Comprehensive Guide to Jonsered 455 Parts Diagram

Maintaining optimal performance of your cutting tool requires a comprehensive understanding of its internal structure. Each element plays a crucial role in ensuring efficient operation, making it essential for users to familiarize themselves with the various sections and their functions. This knowledge not only enhances performance but also simplifies troubleshooting and repair processes.

Within this exploration, we will delve into the intricate relationships between different components. By breaking down the assembly into manageable segments, users can better appreciate how each part contributes to the overall effectiveness of the machine. This clarity can significantly aid in identifying potential issues and addressing them promptly.

Whether you are a seasoned professional or a novice, having access to detailed illustrations and descriptions of these components can be invaluable. Such resources empower users to engage with their equipment more confidently, leading to improved maintenance practices and a longer lifespan for their tools. Understanding the essentials is the first step toward mastery.

Understanding the Jonsered 455 Model

This section delves into the intricate workings of a renowned cutting tool designed for various outdoor tasks. It highlights the essential components that contribute to its efficiency and performance, helping users make informed decisions regarding maintenance and repairs.

Key Features

- Robust Engine: Offers powerful performance for demanding jobs.

- Lightweight Design: Ensures ease of handling during extended use.

- Advanced Safety Mechanisms: Provides users with peace of mind while operating.

Maintenance Considerations

- Regular Cleaning: Prevents debris buildup, ensuring optimal performance.

- Lubrication: Essential for maintaining moving parts and prolonging lifespan.

- Inspection: Routine checks of critical components can avert costly repairs.

Key Features of Jonsered 455

This section highlights the standout characteristics of a renowned chainsaw model, emphasizing its efficiency and reliability for various outdoor tasks. With advanced engineering and thoughtful design, this tool caters to both professionals and enthusiasts in the field of forestry and gardening.

Performance Advantages

- Powerful engine delivering high cutting speed

- Excellent fuel efficiency for prolonged use

- Robust construction ensuring durability under tough conditions

User-Friendly Design

- Lightweight frame for easy maneuverability

- Anti-vibration technology for reduced fatigue

- Ergonomically designed handles for improved grip and control

Overall, this model is designed to meet the needs of a diverse range of users, making it a preferred choice for outdoor tasks.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of individual elements offer invaluable guidance, helping users identify and locate specific items within a complex assembly. This clarity fosters efficiency in troubleshooting and ensures that repairs can be conducted swiftly and accurately.

Moreover, these illustrations serve as a reference for both novice and experienced technicians. They simplify the process of reassembly after disassembly, minimizing the risk of errors that could lead to malfunction or safety hazards. By providing a clear overview, they enable users to recognize wear or damage that may not be immediately apparent.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids help in identifying and understanding each component’s function. |

| Efficient Repairs | Streamlined processes reduce downtime and improve productivity. |

| Accurate Reassembly | Guidance ensures that all parts are correctly replaced, reducing the risk of errors. |

| Safety Assurance | Proper identification of parts helps maintain operational safety standards. |

In summary, visual representations of machinery elements play an essential role in maintenance practices. Their utility extends beyond simple identification; they are vital tools for ensuring the longevity and reliability of equipment.

Common Issues with Jonsered 455

Every powerful outdoor tool can encounter challenges that affect its performance and reliability. Understanding these frequent complications is essential for effective maintenance and troubleshooting. Users often face specific problems that can hinder operation, leading to frustration and decreased efficiency.

