Comprehensive Guide to Milwaukee Parts Diagrams

In the world of power tools and equipment, having a clear understanding of their internal configurations is essential for both professionals and enthusiasts. This section delves into the intricacies of these intricate layouts, providing insights into how various elements interconnect to facilitate optimal performance. By examining these structures, users can enhance their repair and maintenance skills, ensuring longevity and reliability in their devices.

Whether you are a seasoned technician or a DIY hobbyist, knowledge of these schematics equips you with the necessary tools to tackle any challenges that may arise during repairs. Identifying the various components and their functions not only aids in troubleshooting but also fosters a deeper appreciation for the engineering that goes into creating these machines. Each layout serves as a roadmap, guiding users through the complexities of their devices.

By exploring these visual representations, you will gain valuable insights into the assembly and organization of essential elements. This understanding will empower you to make informed decisions when it comes to repairs, replacements, and upgrades, ultimately enhancing the overall efficiency of your equipment. The ability to read and interpret these visual aids is an invaluable skill in today’s fast-paced world of technology and machinery.

Understanding Milwaukee Parts Diagrams

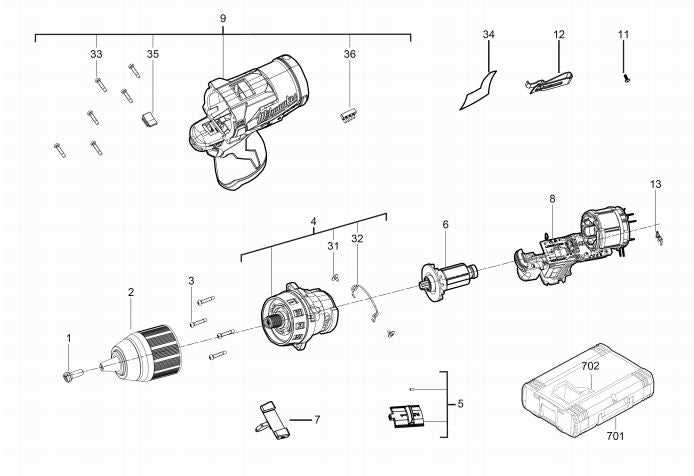

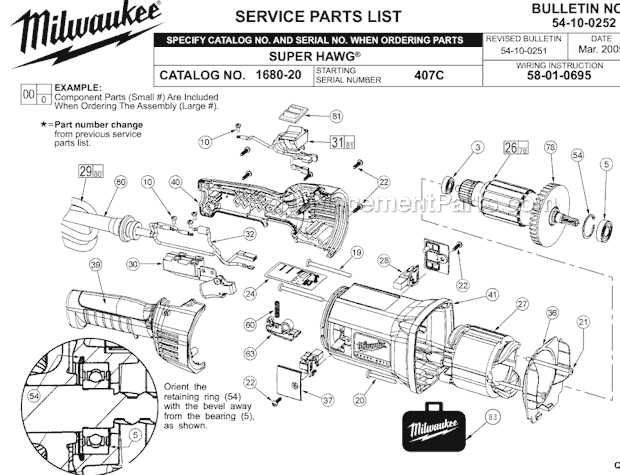

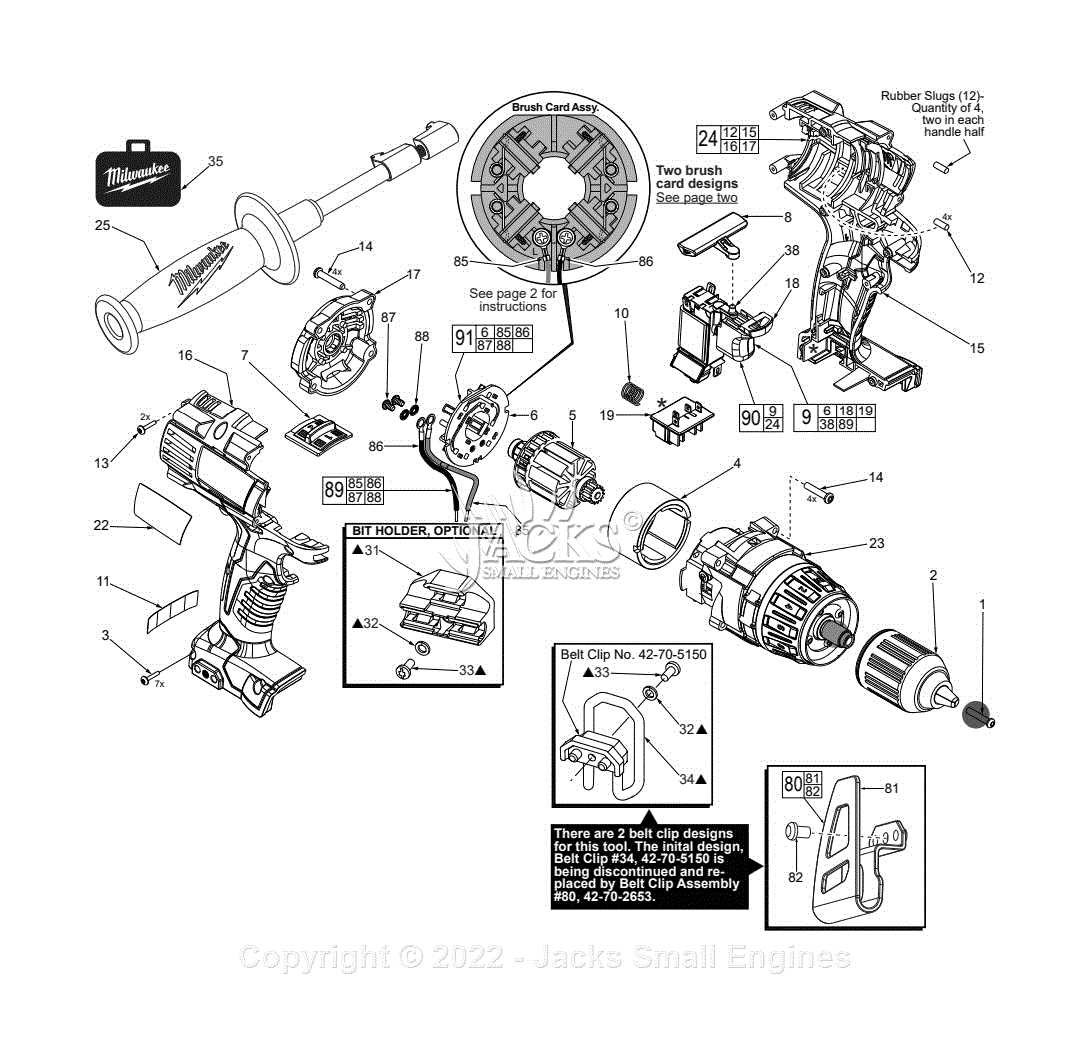

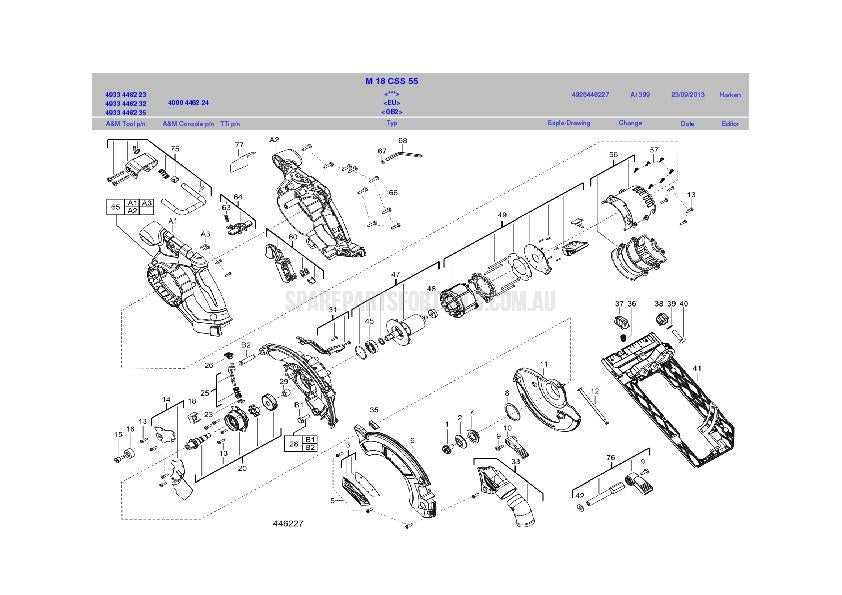

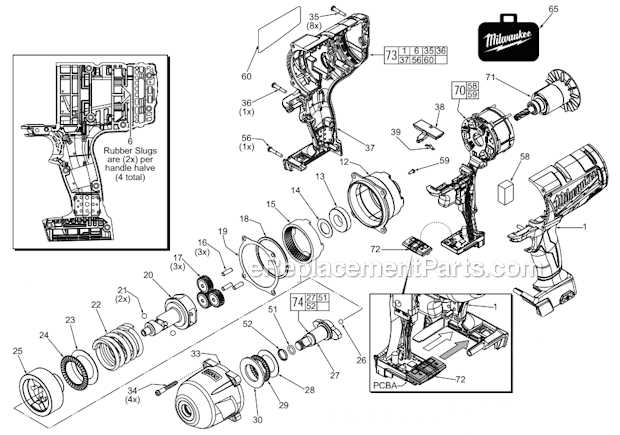

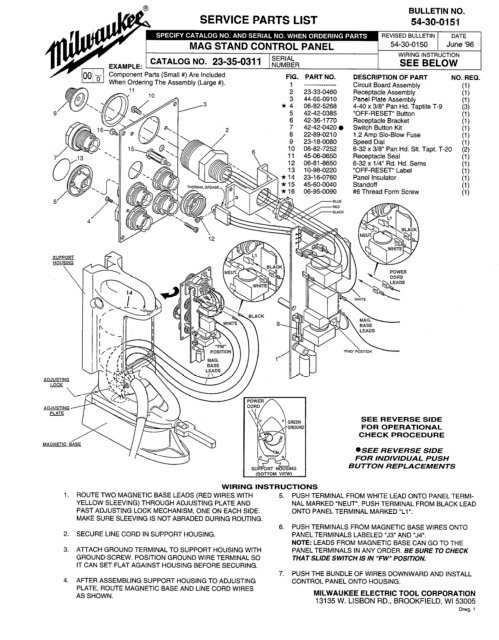

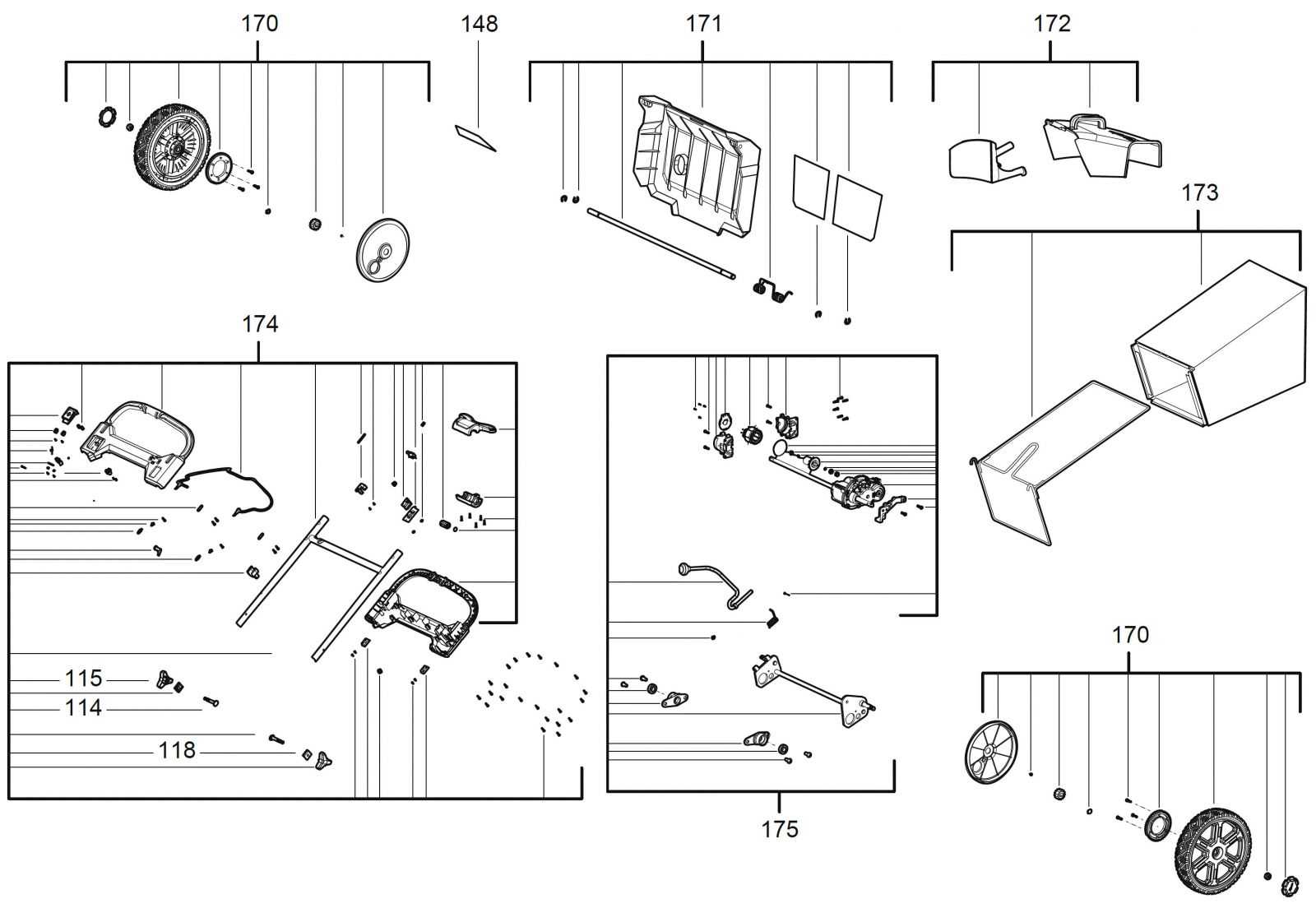

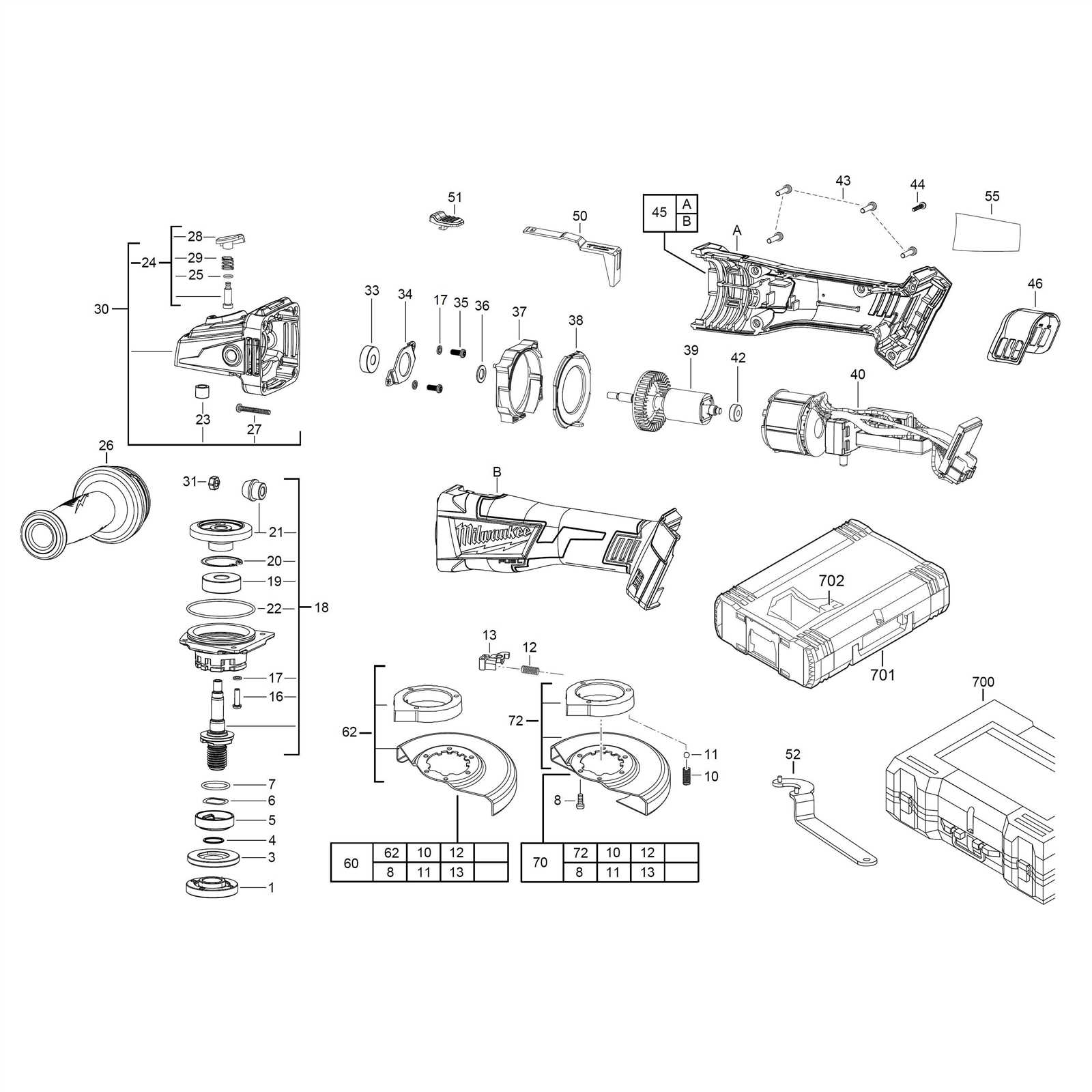

