Comprehensive Guide to Stihl MS 260 Parts Diagram

Exploring the intricate design of a powerful cutting tool reveals the essential elements that work in harmony to ensure efficient operation. A thorough comprehension of these components is vital for anyone seeking to maintain or repair their equipment effectively. By familiarizing oneself with the assembly, users can optimize performance and longevity.

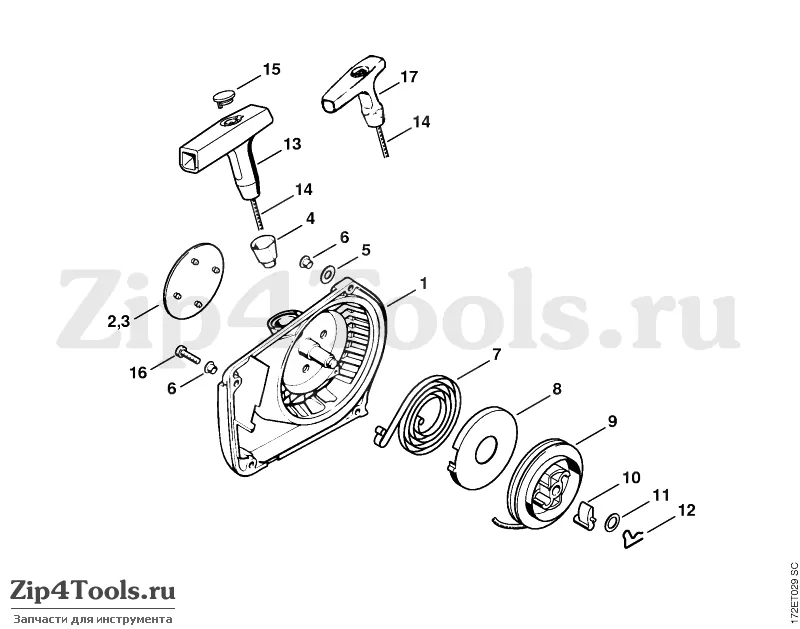

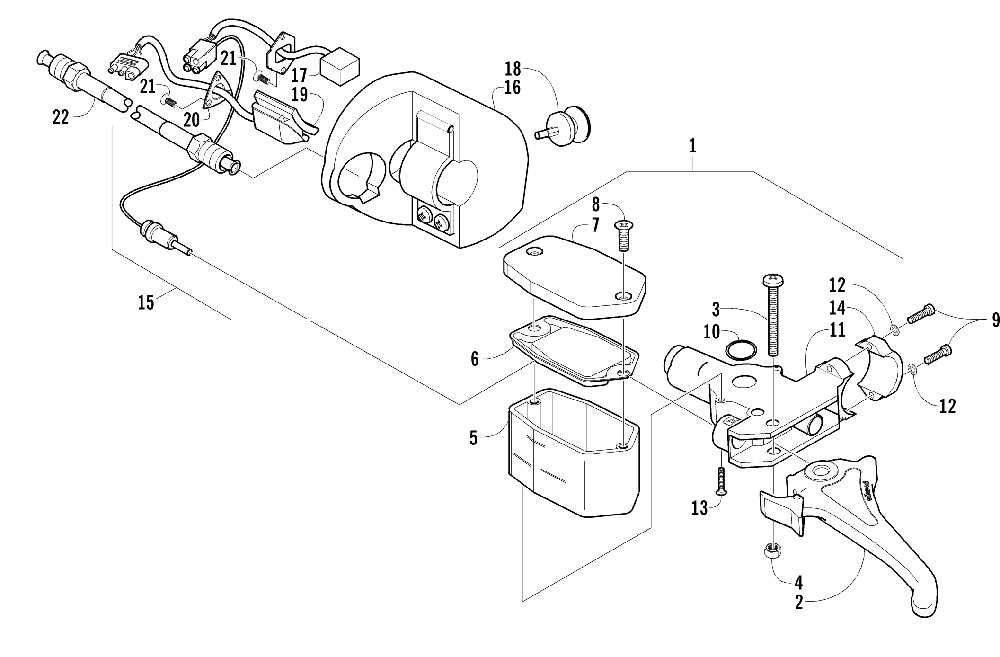

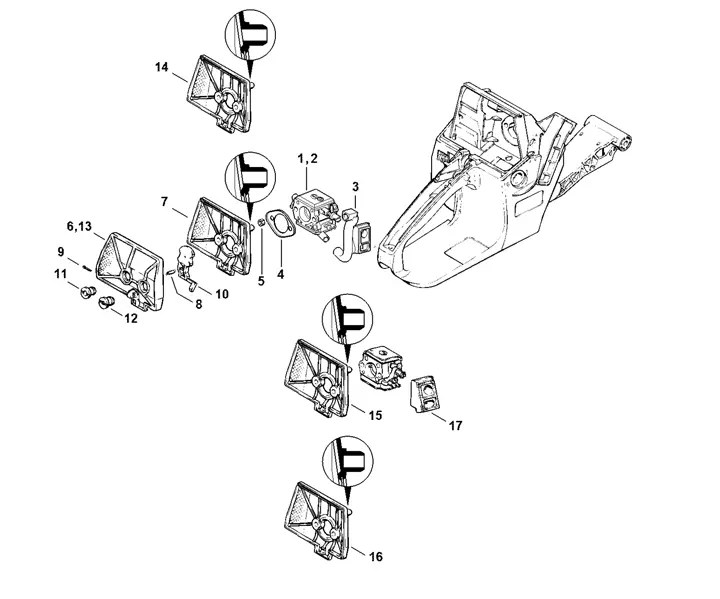

Every piece, from the engine to the cutting mechanisms, plays a crucial role in the overall functionality. A visual representation of these elements provides clarity on their arrangement and interconnectivity. This knowledge not only aids in troubleshooting issues but also empowers users to make informed decisions regarding upgrades and replacements.

As you delve into the specifics of each component, it becomes evident how even the smallest parts contribute to the overall efficiency of the machine. Understanding this interconnectedness enhances not only repair capabilities but also boosts the confidence of operators in handling their tools effectively.

Understanding Stihl MS 260 Components

Exploring the intricacies of a chainsaw reveals a fascinating interplay of various elements that work together to ensure optimal performance. Each component plays a crucial role, contributing to the overall functionality and efficiency of the machine. Understanding these individual parts can greatly enhance maintenance practices and troubleshooting efforts.

The following table highlights key components commonly found in such equipment, along with their primary functions:

| Component | Function |

|---|---|

| Engine | Powers the chainsaw, converting fuel into mechanical energy. |

| Bar | Supports the chain and guides it during operation. |

| Chain | Performs the cutting action, moving rapidly around the bar. |

| Clutch | Engages and disengages the chain from the engine, controlling operation. |

| Fuel Tank | Holds the mixture of fuel and oil necessary for operation. |

| Air Filter | Prevents debris from entering the engine, ensuring clean air intake. |

| Starter | Facilitates the initial engine ignition process. |

| Throttle Trigger | Regulates engine speed and power output based on user input. |

By familiarizing oneself with these essential components, users can better appreciate the engineering behind their equipment and improve their maintenance routines, ensuring longevity and reliability in operation.