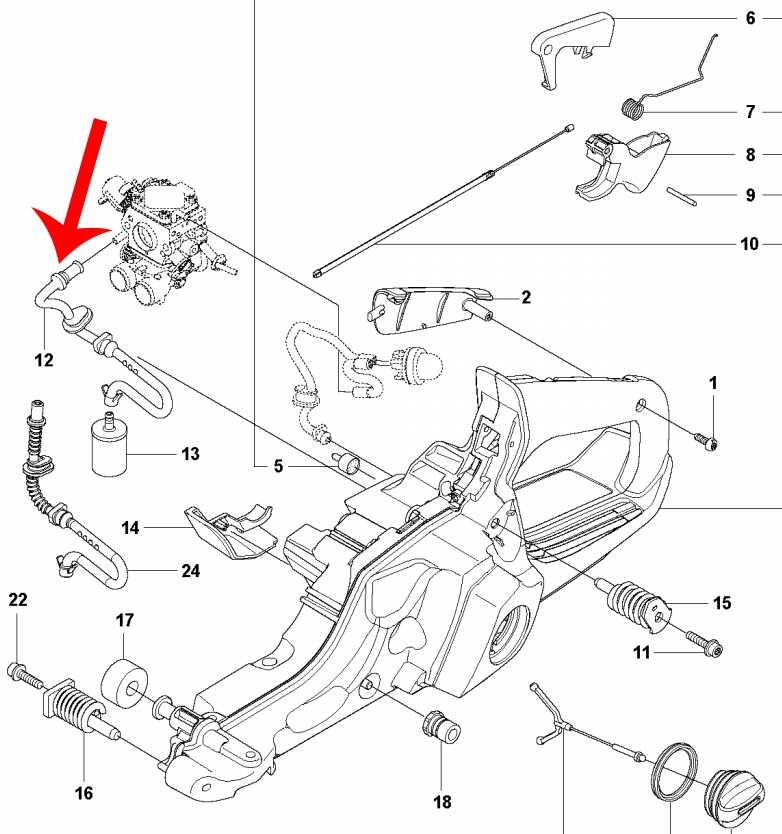

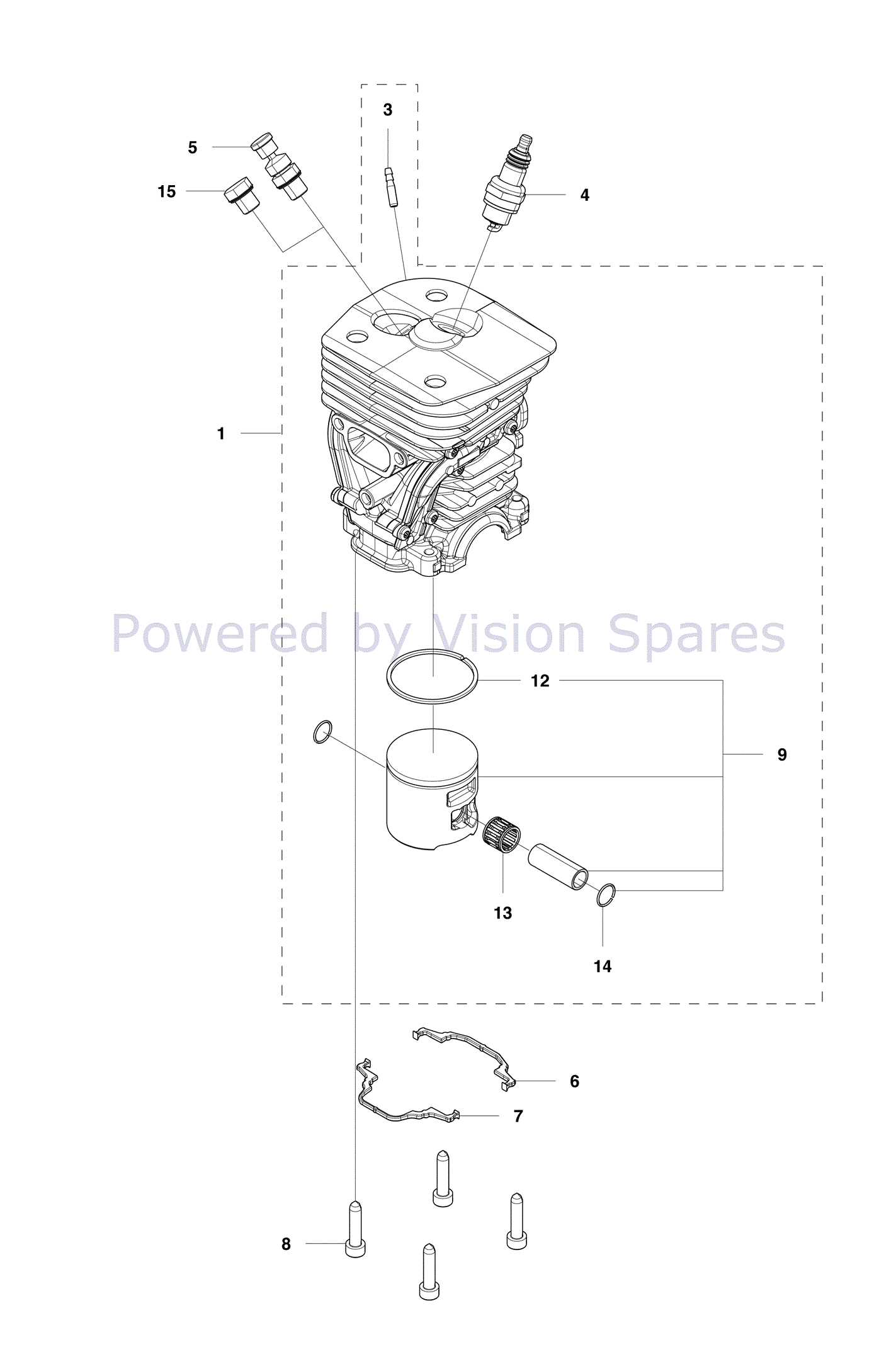

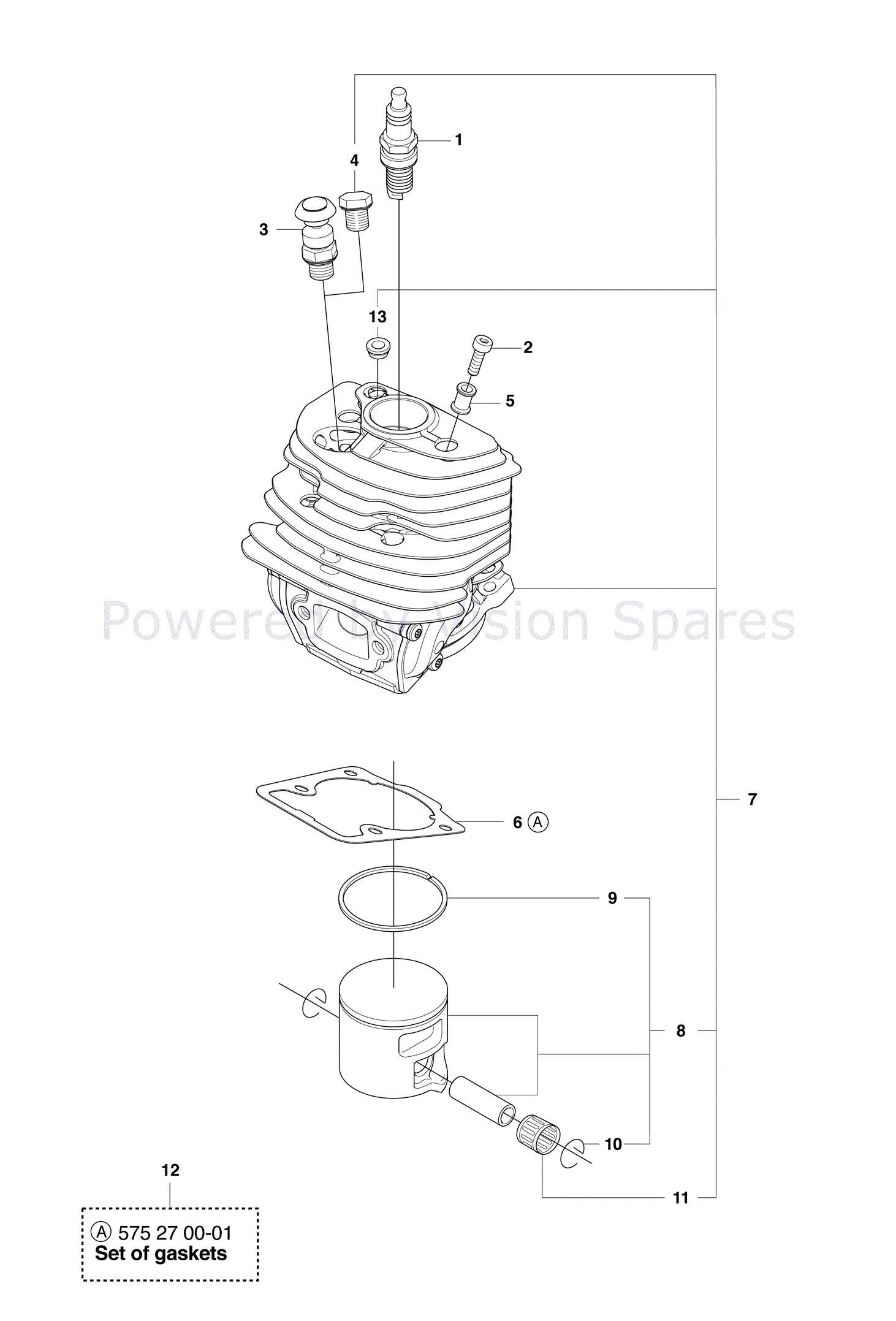

Starting Difficulties: One of the most prevalent issues is trouble initiating the engine. This can result from a variety of factors, such as a clogged fuel filter, incorrect fuel mixture, or a malfunctioning ignition system. Regular inspection of these components can prevent such frustrations.

Chain Stalling: Another common complication involves the cutting chain stalling during operation. This may be attributed to dull blades, improper tension, or even obstructions in the cutting path. Ensuring that the chain is well-maintained and properly adjusted is crucial for smooth operation.

Vibration Problems: Excessive vibration during use can indicate underlying mechanical issues. This might be related to loose screws, worn-out bearings, or an imbalanced cutting mechanism. Addressing these concerns promptly can enhance comfort and performance.

Fuel Leaks: Fuel leaks are not only inconvenient but can also pose safety hazards. Identifying the source of a leak–be it from hoses, gaskets, or the fuel tank itself–allows for timely repairs and safe usage.

Being aware of these common challenges enables users to proactively maintain their equipment, ensuring optimal performance and longevity. Regular inspections and prompt repairs can greatly enhance the experience of operating these powerful tools.

