Onan RV QG 4000 Parts Overview

Understanding the essential components of a recreational vehicle generator is crucial for maintenance and troubleshooting. This section provides a comprehensive overview of various elements that contribute to the generator’s efficient operation. By familiarizing yourself with these components, you can ensure optimal performance and longevity of your equipment.

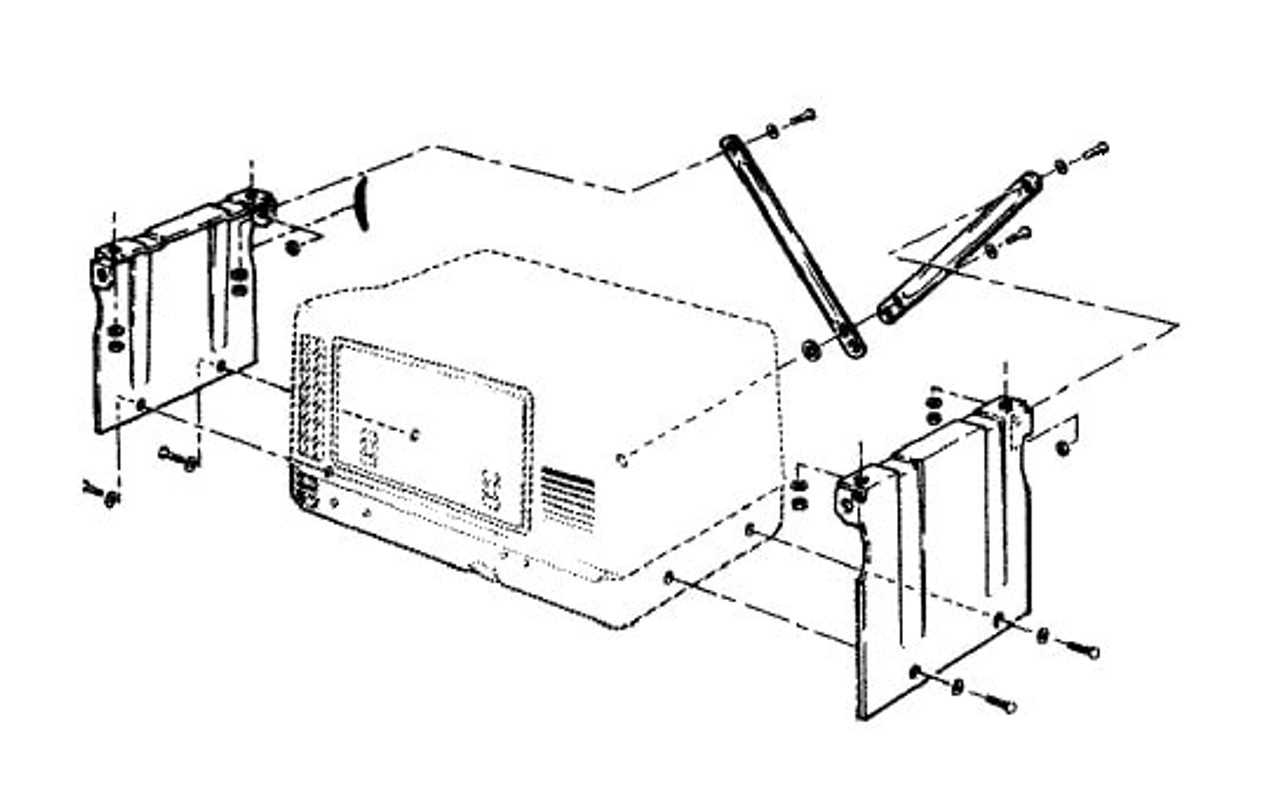

Diagrams are valuable tools for visualizing the arrangement and connection of parts within the generator system. They aid in identifying each component’s role and functionality, making it easier to diagnose potential issues. With a clear understanding of these elements, you can enhance your knowledge of how the generator operates as a whole.

Additionally, having access to accurate representations of these components can significantly improve your ability to perform repairs and maintenance tasks. Whether you’re a seasoned technician or a novice enthusiast, recognizing the intricacies of the generator’s design will empower you to take informed actions regarding upkeep and service.

This section will provide a comprehensive understanding of a specific generator model widely used in recreational vehicles. It aims to highlight the key components that contribute to its functionality, ensuring that users can effectively maintain and troubleshoot the system. By breaking down the elements, readers will gain insights into the essential parts and their roles within the mechanism.

