Understanding the Husky Spray Gun Parts Diagram for Efficient Maintenance

Every intricate tool relies on a well-designed assembly of elements to function optimally. Whether for professional use or home improvement projects, familiarity with the internal structure can significantly enhance performance and longevity. Knowing the arrangement of these elements allows for more effective maintenance and troubleshooting.

In this section, we will delve into the essential components that make up these devices. Each segment plays a crucial role in ensuring efficiency and reliability. By exploring the various features and their interconnections, users can better appreciate the technology at play and the importance of each individual piece.

We aim to provide a clear visual representation of these components, highlighting their functions and how they interact within the overall system. Gaining this understanding will empower users to make informed decisions regarding repairs and upgrades, ultimately leading to improved outcomes in their projects.

Understanding Husky Spray Guns

This section aims to explore the fundamental aspects of a popular tool used for applying coatings. Recognizing its components and functionality can enhance user experience and efficiency.

Key features to consider include:

- Design and ergonomics

- Types of finishes achievable

- Maintenance requirements

- Common applications in various industries

To maximize performance, it’s essential to understand:

- The role of various elements in achieving optimal results

- How to troubleshoot common issues

- Best practices for usage and care

By delving into these topics, users can make informed decisions and ensure longevity of their equipment.

Key Components of Husky Spray Guns

This section explores the essential elements that contribute to the functionality and efficiency of these painting tools. Understanding these components is crucial for effective usage and maintenance.

Main Elements

- Trigger Mechanism

- Nozzle Assembly

- Fluid Cup

- Air Cap

- Pressure Regulator

Supporting Features

- Handle Design

- Air Hose Connector

- Filter System

- Cleaning Kit

Familiarity with these components enhances user experience and ensures optimal performance during operation.