How to Read a Parts Diagram

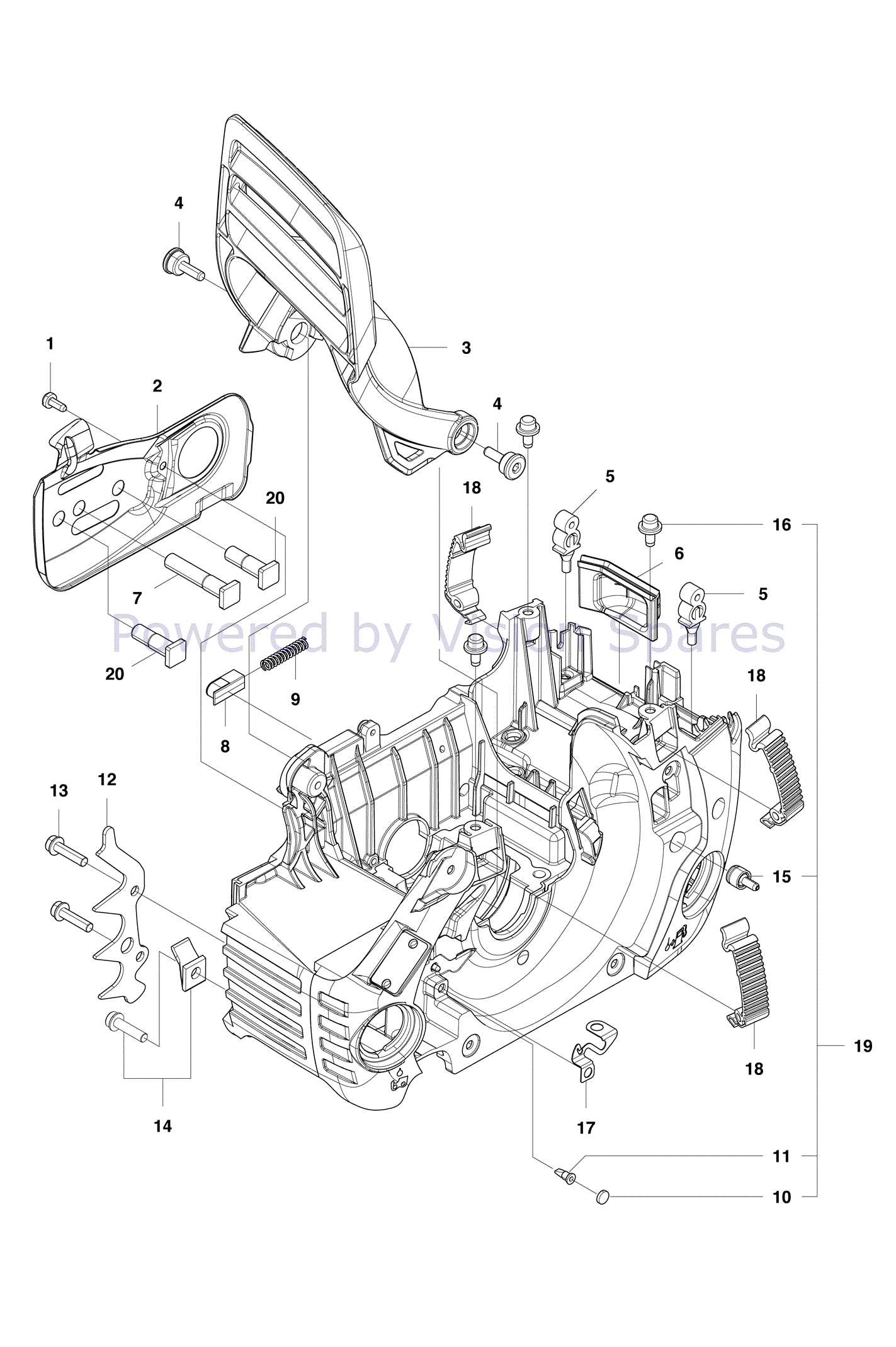

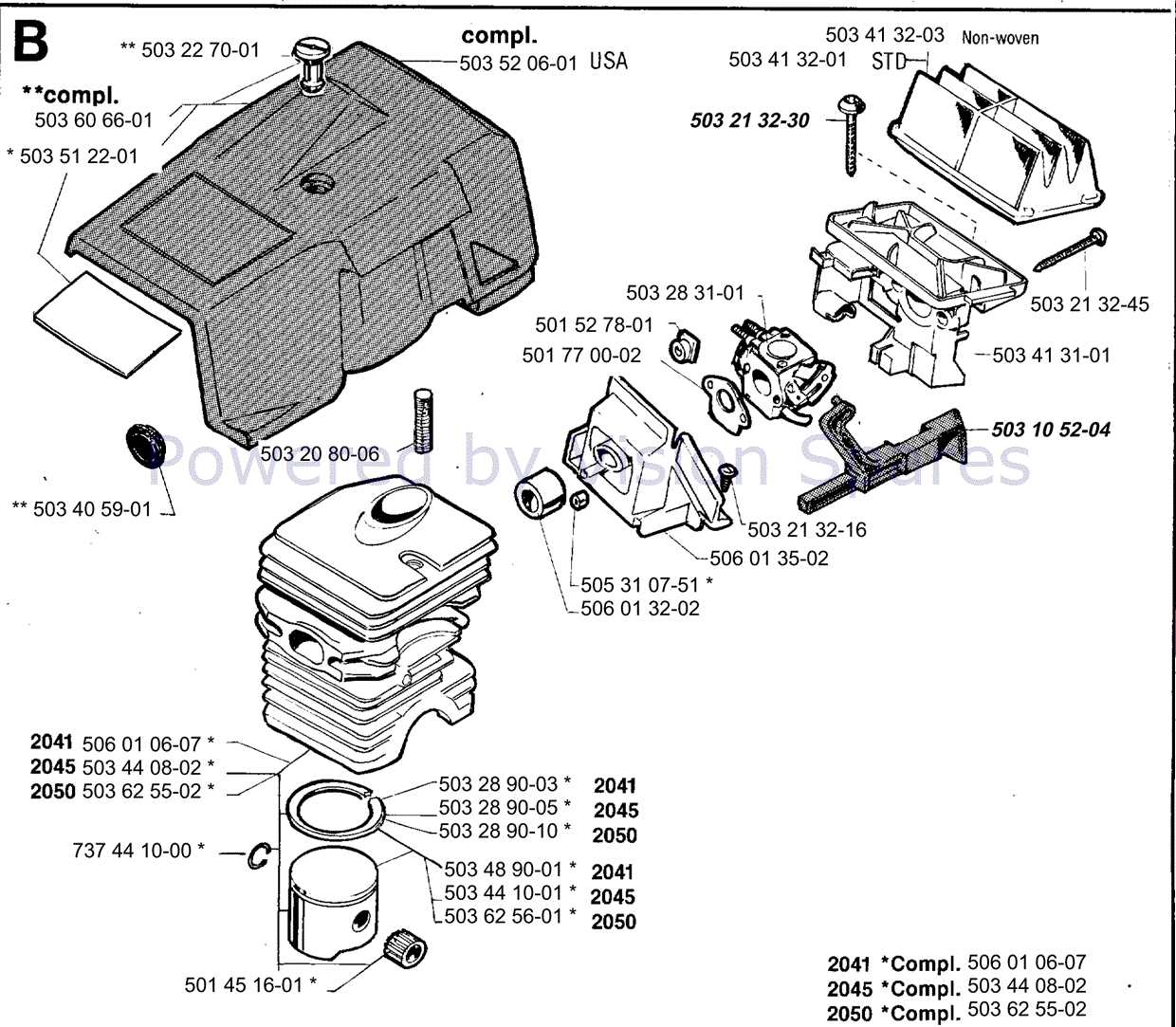

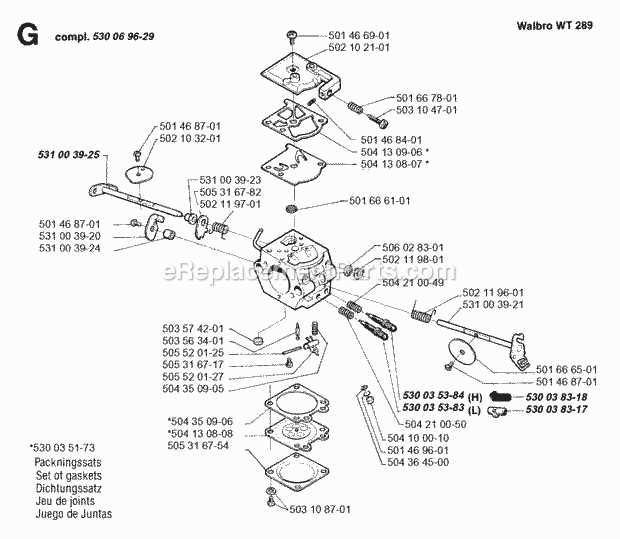

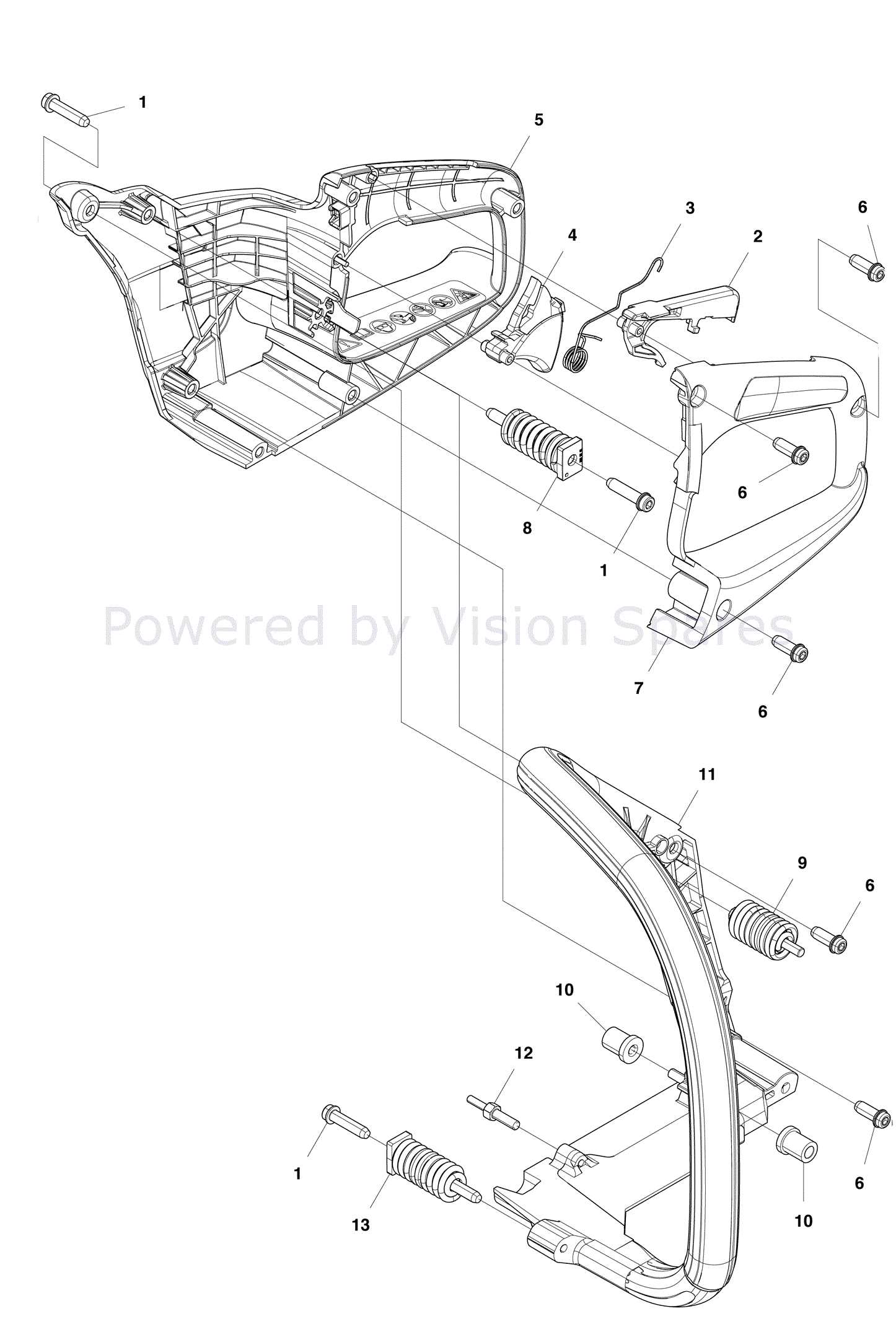

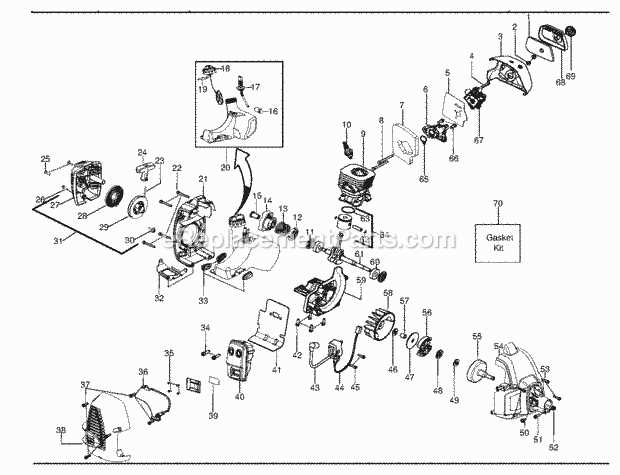

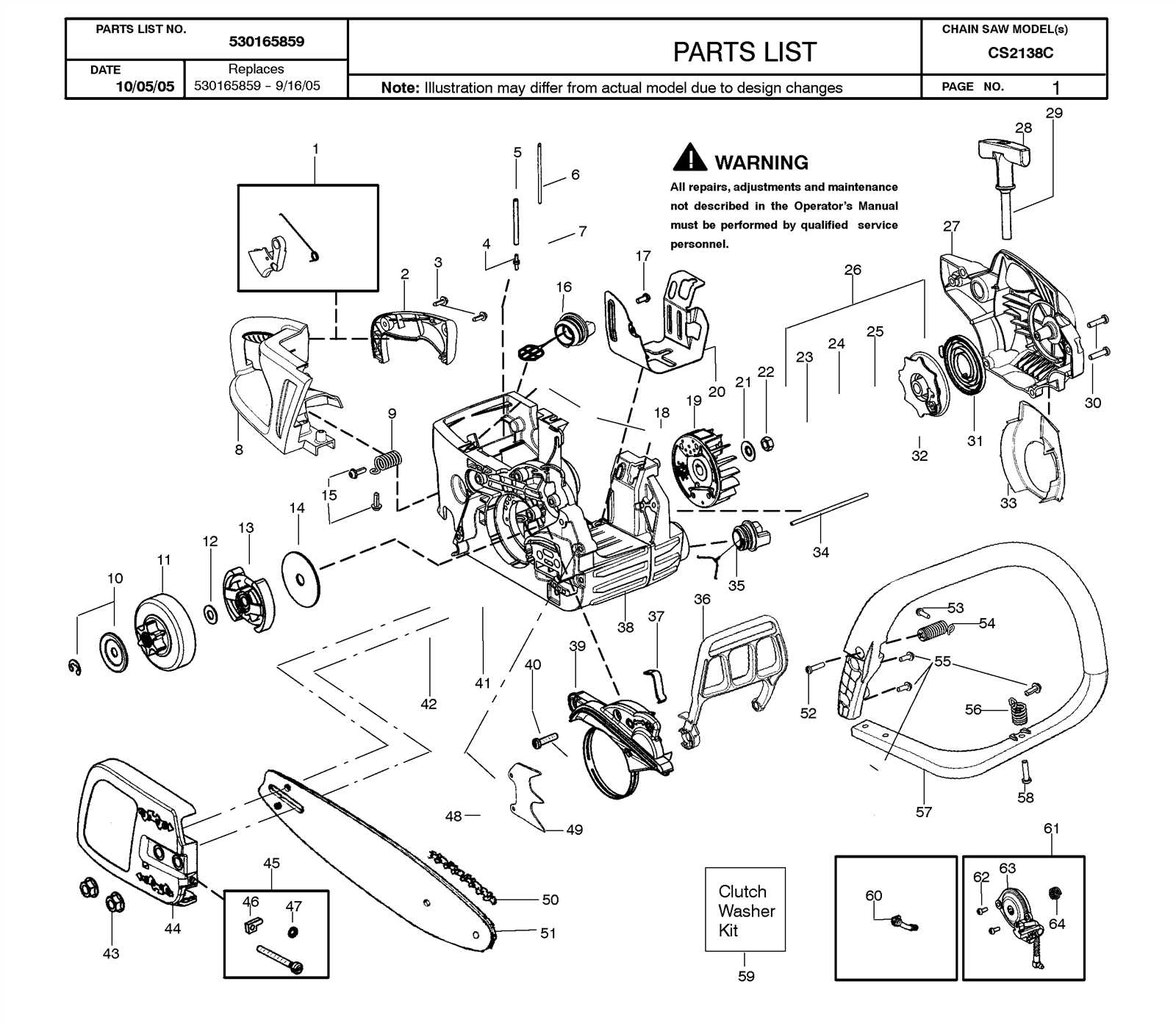

Understanding an assembly illustration is essential for effective maintenance and repair. This visual representation helps you identify components, their arrangement, and how they interact within a larger system. Here’s how to effectively interpret these illustrations for optimal use.

First, familiarize yourself with the layout:

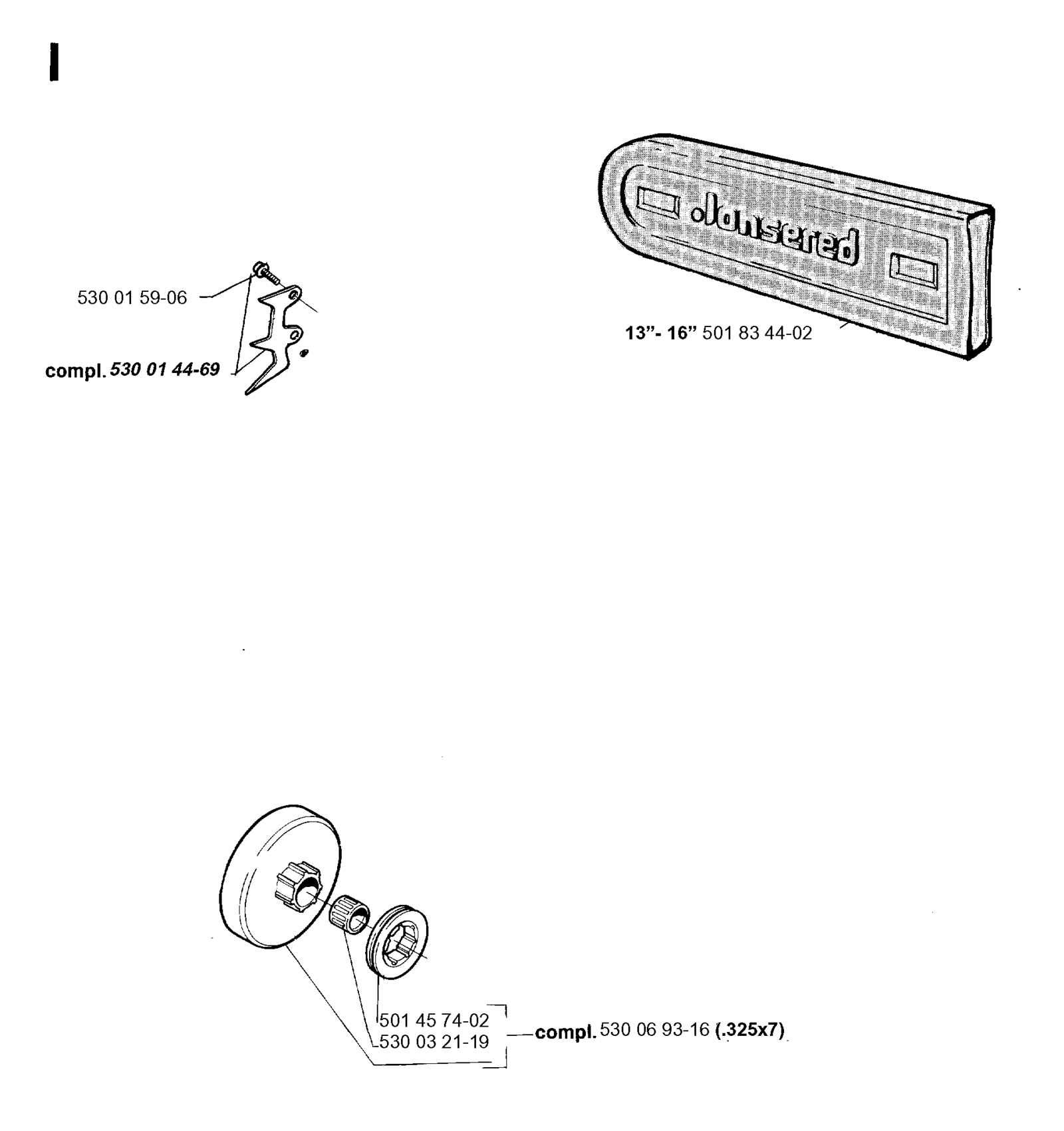

- Components: Each element is labeled, often with a reference number. This is crucial for cross-referencing with a list of items.

- Assembly Order: The illustration usually indicates how parts fit together, showing the sequence of assembly or disassembly.

- Connections: Look for lines or arrows that indicate how components are linked, which can help in understanding functionality.

Next, follow these steps to enhance comprehension:

- Identify Key Parts: Start by locating major sections and noting their relationships to each other.

- Refer to the Legend: Many illustrations include a legend explaining symbols and colors, aiding in better understanding.

- Consult Additional Resources: Pair the illustration with a parts list or manual for more context about each element’s role.

By mastering the interpretation of these visual aids, you can significantly improve your repair skills and troubleshooting efficiency.

Essential Replacement Parts Overview

Understanding the key components of outdoor power equipment is crucial for maintaining optimal performance. Knowing which elements are prone to wear and tear allows users to proactively manage their tools, ensuring longevity and efficiency.