Key Components of the Generator

The generator consists of various integral parts that work together to ensure optimal performance. Each component plays a vital role, from the engine to the electrical system. Understanding these elements is crucial for effective maintenance and repairs.

Functionality and Importance

Knowing the functionality of each section is essential for users. This knowledge aids in troubleshooting common issues and enhances the overall efficiency of the generator. Recognizing how each part interacts with others allows for a more informed approach to usage and care.

Key Features of the Generator

This section highlights the essential characteristics of a reliable power generator, designed to meet various energy needs. Understanding these attributes can help users select the right model for their specific applications.

One notable feature is the generator’s robust design, which ensures durability and longevity even in demanding environments. The compact size allows for easy transport and installation, making it a convenient option for both residential and commercial use.

Another significant aspect is the fuel efficiency, which optimizes operational costs while delivering consistent performance. Additionally, advanced safety mechanisms are integrated to protect against overloads and short circuits, enhancing user confidence.

Moreover, the generator offers versatility with multiple output options, catering to a range of devices and equipment. This flexibility, combined with user-friendly controls, ensures a seamless experience for operators.

Understanding the Parts Diagram

This section aims to provide a comprehensive overview of the schematic representation that illustrates the components of the specified equipment. Familiarity with this visual guide is essential for effective maintenance and repair. Each element plays a crucial role in the overall functionality, and recognizing their interconnections can greatly enhance operational efficiency.

Importance of Visual Representation

A visual representation serves as an invaluable tool for technicians and users alike. It simplifies complex information, allowing for quick identification of individual elements and their functions. By understanding how each component fits into the larger system, users can troubleshoot issues more effectively and streamline repair processes.

Key Features to Note

When examining the schematic, pay attention to the labeling and layout. Each section is often categorized by function, providing clarity on how different parts interact. Recognizing these features helps in pinpointing potential problems and determining the necessary steps for maintenance. Engaging with the visual guide actively can significantly improve one’s ability to manage the equipment efficiently.

Identifying Essential Components

Understanding the fundamental elements of a generator system is crucial for efficient operation and maintenance. Recognizing these key components enables users to troubleshoot issues effectively and ensures optimal performance of the equipment.

The primary elements can be categorized into several critical sections:

- Power Generation Unit: This is the core of the system, responsible for converting fuel into electrical energy.

- Fuel System: This includes the tank and pump, which supply fuel to the generator for operation.

- Cooling Mechanism: Essential for preventing overheating, this system circulates coolant around the engine.

- Electrical Components: These parts manage the distribution of electricity generated and include circuits, fuses, and relays.

- Control Panel: This interface allows users to monitor and manage the generator’s performance, including starting and stopping operations.

By familiarizing oneself with these vital components, users can enhance their understanding of how the generator operates and address potential issues proactively.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Regular maintenance practices play a crucial role in extending the lifespan of machinery and preventing unexpected failures. By adopting a proactive approach, you can safeguard your investment and enhance efficiency.

Routine inspections are essential for identifying potential issues before they escalate. Check for signs of wear and tear, and address any irregularities promptly. Keep all moving parts lubricated to minimize friction and reduce the risk of overheating.

Regular cleaning is equally important. Remove dirt, dust, and debris that can accumulate and hinder performance. A clean environment promotes better airflow and efficiency. Additionally, ensure that all connections and fittings are secure to prevent leaks or malfunctions.

Adhering to the manufacturer’s guidelines for service intervals is vital. Follow recommended schedules for oil changes, filter replacements, and component checks. This not only ensures that your equipment runs smoothly but also helps maintain its value over time.

Finally, invest in quality replacement components when needed. Using subpar parts can lead to further complications down the line. Prioritizing high-quality materials will contribute to the reliability and longevity of your machinery.

Common Replacement Parts Explained

Understanding essential components is crucial for maintaining the efficiency and longevity of any generator system. Each unit consists of various elements that may require occasional replacement due to wear or damage. Familiarizing oneself with these components can aid in timely maintenance and improve overall functionality.

Key Components to Monitor

Several primary components are frequently replaced to ensure optimal performance. These parts play significant roles in the generator’s operation, and recognizing when they need attention is vital for uninterrupted service.

