Understanding the Parts Diagram of Honda XR2600 Pressure Washer

In the world of outdoor maintenance, having a comprehensive grasp of your equipment’s functionality is crucial. Understanding the intricate workings of your cleaning apparatus can greatly enhance its efficiency and lifespan. By familiarizing yourself with the various elements that constitute your machine, you can ensure optimal performance and troubleshoot issues more effectively.

Visual aids can significantly simplify this learning process. Detailed illustrations can help users identify different components and their respective roles in the overall system. Whether you’re a seasoned user or a newcomer, these resources provide invaluable insights, enabling you to take better care of your equipment.

Additionally, knowing how each piece contributes to the operation can aid in effective maintenance and repair. This knowledge empowers you to perform routine checks, replace worn-out elements, and address problems before they escalate. Ultimately, mastering the layout of your cleaning device ensures you are always ready to tackle any task with confidence.

Understanding the Honda XR2600 Pressure Washer

This section provides insights into a powerful cleaning tool designed for various outdoor tasks. Its efficiency in removing dirt and grime makes it an essential asset for homeowners and professionals alike. With a robust engine and innovative design, this equipment is engineered to deliver exceptional performance and durability.

Key Features: The unit boasts a high flow rate and pressure capabilities, ensuring thorough cleaning across different surfaces. Its lightweight construction and ergonomic handle facilitate easy maneuverability, allowing users to reach challenging areas effortlessly.

Maintenance Considerations: Regular upkeep is crucial for optimal functioning. Familiarity with the internal components and their arrangement enhances the longevity of the machine. Understanding how to access and replace worn parts will aid in maintaining peak performance.

By knowing the structure and functionality of this cleaning device, users can maximize its potential, ensuring efficient operation and a cleaner environment.

Key Features of Honda XR2600 Model

This model stands out due to its impressive functionality and user-friendly design. With a focus on delivering superior performance, it caters to a variety of cleaning needs effectively and efficiently.

Powerful Engine: The heart of this unit is its robust motor, which ensures reliable operation and enhances overall efficiency. It delivers ample force, making even the toughest jobs manageable.

Lightweight Construction: Designed for ease of use, this model boasts a lightweight frame. This feature allows for easy maneuverability, reducing user fatigue during extended cleaning sessions.

Adjustable Nozzle: Equipped with an adaptable nozzle, this machine provides flexibility in spray patterns. Users can switch from a gentle mist to a concentrated jet, tailoring the approach to different surfaces and tasks.

Durable Components: Built with high-quality materials, this unit ensures longevity and reliability. Each component is designed to withstand rigorous use, making it a worthwhile investment for regular tasks.

User-Friendly Interface: Featuring intuitive controls, this model simplifies operation. Users can easily adjust settings, making the cleaning process straightforward and efficient.

Environmental Considerations: This model incorporates features that minimize environmental impact, promoting eco-friendly cleaning without sacrificing performance.

Importance of Regular Maintenance

Consistent upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. Neglecting maintenance can lead to reduced efficiency and premature wear, ultimately resulting in costly repairs or replacements. Regular checks not only enhance functionality but also promote safety during usage.

Benefits of Routine Checks

Implementing a regular maintenance schedule offers numerous advantages. Firstly, it helps identify potential issues before they escalate into significant problems. Preventive care minimizes downtime and keeps your equipment running smoothly. Moreover, well-maintained tools can operate at peak efficiency, saving time and energy in the long run.

Impact on Performance and Longevity

The performance of machinery is directly linked to how well it is maintained. Thorough inspections and timely replacements of worn components ensure that all parts work harmoniously. This not only maximizes effectiveness but also extends the lifespan of the equipment, allowing for a better return on investment.

Identifying Common Issues

Understanding typical problems that may arise with your equipment can greatly enhance your maintenance efforts. By recognizing these issues early, you can ensure optimal performance and longevity. This section outlines some frequent challenges users encounter and provides insights on how to address them effectively.

