Understanding the Barreto 2024 TK Parts Diagram

In the realm of machinery and tools, having a comprehensive grasp of the individual elements that constitute a device is essential for effective maintenance and operation. Each segment plays a crucial role in the overall functionality, and recognizing their specific purposes can significantly enhance performance and longevity.

Visualization of these components not only aids in troubleshooting but also empowers users to make informed decisions regarding repairs and upgrades. A clear representation serves as a valuable reference, simplifying complex systems into digestible information.

As we delve into the intricate world of machinery, it becomes apparent that familiarity with the various elements can lead to improved efficiency. Understanding how each part interacts with the others is key to optimizing performance and achieving desired outcomes.

Understanding the Barreto 2024 Model

This section delves into the intricacies of a particular machinery model, focusing on its structural and functional aspects. By analyzing its components and their interactions, one can gain valuable insights into the overall performance and efficiency of the equipment. Such an understanding not only enhances operational capabilities but also promotes better maintenance practices.

Every piece of this equipment serves a specific purpose, contributing to the machine’s overall effectiveness. Familiarity with these elements allows operators to troubleshoot issues more effectively and optimize performance. Comprehending how these components work together is essential for maximizing the lifespan of the machinery.

Moreover, knowing the layout and functionality of various sections can significantly reduce downtime. Operators can quickly identify and rectify problems, ensuring that the equipment runs smoothly and reliably. A thorough grasp of this machinery ultimately leads to improved productivity and enhanced operational success.

Key Features of Barreto Equipment

This section highlights the essential characteristics of the renowned machinery known for its durability and efficiency. These features contribute to superior performance and user satisfaction, making it a preferred choice for various applications in landscaping and construction.

Durability and Reliability

- Constructed with high-quality materials to withstand tough conditions.

- Designed for long-lasting performance with minimal maintenance.

- Robust engineering ensures reliable operation across different terrains.

Advanced Technology

- Incorporates innovative designs that enhance productivity.

- Equipped with user-friendly controls for ease of operation.

- Utilizes efficient engines that optimize fuel consumption.

These key attributes make this machinery a standout option for professionals seeking efficiency and effectiveness in their projects.

Importance of TK Parts in Machinery

Components play a crucial role in the functionality and efficiency of machinery. Their design and quality directly influence the performance, durability, and overall reliability of equipment. Understanding the significance of these elements is essential for ensuring optimal operation and maintenance of machines in various industries.

High-quality components contribute to seamless integration within mechanical systems, reducing the likelihood of failures and downtime. Properly engineered elements enhance the machine’s operational capabilities, leading to improved productivity and reduced operational costs. Furthermore, the interchangeability of certain components allows for easier repairs and upgrades, promoting a longer lifespan for the equipment.

| Benefits | Description |

|---|---|

| Reliability | Well-designed components ensure consistent performance and minimize unexpected breakdowns. |

| Efficiency | Quality components optimize energy usage and reduce waste during operation. |

| Maintenance | Standardized elements simplify repairs, enabling quicker and more cost-effective servicing. |

| Longevity | Durable components enhance the overall lifespan of machinery, resulting in better return on investment. |

In summary, the significance of well-crafted components cannot be overstated. Their role in maintaining the integrity and functionality of machinery is vital for achieving operational excellence and ensuring long-term success in any industrial setting.

Common Issues with TK Components

Components in various machinery often face a range of challenges that can impact performance and longevity. Understanding these issues is crucial for maintaining efficiency and minimizing downtime. Common concerns include wear and tear, improper installation, and compatibility with other elements.

Wear and Tear: Over time, many components experience degradation due to regular use. This can lead to reduced functionality and the need for timely replacements.

Improper Installation: Incorrect setup can cause malfunctions and lead to increased strain on parts. Ensuring correct installation is vital for optimal performance.

Compatibility Issues: Using components that are not designed to work together can result in operational failures. Always verify compatibility to avoid significant problems down the line.

Addressing these common issues proactively can enhance the reliability of machinery and extend the life of critical components.

Step-by-Step Repair Guide

This guide aims to provide a clear and concise process for repairing equipment, ensuring users can confidently tackle issues that may arise. By following these structured steps, you can efficiently restore functionality to your machinery.

- Identify the issue: Observe the equipment and note any unusual behavior or sounds.

- Gather necessary tools: Ensure you have all required instruments and replacement components ready.

- Disconnect power: Always prioritize safety by unplugging the unit before starting repairs.

- Access the interior: Carefully remove covers or panels to reach the internal mechanisms.

- Examine components: Look for any signs of wear, damage, or disconnections that could cause malfunctions.

- Replace damaged parts: Swap out any faulty components with new or functional alternatives.

- Reassemble the unit: Put back all covers and ensure everything is secure.

- Test functionality: Plug the equipment back in and conduct a thorough test to ensure repairs were successful.

Following this systematic approach can greatly enhance your repair experience, leading to optimal results.