Maintenance Considerations

Regular inspections and prompt replacements of these elements can prevent larger issues down the line. It’s advisable to keep a checklist of common components and their maintenance schedules to enhance reliability.

| Component | Function | Replacement Frequency |

|---|---|---|

| Air Filter | Filters incoming air for combustion efficiency. | Every 100 hours of operation. |

| Fuel Filter | Removes impurities from fuel to protect the engine. | Every 200 hours of operation. |

| Spark Plug | Ignites the air-fuel mixture in the combustion chamber. | Every 100 hours of operation or annually. |

| Oil Filter | Maintains oil cleanliness, ensuring smooth operation. | Every 100 hours of operation or with oil change. |

Troubleshooting Common Issues

Addressing frequent complications in equipment operation is essential for maintaining efficiency and reliability. This section aims to guide users through identifying and resolving typical problems encountered during usage. By following systematic troubleshooting steps, one can ensure the optimal performance of their machinery.

Identifying Symptoms

Recognizing the signs of malfunction is the first step in effective troubleshooting. Common indicators include:

- Unusual noises during operation

- Inconsistent power output

- Excessive vibrations

- Difficulty starting the unit

Basic Solutions

Once the symptoms are identified, consider the following preliminary solutions:

- Check fuel levels and ensure the fuel is clean and fresh.

- Inspect electrical connections for corrosion or loose wires.

- Examine air filters and replace them if they are clogged.

- Look for any visible signs of wear on belts and hoses.

By implementing these troubleshooting strategies, users can often resolve minor issues without the need for professional assistance. Regular maintenance and prompt attention to emerging problems will enhance the longevity of the equipment.

Importance of Regular Inspections

Regular evaluations of machinery are crucial for ensuring optimal performance and longevity. Consistent monitoring allows for the early detection of potential issues, which can prevent costly repairs and downtime. By adhering to a systematic inspection schedule, operators can maintain efficiency and enhance the reliability of their equipment.

Implementing routine assessments contributes to a safer work environment. When machines are inspected regularly, the risk of unexpected failures diminishes, safeguarding both personnel and surrounding infrastructure. Furthermore, these evaluations help in complying with safety regulations, thus promoting operational integrity.

| Inspection Frequency | Benefits |

|---|---|

| Daily | Immediate identification of issues |

| Weekly | Enhanced operational efficiency |

| Monthly | Long-term cost savings |

| Yearly | Comprehensive performance review |

Where to Buy Replacement Parts

Finding the right components for maintenance and repairs can significantly extend the lifespan of your equipment. Whether you’re a seasoned technician or a DIY enthusiast, knowing where to source high-quality alternatives is crucial for efficient functioning.

Authorized Dealers

One of the most reliable places to obtain necessary components is through authorized distributors. These vendors guarantee the authenticity of their products, ensuring compatibility and performance. They often provide warranties and customer support for added assurance.

Online Retailers

The internet offers a plethora of options for purchasing replacement components. Many reputable e-commerce platforms specialize in industrial and mechanical supplies. Customer reviews and ratings can help guide your selection process.

| Vendor Type | Benefits | Considerations |

|---|---|---|

| Authorized Dealers | Genuine products, warranty support | Potentially higher prices |

| Online Retailers | Wide selection, competitive pricing | Need to verify seller credibility |

| Local Hardware Stores | Immediate access, personal assistance | Limited stock options |

Installation Guidelines for New Parts

When integrating replacement components into your equipment, following precise procedures is essential for ensuring optimal performance and longevity. Proper installation not only enhances functionality but also minimizes the risk of potential issues arising from incorrect fittings.

Preparation Steps

Before commencing the installation, gather all necessary tools and new components. Ensure that the workspace is clean and well-lit to facilitate easy access and visibility. Reviewing the user manual or installation guide beforehand can also provide valuable insights and step-by-step instructions.

Installation Process

Begin by carefully removing any existing components that require replacement. Take note of how these parts are secured and positioned. When installing the new elements, ensure they are aligned correctly and securely fastened. It is advisable to double-check connections and fittings to guarantee everything is tightly in place. Finally, run a test to confirm that the equipment operates smoothly after the replacement.

Customer Support and Resources

Reliable assistance and valuable resources are essential for ensuring optimal performance and longevity of your equipment. Customers can access a variety of support options that cater to different needs, from troubleshooting to maintenance advice.

Support Services: The customer support team is dedicated to providing expert guidance for any inquiries or concerns. This team is equipped to handle a range of issues, ensuring that users receive timely and accurate information.

Online Resources: Users can find comprehensive materials online, including user manuals, maintenance guidelines, and troubleshooting steps. These resources are designed to empower customers with the knowledge needed to address common challenges effectively.

Community Forums: Engaging with other users through community forums can be an excellent way to share experiences and solutions. These platforms allow individuals to exchange tips and insights, fostering a collaborative environment.

By utilizing these support options and resources, users can enhance their understanding and experience, ultimately leading to improved functionality and satisfaction with their equipment.