Frequent Challenges

- Inconsistent performance or low output

- Difficulty in starting the engine

- Unusual noises during operation

- Leaks from connections or hoses

- Clogged nozzles or spray tips

Troubleshooting Tips

- Check fuel levels and quality to ensure proper ignition.

- Inspect all connections for tightness to prevent leaks.

- Clean or replace clogged components to restore functionality.

- Consult the manual for specific operational guidelines.

- Seek professional assistance if problems persist.

By staying vigilant and addressing these common issues promptly, users can maintain efficiency and avoid potential setbacks.

Where to Find Replacement Parts

Locating components for your equipment can seem daunting, but numerous resources are available to simplify the process. Understanding where to look and what to seek will ensure your machine continues to operate efficiently. Whether you are seeking a specific element or a comprehensive kit, various options can meet your needs.

Online Retailers

One of the most convenient ways to source components is through online retailers. Websites specializing in machinery supplies often provide detailed catalogs, allowing you to search for the exact item you require. Reputable platforms frequently include customer reviews and ratings, helping you make informed decisions. Additionally, many sites offer shipping services, making it easier to receive items directly at your doorstep.

Local Repair Shops

Another valuable resource is local repair shops. These establishments not only offer replacement components but also possess expert knowledge regarding compatibility and installation. Engaging with professionals can lead to insightful advice, ensuring you select the correct parts for your machinery. Moreover, supporting local businesses can foster community connections while obtaining the necessary supplies.

Tools Needed for Repair

When undertaking maintenance or repairs on any equipment, having the right tools is essential for efficiency and effectiveness. This section will outline the necessary instruments that will assist you in successfully completing your tasks.

To begin, ensure you have the following tools at your disposal:

- Socket Set: A comprehensive socket set is crucial for loosening and tightening various fasteners.

- Wrenches: Both adjustable and fixed wrenches will allow you to handle different sizes of nuts and bolts.

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for various screws found in the assembly.

- Pliers: Needle-nose and standard pliers will aid in gripping and manipulating components effectively.

- Utility Knife: For cutting through packaging or other materials, a utility knife can be very useful.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications.

In addition to these basic tools, consider having the following specialized instruments on hand:

- Multimeter: For checking electrical connections and diagnosing issues.

- Fuel Line Wrench: Helpful for working on fuel systems without damaging components.

- Cleaning Brushes: Essential for removing debris and maintaining cleanliness during repairs.

With these tools ready, you will be well-equipped to tackle any maintenance challenges that may arise, ensuring that the equipment remains in optimal working condition.

Step-by-Step Repair Process

Repairing equipment can seem daunting, but with a systematic approach, you can tackle issues effectively. This section outlines a comprehensive method to identify and fix common problems, ensuring your machine operates smoothly once again.

1. Gather Tools and Materials: Before you begin, assemble all necessary tools and replacement components. This may include wrenches, screwdrivers, and seals specific to your model. Having everything on hand will streamline the process.

2. Disconnect and Prepare: Always start by disconnecting the power source. This is crucial for safety. Once disconnected, inspect the unit for any visible damage or wear.

3. Consult the Manual: Refer to the user manual for troubleshooting tips. This resource often contains valuable insights into common issues and detailed repair instructions tailored to your device.

4. Disassemble Carefully: Begin disassembling the unit by removing screws and components methodically. Keep track of all parts, as this will make reassembly easier. It’s helpful to organize screws and small items in labeled containers.

5. Inspect Each Component: Examine all internal parts for signs of wear or damage. Look for cracks, rust, or any other irregularities that might affect performance. This step is essential to determine what needs replacing.

6. Replace Faulty Parts: Once you’ve identified defective components, replace them with new or refurbished parts. Ensure that the replacements are compatible with your specific model to avoid further issues.

