Comprehensive Guide to Shopsmith Parts Diagram

Every woodworking enthusiast knows that having a reliable and efficient machine is crucial for achieving the best results. Understanding the various components of your equipment not only enhances your ability to operate it effectively but also ensures that maintenance and repairs are handled swiftly and accurately. This knowledge transforms a complex assembly into a manageable system, allowing for smoother workflows and creative projects.

When working with intricate machinery, familiarity with its individual elements can significantly impact performance. Whether you are a seasoned craftsman or a beginner, visual representations of each part can serve as invaluable guides. They provide clarity, helping you identify where issues may arise and how to resolve them efficiently. By leveraging these resources, you can extend the lifespan of your tools and improve your overall craftsmanship.

In this section, we will explore a comprehensive overview of the essential features of your equipment. You’ll discover how each piece contributes to the functionality of the whole, enabling you to make informed decisions regarding upgrades, repairs, or replacements. With a detailed visual reference, you’ll gain the confidence to tackle any project that comes your way, ensuring that your creative pursuits remain uninterrupted.

Understanding Shopsmith Parts Diagrams

Comprehending the layout of a multi-functional woodworking tool is essential for effective use and maintenance. Visual representations play a crucial role in identifying components, understanding assembly, and troubleshooting issues. This knowledge empowers users to maximize their equipment’s capabilities and extend its lifespan.

The Importance of Visual Guides

Visual aids serve as invaluable resources for both novice and experienced craftsmen. They help in several ways:

- Clarifying component names and functions

- Assisting in the reassembly of equipment after maintenance

- Highlighting compatible accessories and attachments

- Facilitating troubleshooting by pinpointing specific areas of concern

How to Read These Visual Aids

Interpreting these layouts involves several key steps:

- Familiarize yourself with the overall layout to understand the tool’s configuration.

- Identify individual elements by following the numbering or labeling system provided.

- Refer to the accompanying documentation for detailed descriptions and specifications.

- Use the visual guide to locate replacement components or upgrades efficiently.

By mastering these representations, users can enhance their woodworking experience, ensuring that they utilize their tools effectively and safely.

Importance of Parts Diagrams

Understanding the layout and components of any complex tool is crucial for effective operation and maintenance. Visual representations serve as essential guides, enabling users to identify each segment and its function with clarity.

These illustrations provide numerous benefits:

- Facilitates Repairs: Clear visuals help in pinpointing damaged components, making the repair process more efficient.

- Enhances Assembly: Proper schematics simplify the reassembly of parts after maintenance or replacement, reducing the risk of errors.

- Improves Communication: Detailed visuals can be used to effectively convey issues and solutions between users and technicians.

- Supports Education: These resources serve as excellent teaching tools, aiding new users in learning the intricacies of the equipment.

In summary, accurate visual representations are indispensable for anyone looking to maintain, repair, or understand complex machinery. They streamline processes, enhance safety, and ultimately lead to better performance and longevity of the tools involved.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for anyone looking to maintain or repair equipment. These visual guides simplify complex structures, allowing users to identify components and their relationships. Familiarity with these visuals can greatly enhance your ability to navigate the assembly and disassembly processes.

When examining an illustration, start by identifying the main sections. Typically, these visuals are divided into segments that group related items, making it easier to focus on specific areas. Pay attention to any labels or legends, as they provide essential information about each component’s designation and function.

| Element | Description |

|---|---|

| Legend | A key that explains the symbols or numbers used in the illustration. |

| Numbering | Items are often numbered to correlate with a list of components. |

| Arrows | Indicators that show the direction of assembly or movement. |

| Groupings | Clusters of related items that are visually separated for clarity. |

By taking the time to carefully analyze the illustration, you can effectively identify what is needed for repairs or upgrades. This understanding will ultimately lead to more efficient troubleshooting and a smoother repair experience.

Common Parts in Shopsmith Machines

In woodworking equipment, various components play crucial roles in ensuring functionality and efficiency. Understanding these essential elements can significantly enhance the user experience and maintenance practices. This section will delve into the most frequently encountered components found in such versatile machinery.