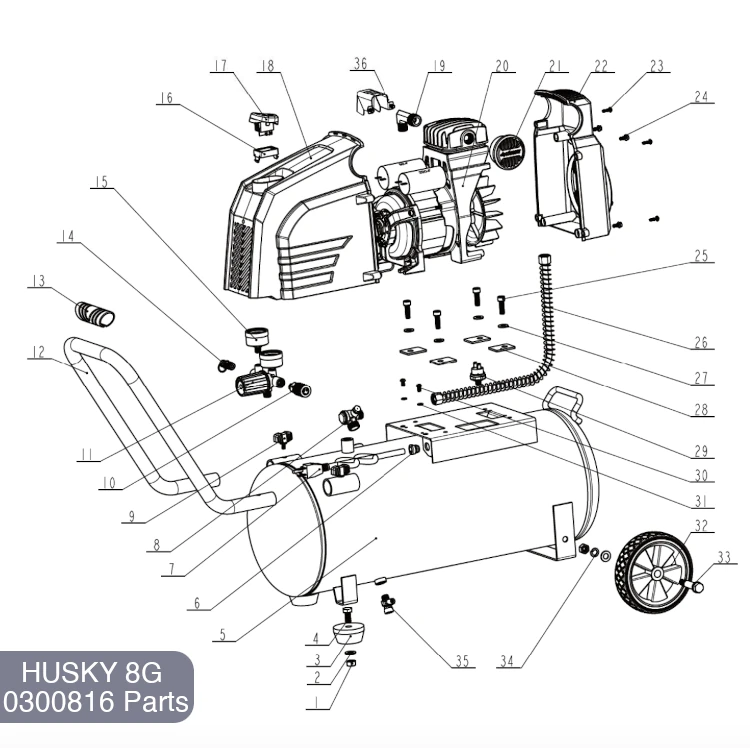

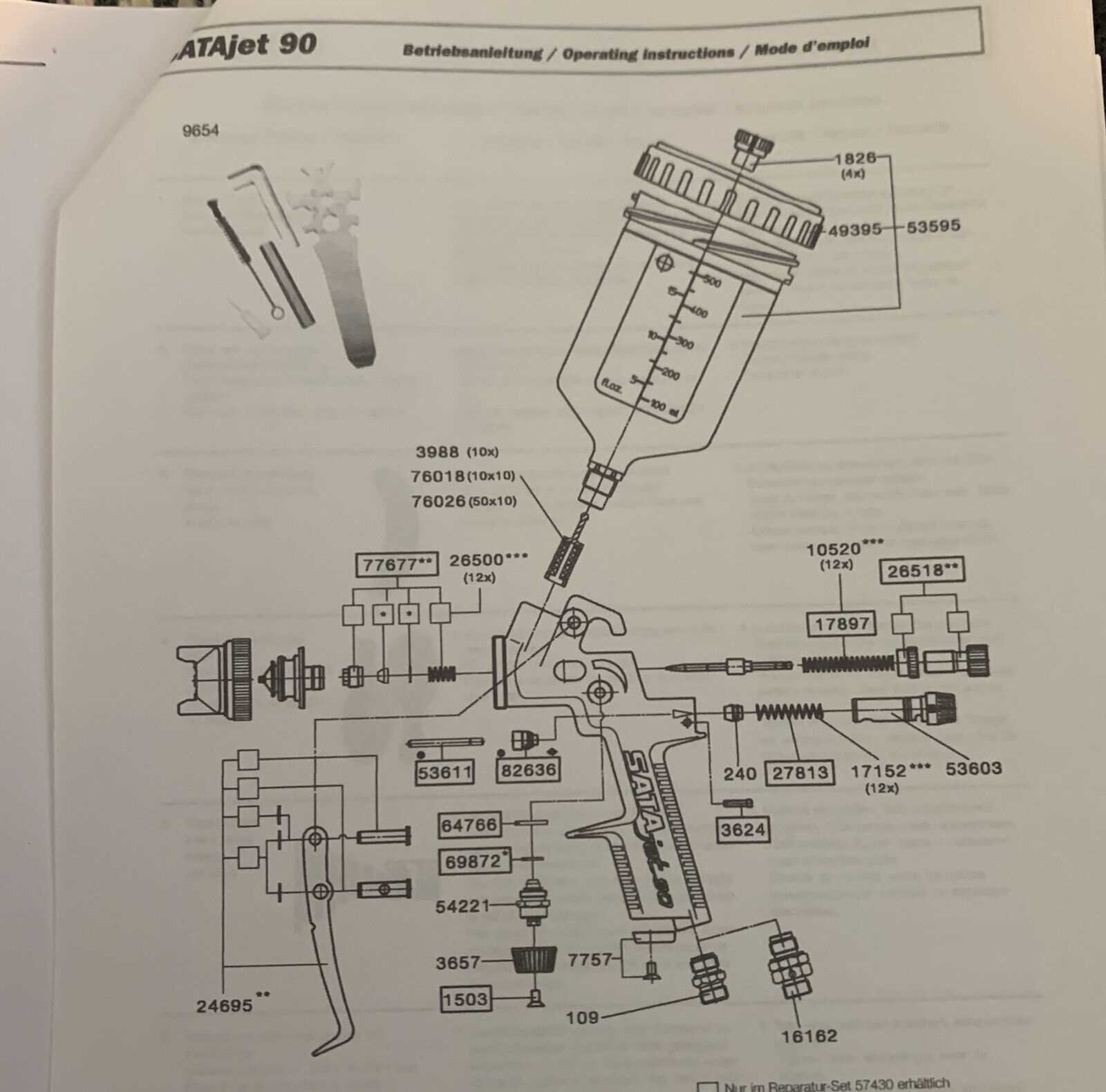

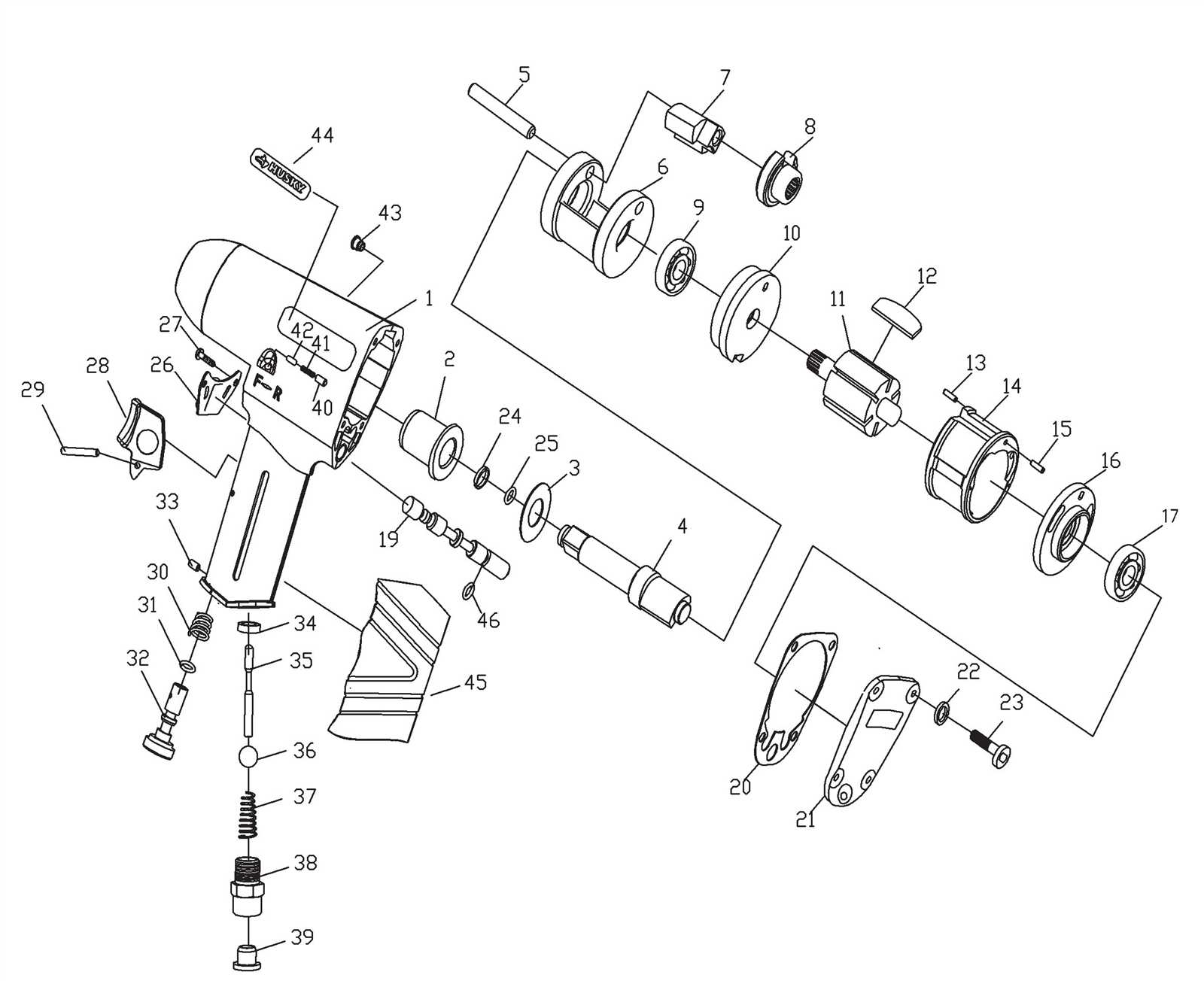

Importance of Parts Diagrams

Understanding the structure and components of any tool is essential for effective maintenance and repair. Visual representations of these elements serve as vital resources, providing clarity and aiding in the identification of each segment’s role. This knowledge empowers users to troubleshoot issues more efficiently.

Clear visualization enhances comprehension, allowing individuals to grasp how each component interconnects. When users encounter a malfunction, having a detailed reference can facilitate faster resolutions, ultimately saving time and reducing frustration. Additionally, it fosters a deeper appreciation of the equipment’s design and functionality.

Moreover, accurate illustrations are invaluable during assembly and disassembly processes, ensuring that each element is correctly positioned. This minimizes the risk of errors that could lead to further complications. In summary, well-crafted representations are not just helpful–they are essential for anyone looking to maintain their tools effectively.