7. Reassemble the Unit: After replacing any damaged parts, reassemble the device in reverse order of disassembly. Be cautious to align all components correctly and tighten screws securely without over-torquing.

8. Test the Equipment: Once everything is reassembled, reconnect the power source and conduct a thorough test. Check for leaks or unusual noises, and ensure that the unit operates as intended.

9. Regular Maintenance: After successful repairs, establish a routine maintenance schedule. Regularly checking and cleaning components will prolong the lifespan of your equipment and prevent future issues.

Following this methodical repair process will help you efficiently address and resolve common problems, ensuring your equipment remains in optimal working condition.

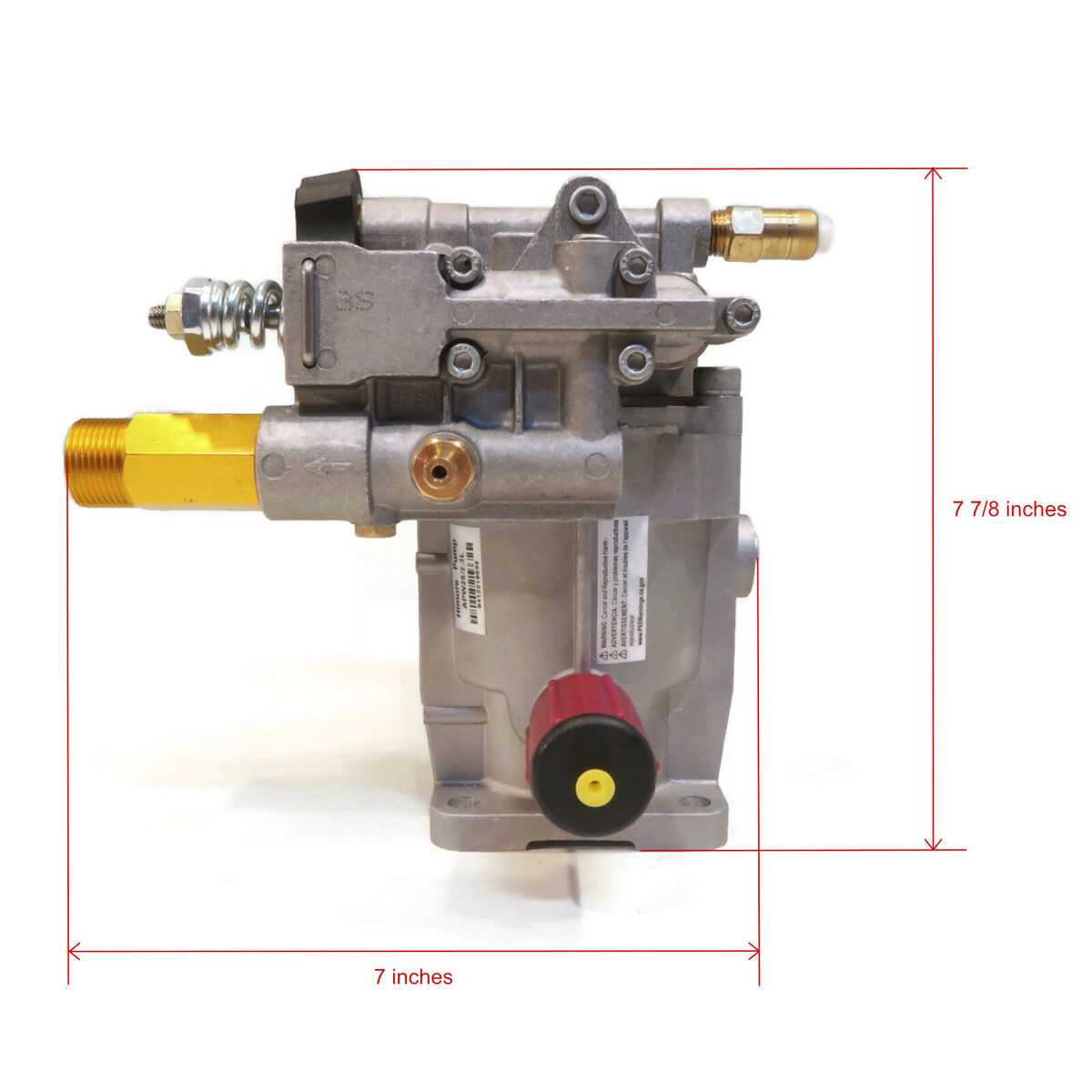

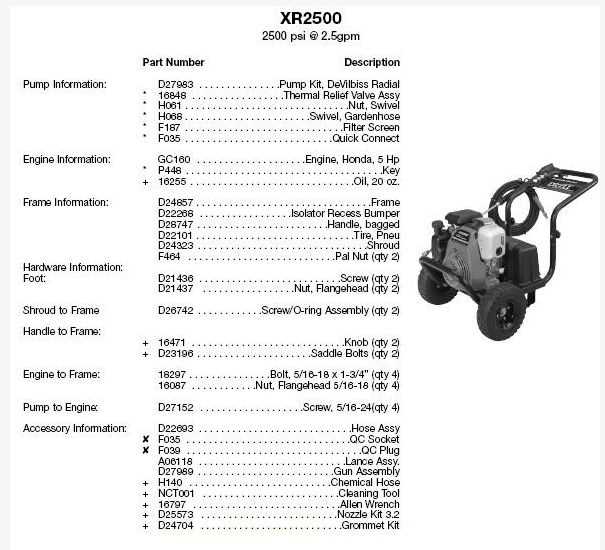

Understanding the Parts Diagram

Grasping the layout of components in a machine is essential for effective maintenance and troubleshooting. A visual representation provides clarity on how different elements interconnect, facilitating easier repairs and replacements. This guide will help you navigate through the various sections of the schematic, ensuring you can identify and understand each crucial element.

| Component | Description | Function |

|---|---|---|

| Motor | The primary driving unit | Powers the entire system |

| Pump | Fluid pressurization device | Generates necessary pressure for operation |

| Hoses | Flexible tubes | Convey liquids from one point to another |

| Nozzle | Dispensing tip | Controls the flow and direction of the fluid |

| Frame | Structural support | Holds all components together |

By familiarizing yourself with this layout, you can enhance your ability to address issues efficiently, ensuring longevity and optimal performance of the equipment.

