Comprehensive Guide to Stihl MS 362 CM Parts Diagram

When it comes to the maintenance and operation of a high-performance cutting tool, familiarity with its internal elements is essential. Every component plays a crucial role in ensuring optimal functionality and longevity. This section delves into the intricate details of a specific chainsaw variant, offering insights into its assembly and the relationships between various parts.

By examining the configuration of each segment, users can gain a better understanding of how to effectively troubleshoot issues and perform necessary repairs. This knowledge not only empowers owners to enhance the efficiency of their equipment but also helps in making informed decisions when sourcing replacements or upgrades.

In this guide, you will find a comprehensive overview that highlights the various segments, their purposes, and how they interconnect to contribute to the overall performance of the machine. Whether you’re a seasoned user or a novice, understanding these components will significantly enhance your experience and proficiency with this powerful tool.

Understanding the Stihl MS 362 CM

This section explores a popular model of power tools designed for cutting and pruning tasks. These machines are well-regarded for their efficiency, durability, and user-friendly features, making them suitable for both professionals and enthusiasts alike. Understanding their components and functionality can enhance performance and extend lifespan.

Key Features

The highlighted model is equipped with a robust engine that balances power and weight, allowing for prolonged use without excessive fatigue. Its ergonomic design contributes to user comfort, while advanced technologies ensure optimal fuel efficiency and reduced emissions.

Maintenance Considerations

Regular upkeep is essential for maintaining peak performance. Familiarizing oneself with the various elements, such as the air filter and chain tensioning system, can significantly affect the tool’s operational longevity. Knowledge of these components enables timely interventions and minimizes downtime.

Usage Applications

This machine excels in various scenarios, from professional landscaping to home gardening tasks. Its versatility makes it an indispensable tool for anyone seeking to manage vegetation effectively.

Key Features of the MS 362 CM

The model under discussion is designed to offer a blend of efficiency, power, and user-friendly features that make it suitable for both professionals and hobbyists. With advanced technology and durable components, this tool stands out in its category, ensuring reliable performance for various cutting tasks.

Performance and Power

This equipment is equipped with a high-performance engine that delivers exceptional cutting speed and efficiency. Some notable attributes include:

- Powerful motor for increased productivity.

- Fuel-efficient design reducing consumption.

- Quick acceleration for swift operation.

User Comfort and Safety

To enhance the user experience, several ergonomic features have been incorporated:

- Lightweight construction for easy handling.

- Anti-vibration system that minimizes fatigue.

- Safety mechanisms to protect the operator during use.

These elements combine to make this model an excellent choice for those seeking reliability and ease of use in their cutting tasks.