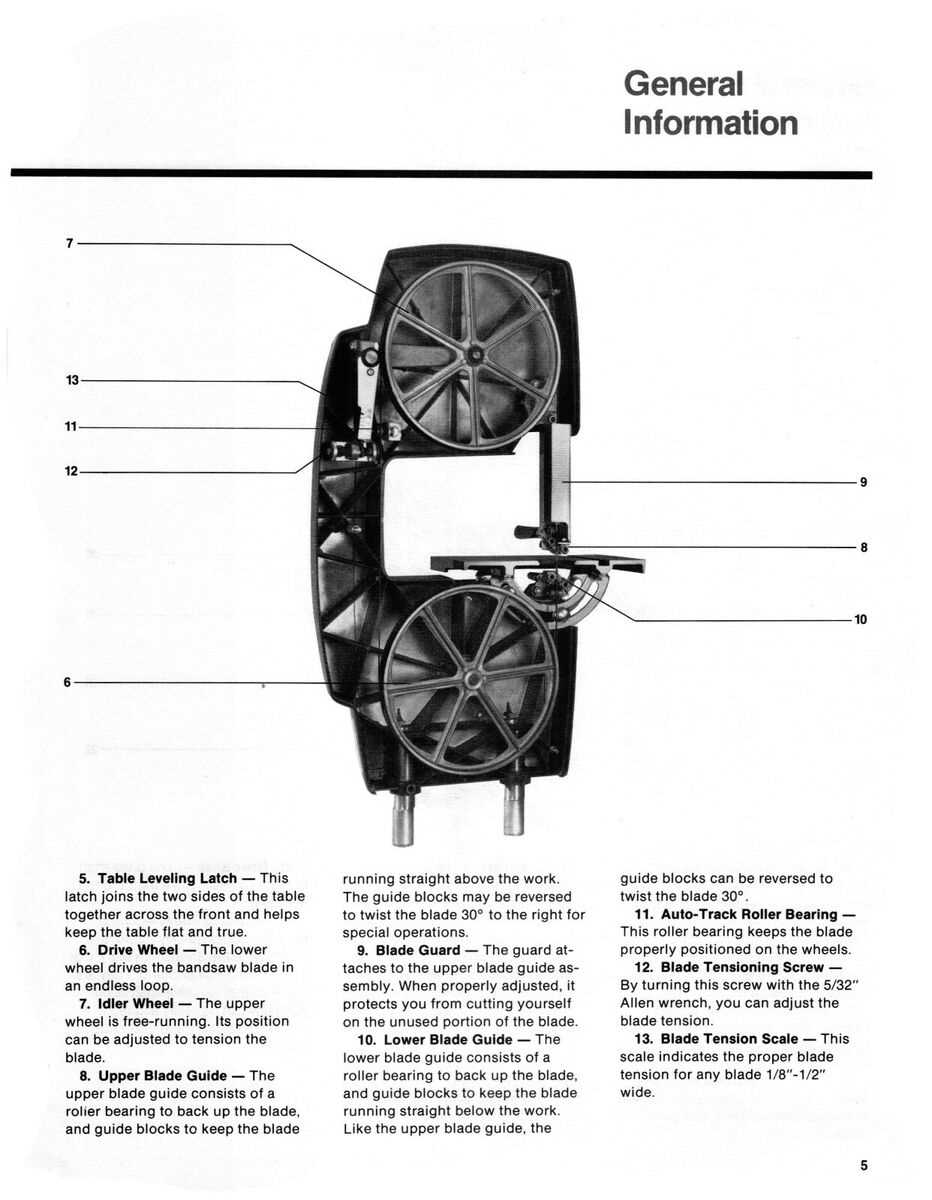

Motor is the powerhouse of the machine, providing the necessary energy to operate various functions. It is vital for achieving different speeds and performance levels, making it an integral part of any woodworking setup.

Table serves as the primary workspace, where materials are secured for cutting, shaping, or drilling. A sturdy and well-aligned table is essential for accuracy and ease of use.

Fence acts as a guide for precision cuts, ensuring straight lines and consistent dimensions. Its adjustability allows users to customize the setup according to specific project requirements.

Blades, whether for sawing or shaping, come in various types tailored for specific tasks. Choosing the right blade can significantly affect the quality of the finish and the efficiency of the work.

Accessories enhance the machine’s versatility, allowing it to perform a wider range of tasks. Items like jigs, extensions, and dust collection systems contribute to both functionality and safety in the workshop.