When considering replacements, several critical components stand out:

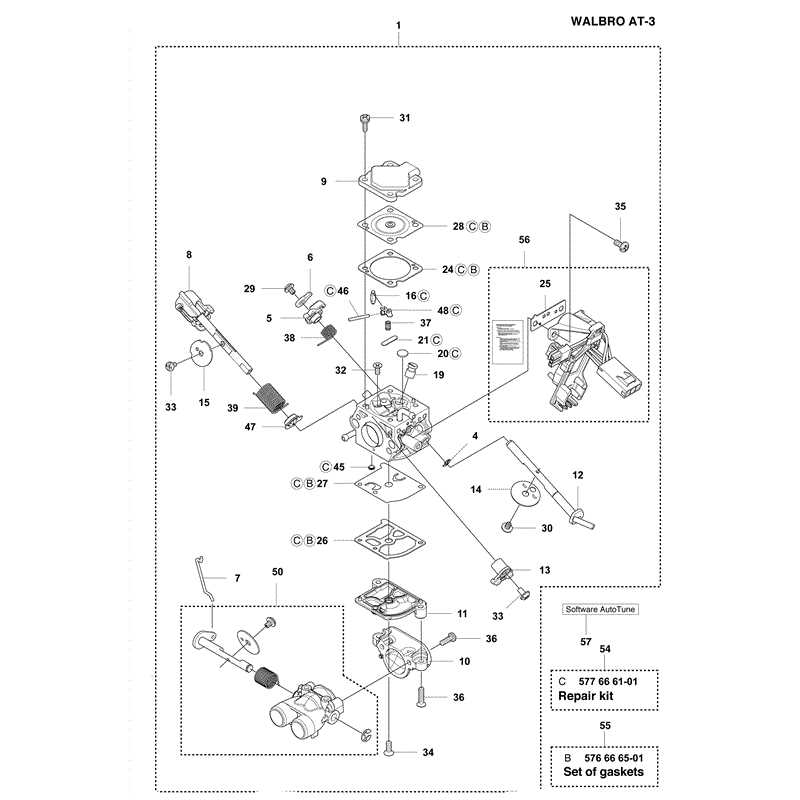

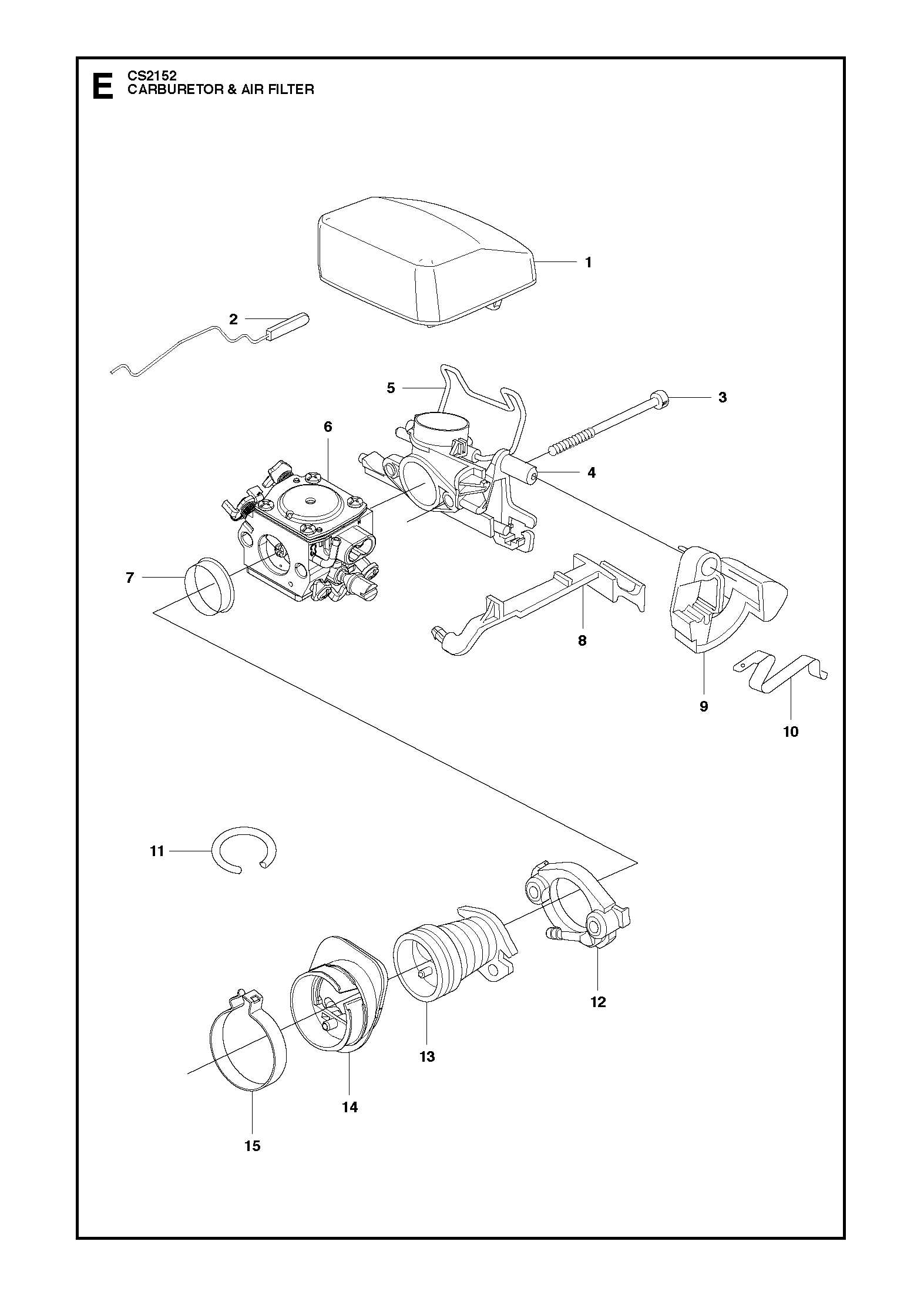

- Fuel System: Includes elements like the fuel filter and carburetor, essential for proper engine function.

- Ignition Components: Spark plugs and ignition coils play a vital role in starting the engine and maintaining its performance.

- Chain Assembly: The chain and bar are critical for cutting efficiency, requiring regular inspection and replacement to ensure safety.

- Air Filtration: A clean air filter is necessary for optimal engine performance, preventing dust and debris from causing damage.

- Drive Mechanisms: Gears and clutches facilitate the transfer of power, making them essential for effective operation.