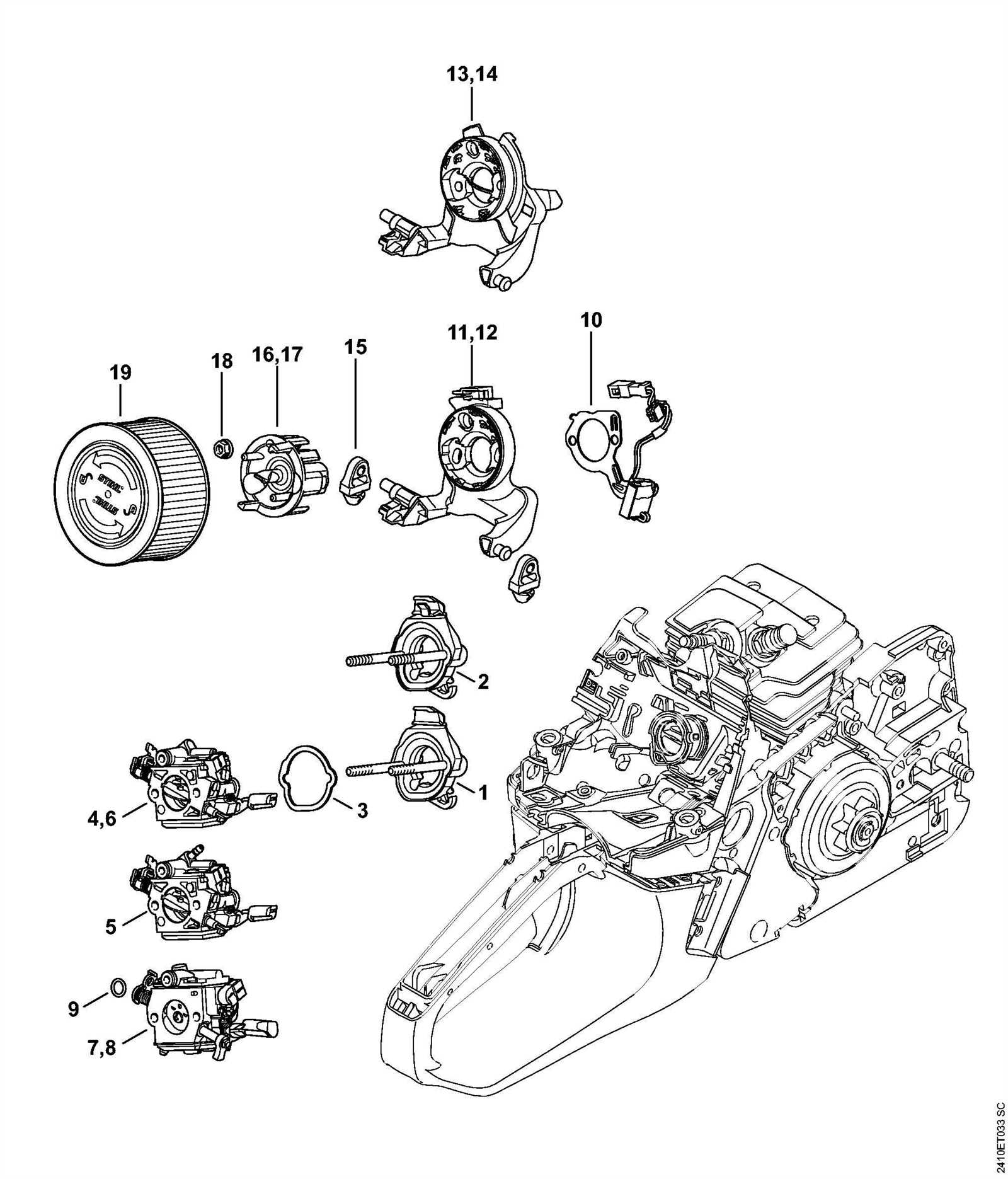

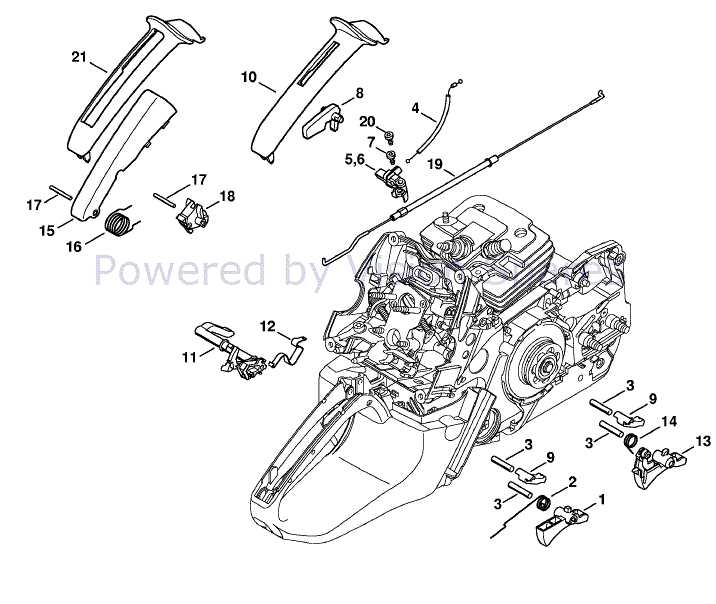

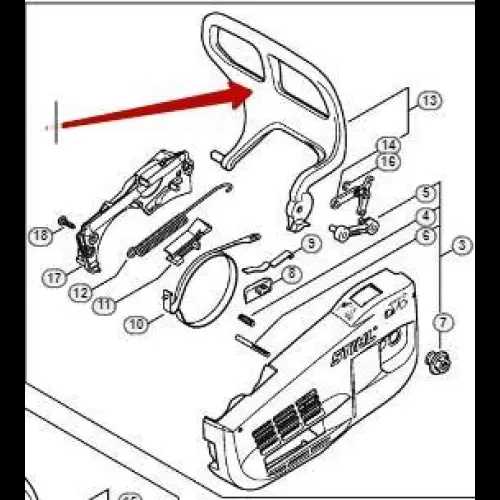

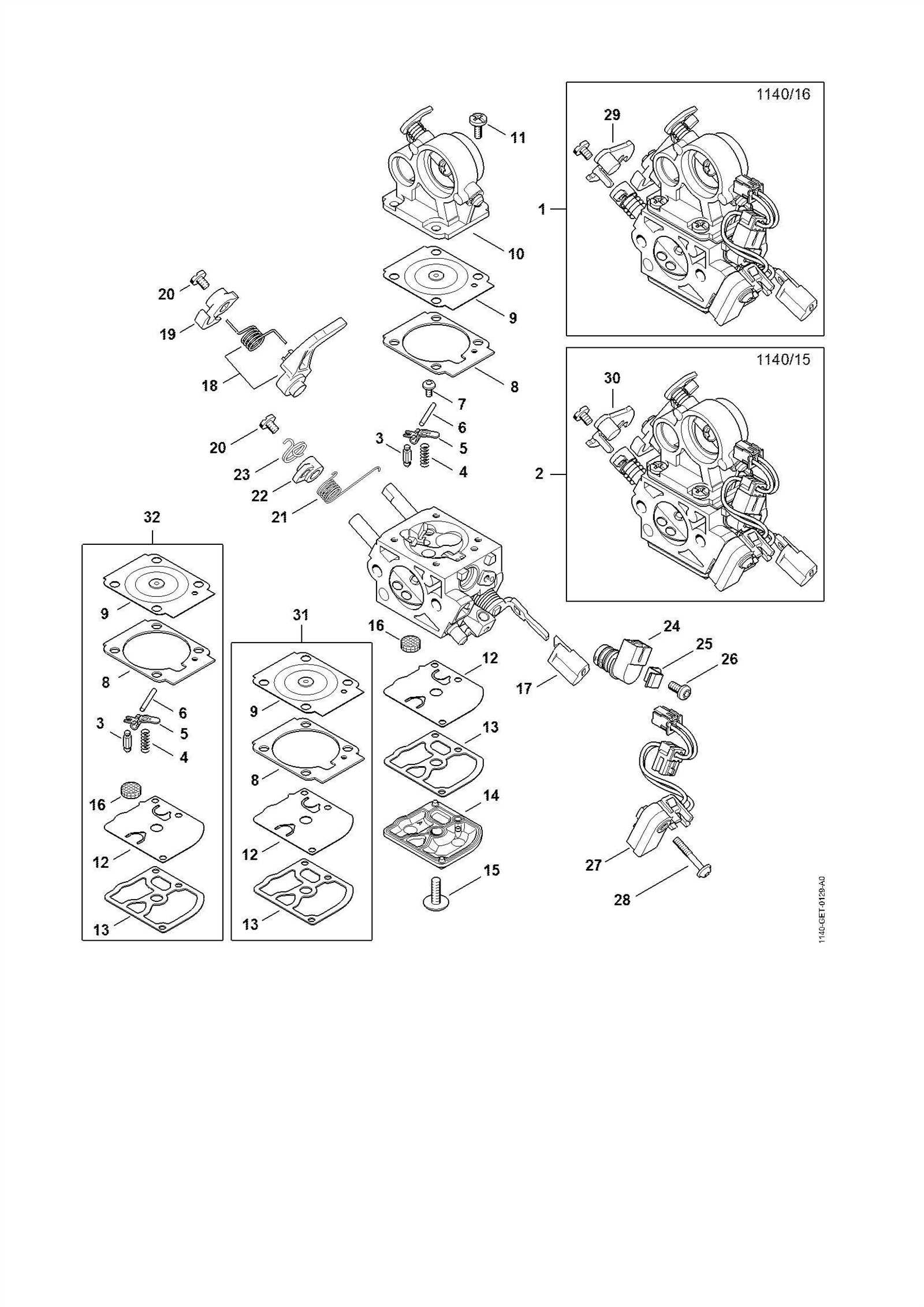

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations of these elements serve as crucial tools for both professionals and enthusiasts, enabling them to identify, locate, and understand the functionality of each piece. These illustrations simplify complex systems, making it easier to troubleshoot issues and perform necessary replacements.