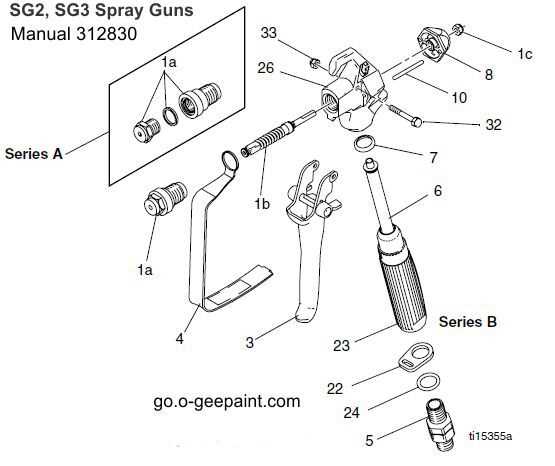

How to Read a Parts Diagram

Understanding a component illustration is essential for effective maintenance and repairs. Such illustrations provide a visual representation of the various elements involved, aiding in identifying, organizing, and replacing parts when necessary. By mastering this skill, one can streamline their workflow and enhance overall efficiency.

Familiarizing with Symbols and Labels

Each illustration typically includes unique symbols and labels that correspond to specific components. Recognizing these markings is crucial, as they offer insights into the functionality and placement of each item. Pay attention to any accompanying legends or notes, as they clarify the meaning of various elements.

Interpreting Connections and Layout

A key aspect of any component illustration is understanding how different parts interact. Observing the connections and layout helps visualize assembly and disassembly processes. This knowledge is vital for troubleshooting issues and ensuring that all elements function harmoniously together.

Common Issues with Spray Gun Parts

Understanding the frequent challenges encountered with application tools can significantly enhance their performance and longevity. Users often face a variety of malfunctions that can impede functionality, leading to suboptimal results during usage. Addressing these common hurdles is essential for maintaining efficiency and ensuring a smooth application process.

One prevalent issue is clogging, which can occur due to dried material or improper cleaning after use. This can result in uneven application and decreased performance. Another common problem is leaking, often caused by worn seals or loose connections, leading to waste and messy workspaces. Users may also experience inconsistent pressure, which can affect the quality of the finish. Regular maintenance and prompt troubleshooting can help mitigate these problems and extend the lifespan of the equipment.

Maintenance Tips for Spray Guns

Regular upkeep of your equipment is essential for optimal performance and longevity. By implementing a few simple practices, you can ensure that your tools function efficiently and produce high-quality results. Consistent maintenance not only enhances effectiveness but also prevents costly repairs in the future.

Cleaning Procedures

After each use, thoroughly clean all components to remove any residue. Disassemble the unit according to the manufacturer’s instructions and use appropriate cleaning solutions to dissolve any build-up. This step is crucial to maintaining functionality and preventing clogs.

Storage Recommendations

Store your equipment in a dry, cool place to prevent rust and degradation. Protect the unit with a cover or case to shield it from dust and moisture. Proper storage practices can greatly extend the lifespan of your tools.

Replacing Worn-Out Components

Over time, certain elements of your equipment may become less effective due to wear and tear. Identifying and replacing these diminished components is crucial for maintaining optimal performance and ensuring longevity. This section provides guidance on recognizing signs of wear and the steps to replace these essential parts.

Identifying Signs of Wear

Common indicators of deterioration include inconsistent output, unusual noises, or visible damage to the exterior. Regular inspection can help you catch these issues early, allowing for timely replacements that prevent further complications. Pay close attention to components that experience frequent friction or exposure to harsh materials, as they are more prone to wear.

Steps for Replacement

Once you have identified a worn-out element, the replacement process typically involves disassembly of the unit, careful removal of the old component, and installation of the new one. Always consult the manufacturer’s guidelines for specific instructions. Proper maintenance, including regular cleaning and lubrication, can also prolong the lifespan of your equipment and minimize the need for replacements.

Choosing the Right Replacement Parts

Finding suitable components for your equipment is essential for maintaining optimal performance and longevity. The selection process requires careful consideration of compatibility, quality, and functionality. Understanding the specific requirements of your device will help you make informed decisions and avoid unnecessary complications.

Factors to Consider

- Compatibility: Ensure that the new components are designed to fit seamlessly with your existing setup.

- Quality: Opt for high-quality materials to enhance durability and reduce the frequency of replacements.

- Manufacturer Reputation: Choose products from reputable brands known for their reliability and performance.

