Understanding the Stihl 023 Parts Diagram for Efficient Maintenance

When it comes to maintaining a reliable tool for cutting wood, having a clear understanding of its individual elements is crucial. Each piece plays a significant role in the overall performance and efficiency of the machine. Recognizing how these parts interconnect can aid in effective troubleshooting and ensure longevity.

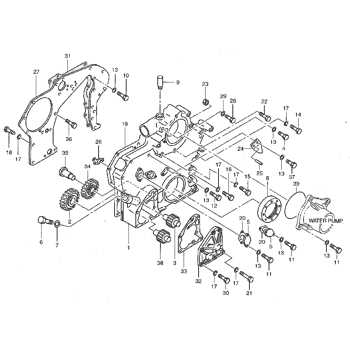

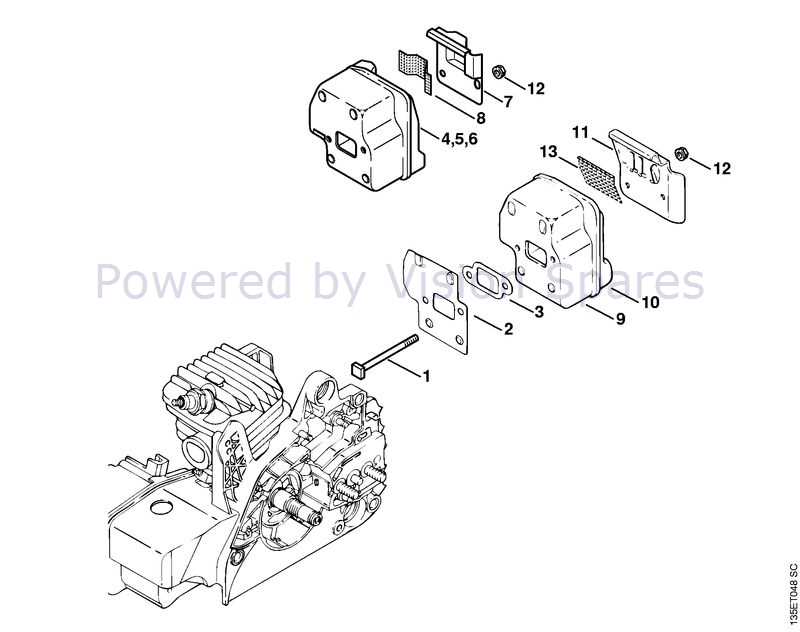

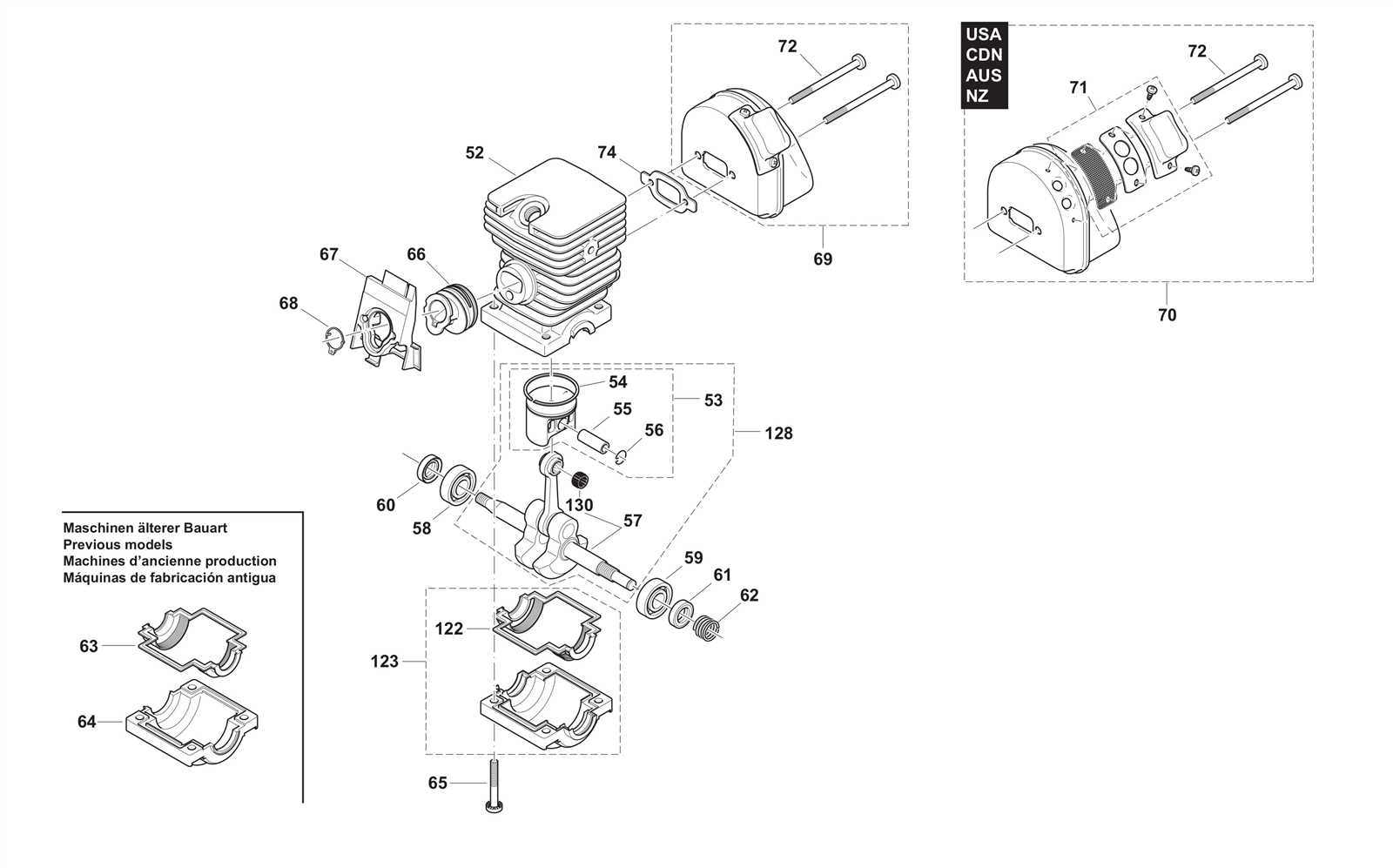

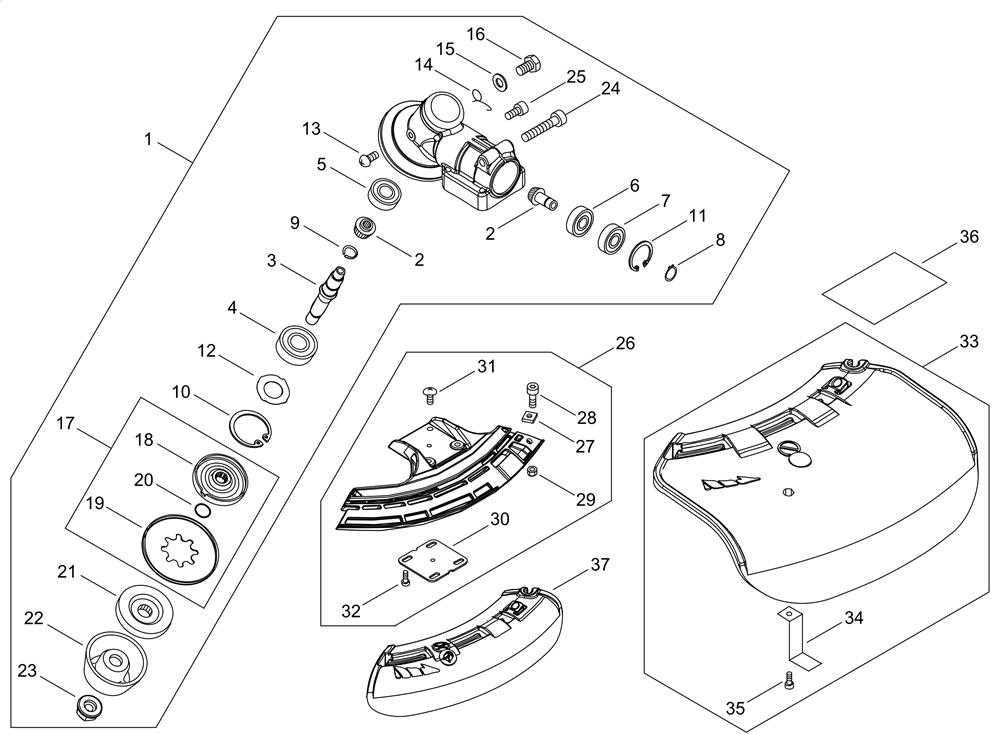

Visual aids can greatly enhance comprehension of the various components, offering a clear perspective on their arrangement and function. Whether you’re a seasoned user or a novice, having access to a visual representation can simplify the process of identifying parts during maintenance or repair.

In this section, we will explore the essential elements that make up your cutting tool, focusing on their specific roles and how they contribute to the overall operation. Understanding these components will empower you to keep your equipment in top shape, ensuring that it performs optimally for years to come.