Recognizing these vital components not only aids in better operation but also supports effective troubleshooting and maintenance, ensuring longevity and performance of the equipment.

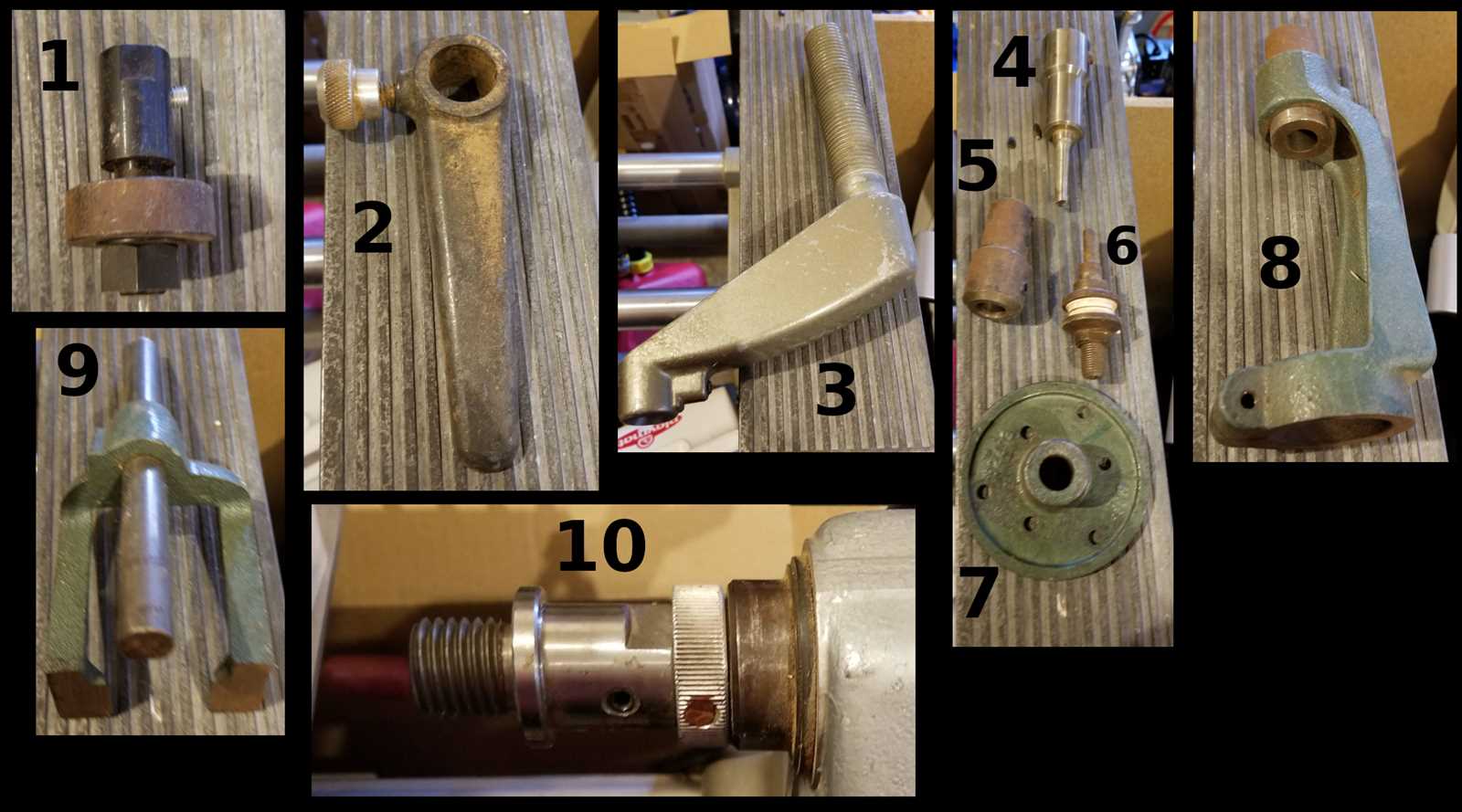

Identifying Missing Components

Understanding the full assembly of your equipment is crucial for its proper functionality. When components are absent, it can hinder performance and lead to frustration. This section will guide you through recognizing and addressing any missing items that may affect your setup.