Maintaining an inventory of these fundamental components can enhance the operational lifespan of your equipment, allowing for timely repairs and consistent performance. Always consult the manufacturer’s recommendations for specific compatibility and maintenance guidelines.

Where to Find Parts Diagrams

Finding detailed illustrations of components for machinery can significantly simplify the repair and maintenance process. These resources provide clarity on the various elements and their configurations, making it easier to identify what is needed for your specific model.

There are several reliable sources where you can access these valuable resources:

- Manufacturer Websites: Most brands offer downloadable manuals and visuals on their official sites. Look for sections dedicated to support or customer service.

- Online Retailers: Websites that specialize in equipment sales often provide access to schematic illustrations along with the option to purchase parts directly.

- Forums and Communities: Online communities and discussion forums focused on machinery can be excellent places to find shared resources. Experienced users often upload diagrams for various models.

- Service Centers: Authorized service centers can provide official documentation upon request. They may also assist in identifying and ordering the correct components.

- Specialty Books and Guides: Many publications focus on maintenance and repair, including detailed schematics for various types of equipment.

Utilizing these resources will not only aid in finding the necessary components but also enhance your understanding of the equipment’s structure and functionality.

Maintenance Tips for Jonsered Chainsaws

Proper upkeep is essential for ensuring the longevity and performance of your cutting tool. Regular maintenance helps prevent breakdowns, enhances efficiency, and ensures safe operation. Below are some key practices that will help keep your equipment in top condition.

Begin with routine inspections to identify any wear and tear on vital components. This includes checking the chain, bar, and air filter for damage or clogging. Regular cleaning and lubrication are crucial to prevent rust and ensure smooth operation.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Inspect the Chain | After every use | Look for dullness or damage; sharpen or replace as needed. |

| Check the Bar | Weekly | Ensure it’s free of debris and well-lubricated. |

| Clean the Air Filter | Monthly | Remove dust and debris; replace if excessively dirty. |

| Inspect Fuel System | Before each use | Ensure fuel is fresh and lines are free of leaks. |

| Sharpen the Chain | As needed | Use the appropriate tools for sharpening; maintain the correct angle. |

Following these guidelines will help maintain optimal performance and extend the life of your cutting tool. Always refer to the manufacturer’s recommendations for specific maintenance tasks and intervals.

Ordering Parts for Your Chainsaw

Maintaining your power tool in optimal condition requires access to quality components. Whether you’re conducting routine maintenance or addressing a specific issue, knowing how to procure the necessary items efficiently can make a significant difference. This section will guide you through the process of acquiring the right replacements for your machine.

Where to Find Components

- Authorized Dealers: Start by checking with certified retailers who specialize in your brand. They often have the most reliable stock and expert advice.

- Online Stores: Numerous e-commerce platforms offer a wide selection of items. Ensure that you are purchasing from reputable websites to avoid counterfeit products.

- Local Repair Shops: Visiting nearby service centers can be beneficial. They may have spare items available or can order them for you.

Tips for Ordering

- Identify the Correct Item: Before making a purchase, ensure you know the exact name or number of the component you need. This will prevent mix-ups.

- Check Compatibility: Verify that the part is suitable for your specific model to avoid compatibility issues.

- Review Return Policies: Familiarize yourself with the return options in case the item does not meet your expectations or is incorrect.

- Compare Prices: Look at various sources to find competitive pricing. Sometimes, shipping costs can significantly affect the overall price.

Identifying Components in the Diagram

Understanding the intricate layout of a machine can significantly enhance maintenance and repair efforts. By examining the visual representation of its elements, users can more easily pinpoint specific parts and their functions. This clarity not only aids in troubleshooting but also facilitates efficient assembly and disassembly processes.

Key Features to Recognize

When analyzing the visual schematic, focus on color coding and labeling. Different hues may indicate various categories of components, while labels provide essential information regarding each part’s role. Familiarizing yourself with these features allows for quicker identification and comprehension of the overall system.

Common Component Categories

Components can typically be grouped into several categories, such as mechanical, electrical, and structural elements. Recognizing these groups will streamline the identification process, making it easier to locate specific parts when needed. Additionally, understanding the relationship between these categories enhances the user’s ability to diagnose issues effectively.

Aftermarket vs. Original Parts

When it comes to maintaining outdoor power equipment, the choice between alternative components and manufacturer-specific items can significantly impact performance and longevity. Understanding the advantages and disadvantages of each option is crucial for making informed decisions that align with individual needs and budget constraints.

Original components are designed specifically for particular models, ensuring compatibility and optimal functionality. Here are some of their benefits:

- Guaranteed fit and performance.

- Manufactured to meet industry standards.

- Typically come with warranties or guarantees.

On the other hand, aftermarket alternatives often attract users due to their lower price points and availability. Some key points to consider include:

- Cost-effective options that can save money.

- A wide variety of choices from different manufacturers.

- Potential for improved features or performance enhancements.

However, it is important to weigh these factors carefully. While alternative items may offer immediate savings, they might not always deliver the same quality or durability as their original counterparts. Additionally, using non-standard components could potentially void warranties or lead to compatibility issues.

Ultimately, the decision between these two types of components should be based on a balance of budget, expected use, and long-term maintenance plans.

DIY Repairs Using the Diagram

Understanding the layout and components of your equipment can significantly enhance your ability to perform maintenance and repairs. Utilizing a detailed schematic allows enthusiasts and professionals alike to identify issues and replace faulty elements with ease. This section will explore how to effectively use a visual reference for do-it-yourself fixes.

By following a clear visual guide, you can:

- Quickly locate specific components that may need attention.

- Gain insight into the assembly and disassembly process.

- Understand the relationships between various parts and systems.

Here’s a step-by-step approach to make the most of your reference:

- Identify the Issue: Start by diagnosing the problem you are facing.

- Consult the Visual Aid: Use the schematic to pinpoint the relevant section related to your issue.

- Gather Tools: Ensure you have the necessary tools and replacement elements on hand before beginning the repair.

- Follow the Steps: Carefully follow the instructions, using the visual guide as your roadmap.

- Test Your Work: After completing the repair, test the equipment to confirm that it functions correctly.

With a little patience and the right approach, you can tackle many repairs yourself, ensuring your equipment remains in optimal condition for years to come.