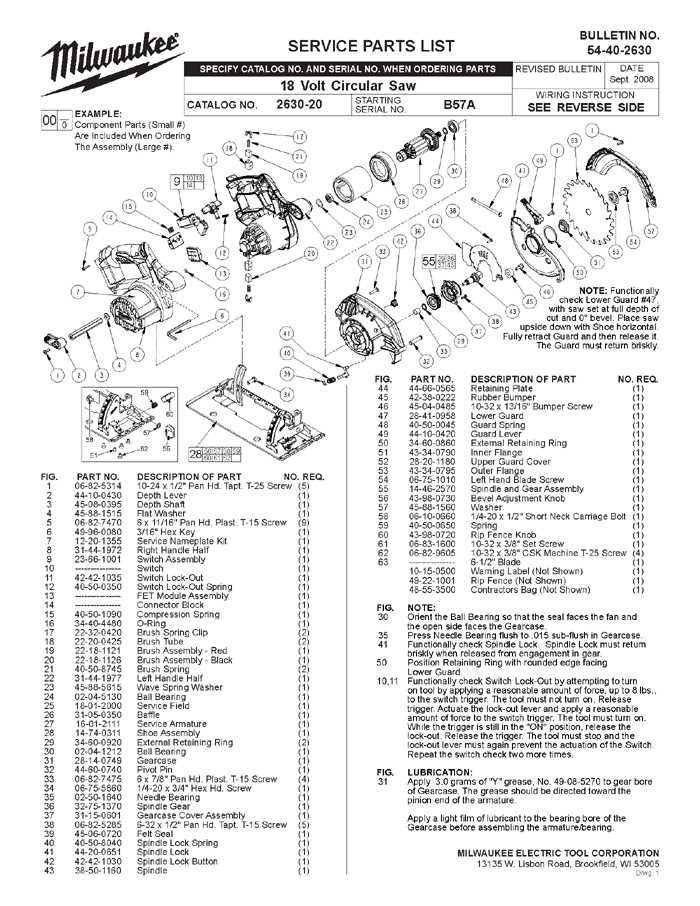

In the realm of machinery and equipment, visual representations play a crucial role in aiding comprehension and facilitating repairs. These illustrations serve as invaluable tools for users to identify components and their respective functions within various models. By analyzing these visuals, individuals can gain insights into assembly, disassembly, and troubleshooting processes.