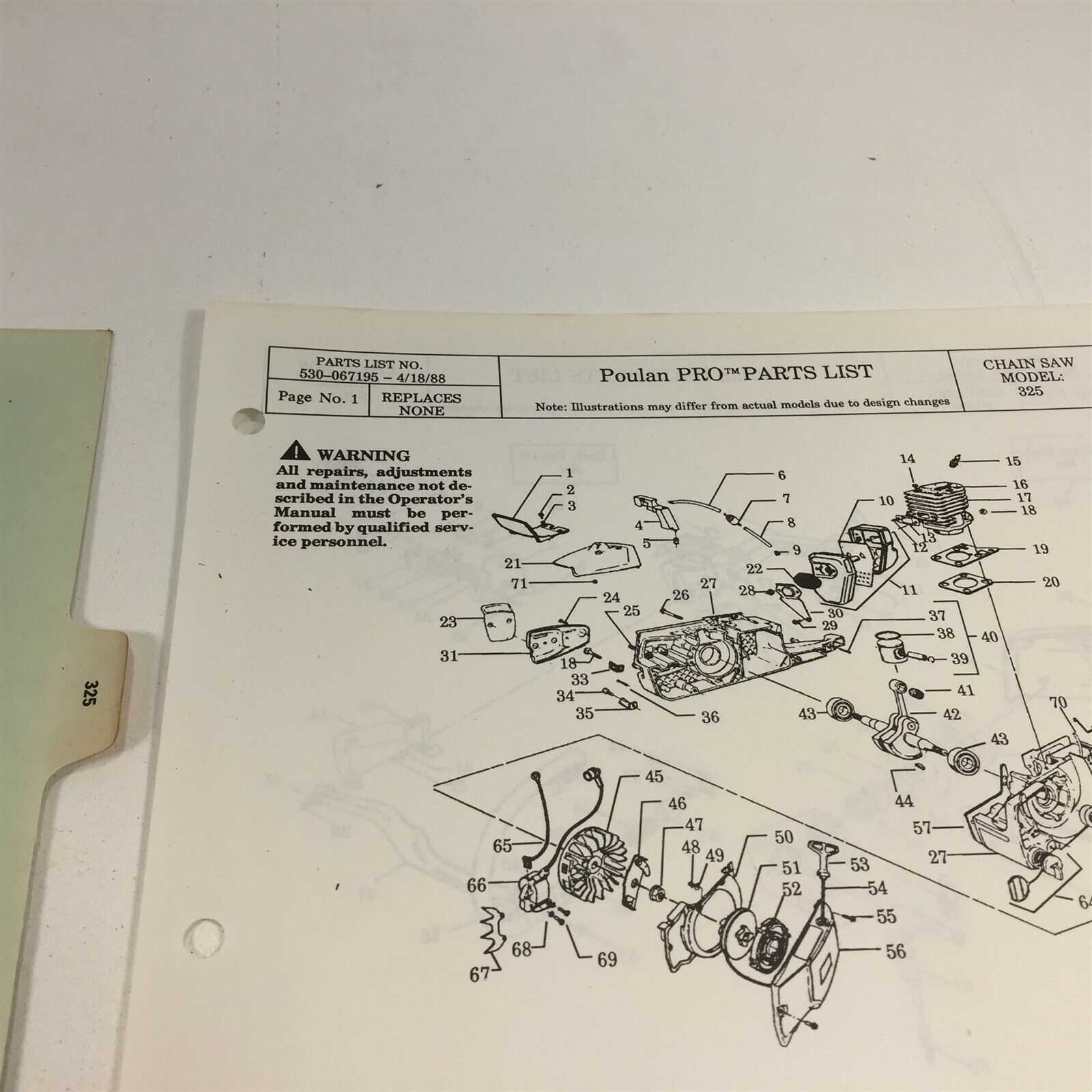

Importance of a Parts Diagram

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components allow users to identify individual elements and their relationships within the overall system. This knowledge is crucial for ensuring optimal performance and longevity of equipment.

Facilitating Repairs

A comprehensive visual guide simplifies the repair process by providing clarity on where each component fits. This reduces the chances of mistakes and accelerates the time taken to complete tasks, making it easier for both professionals and enthusiasts to handle repairs efficiently.

Enhancing Maintenance Practices

Regular upkeep is vital for any machinery. Having a visual reference encourages proactive maintenance by highlighting areas that require attention. This can lead to early detection of potential issues, ultimately saving time and resources in the long run.

Key Features of the Stihl MS 260

This robust cutting tool is designed for efficiency and reliability, making it a favorite among both professionals and enthusiasts. Its advanced engineering ensures optimal performance, providing users with a seamless experience during operation.

One of the standout attributes is the powerful engine that delivers exceptional torque, allowing for smooth cutting through various types of wood. Additionally, the lightweight design enhances maneuverability, reducing fatigue during extended use.

The integrated safety features promote secure handling, including an effective chain brake system that responds quickly to prevent accidents. Furthermore, the easy-access air filter simplifies maintenance, ensuring that the equipment remains in peak condition with minimal effort.

With a focus on durability, the materials used in construction withstand demanding conditions, making it suitable for both casual and heavy-duty tasks. This combination of power, safety, and ease of maintenance solidifies its reputation as a top choice in the market.