Begin by familiarizing yourself with the complete list of essential elements. Knowing what should be present allows for easier identification of discrepancies. You can then take steps to acquire replacements, ensuring that everything operates smoothly.

| Component Name | Description | Common Issues When Missing |

|---|---|---|

| Base | The foundation that supports the entire unit. | Instability and improper alignment. |

| Motor | Drives the operational functions of the machinery. | Complete inoperability. |

| Blade Guard | Protects users from contact with sharp edges. | Increased risk of accidents and injuries. |

| Table Extension | Provides additional workspace for larger projects. | Difficulty handling larger materials. |

By systematically evaluating these key elements, you can ensure that all necessary pieces are accounted for and functioning effectively. This proactive approach not only enhances safety but also improves overall productivity.

Benefits of Using Original Parts

Choosing components from the original manufacturer can greatly enhance the performance and longevity of your equipment. These authentic items are designed specifically for compatibility and reliability, ensuring that your tools function at their best.

Quality Assurance

Original components undergo rigorous testing and quality control measures. This guarantees that each piece meets high standards for durability and performance, reducing the likelihood of malfunction or breakdown.

Enhanced Compatibility

Using genuine items ensures perfect compatibility with your machinery. This minimizes the risk of installation issues and ensures optimal functionality, ultimately leading to better results in your projects.

| Benefit | Description |

|---|---|

| Durability | Manufactured to withstand wear and tear over time. |

| Performance | Designed to maintain the efficiency of your equipment. |

| Warranty Support | Often includes warranty protection when original items are used. |

| Safety | Engineered to comply with safety standards, reducing hazards. |

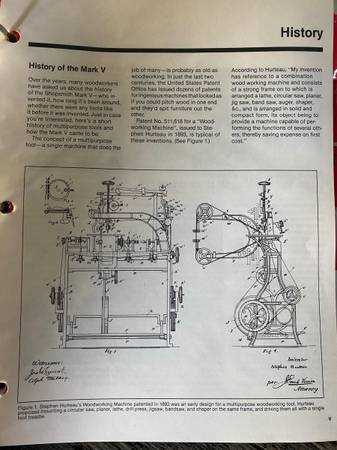

Where to Find Diagrams Online

Locating visual representations of mechanical components can greatly enhance your understanding and maintenance of various tools. Fortunately, there are numerous resources available online where enthusiasts and professionals can access these valuable illustrations.

- Manufacturer Websites: Most companies provide detailed resources, including visual guides, on their official platforms.

- Online Retailers: E-commerce sites often feature diagrams alongside product listings, helping users identify the necessary parts.

- Forums and Community Groups: Many online communities share user-generated content, including helpful visuals and tips.

- Technical Manuals: Digital copies of manuals are frequently available through various websites, offering in-depth information.

- DIY Blogs and YouTube Channels: Content creators often share step-by-step guides and illustrations to assist with repairs and upgrades.

By exploring these resources, you can find the illustrations needed for successful maintenance and enhancement of your tools.

Ordering Replacement Parts Easily

Finding the right components for your equipment can be a straightforward process when you know the right steps to follow. Understanding how to navigate the options available can save you time and ensure you get exactly what you need for repairs or upgrades.

Steps to Simplify Your Ordering Process

- Identify the Component Needed:

- Check your manual or documentation.

- Look for identifying numbers or names on the item itself.

- Use Reliable Resources:

- Visit official websites or trusted retailers.

- Search for community forums or groups for recommendations.

- Compare Options:

- Review pricing from different suppliers.

- Check for availability and shipping options.

- Place Your Order:

- Ensure all information is accurate before finalizing.

- Keep a record of your order confirmation for future reference.

Tips for Smooth Transactions

- Look for customer reviews to gauge reliability.

- Inquire about return policies in case of issues.

- Consider reaching out to customer service if you have questions.

Maintenance Tips for Shopsmith Equipment

Proper upkeep of your multifunctional woodworking tools is essential to ensure their longevity and optimal performance. Regular maintenance not only enhances efficiency but also helps prevent costly repairs. Here are some key practices to keep your equipment running smoothly.

Regular Cleaning

Keeping your tools clean is fundamental. Dust and debris can accumulate and interfere with operations. Consider the following steps:

- Use a soft brush or compressed air to remove sawdust and shavings from crevices.