How to Read Technical Diagrams

Understanding technical illustrations is essential for anyone looking to repair or maintain machinery. These visual representations provide crucial information about the components and their relationships, facilitating troubleshooting and assembly. By grasping how to interpret these graphics, you can save time and enhance your ability to work effectively with equipment.

Familiarize Yourself with Symbols

Each illustration contains specific symbols and notations that convey important information about the items depicted. Familiarizing yourself with these symbols is the first step in comprehending the overall layout. Many guides provide a legend or key that explains each symbol, making it easier to decode the visual information.

Follow the Flow of Components

When examining an illustration, pay attention to how the components connect and interact with one another. Often, diagrams are organized to show the sequence of assembly or the flow of processes. Understanding this flow can help you visualize how to approach repairs or modifications, ensuring that you maintain the correct order and functionality.

Choosing Quality Replacement Components

When it comes to maintaining outdoor equipment, selecting high-quality replacement items is crucial for ensuring optimal performance and longevity. Choosing the right components not only enhances the efficiency of your device but also minimizes the risk of future repairs and replacements.

Benefits of Quality Components

- Durability: Premium components are designed to withstand wear and tear, providing a longer lifespan.

- Performance: Quality items ensure that your equipment operates at its best, enhancing overall functionality.

- Cost-effectiveness: While high-quality parts may come with a higher initial cost, they often save money in the long run by reducing maintenance needs.