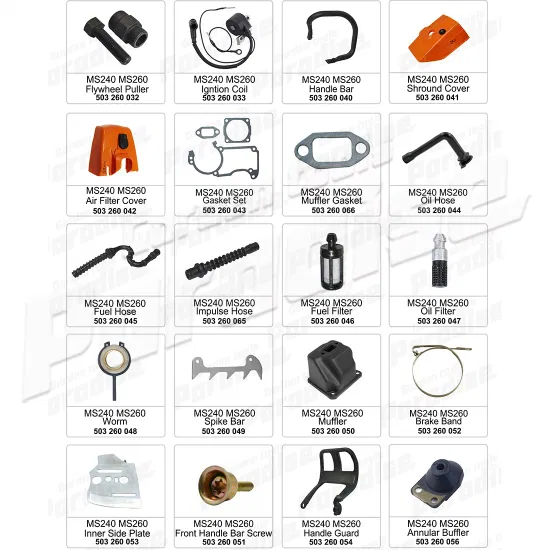

Identifying Common Replacement Parts

Understanding the essential components of your equipment is crucial for maintaining its optimal performance. Recognizing which elements may require replacement can help extend the life of your machine and enhance its efficiency. This section highlights the frequently needed components and provides guidance on how to identify them.

Essential Components

Among the vital elements are the air filter, spark plug, and fuel filter. These components play significant roles in the overall functionality of your device. Regularly checking and replacing these items can prevent potential issues and ensure smooth operation. Look for signs of wear, such as discoloration or clogging, which indicate that a replacement is necessary.

Wear Indicators

Monitoring specific indicators can aid in recognizing when a component is due for replacement. Unusual noises, reduced power, and increased fuel consumption are common signs that something may be amiss. Familiarizing yourself with these symptoms will help you act promptly, ensuring your equipment remains in top condition.