Understanding Stihl 023 Chainsaw Basics

This section explores the fundamental aspects of a popular cutting tool used for various outdoor tasks. By gaining insight into its components and functionality, users can better appreciate its capabilities and maintenance requirements.

| Component | Function |

|---|---|

| Engine | Powers the device for cutting operations. |

| Guide Bar | Directs the chain and helps in achieving precise cuts. |

| Chain | Interacts with the guide bar to slice through material. |

| Fuel System | Supplies energy to the engine for operation. |

| Safety Features | Protects the user from potential hazards during use. |

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools for identifying individual elements and their relationships within a system. By providing clarity, these illustrations enhance the overall efficiency of troubleshooting and assembling various devices.

Facilitating Repairs

When a piece of equipment malfunctions, having a clear visual reference simplifies the repair process. Users can easily locate and assess the condition of specific parts, allowing for swift identification of issues. This not only saves time but also minimizes the risk of misplacing or damaging components during repairs.

Enhancing User Knowledge

Illustrations also play a significant role in educating users about their machinery. By visually breaking down the structure, individuals can gain a deeper understanding of how each component functions and interacts. This knowledge empowers users to perform maintenance tasks with confidence, ensuring longevity and optimal performance of their equipment.

Common Issues with Stihl 023

Many users encounter various challenges when operating their chainsaw. Understanding these problems can enhance performance and prolong the tool’s lifespan.

- Fuel Issues:

- Old or contaminated fuel can lead to poor performance.

- Incorrect fuel mixture may cause starting difficulties.

- Starting Problems:

- Faulty spark plug can prevent ignition.

- Clogged air filter restricts airflow, impacting starting.

- Chain Issues:

- Worn chain can lead to inefficient cutting.

- Improper tension affects operation and safety.

- Bar Problems:

- Worn bar can cause uneven cutting.

- Debris buildup can lead to overheating.

Addressing these common issues promptly can ensure optimal functionality and safety during use.

Essential Tools for Maintenance

Proper upkeep of equipment requires a selection of crucial implements designed to enhance performance and longevity. Utilizing the right tools not only facilitates efficient repairs but also ensures that the machinery operates at its peak. A well-organized toolkit can significantly reduce downtime and improve overall functionality.

Basic Tools

Essential instruments include wrenches, screwdrivers, and pliers, which are fundamental for making adjustments and repairs. Having a good set of these tools allows for quick fixes and routine inspections, ensuring everything is in optimal condition.

Specialized Equipment

In addition to standard tools, specialized devices like chain sharpeners and tension gauges are invaluable for specific maintenance tasks. These tools enable detailed attention to parts that require precision, ultimately contributing to the efficiency and safety of the machinery.

Step-by-Step Repair Process

Repairing a machinery component can seem daunting, but breaking it down into manageable steps makes the task achievable. This guide provides a systematic approach to diagnosing issues and restoring functionality.

- Preparation:

- Gather necessary tools and safety gear.

- Ensure a clean workspace to avoid losing small parts.

- Identification:

- Examine the equipment to identify visible damage.

- Refer to manuals for specific issues related to your model.

- Disassembly:

- Carefully remove covers and components, noting their arrangement.

- Organize parts to prevent confusion during reassembly.

- Repair or Replace:

- Assess each component for wear and determine if it needs fixing or replacement.

- Use quality replacements to ensure longevity.

- Reassembly:

- Reassemble components in the reverse order of disassembly.

- Ensure all parts are securely fastened and aligned correctly.

- Testing:

- Start the machine and monitor its performance.

- Check for any unusual sounds or behaviors.

By following these steps, you can effectively restore your equipment to optimal working condition, ensuring reliability and efficiency.

Identifying Replacement Parts

When maintaining outdoor power equipment, understanding how to recognize and source components is crucial for ensuring optimal performance. This section will guide you through the essential steps for identifying necessary replacements, helping you keep your machinery running smoothly.

The first step in the identification process involves familiarizing yourself with the model’s specific features and components. Referencing the user manual can provide valuable insights into the assembly and individual parts. It often includes detailed descriptions and can help pinpoint the exact items you need.

Next, utilizing online resources, such as manufacturer websites or dedicated forums, can facilitate a clearer understanding of the components. These platforms often offer visuals and specifications that aid in accurate identification, ensuring you select the correct items for replacement.

Moreover, consulting with local retailers or repair specialists can be beneficial. Their expertise allows for informed recommendations and can assist in finding compatible alternatives if original components are unavailable.

Lastly, maintaining a systematic approach by cataloging the components and their conditions will help streamline future maintenance efforts. Keeping track of wear and tear on specific items allows for proactive replacements, thereby extending the life of your equipment.

Where to Find Parts Diagrams

Locating detailed illustrations of components for equipment can be essential for maintenance and repair. Various resources are available to help enthusiasts and professionals access these visual guides efficiently. Online platforms, manufacturer websites, and specialized forums often host comprehensive catalogs that can be easily navigated.