Clarity and Efficiency: One of the primary advantages of these visual aids is the clarity they provide. They break down intricate designs into manageable sections, allowing users to quickly find the specific components they need to address. This efficiency is vital in minimizing downtime, particularly in commercial settings where every moment counts.

Enhanced Learning: For those new to machinery, these visuals act as educational resources. They help individuals familiarize themselves with various parts, promoting a deeper understanding of how everything functions together. This knowledge not only aids in repairs but also boosts confidence in handling equipment safely and effectively.

Streamlined Communication: When discussing repairs or upgrades, these illustrations serve as a common reference point. Technicians can convey information more effectively, ensuring that everyone involved understands the specifics of the job. This minimizes the risk of errors and enhances collaboration among team members.

Overall, these visual tools are indispensable for anyone looking to maintain or repair machinery. They not only facilitate immediate tasks but also contribute to a broader understanding of mechanical systems.

Common Replacement Parts Overview

Maintaining outdoor power tools requires a thorough understanding of essential components that may need periodic renewal. This section highlights the frequently replaced items that ensure optimal performance and longevity of your equipment. Regular checks and timely replacements can significantly enhance functionality and prevent unexpected breakdowns.

Air Filters: A crucial element for engine efficiency, air filters prevent dirt and debris from entering the combustion chamber. Regular replacement is necessary to maintain airflow and performance.

Chains: The cutting chain is fundamental for effective operation. Worn or damaged chains can lead to inefficient cutting and increased wear on other components. Routine inspection and replacement are vital.

Bars: The guide bar directs the chain and provides stability during operation. Over time, bars can wear down or become bent, necessitating replacement to ensure smooth cutting actions.

Fuel Filters: These filters are essential for keeping the fuel system clean. A clogged filter can hinder performance and fuel delivery, making regular checks important.

Spark Plugs: A healthy spark plug is key to reliable ignition. Replacing worn plugs can lead to improved starting and overall engine efficiency.

By focusing on these vital components, users can enhance the reliability and efficiency of their tools, ensuring they are always ready for the task at hand.

Where to Find Parts Diagrams

Accessing detailed visual representations of equipment components is essential for maintenance and repairs. These resources not only help identify individual elements but also provide valuable insights into assembly and functionality. Various platforms and methods exist to acquire these illustrations, ensuring users can effectively manage their tools.

Online Resources

- Manufacturer Websites: Official sites often offer downloadable manuals and schematic illustrations specific to their products.

- Authorized Dealers: Local or online dealers frequently have access to extensive catalogs that include comprehensive visuals for various models.

- Community Forums: Engaging in dedicated online forums can yield shared resources, including scanned manuals and diagrams from other users.

Print Media and Local Libraries

- Service Manuals: Printed guides are available for purchase and often include detailed breakdowns of all necessary components.

- Library Resources: Many libraries maintain a collection of technical manuals and guides that can be borrowed for free.

- Workshops: Local workshops or technical schools may have reference materials that can be accessed by the public.