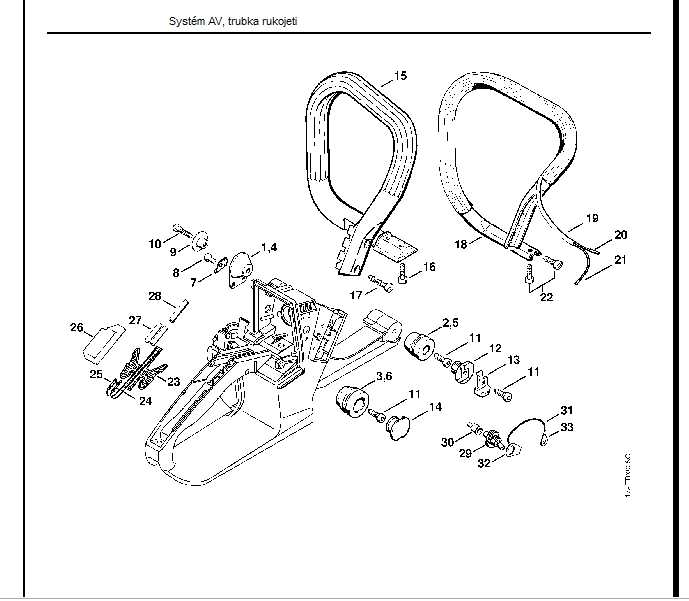

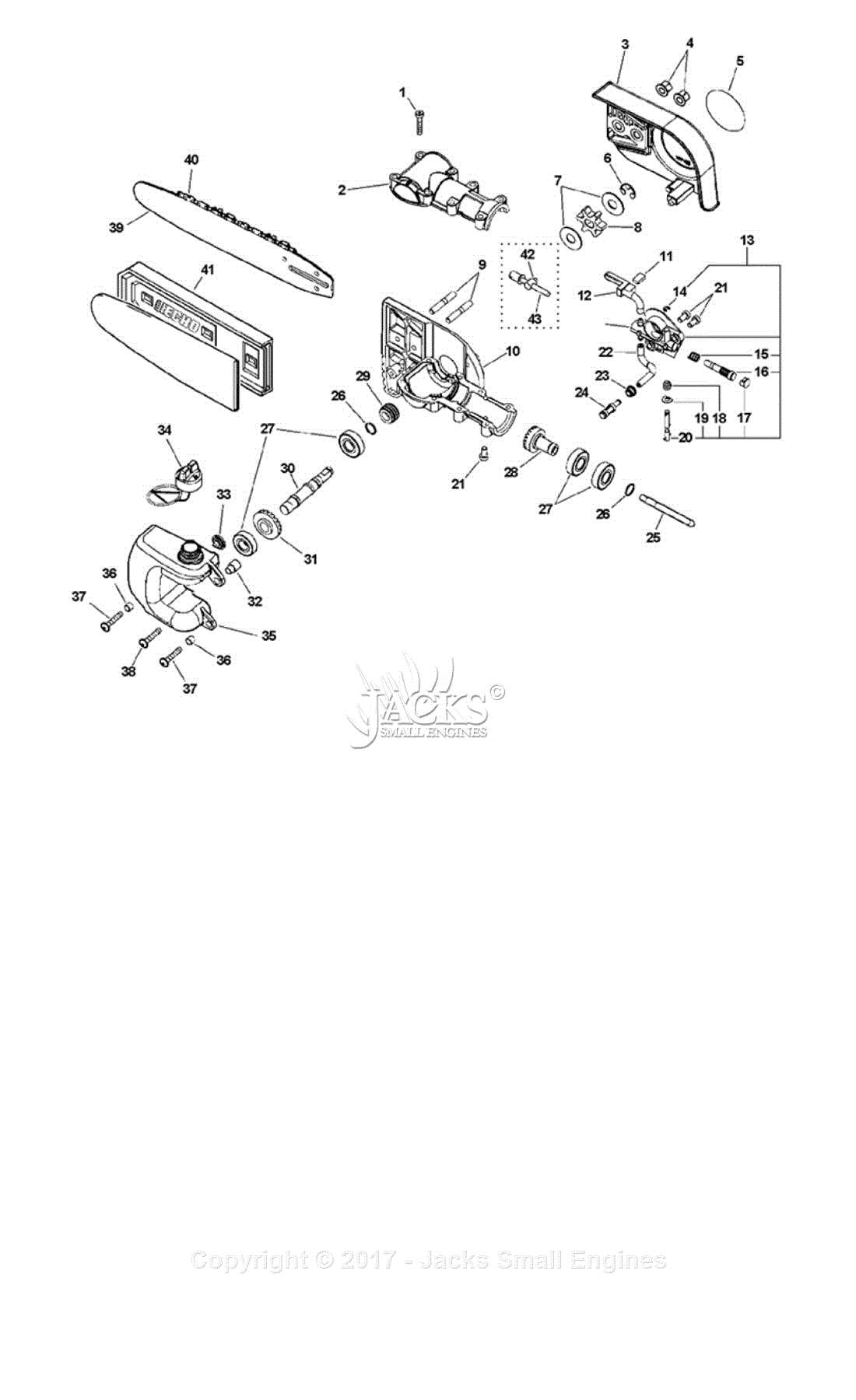

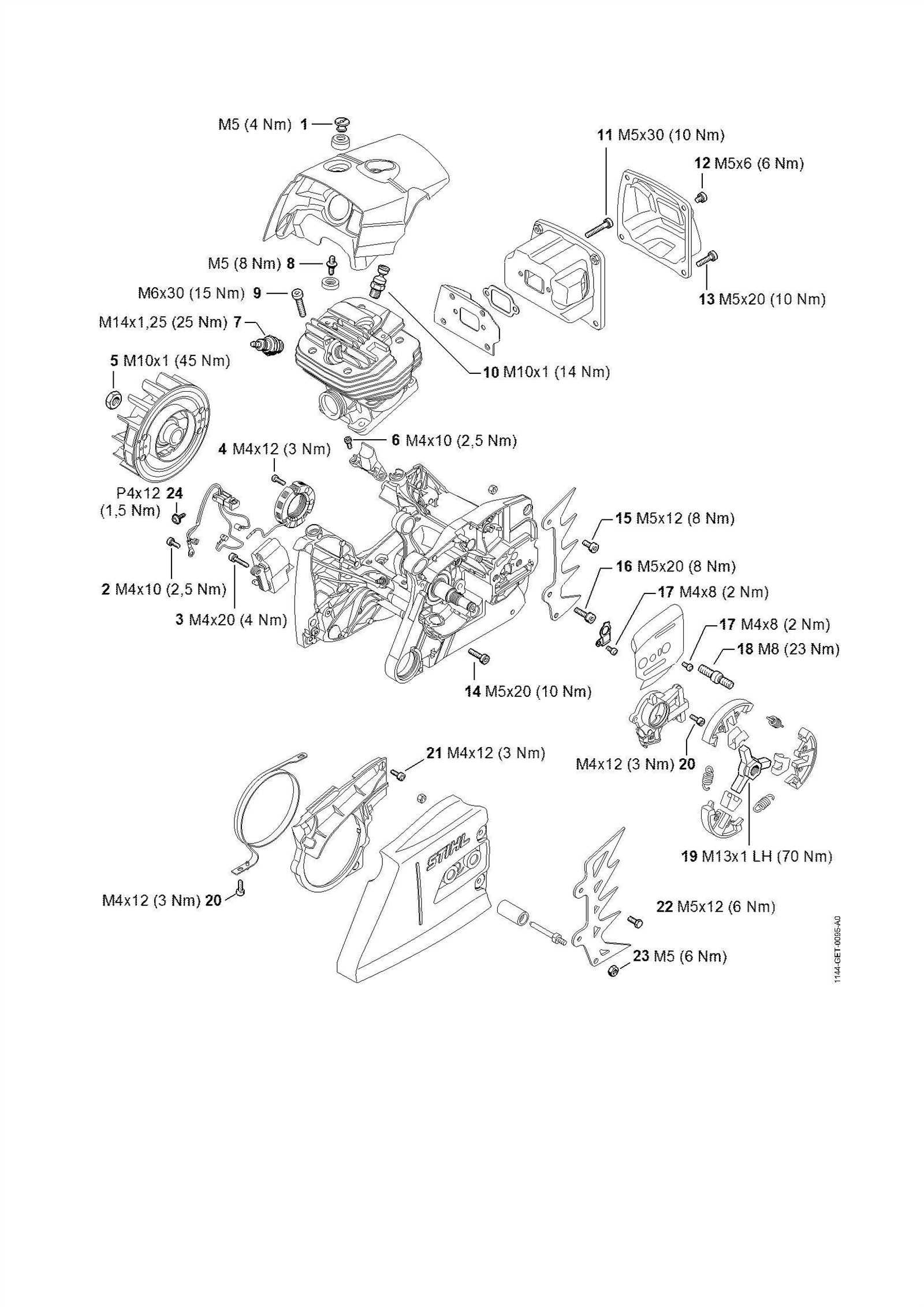

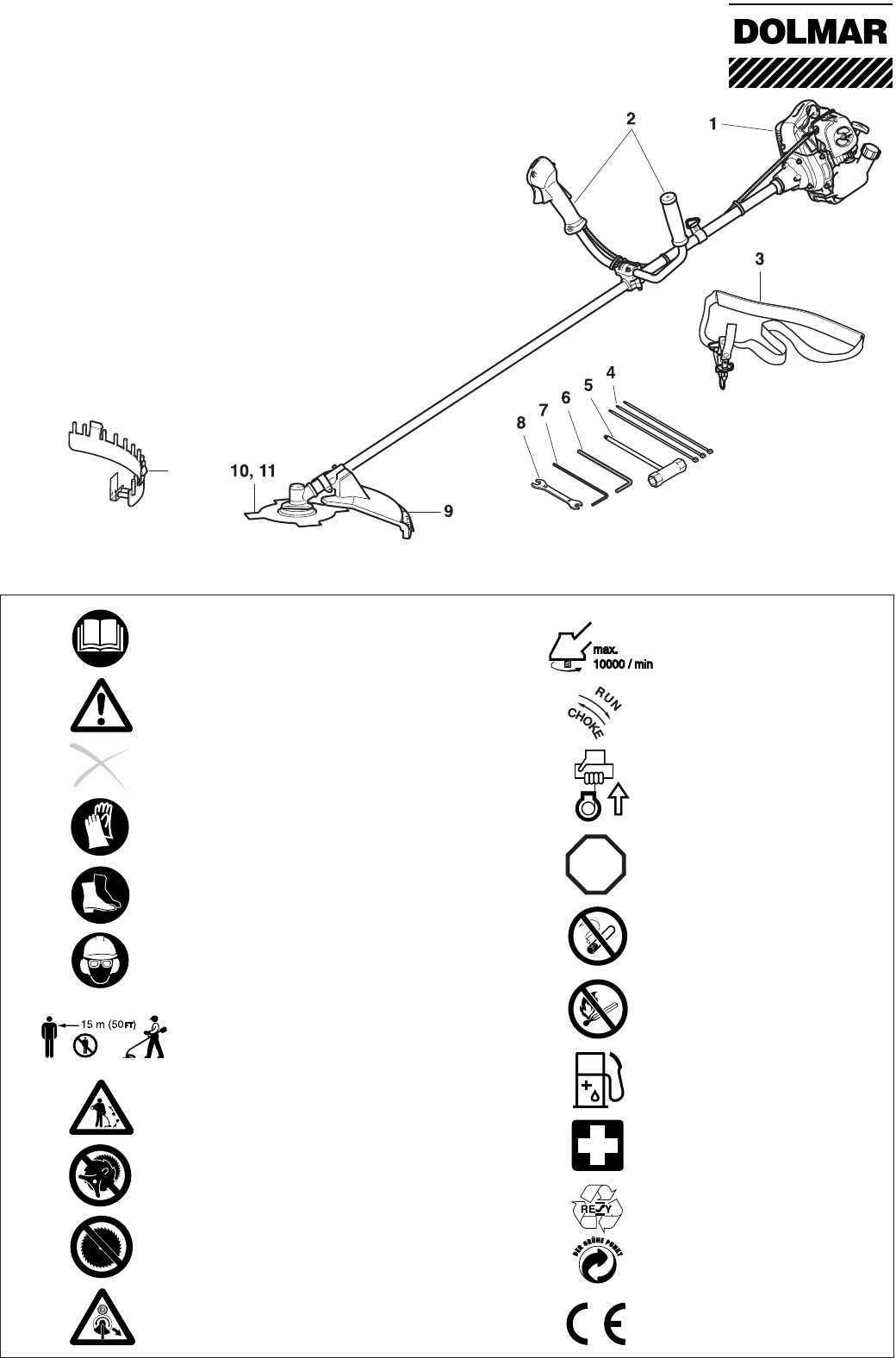

How to Read the Diagram Effectively

Understanding technical illustrations is crucial for anyone looking to maintain or repair machinery. These visual aids offer a structured representation of components, helping users identify parts and their functions efficiently. Familiarity with the layout and symbols used in these graphics enhances comprehension and enables effective troubleshooting.

Begin by examining the legend or key that accompanies the illustration. This section typically explains the symbols and color codes used, providing context for each component’s role. Take note of the arrangement; components are often grouped logically, which can help you follow the flow of the assembly.