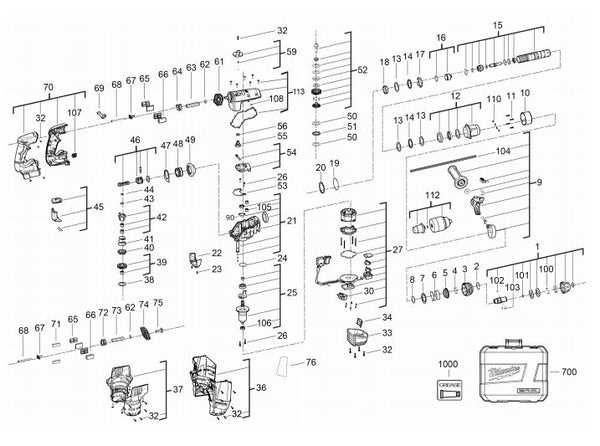

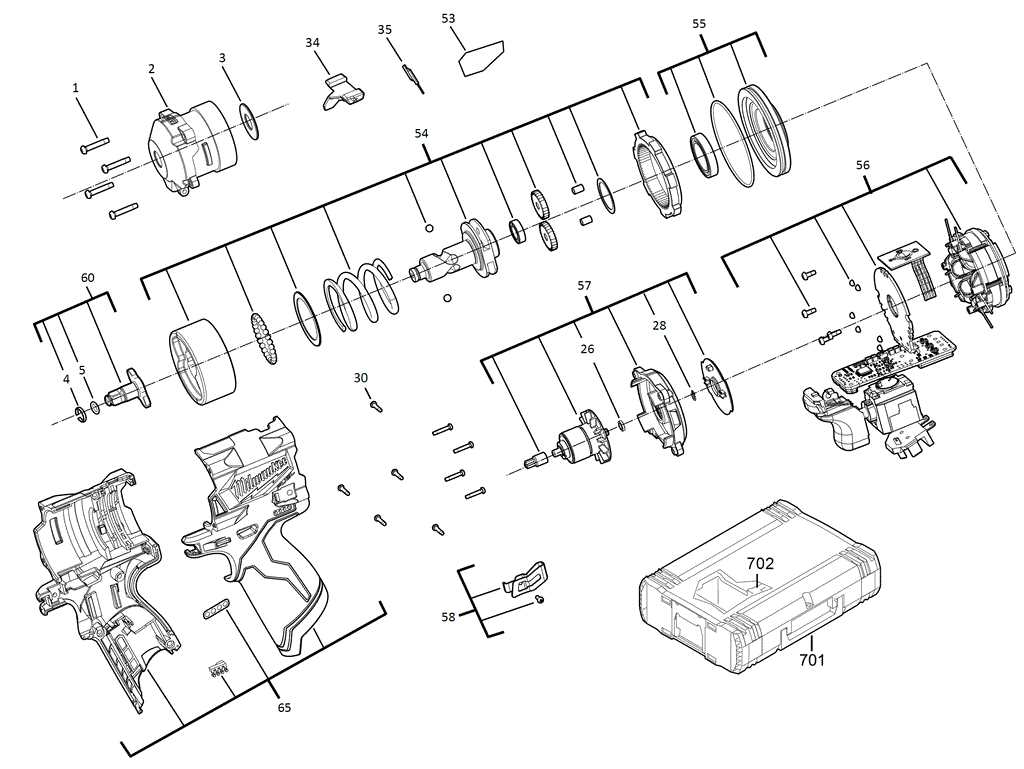

Familiarity with these illustrations enhances one’s ability to navigate through complex structures. Each element is often labeled, providing clarity on the relationship between different components. Moreover, understanding the layout can significantly streamline maintenance tasks, reducing downtime and improving efficiency.

Utilizing these visual aids not only simplifies the repair process but also empowers users with knowledge. As they become adept at interpreting these visuals, individuals can make informed decisions regarding repairs and replacements, ultimately prolonging the lifespan of their equipment. Embracing this understanding is essential for anyone seeking to optimize performance and reliability.

Importance of Accurate Parts Diagrams

Clear and precise visual references are essential for ensuring smooth maintenance and repair processes. When working with intricate machinery, having a detailed illustration that outlines the correct placement and alignment of each component can significantly reduce errors and misunderstandings during assembly or replacement.

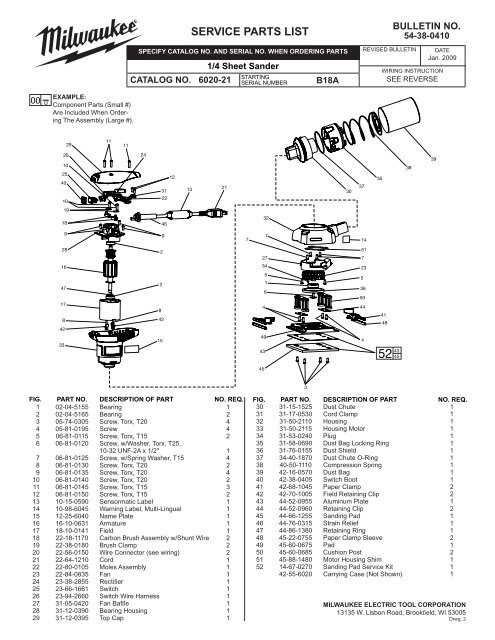

Using comprehensive visual guides helps technicians and users quickly identify the correct pieces, minimizing downtime and potential damage caused by incorrect installation. This level of accuracy also ensures that the longevity and performance of equipment are maintained, as each element is placed correctly, following the manufacturer’s intended design.