How to Read a Parts Diagram

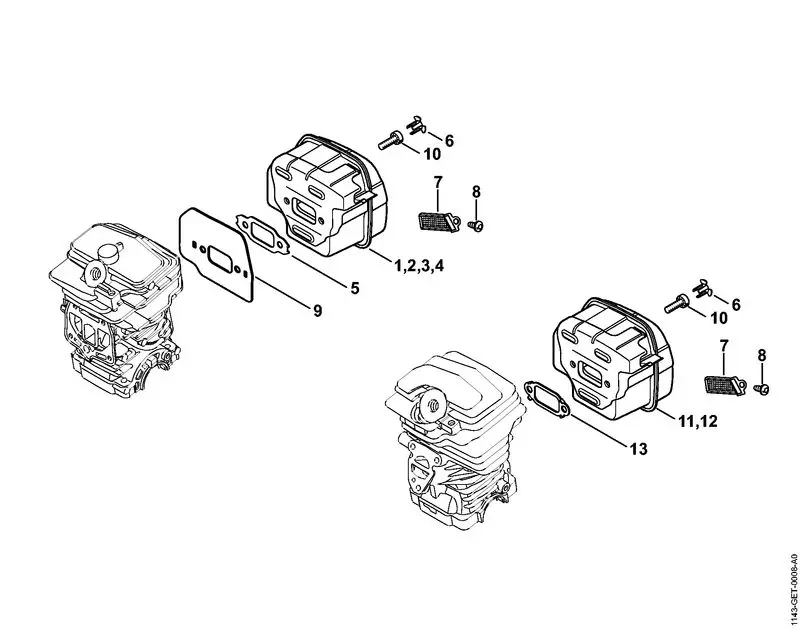

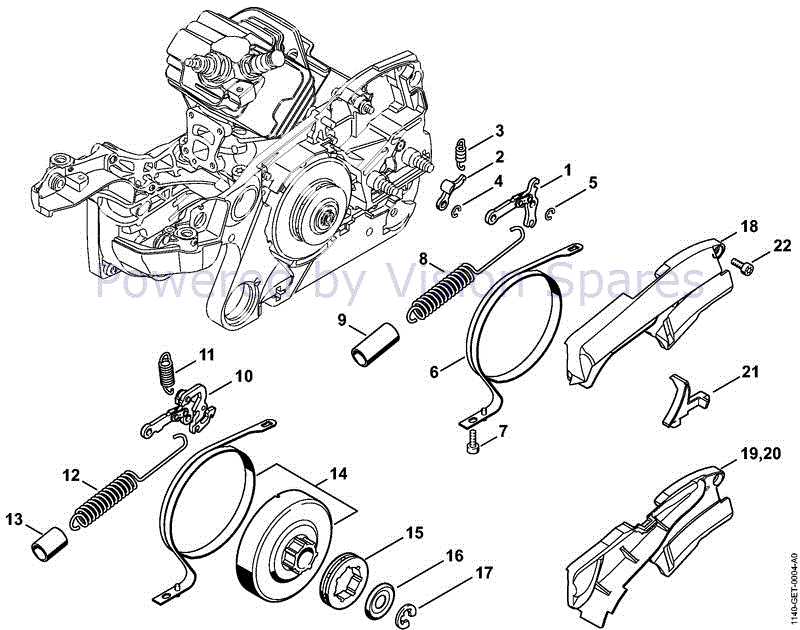

Understanding a schematic representation of components can greatly enhance your ability to maintain and repair machinery. This visual tool simplifies the identification of individual elements and their relationships, allowing users to quickly locate specific items needed for repairs or replacements.

Key Components of a Schematic

When examining a schematic, it is important to recognize several key aspects:

| Feature | Description |

|---|---|

| Labels | Each component is usually marked with a unique identifier, making it easier to find the correct part. |

| Connections | Lines or arrows indicate how components are linked, providing insight into how the assembly functions. |

| Legend | A key or legend explains the symbols used, clarifying what each element represents. |

Steps to Interpret the Visual Representation

To effectively interpret the schematic, follow these steps:

- Start by reviewing the legend to familiarize yourself with the symbols.

- Identify the main components and their corresponding labels.

- Trace the connections to understand how parts interact within the assembly.

- Cross-reference any unfamiliar labels with a manual or online resources for further details.

Maintenance Tips for MS 362 CM

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular maintenance can prevent costly repairs and ensure that your machine operates efficiently. Here are some key practices to keep your tool in top condition.

Routine Checks

- Inspect the air filter regularly. A clean filter ensures proper airflow and engine performance.

- Examine the spark plug for wear and carbon buildup. Replace it if necessary to maintain ignition efficiency.

- Check the fuel system for leaks or blockages. Fresh fuel should be used to avoid performance issues.

Cleaning and Lubrication

- Clean the exterior of the unit to remove dirt and debris. This helps prevent overheating and allows for better cooling.

- Lubricate moving parts according to the manufacturer’s recommendations to reduce friction and wear.

- Inspect and clean the chain regularly to ensure smooth operation and prevent premature wear.

By adhering to these maintenance tips, you can enhance the efficiency and lifespan of your equipment, ensuring it remains reliable for all your tasks.

Identifying Components in Diagrams

Understanding the various elements within technical illustrations is crucial for effective maintenance and repair. These visual representations provide an overview of the assembly, helping users to recognize individual parts and their functions. Familiarity with these components enhances the ability to troubleshoot issues and perform replacements with confidence.