Next, trace the connections between various elements. Lines and arrows usually indicate relationships or pathways, allowing you to visualize how parts interact. Pay attention to numbered sequences that can guide you through the assembly process step-by-step, ensuring no detail is overlooked.

Lastly, compare the illustration with the physical machinery. This practice reinforces your understanding and allows for practical application of the information presented. Engaging with both the visual and the tangible will ultimately deepen your grasp of the entire system.

Essential Maintenance Tips for Longevity

Proper care and attention can significantly extend the lifespan of your equipment. Regular maintenance not only ensures optimal performance but also minimizes the risk of unexpected breakdowns. Here are key practices to keep your tool in top condition.

Regular Cleaning

Keeping your machine clean is vital. Remove debris after each use to prevent build-up, which can cause wear and tear. Use a soft brush and compressed air for hard-to-reach areas.

Routine Inspections

Conduct frequent inspections to identify any signs of damage or wear. Pay close attention to critical components, and replace any worn parts promptly to maintain peak efficiency. Neglecting small issues can lead to more significant problems down the line.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Utilizing genuine items ensures reliability, as these are specifically designed to fit and function perfectly with your machine.

Official Dealers

One of the most reliable sources for original components is through authorized distributors. These establishments often carry a full range of items tailored for your equipment, providing peace of mind in quality and compatibility.

Online Retailers

Many reputable online platforms offer a vast selection of genuine components. When shopping online, it’s essential to verify the seller’s credibility and check customer reviews to ensure you’re receiving authentic products.