- Wipe down surfaces with a damp cloth to eliminate residue.

- Ensure that all moving parts are free of obstructions.

Lubrication and Inspection

Regularly inspecting and lubricating components is crucial for maintaining functionality. Follow these recommendations:

- Check all moving parts for wear and tear, replacing any damaged components as needed.

- Apply appropriate lubricant to bearings and pivot points to reduce friction.

- Inspect electrical connections and cords for signs of wear to prevent hazards.

By adhering to these maintenance tips, you can significantly extend the life of your equipment and ensure it remains in top condition for all your woodworking projects.

Common Issues and Their Solutions

In the world of woodworking equipment, encountering challenges is a common experience for many users. Understanding typical problems and their remedies can significantly enhance the efficiency and longevity of your tools. This section aims to provide insights into frequent malfunctions and practical solutions to ensure a smoother operation.

One prevalent issue is difficulty in achieving proper alignment. Users may notice that components do not align correctly during use. This can often be resolved by checking the adjustment settings and recalibrating them according to the manufacturer’s guidelines.

Another common challenge is inconsistent performance during operation. If the machinery exhibits fluctuations in speed or power, inspecting the motor connections and ensuring that all parts are securely fastened can often rectify the situation. Additionally, cleaning any dust or debris that may hinder functionality is crucial.

Noise during operation can also indicate underlying problems. Unusual sounds might suggest wear and tear or insufficient lubrication. Regular maintenance, including lubrication of moving parts and inspection for signs of damage, can help prevent further issues and extend the lifespan of your equipment.

Lastly, electrical malfunctions can lead to unexpected shutdowns or failures to start. Checking the power supply, ensuring proper connections, and examining fuses can often resolve these issues. Keeping an eye on the electrical components and replacing worn parts promptly will help maintain reliable operation.

Community Resources for Repairs

When it comes to maintaining and restoring machinery, community-driven support can be invaluable. Enthusiasts and hobbyists often share their knowledge and experience, offering a wealth of resources for troubleshooting, fixing, and enhancing equipment. Engaging with local groups or online forums can connect individuals with others who have faced similar challenges, making the repair process more manageable and enjoyable.

Below is a table highlighting various community resources that can aid in repairs:

| Resource Type | Description | Where to Find |

|---|---|---|

| Online Forums | Discussion platforms where users can ask questions, share tips, and exchange ideas. | Various websites dedicated to woodworking and machinery. |

| Local Workshops | Hands-on classes or meetups that focus on repair techniques and maintenance skills. | Community centers or maker spaces. |

| Social Media Groups | Dedicated groups on platforms like Facebook where members can share advice and resources. | Facebook, Reddit, and similar platforms. |

| Instructional Videos | Visual guides and tutorials that provide step-by-step instructions for repairs. | YouTube and other video-sharing platforms. |

| Local Repair Shops | Professionals who offer repair services and may provide consultations or workshops. | Neighborhood hardware stores or specialized repair shops. |

By tapping into these community resources, individuals can enhance their skills, find the support they need, and contribute to a culture of collaboration and knowledge-sharing in the realm of repairs.

DIY Projects Using Shopsmith Parts

Creating your own projects can be both fulfilling and practical, especially when you have a versatile tool system at your disposal. By utilizing various components designed for woodworking, you can craft unique items that enhance your home, office, or workshop. These elements allow you to unleash your creativity while honing your skills, turning raw materials into functional art.

Custom Furniture Creation

One of the most rewarding endeavors is building custom furniture. Whether it’s a coffee table, bookshelf, or chair, having the right tools makes the process smoother. Begin with a clear plan and gather your materials. With the ability to cut, shape, and assemble, you can create pieces that fit perfectly into your space. Personal touches, such as intricate designs or personalized finishes, can transform a simple project into a centerpiece.

Home Décor and Accessories

Beyond furniture, there are numerous opportunities to enhance your living space with decorative items. Consider crafting wall art, picture frames, or even garden accessories. Utilizing various attachments allows for intricate designs and smooth finishes. Embrace your artistic side and experiment with different styles, ensuring each piece reflects your personal taste. Not only will these projects beautify your surroundings, but they will also serve as conversation starters.