When analyzing technical illustrations, it is important to focus on specific features and identifiers associated with each part. This can include notations, numbers, and color coding that simplify the identification process. Below is a table highlighting common identifiers and their meanings.

| Identifier | Description |

|---|---|

| Part Number | A unique code assigned to each component, facilitating easy ordering and replacement. |

| Labeling | Textual annotations that describe the function or specifications of a part. |

| Symbols | Visual icons that represent various functions or characteristics, aiding in quick recognition. |

| Color Coding | Use of different colors to categorize components based on type or function. |

By mastering these identifiers, users can navigate technical illustrations with greater ease, ultimately improving their repair and maintenance skills.

Ordering Parts: A Step-by-Step Guide

Acquiring components for your equipment can seem daunting, but with the right approach, the process becomes straightforward and efficient. This guide will provide you with essential steps to ensure that you obtain the necessary items without unnecessary hassle. Understanding how to navigate the ordering process is crucial for maintaining your tools in optimal condition.

Step 1: Identify Your Needs

Begin by assessing what you require. Inspect your equipment and determine which components are damaged or need replacement. Having a clear list will help streamline your search and ensure you don’t overlook any critical elements.

Step 2: Gather Information

Once you know what you need, collect detailed information about each component. This includes model numbers, descriptions, and any specifications that may be relevant. The more information you have, the easier it will be to find the right items.

| Component | Model Number | Description |

|---|---|---|

| Chain | 12345 | Standard cutting chain |

| Filter | 67890 | Air filter for optimal performance |

| Sprocket | 54321 | Drive sprocket for power transmission |

With this information at hand, you’re ready to proceed to the next steps in the ordering process, ensuring a smooth experience in acquiring your necessary components.

Comparing MS 362 CM with Other Models

When evaluating different models of power saws, it’s essential to consider various features and specifications that set them apart. Each model serves specific needs and preferences, making it crucial to understand how they compare in terms of performance, usability, and efficiency.

Here are some key aspects to consider when comparing this particular model with others:

- Engine Power: Assess the engine capacity and power output, which directly influences cutting performance.

- Weight and Balance: Lighter models may be easier to handle, while others might offer better stability during use.

- Cutting Capacity: Look at the maximum bar length compatible with each saw, which impacts the thickness of wood that can be processed.

- Fuel Efficiency: Evaluate the consumption rate of fuel, as more efficient models can lead to cost savings over time.

- Maintenance Requirements: Some models may require more frequent servicing, affecting long-term usability.

When choosing between different models, it’s beneficial to prioritize features that align with your specific cutting tasks. Whether for professional use or casual gardening, understanding these distinctions will help in making an informed decision.

Additionally, user reviews and expert opinions can provide valuable insights into how each model performs in real-world conditions, further aiding in the selection process.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance and longevity. These original elements are specifically designed to fit and function seamlessly within your equipment, ensuring optimal operation.

- Quality Assurance: Genuine components undergo rigorous testing to meet high standards of quality, which helps prevent premature failures.

- Perfect Compatibility: Original items are crafted to match the exact specifications of the machinery, minimizing the risk of malfunction.

- Enhanced Durability: Authentic parts are made from superior materials, contributing to extended lifespan and reliability.

- Improved Performance: Using original components ensures that your equipment operates at its best, maintaining efficiency and power.

- Warranty Protection: Many manufacturers offer warranties on their products, which are often voided if non-genuine components are used.

In summary, opting for original elements not only supports the equipment’s performance but also protects your investment in the long run. The choice of genuine parts translates into peace of mind and a more efficient working experience.

FAQs About MS 362 CM Parts

This section addresses common inquiries related to components of a specific model, providing clarity and guidance for users. Understanding the various elements can enhance maintenance practices and improve the overall functionality of the equipment.

What are the most commonly replaced components? Many users frequently need to replace items such as the air filter, spark plug, and chain. Regular checks can help identify when these should be renewed to maintain optimal performance.

How can I identify the correct components for my model? It’s crucial to refer to the manufacturer’s manual or an authorized dealer for accurate identification. Each model has specific requirements that ensure compatibility and efficiency.

Are there any aftermarket options available? Yes, there are alternative manufacturers that produce compatible items. However, it’s essential to ensure that these meet quality standards to avoid potential issues.

How often should maintenance be performed? Regular upkeep is recommended, typically every 10-15 hours of operation. This includes inspecting and replacing wear items to prevent larger problems down the line.

Can I perform repairs myself? Many users are capable of conducting simple repairs with the right tools and knowledge. However, for complex issues, seeking professional assistance is advisable to ensure proper handling.