Comparing Aftermarket vs. Original Parts

When it comes to maintaining machinery, the choice between factory components and alternative replacements is crucial. Each option offers distinct advantages and disadvantages that can impact performance, longevity, and cost. Understanding these differences can help users make informed decisions tailored to their specific needs.

| Criteria | Original Components | Aftermarket Alternatives |

|---|---|---|

| Quality | Generally higher, designed to meet specific standards. | Varies widely; some may match or exceed quality, while others may fall short. |

| Cost | Typically more expensive due to brand assurance. | Usually more affordable, offering potential savings. |

| Availability | Readily available through authorized dealers. | Often found at various retailers, but availability can vary. |

| Warranty | Often comes with a manufacturer’s warranty. | May have limited or no warranty, depending on the supplier. |

| Compatibility | Guaranteed to fit and function as intended. | Compatibility can be inconsistent; may require additional adjustments. |

Ultimately, the decision hinges on individual priorities, whether it’s ensuring top performance with original components or seeking cost-effective solutions with aftermarket options. Understanding these factors is essential for making the right choice in maintenance and repair endeavors.

Assembly Instructions for Key Components

Assembling essential elements of a power tool requires careful attention to detail and a methodical approach. Proper installation ensures optimal performance and longevity of the equipment. This section provides step-by-step guidance for assembling crucial components to guarantee seamless functionality.

Step-by-Step Assembly

Follow these instructions to assemble the main components effectively:

| Component | Assembly Instructions |

|---|---|

| Engine | Align the mounting points and secure with the provided bolts, ensuring a tight fit to prevent vibrations. |

| Fuel Tank | Attach the fuel tank by aligning it with the designated slots and fasten it using the screws provided in the kit. |

| Guide Bar | Place the guide bar onto the drive sprocket and tighten the adjusting nuts to secure it in position. |

| Chain | Thread the chain through the guide bar, ensuring the cutting teeth face in the correct direction, then adjust the tension. |

Final Checks

After assembling the components, perform a thorough inspection to ensure everything is securely fastened and aligned. This will enhance safety and ensure the equipment operates efficiently during use.

Common Issues and Solutions

This section highlights typical problems encountered with outdoor power tools and offers effective remedies to enhance their performance and longevity.

-

Starting Difficulties:

When the engine won’t start, check for:

- Fuel quality and level

- Clogged air filter

- Defective spark plug

-

Overheating:

To prevent overheating, consider:

- Regular cleaning of cooling fins

- Using the correct fuel mixture

- Avoiding prolonged idling

-

Loss of Power:

When power diminishes, address:

- Dirty fuel filter

- Worn-out carburetor components

- Improper spark timing

-

Vibration Issues:

To minimize excessive vibrations:

- Inspect and replace worn parts

- Ensure proper assembly

- Balance the cutting attachments

Safety Precautions During Repairs

When undertaking maintenance or repair tasks on outdoor power equipment, it is crucial to prioritize safety. Proper precautions help prevent accidents and injuries, ensuring a secure environment for both the technician and the equipment. Familiarizing oneself with the necessary safety measures is essential for a successful and hazard-free repair process.

Before starting any work, always wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and sturdy footwear. These items provide a barrier against potential hazards, such as sharp components or flying debris. Additionally, ensure that the workspace is well-lit and organized, minimizing the risk of tripping or misplacing tools.

Disconnecting the power source is a fundamental step that should never be overlooked. This action prevents unintended activation, safeguarding both the individual performing the repair and the machinery itself. Furthermore, it is advisable to consult the user manual for specific safety instructions relevant to the equipment, as manufacturers often provide crucial guidelines for safe handling.

Maintaining a clear understanding of the tools required for the job is equally important. Using the correct tools not only improves efficiency but also reduces the likelihood of accidents caused by improper handling. Lastly, if unsure about any aspect of the repair, seek assistance or guidance from a knowledgeable individual to ensure a safe and effective repair experience.

Resources for Further Learning

Exploring additional resources can significantly enhance your understanding of maintenance and repair for outdoor power equipment. Accessing the right materials ensures that you grasp essential concepts and techniques necessary for efficient operation and troubleshooting.

Online Communities

Participating in forums and discussion groups dedicated to machinery enthusiasts allows you to share knowledge and gain insights from experienced users. These platforms often provide invaluable advice and real-world experiences that can guide you in your endeavors.

Technical Manuals and Guides

Investing in comprehensive manuals or online guides can provide detailed instructions and schematics. These resources are indispensable for anyone looking to deepen their technical skills and ensure optimal functionality of their equipment.