Common Components in Milwaukee Tools

Various hand-held and power devices share a core set of components that ensure their durability, performance, and reliability. These elements are essential for smooth operation and effective functionality, making them vital in the design and assembly of many professional tools.

Among these essential parts are the motors, which provide the driving force needed for operation, and the gear systems, which help regulate speed and torque. Durable housings protect internal mechanisms from wear, while switches and triggers offer precise control to the user.

Additional key elements include batteries for cordless versions, enabling mobility and convenience, and cooling systems that prevent overheating during intensive use. These shared features allow for consistency and efficiency across a wide range of tool types.

How to Read Parts Diagrams

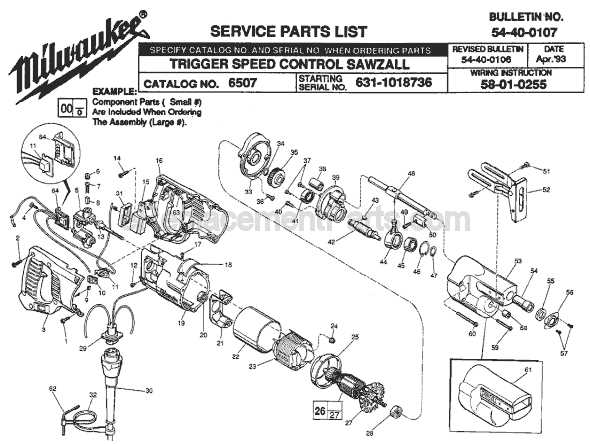

Understanding technical schematics is a valuable skill when working with mechanical or electrical equipment. These visual guides help in identifying individual components, their placement, and how they connect to form a functional system. Properly interpreting these drawings ensures correct assembly, repair, and maintenance.

Recognizing Symbols and Labels

Schematics use standardized symbols to represent various elements. These symbols may vary slightly depending on the type of equipment, but most follow a consistent pattern. Labels and numbers usually accompany these symbols, indicating the exact position and specification of each component. Learning these conventions is essential to avoid mistakes during assembly or repairs.

Follow the Flow

Another key aspect of interpreting technical schematics is to follow the logical flow of the design. Elements are often arranged to depict the sequence of operations or the path of energy, fluids, or signals. Reading from left to right or top to bottom, depending on the diagram, allows for a better understanding of how components interact and function together as a unit.

Identifying Replacement Parts Quickly

When it comes to repairing equipment, the ability to find necessary components in a timely manner can significantly reduce downtime. An organized approach to sourcing replacements can streamline the entire repair process, ensuring minimal delays and effective results.

Using Model Numbers and Serial Information

One of the most efficient ways to track down the right component is by utilizing model numbers and serial codes. These unique identifiers help pinpoint the correct item quickly, avoiding confusion with similar components. Always check the label or manufacturer details to ensure accuracy when searching.

Consulting Detailed Guides

Comprehensive guides often include breakdowns of assemblies, making it easier to locate specific components. These documents can offer visual aids and lists of essential parts, speeding up the process of identification. They are an invaluable resource when dealing with complex systems.

Resources for Milwaukee Parts Diagrams

Understanding how to maintain and repair various tools requires access to accurate visual guides and detailed breakdowns. These references are essential for anyone looking to restore equipment to peak performance. By using visual aids and comprehensive breakdowns, users can ensure proper handling and upkeep of their tools.

Official Platforms

Many manufacturers offer comprehensive online resources where users can access illustrations and detailed instructions for their devices. These platforms typically provide easy navigation and allow users to quickly find what they need for repair or maintenance.

Third-Party Providers

Apart from official platforms, there are numerous third-party sites that specialize in offering repair guides and visual aids. These platforms can serve as a valuable alternative when looking for hard-to-find resources, ensuring that even older models are well-supported.

Tips for Maintaining Your Tools

Proper care and regular upkeep are essential to ensure your equipment functions reliably over time. Consistent attention to cleanliness, lubrication, and storage practices can significantly extend the lifespan of your devices, helping you avoid costly repairs or replacements.

