Comprehensive Parts Diagram for John Deere X370

For enthusiasts and owners of outdoor equipment, comprehending the intricate details of their machinery is essential for optimal performance and longevity. Each model contains a unique arrangement of essential elements that contribute to its functionality. Familiarity with these components not only enhances maintenance practices but also empowers users to make informed decisions regarding repairs and upgrades.

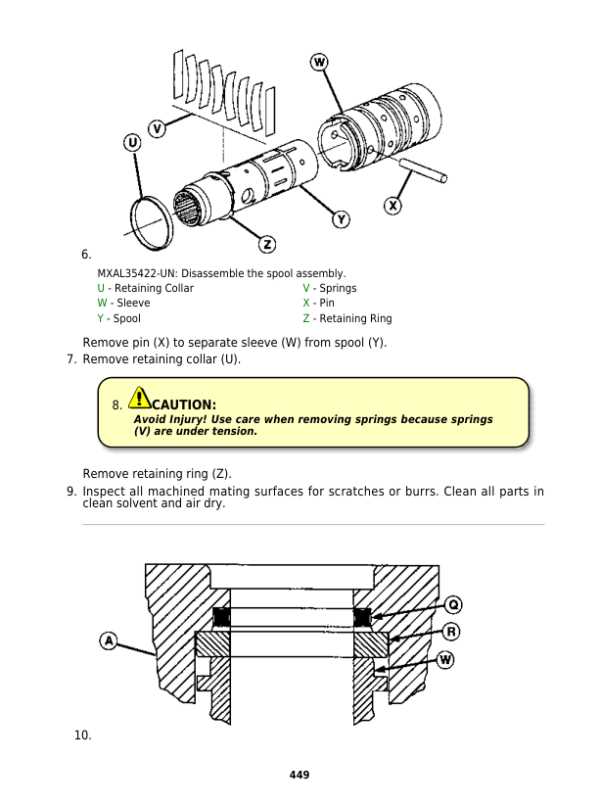

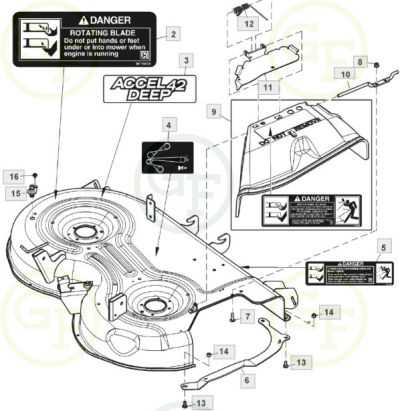

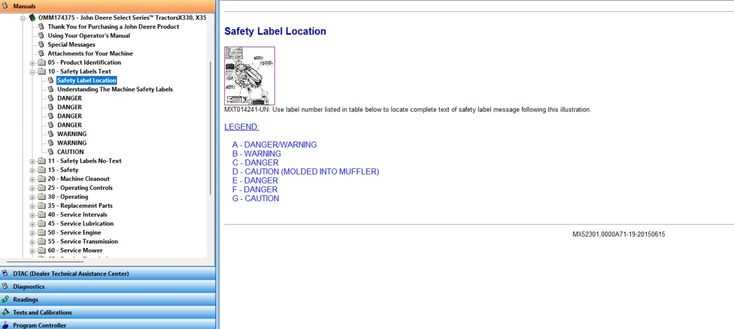

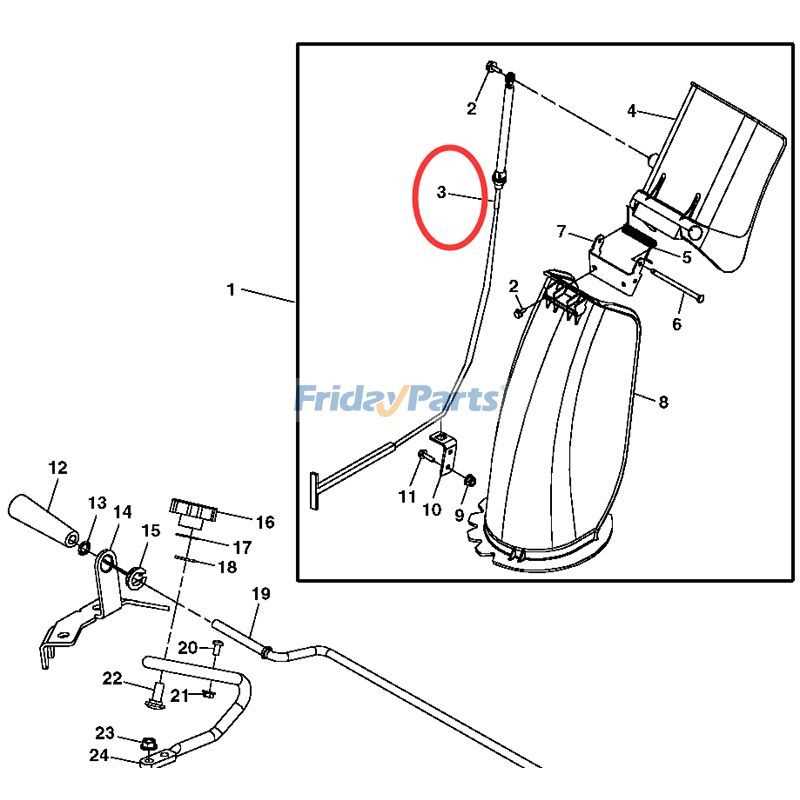

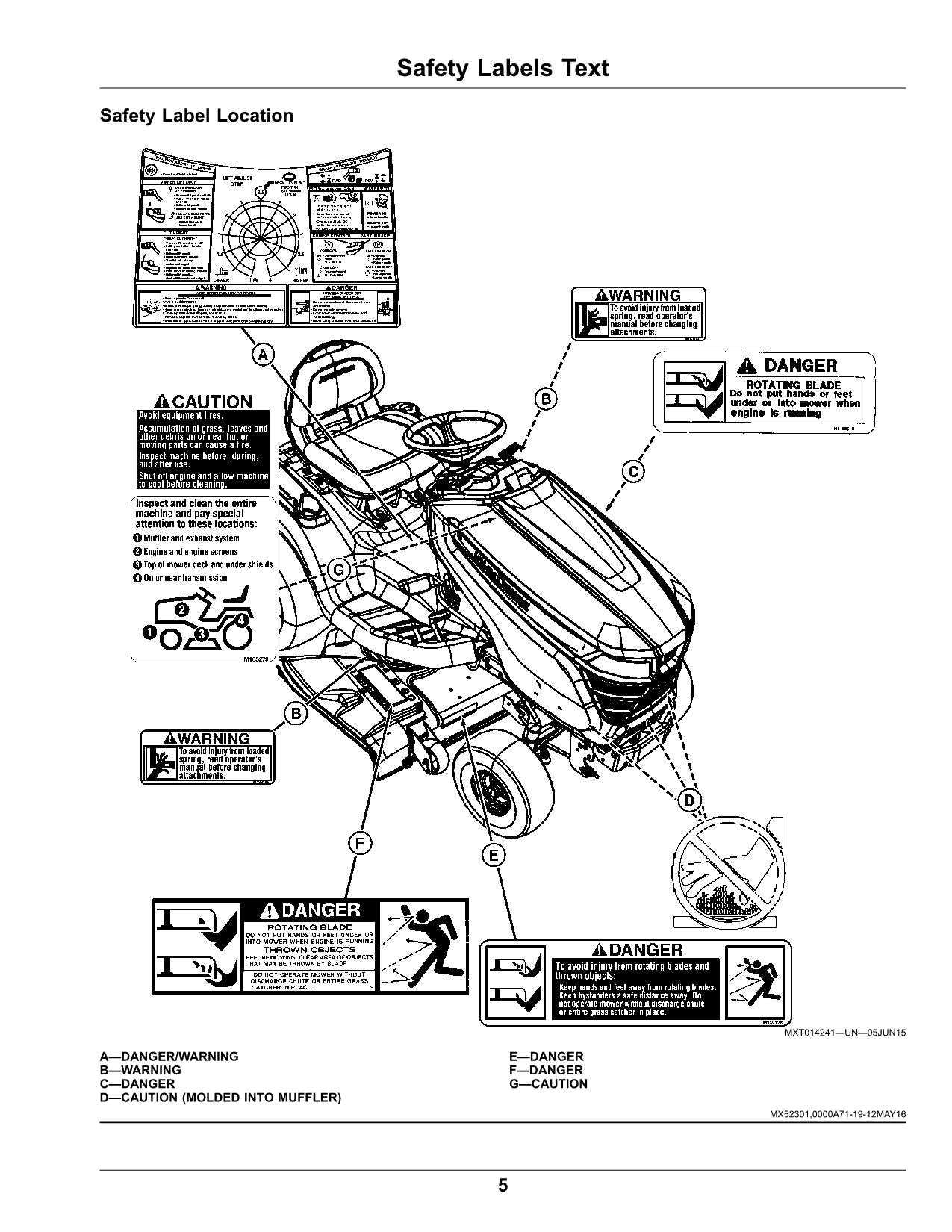

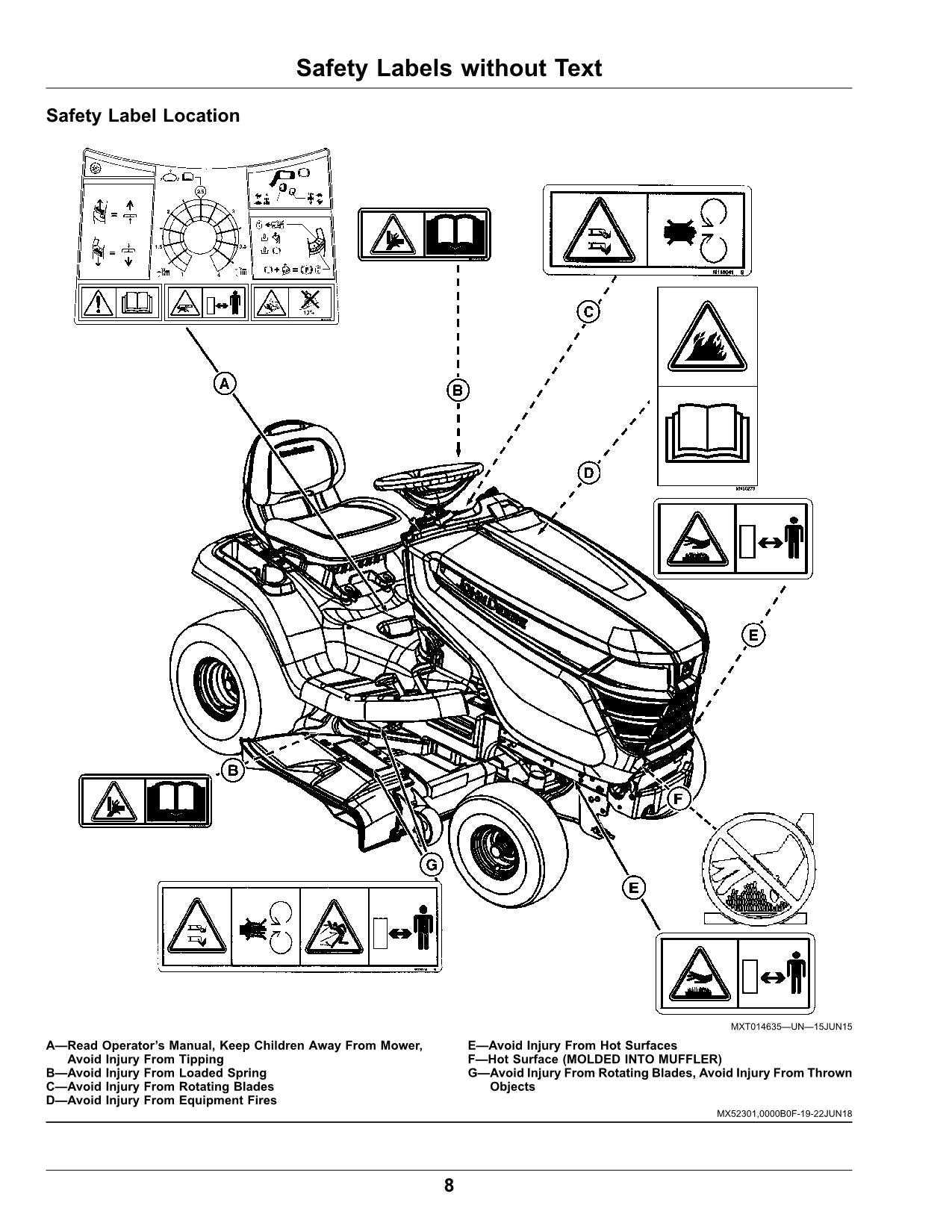

Visual aids play a crucial role in this journey of understanding. They provide clarity and insight into the relationship between different elements, allowing operators to identify parts easily and recognize their significance within the overall system. A well-organized visual representation can be the ultimate tool for anyone looking to delve deeper into the workings of their machine.