One effective approach is to visit the official website of the manufacturer, where users can often find searchable databases. Additionally, aftermarket suppliers frequently provide manuals and exploded views that can assist in identifying necessary items for specific models. Engaging with online communities can also yield valuable insights and links to relevant resources.

Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Adopting a few simple practices can significantly enhance functionality and prevent costly repairs. This guide provides key strategies for effective care.

Routine Checks

Conducting frequent inspections helps identify potential issues before they escalate. Focus on the following components:

| Component | Check Frequency | Notes |

|---|---|---|

| Air Filter | Every 10 hours | Clean or replace as needed. |

| Chain Tension | Before each use | Ensure proper tension for safety. |

| Fuel System | Every 20 hours | Inspect for leaks and clogs. |

Seasonal Maintenance

Seasonal care ensures your equipment remains in peak condition. Consider these steps:

| Task | Recommended Timing |

|---|---|

| Oil Change | At least once a year |

| Spark Plug Replacement | Every 100 hours |

How to Order Replacement Parts

When seeking to procure components for your equipment, understanding the process can streamline your experience. Knowing where to look and how to ensure compatibility is essential for maintaining optimal functionality.

Start by identifying the specific component you need. Many manufacturers offer online catalogs where you can search by model or description. It’s advisable to gather any relevant details such as model numbers or specifications before proceeding.

| Step | Action |

|---|---|

| 1 | Visit the manufacturer’s website or authorized dealer. |

| 2 | Search for the component using model information. |

| 3 | Confirm compatibility with your equipment. |

| 4 | Add the component to your cart and proceed to checkout. |

| 5 | Review your order and complete the purchase. |

Lastly, keep an eye out for any warranty or return policies that may apply to your purchase, ensuring peace of mind with your transaction.

Safety Precautions When Repairing

When undertaking maintenance or repair tasks, ensuring personal safety should always be the top priority. Engaging with machinery can pose various hazards, and it is essential to follow proper procedures to minimize risks. Being prepared and informed can help prevent accidents and injuries during the repair process.

First and foremost, always wear appropriate protective gear. This includes safety goggles to shield your eyes from debris, gloves to protect your hands, and sturdy footwear to safeguard your feet. If working with loud equipment, consider using ear protection to prevent hearing damage.

Before starting any repair work, disconnect the power source to eliminate the risk of accidental activation. Familiarize yourself with the tool or device you are working on, including its components and potential hazards. Keeping a clean and organized workspace is crucial, as it reduces the chances of accidents caused by clutter or misplaced tools.

Utilize the correct tools for each specific task, as using inappropriate equipment can lead to injuries or damage. When handling sharp or heavy parts, exercise caution and ensure you have a firm grip. If unsure about a procedure, consult the manufacturer’s guidelines or seek assistance from a knowledgeable individual.

Lastly, take regular breaks to stay alert and focused. Fatigue can impair judgment and increase the likelihood of mistakes. By prioritizing safety, you can effectively manage repairs while protecting yourself and those around you.

Upgrading Components for Performance

Enhancing the efficiency and functionality of your outdoor equipment can significantly improve its overall performance. By focusing on key elements that can be upgraded, users can achieve better power output, increased durability, and improved ease of use. Whether you are aiming for heightened speed, efficiency, or reliability, the right modifications can make a considerable difference.

When considering upgrades, it is essential to identify which components will yield the most noticeable benefits. Below is a table outlining common areas for enhancement and their potential impacts:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | Performance Carburetor | Improved fuel efficiency and power output |

| Air Filter | High-Flow Filter | Enhanced airflow for better combustion |

| Exhaust System | Upgraded Muffler | Reduced noise and improved exhaust flow |

| Blade | Premium Cutting Blade | Superior cutting performance and longevity |

| Fuel System | High-Performance Fuel Lines | Increased fuel delivery and reduced risk of leaks |

By strategically upgrading these components, users can maximize their equipment’s capabilities and ensure a more enjoyable and efficient experience during operation. Regular maintenance and careful selection of enhancements will contribute to the longevity and reliability of your machinery.

Frequently Asked Questions About Stihl 023

This section addresses common inquiries regarding a specific model of a well-known brand of outdoor power equipment. Users often seek guidance on maintenance, troubleshooting, and replacement components to ensure optimal performance and longevity.

What are the most common issues experienced with this model?

Common challenges include starting difficulties, excessive vibrations, and fuel leaks. Regular maintenance and timely inspections can help mitigate these issues. If persistent problems arise, consulting a professional may be necessary.

Where can I find replacement components for my equipment?

Replacement components can be sourced from authorized dealers, online retailers, and specialty stores. It is advisable to use original equipment to ensure compatibility and reliability. Additionally, user manuals often provide detailed information on compatible parts.