Keep Your Tools Clean

After each use, clean your tools thoroughly to remove dust, debris, and any build-up that might hinder their performance. Use a soft brush or a damp cloth to wipe surfaces, and ensure no moisture remains, as it can lead to rust or corrosion. Keeping them clean not only improves functionality but also contributes to their longevity.

Regular Lubrication

Lubricating moving parts is essential for smooth operation. Apply oil or grease to joints, bearings, and other mechanisms to reduce friction. Regular lubrication prevents wear and tear, ensuring optimal efficiency and performance. Check manufacturer recommendations for the type of lubricant suitable for your equipment.

Store Tools Properly

Proper storage is crucial for maintaining your tools in good working order. Keep them in a dry, cool place, and ensure they are protected from dust and moisture. Using cases, racks, or toolboxes can help organize your collection, reducing the risk of damage and making them easily accessible for the next use.

Understanding Model Numbers and Their Significance

Model numbers play a crucial role in identifying specific products and their variations. They serve as unique identifiers, allowing users to quickly differentiate between different versions of similar tools or equipment. Understanding these numbers can provide valuable insight into the features, production year, and compatibility of a given item.

By decoding model numbers, individuals can also ensure that they are selecting the right components, upgrades, or accessories that are designed to work seamlessly with their equipment. This helps to avoid compatibility issues and ensures efficient operation. Proper comprehension of these codes is essential for maintenance, repair, and ensuring long-term performance.

Where to Find Genuine Parts

Finding authentic components for your equipment ensures reliability and longevity. These items are designed specifically for your tools, providing a perfect fit and performance that generic alternatives cannot match.

Authorized retailers are the most reliable sources for these original items. They maintain a direct connection with manufacturers and ensure every product is genuine. When purchasing from these suppliers, you are guaranteed to receive exactly what your tool needs for optimal operation.

Online platforms also provide a wide selection, but caution is required to avoid counterfeit products. Always verify the credibility of the source, checking reviews and certifications, to ensure the components are original. Reputable websites often offer warranties or return policies, further ensuring authenticity.

Finally, many brick-and-mortar stores have dedicated sections for original components. Visiting them allows you to inspect items firsthand, ensuring quality before purchasing. Staff at these locations can also provide advice and support in finding the right component for your device.

Common Issues and Troubleshooting Tips

When working with complex equipment, various malfunctions can occur, affecting performance and reliability. Identifying the source of the problem and applying the right solution is crucial for maintaining operational efficiency. Below are some frequent challenges and effective ways to address them.

Overheating Problems

Overheating is a common issue that can lead to reduced lifespan or even damage to the equipment. Ensure proper ventilation and check for blockages that may restrict airflow. Regularly cleaning cooling components can help prevent this issue.

Electrical Failures

Electrical issues can result in the device not powering on or functioning intermittently. Check for loose connections, inspect wiring, and verify the power source. Replacing damaged cables or connectors often resolves the problem.

Performance Degradation

Over time, equipment may exhibit reduced performance. This can stem from wear and tear or improper maintenance. Lubricate moving parts and replace worn components to

Comparing Parts for Different Models

When analyzing various models, it’s important to evaluate how components differ in functionality and design. Understanding the variations between models helps identify compatibility and performance improvements.

Key Differences in Components

- Some models may have improved materials that enhance durability.

- Design modifications can affect how certain elements fit together.

- Advanced features may only be present in newer iterations.

Performance and Compatibility

- Older versions may lack certain optimizations found in newer models.

- Component upgrades could require additional compatibility checks.

- Consider the availability of spare components when choosing between models.

Benefits of Using Diagrams for Repairs

Visual representations play a crucial role in the repair process, providing clarity and guidance for technicians and DIY enthusiasts alike. By illustrating the components and their relationships, these graphical aids simplify complex tasks and enhance understanding.

One significant advantage of utilizing visual guides is the reduction of errors during repairs. When individuals can see how parts fit together, they are less likely to make mistakes that could lead to further damage or complications. This clarity can save both time and money, as accurate repairs are completed more efficiently.

Additionally, such representations facilitate effective troubleshooting. By highlighting various sections and mechanisms, they enable users to pinpoint issues quickly. Being able to identify problems at a glance enhances the overall repair experience, making it less daunting and more manageable.

Moreover, these visual tools serve as excellent educational resources. For newcomers to the field, having a clear visual reference can significantly boost their confidence and skill set. Learning through images often leads to better retention of information and more successful outcomes in future repair endeavors.