Whether you’re a seasoned professional or a new user, having access to detailed illustrations can significantly improve your hands-on experience. By exploring the arrangement of each segment, you’ll gain confidence in addressing issues as they arise, ensuring your equipment remains in peak condition throughout its service life.

Understanding John Deere X370 Components

Familiarizing oneself with the various elements of a lawn care machine is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring that the equipment functions smoothly and effectively, contributing to the overall performance and longevity of the unit.

Key Features and Functions

The primary attributes of this equipment include the engine, transmission, and cutting system. The engine serves as the powerhouse, providing the necessary energy for movement and operation. The transmission system ensures that power is effectively transferred, allowing for seamless navigation across different terrains. Meanwhile, the cutting mechanism is designed to deliver a clean and precise finish to the lawn, enhancing the overall aesthetic.

Maintenance and Care

Regular upkeep of these components is vital to prevent wear and tear. Routine checks on the engine oil, air filters, and blades can significantly extend the life of the machine. Understanding the function of each part facilitates informed decisions regarding repairs and replacements, ultimately leading to a more enjoyable and efficient lawn care experience.

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools that simplify complex systems, making it easier for users to identify components and their interconnections.

Utilizing these illustrations offers several advantages:

- Enhanced clarity in identifying individual components.

- Streamlined troubleshooting by visualizing assembly layouts.

- Facilitated ordering of replacements by clearly showing necessary items.

Moreover, these visual aids promote effective communication among technicians and users, ensuring everyone involved shares a common understanding of the equipment.

In summary, well-structured visual guides are invaluable for anyone involved in the upkeep of machinery, providing essential support for efficient operation and maintenance.

Common Issues with X370 Parts

When it comes to maintaining your equipment, certain components can often present challenges that may affect performance and longevity. Understanding these frequent complications can help in ensuring a smoother operation and timely repairs.

Wear and Tear: Over time, many elements experience natural degradation. This can lead to decreased efficiency and, in some cases, complete failure. Regular inspections can help identify these issues early.

Improper Installation: A common problem arises when components are not installed correctly. This can result in misalignment or inadequate functionality, ultimately affecting the overall operation of the machinery.

Environmental Impact: Exposure to harsh weather conditions can also take a toll. Elements may corrode or become damaged due to extreme temperatures, moisture, or debris accumulation, necessitating more frequent replacements.

Lack of Maintenance: Neglecting routine upkeep can lead to serious complications. Regular cleaning, lubrication, and adjustments are essential to prevent more significant issues down the line.

Compatibility Issues: Using components that are not designed for your specific model can lead to various problems. It’s crucial to ensure that all replacements meet the necessary specifications for optimal performance.

Maintenance Tips for X370 Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your lawn care equipment. Regular attention to maintenance tasks can help prevent costly repairs and keep your machine operating at peak performance.

Here are some essential maintenance tips to consider:

- Regularly inspect and clean the air filter to ensure optimal airflow.

- Change the engine oil and replace the oil filter at recommended intervals to maintain engine health.

- Sharpen the blades frequently to achieve a clean cut and enhance the appearance of your lawn.

- Check tire pressure and inspect for wear to ensure safe and efficient operation.

- Lubricate moving parts as per the manufacturer’s guidelines to reduce friction and wear.

Following these simple steps can significantly extend the life of your equipment and improve its overall performance.

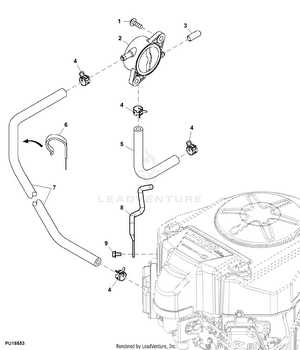

Identifying Key Replacement Parts

Understanding essential components for machinery maintenance is crucial for optimal performance. Recognizing these elements allows users to effectively address wear and tear, ensuring longevity and efficiency. Proper identification not only streamlines repairs but also enhances overall functionality.

Commonly, key elements include blades, belts, and filters, each playing a significant role in operation. Blades must be sharp for effective cutting, while belts ensure proper movement between systems. Filters maintain cleanliness, preventing damage from debris and contaminants.

To assist in finding the right components, manuals often provide detailed illustrations. Utilizing these references helps pinpoint specific items needed for replacement, reducing downtime and improving maintenance efficiency. Knowing where to locate these crucial components is the ultimate step toward successful upkeep.

Where to Find X370 Parts Diagrams

Locating detailed illustrations for specific machinery components can greatly enhance maintenance and repair efforts. These visuals serve as invaluable resources, helping users identify and source the necessary elements for optimal performance.