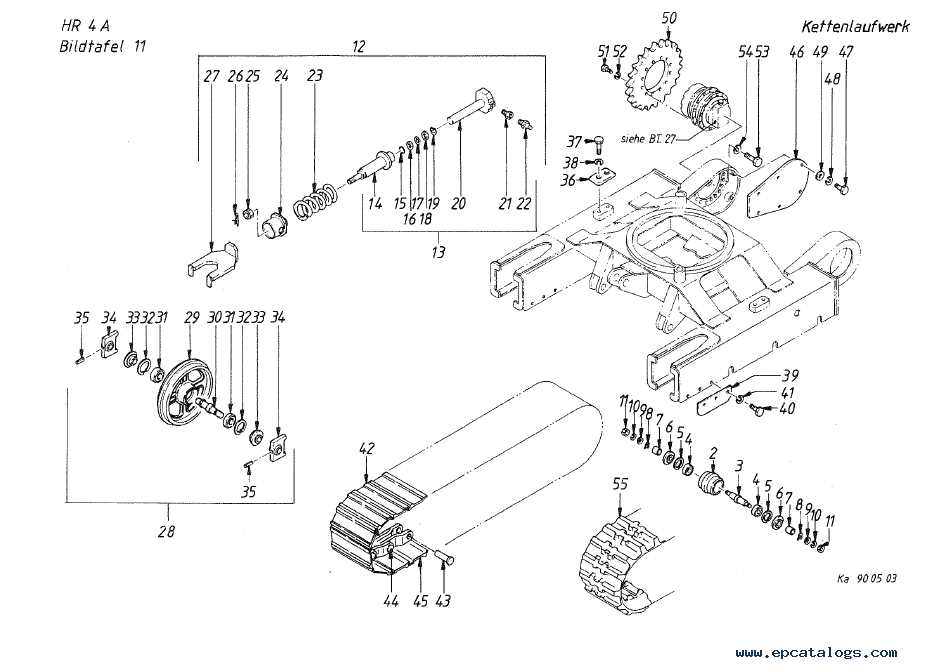

Identifying Parts Using Diagrams

Understanding the components of machinery or equipment is crucial for maintenance and repair. Visual representations provide clarity, helping users pinpoint each element’s role and function within the assembly. By analyzing these visuals, one can navigate the intricacies of mechanical systems with confidence.

Benefits of Visual Guides

- Enhanced comprehension of complex structures

- Streamlined identification of individual elements

- Facilitated troubleshooting and repair processes

Steps for Effective Identification

- Examine the overall layout to grasp the system’s configuration.

- Focus on individual sections, identifying each component’s purpose.

- Cross-reference with technical manuals for detailed specifications.

- Practice with real components to reinforce learning.

Using visuals effectively transforms the way one interacts with machinery, making the identification process more intuitive and efficient.

Where to Find Replacement Parts

Locating components for machinery can be essential for maintaining optimal performance and ensuring longevity. Various resources are available to help enthusiasts and professionals alike in sourcing what they need efficiently.

Online retailers often offer a wide selection, allowing users to compare prices and availability. Manufacturer websites frequently provide direct links to authorized sellers, ensuring authenticity. Local hardware stores or specialized shops may also carry essential items, providing the advantage of immediate access.

Forums and community groups can serve as valuable platforms for recommendations and advice on where to find specific components. Networking with fellow users can uncover hidden gems and trusted sources that might not be widely known.

Utilizing social media can also enhance your search, as many groups focus on equipment maintenance and offer insights on reliable vendors. Always verify the credibility of the sources to ensure high-quality purchases.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of any machinery. By implementing routine care and attention, users can significantly extend the lifespan of their equipment, avoiding costly repairs and downtime.

Regular Inspections

Conduct frequent evaluations to identify wear and tear. Look for signs of damage or malfunction early to address issues before they escalate. Proactive measures can save time and resources.

Cleaning and Lubrication

Keep components clean and well-lubricated to minimize friction and prevent corrosion. Routine cleaning removes debris, while regular lubrication ensures smooth operation, ultimately enhancing efficiency and reliability.

Comparison with Previous Barreto Models

This section explores the advancements and enhancements found in the latest machinery when compared to its earlier versions. By examining the changes in design and functionality, we can gain insight into the evolution of this equipment, highlighting improvements in efficiency and user experience.

Innovative Features

Recent models showcase cutting-edge technology that sets them apart from their predecessors. Key upgrades include enhanced engine performance and improved ergonomics, which significantly contribute to operational ease.

Durability and Maintenance

Another notable aspect is the increased durability and lower maintenance requirements. The latest iterations incorporate more robust materials and streamlined components, leading to longer lifespan and reduced downtime, thus making them more reliable for users.

Customer Reviews on Performance

This section explores the insights shared by users regarding the functionality and efficiency of the equipment. The feedback reflects a variety of experiences that highlight both strengths and areas for improvement.

Many customers express appreciation for the reliability of the machinery, noting its ability to handle demanding tasks with ease. Users frequently mention the power and durability that contribute to enhanced productivity in their operations.

Conversely, some reviews indicate challenges related to maintenance and operational adjustments. These insights suggest a need for further enhancements to optimize the overall user experience and ensure seamless functionality.

Ultimately, the shared experiences provide valuable perspectives for potential buyers, guiding them toward informed decisions based on real-world performance evaluations.