How to Identify Quality Components

- Check for Manufacturer Reputation: Research brands known for producing reliable items.

- Look for Warranty Offers: Quality products often come with warranties that protect your investment.

- Read Customer Reviews: Feedback from other users can provide insight into the performance and durability of specific components.

By focusing on these factors, you can make informed choices that lead to enhanced functionality and extended service life for your equipment.

Tips for Efficient Troubleshooting

When facing issues with your cleaning equipment, having a systematic approach can make the process more effective and less frustrating. By following a series of logical steps, you can quickly identify the root cause of the problem and implement a solution.

- Start with Observation: Carefully inspect the machine for any visible signs of wear or damage. Look for leaks, cracks, or any components that appear out of place.

- Consult the Manual: Refer to the user manual for troubleshooting guidance. It often contains valuable insights and troubleshooting steps specific to your model.

- Check Connections: Ensure all hoses and fittings are securely connected. Loose or damaged connections can lead to performance issues.

- Test Components Individually: If the device has multiple parts, test them one at a time to isolate the issue. This methodical approach can help pinpoint the malfunctioning component.

- Look for Blockages: Inspect any filters, nozzles, or tubes for clogs. Blockages can severely impact efficiency and may be the source of the problem.

- Monitor Performance: After making adjustments or repairs, observe the equipment’s performance closely. Take note of any changes, as this can help further identify persistent issues.

- Seek Professional Help: If you’re unable to resolve the issue on your own, consider contacting a technician. Sometimes expert assistance is the quickest way to restore functionality.

By employing these strategies, you can enhance your troubleshooting efforts and ensure your equipment operates smoothly and efficiently.

Safety Precautions During Repairs

When undertaking maintenance on any equipment, ensuring safety is paramount. Proper precautions not only protect the individual performing the repairs but also preserve the integrity of the machinery. By adhering to essential guidelines, one can minimize the risk of accidents and injuries, fostering a secure work environment.

Personal Protective Equipment

Wearing appropriate personal protective gear is critical during any repair task. Items such as safety goggles, gloves, and sturdy footwear provide essential protection against potential hazards. Additionally, ensuring that clothing is fitted and free from loose elements helps prevent entanglement with moving parts.

Work Environment Safety

Maintaining a clean and organized workspace is vital for reducing risks. Ensure that tools are readily accessible and that surfaces are clear of debris. Adequate lighting is also important to enhance visibility, allowing for accurate repairs while minimizing the likelihood of accidents. Always disconnect power sources before beginning any work to avoid electrical hazards.

Best Practices for Pressure Washer Care

Maintaining your cleaning equipment is essential for ensuring optimal performance and longevity. Proper upkeep not only enhances efficiency but also minimizes the risk of breakdowns and costly repairs. Adopting a few key practices can significantly extend the lifespan of your machine.

Regular Cleaning: After each use, it’s vital to clean the exterior of the equipment to remove dirt and debris. This helps prevent rust and corrosion. Additionally, checking and clearing the nozzles ensures that they remain unobstructed for the best performance.

Check Fluid Levels: Regularly inspect the levels of oil and cleaning solutions. Keeping these at the appropriate levels not only maximizes performance but also protects the internal components from wear and tear.

Storage: Proper storage is crucial for the durability of your machine. Store it in a dry, sheltered area to protect it from moisture and extreme temperatures. Additionally, coiling the hose carefully prevents kinks that could lead to damage.

Scheduled Maintenance: Following the manufacturer’s recommendations for maintenance is essential. This includes changing filters, inspecting belts, and ensuring that all parts are in good working condition. Regular checks can identify potential issues before they become major problems.

Use Quality Products: Utilizing high-quality cleaning solutions and accessories ensures compatibility and enhances effectiveness. Avoiding harsh chemicals can also protect the integrity of your equipment.

By following these best practices, you can ensure that your cleaning machine remains in excellent condition, providing reliable service for years to come.