Online Resources: Numerous websites offer comprehensive collections of schematics, making it easy to access crucial information from the comfort of your home. Search for dedicated forums or official sites that specialize in equipment.

Local Dealers: Authorized retailers often have physical and digital catalogs available. Visiting or contacting them can yield precise and reliable schematics tailored to your needs.

Repair Manuals: Investing in an official repair guide can provide not only illustrations but also detailed instructions for repairs. These manuals are specifically designed for users seeking thorough understanding.

Community Groups: Engaging with online communities and social media groups can lead to shared resources and personal experiences that may include valuable links to diagrams.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures optimal performance and longevity of machinery. These items are specifically designed to meet precise specifications, providing a perfect fit and enhancing overall efficiency.

| Advantage | Description |

|---|---|

| Quality Assurance | OEM components undergo rigorous testing, ensuring reliability and durability. |

| Compatibility | Designed for specific models, these items guarantee seamless integration. |

| Warranty Protection | Using OEM components often preserves manufacturer warranties, safeguarding your investment. |

| Resale Value | Maintaining original components can enhance the resale value of your equipment. |

DIY Repairs for X370 Machines

Engaging in self-repair for your equipment can save time and money, while also enhancing your understanding of its components. By familiarizing yourself with common issues and solutions, you can effectively maintain your machinery and extend its lifespan. This guide will provide insights into essential repairs that can be tackled with basic tools and a bit of knowledge.

Common Issues and Solutions

- Engine Problems: Regularly check the spark plug and air filter. Cleaning or replacing these can resolve many starting issues.

- Battery Maintenance: Ensure that the battery terminals are clean and secure. If the battery is not holding a charge, it may need replacement.

- Blade Issues: Dull blades can affect performance. Sharpening or replacing them can improve cutting efficiency.

Tools Needed

- Socket wrench set

- Screwdrivers (flat and Phillips)

- Air compressor or can of compressed air

- Oil and lubricant

- Replacement parts as necessary

By following these guidelines, you can perform effective repairs and maintenance on your equipment, ensuring it runs smoothly and efficiently for years to come.

Safety Precautions During Maintenance

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions should be taken to create a secure working environment, safeguarding both the individual performing the task and the equipment itself.

Always wear appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear. This minimizes the risk of injuries from sharp objects or hazardous materials. Additionally, it’s essential to work in a well-ventilated area, especially when dealing with chemicals or fuels.

Before starting any maintenance, disconnect power sources and ensure that the machine is stable. Utilize proper lifting techniques and equipment to handle heavy components, reducing the chance of strain or injury. Lastly, maintain clear communication with others nearby to avoid unexpected disturbances.

Upgrading Components for Better Performance

Enhancing machinery efficiency can lead to significant improvements in productivity and longevity. By focusing on specific elements, users can achieve optimal results and maximize their investment.

- Engine Enhancements: Upgrading the engine can provide increased horsepower and torque.

- Transmission Improvements: Better transmission systems can ensure smoother operation and better power transfer.

- Electrical System Upgrades: Enhanced electrical components can improve reliability and performance.

Consider evaluating the following components for potential upgrades:

- Fuel system

- Exhaust systems

- Cooling mechanisms

Investing in quality replacements can result in significant performance gains and ensure that equipment operates at its ultimate potential.

Community Resources for X370 Support

Accessing reliable information and support for your equipment can greatly enhance your experience and ensure smooth operation. Engaging with community resources allows users to share knowledge, troubleshoot issues, and find solutions tailored to their specific needs. From forums to social media groups, various platforms facilitate interaction among enthusiasts and experts alike.

| Resource Type | Description | Benefits |

|---|---|---|

| Online Forums | Dedicated discussion boards where users can post questions and share experiences. | Access to a wide range of topics and the ability to connect with fellow users. |

| Social Media Groups | Facebook and other platforms host groups focused on specific machinery. | Real-time updates, tips, and community-driven support. |

| YouTube Channels | Video tutorials and reviews related to maintenance and operation. | Visual guidance helps in understanding complex tasks easily. |

| Local Clubs | Community gatherings where enthusiasts meet to share knowledge. | Networking opportunities and hands-on demonstrations. |

Utilizing these resources can significantly enhance your ability to manage and maintain your machinery efficiently. Engaging with the community fosters a spirit of collaboration, ensuring that you are never alone in your journey.