Numbering System: Components are typically labeled with numbers or letters, guiding you through the assembly sequence.

By grasping these basics, you’ll be better equipped to navigate the complexities of the visual layout and streamline your repair or assembly tasks.

Identifying Major Assemblies

Understanding the key components of a system is essential for effective maintenance and operation. Recognizing these significant groups allows for better troubleshooting and performance optimization.

When examining the structure, consider the following categories:

- Engine Assembly: The heart of the system, encompassing the core functions.

- Transmission Unit: Responsible for power transfer and gear management.

- Chassis Framework: Provides structural integrity and support.

- Electrical System: Integrates controls and power supply for various functionalities.

- Hydraulic Components: Facilitates movement and operation of essential mechanisms.

By focusing on these primary groupings, one can efficiently delve into the intricacies of the overall setup and ensure optimal functionality.

Typical Issues with Fs 90 Parts

When dealing with the various components of the Fs 90, users often encounter a range of challenges that can affect performance and reliability. Understanding these common difficulties is essential for effective maintenance and troubleshooting.

One frequent concern involves wear and tear, which can lead to diminished efficiency over time. This deterioration may manifest as unusual noises or reduced functionality, prompting users to seek replacements or repairs.

Another issue arises from improper installation or alignment of individual elements. Such mistakes can cause miscommunication between parts, resulting in operational failures or unexpected behavior. Regular checks and adjustments are crucial to ensure everything functions harmoniously.

Additionally, exposure to harsh environmental conditions can impact the integrity of specific components. Corrosion or damage from moisture can significantly reduce their lifespan, necessitating timely intervention to prevent more extensive issues.

Lastly, outdated or incompatible replacements can lead to further complications. It is vital to ensure that any substitutions are not only compatible but also meet the required specifications to maintain optimal performance.

Maintenance Tips for Longevity

Ensuring the prolonged efficiency of your equipment requires a commitment to regular upkeep and attention to detail. By adopting a systematic approach to maintenance, you can significantly enhance performance and extend the lifespan of your machinery. Here are some essential strategies to keep in mind.

Regular Inspection

Conducting frequent examinations is crucial. This allows for the early identification of potential issues before they escalate. Look for signs of wear and tear, unusual noises, or any irregularities in operation. Establish a routine schedule for these checks to maintain consistency.

Proper Cleaning

Keeping your equipment clean is vital for optimal functioning. Accumulation of dirt and debris can hinder performance and lead to premature failure. Use appropriate cleaning agents and techniques to ensure all surfaces are maintained without causing damage.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for visible signs of wear. |

| Cleaning | Monthly | Use appropriate tools and solutions. |

| Lubrication | Quarterly | Follow manufacturer’s guidelines. |

| Component Replacement | As Needed | Replace worn components promptly. |

Where to Find Replacement Parts

When it comes to maintaining and restoring machinery, locating the necessary components is crucial for ensuring optimal performance. Whether you’re looking to repair an old model or enhance a new one, there are several reliable avenues to explore.

- Online Retailers: Many websites specialize in selling a wide range of components. Some popular platforms include:

- Amazon

- eBay

- Specialty stores dedicated to specific brands

- Manufacturer’s Website: Directly visiting the official site of the manufacturer can provide access to original equipment and specific information about compatible items.

- Local Dealerships: Authorized dealers often have the latest and most reliable options available. It’s a good idea to contact them for inquiries about availability.

- Salvage Yards: For older models, checking salvage yards can yield unexpected finds at lower prices. This can be a treasure trove for rare components.

- Online Forums and Communities: Engaging with online groups dedicated to your machinery can lead to valuable insights. Members often share sources for hard-to-find items or even sell their own.

lessCopy code

By exploring these resources, you can effectively track down the components needed for repairs or upgrades, ensuring your machinery remains functional and efficient.

Impact of Quality on Performance

The caliber of components in any system significantly influences its overall functionality and efficiency. When elements are crafted with precision and care, the resulting synergy enhances operational reliability and user satisfaction. Conversely, deficiencies in quality can lead to failures, inefficiencies, and increased maintenance costs.

Reliability and Durability

Cost Efficiency

DIY Repairs Using the Diagram

Engaging in home repairs can be both fulfilling and cost-effective. By utilizing a visual representation of components, you can navigate the intricacies of your project with greater ease. This section explores practical strategies for undertaking repairs independently.

Benefits of Self-Repair

- Cost savings on professional services

- Increased understanding of your equipment

- Empowerment through hands-on experience

Steps to Follow

- Identify the issue by closely examining your equipment.

- Refer to the visual guide to locate relevant components.

- Gather necessary tools and replacement items.

- Carefully follow the outlined steps for disassembly and reassembly.

- Test the equipment after completing the repairs.

Professional Help vs. DIY

When it comes to tackling mechanical issues, individuals often face a choice between seeking expert assistance or attempting the task themselves. Each option has its own set of advantages and challenges, making it essential to evaluate the situation carefully.

Choosing professional assistance can provide:

- Expertise and experience

- Access to specialized tools

- Time efficiency

- Guaranteed quality of work

On the other hand, a DIY approach offers:

- Cost savings

- Flexibility in scheduling

- Personal satisfaction from completing a task

- Opportunity to learn and gain skills

Ultimately, the decision should depend on the complexity of the task, available resources, and individual confidence in handling such projects.

Understanding Part Numbering Systems

In any technical field, the classification of components plays a crucial role in ensuring clarity and efficiency. A well-structured identification scheme facilitates easy retrieval, inventory management, and communication among stakeholders. By employing a systematic approach, organizations can streamline processes and enhance operational effectiveness.

Typically, a numbering system incorporates various elements that denote attributes such as type, size, and functionality. Each segment provides vital information, allowing users to quickly ascertain essential details without confusion. This is particularly beneficial in complex industries where precision is paramount.

Moreover, such systems often vary across sectors, reflecting the unique requirements and standards of each domain. Understanding these variations is essential for effective collaboration and interoperability. As organizations continue to evolve, so too must their classification methodologies to meet the demands of modern practices.

Resources for Further Learning

To enhance your understanding and expertise in this area, a variety of educational materials and tools are available. Engaging with these resources can provide deeper insights and practical knowledge that are essential for mastering complex concepts.

Online platforms offer a wealth of tutorials and instructional videos, catering to different learning styles. Websites dedicated to technical education often feature comprehensive courses and forums for discussion.

Books written by industry experts can serve as valuable references, offering both theoretical frameworks and practical applications. Additionally, joining community groups or attending workshops can foster collaborative learning and hands-on experience.

For those seeking to expand their skills further, academic journals and publications provide the latest research and developments, ensuring you stay informed about innovations in the field.