Where to Find Components

- Local hardware stores often carry a selection of essential items.

- Online retailers provide a wider range of options and often feature customer reviews.

- Specialty shops may offer expert advice and specialized products tailored to your needs.

DIY Repairs for Spray Gun Issues

Maintaining your equipment can often save you time and money. Understanding common problems and how to troubleshoot them empowers you to resolve issues quickly and effectively. This section explores practical solutions to frequently encountered difficulties, enabling a smoother workflow.

Identifying Leaks: If you notice unexpected drips, it may indicate a worn or misaligned seal. Carefully inspect all connections and seals, tightening or replacing them as necessary.

Clogged Nozzles: Blockages can hinder performance. Soak the nozzle in a suitable solvent and use a small brush to gently clear any obstructions.

Poor Finish Quality: An uneven application might stem from improper settings or equipment condition. Adjust the fluid and air pressure settings, ensuring a consistent spray pattern.

Regular Maintenance: Routine cleaning and inspection are crucial. After each use, dismantle your tools, clean components thoroughly, and reassemble to prolong their lifespan.

By addressing these common challenges, you can enhance the longevity and efficiency of your equipment.

Best Practices for Spray Gun Usage

Utilizing a painting device effectively can significantly enhance the quality of your work while ensuring safety and efficiency. Understanding the essential techniques and maintenance practices will lead to optimal performance and longevity of the equipment. This section outlines crucial strategies to achieve the best results during operation.

Preparation is Key

Before starting any project, thorough preparation is vital. Ensure the surface to be treated is clean, dry, and free of debris. Proper masking of surrounding areas will prevent unwanted overspray and ensure crisp lines. Additionally, selecting the right viscosity of the coating material is crucial; always refer to the manufacturer’s guidelines for thinning and mixing.

Technique Matters

Employing the right technique can make a significant difference in the final appearance. Hold the device at a consistent distance from the surface, usually between 6 to 12 inches, and maintain a steady motion. Overlapping each pass by 50% will create an even finish. Always test the application on a scrap surface to adjust settings as needed. Remember: patience and practice are essential to mastering this skill.

Comparing Different Husky Models

This section explores the variations among various models, highlighting their unique features and functionalities. By examining the distinctions, users can make informed choices based on their specific needs and preferences.

Design Features

Each model showcases distinct design elements that cater to different tasks. For instance, some are engineered for precision and control, while others prioritize efficiency and speed. Understanding these features is essential for selecting the right option for your projects.

Performance Capabilities

The performance of each variant varies significantly. While one may excel in heavy-duty applications, another could be ideal for finer work. Evaluating these capabilities allows users to identify the ultimate match for their requirements, ensuring optimal results.

Where to Find Parts Diagrams Online

Accessing comprehensive visual references for equipment components is essential for effective maintenance and repair. Various online platforms offer valuable resources for enthusiasts and professionals alike, making it easier to locate specific illustrations and information needed for repairs.

Popular Online Resources

Several websites provide extensive libraries of technical illustrations, including:

| Website | Description |

|---|---|

| Manufacturer’s Official Site | Often the best source for accurate and detailed illustrations. |

| Repair Forums | Communities where users share diagrams and troubleshooting tips. |

| Online Retailers | Many offer downloadable resources alongside product listings. |

Utilizing Search Engines

Incorporating specific keywords into your search can yield targeted results. Try including model numbers or descriptions to refine your search and quickly locate the desired visual aids.

Understanding Warranty and Service Options

When investing in tools and equipment, it’s essential to be aware of the support and guarantees available to you. Knowing your coverage can enhance your experience, ensuring peace of mind in case of unexpected issues. This section explores the various warranty terms and service alternatives that may accompany your purchase.

Warranty Coverage

Most manufacturers provide a warranty that outlines the duration and scope of protection for defects and malfunctions. Understanding what is covered–such as repairs or replacements–and the conditions that might void the warranty is crucial for maintaining your investment.

Service and Repair Options

In addition to warranties, many companies offer repair services, either through authorized centers or direct assistance. Familiarizing yourself with these options, including the process for accessing support and any associated costs, can significantly enhance your ownership experience.