Aqua Flo XP2 Parts Diagram Overview

In the realm of pool maintenance and management, having a clear understanding of the internal structure of your equipment is essential. A comprehensive overview of the various elements within your system can significantly enhance both performance and efficiency. By familiarizing yourself with the arrangement of these crucial components, you can ensure optimal operation and prolong the lifespan of your setup.

Visualizing the arrangement of different units plays a vital role in troubleshooting and repairs. Recognizing how each part interconnects allows for more informed decisions when addressing issues or planning upgrades. With this knowledge, you empower yourself to take charge of maintenance, minimizing downtime and costly repairs.

This exploration not only benefits experienced users but also serves as an invaluable resource for newcomers. By breaking down the intricate network of components, we can demystify the inner workings and help you gain confidence in managing your equipment. Let’s delve into this insightful analysis, paving the way for more efficient upkeep and operation.

Aqua Flo XP2 Overview

This section provides an insight into a specific type of equipment used for circulation and filtration in aquatic environments. Its design focuses on efficiency, durability, and performance, making it a popular choice among enthusiasts and professionals alike.

Key Features

The system boasts several advanced characteristics that enhance its functionality. It includes a robust motor, superior energy efficiency, and a streamlined structure that allows for easy installation and maintenance.

Applications

This equipment is suitable for various settings, including residential pools, spas, and commercial facilities. Its versatility ensures optimal performance across different water conditions and usage scenarios.

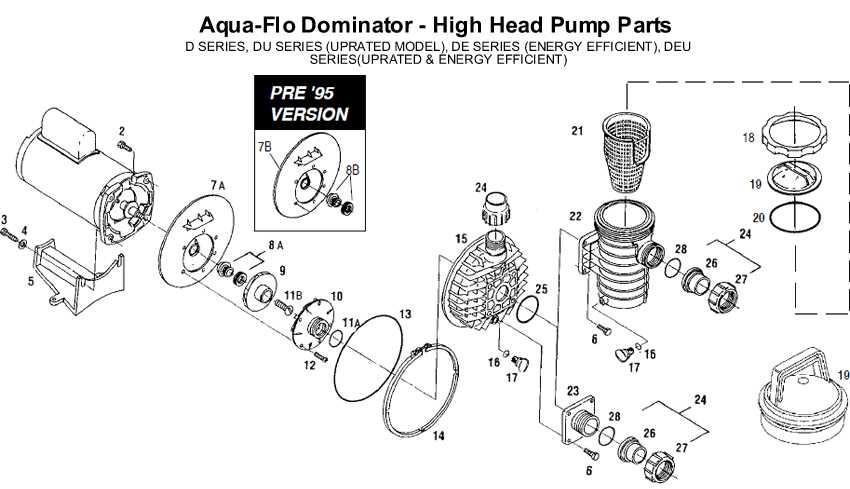

Key Components of the XP2 System

The efficient operation of this advanced setup relies on several essential elements that work in harmony to deliver optimal performance. Each component plays a critical role in ensuring reliability and effectiveness, contributing to the overall functionality of the system.

| Component | Description |

|---|---|

| Motor | Powers the entire system, ensuring smooth operation and adequate flow rates. |

| Filter | Removes debris and contaminants from the water, maintaining cleanliness and clarity. |

| Pump Housing | Encases the pump and protects it from external elements, providing structural integrity. |

| Impeller | Facilitates the movement of water, crucial for maintaining circulation and pressure. |

| Control System | Regulates the operation of the system, allowing for adjustments and monitoring of performance. |

Understanding these fundamental elements is key to troubleshooting and optimizing the system’s capabilities. Proper maintenance and knowledge of each component can significantly enhance longevity and efficiency.

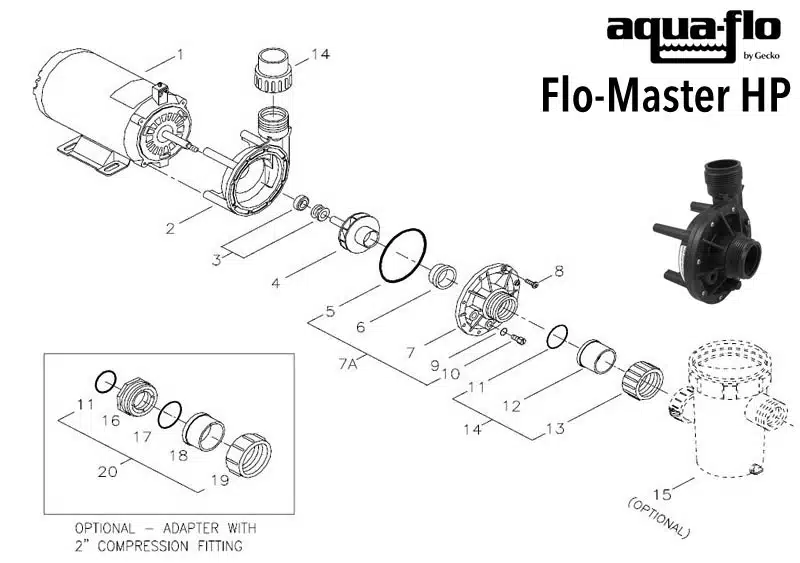

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for efficient maintenance and repair. This illustration serves as a roadmap, guiding users through the various elements and their interconnections. By familiarizing oneself with these details, one can enhance the performance and longevity of the equipment.

Key Elements Explained

Each segment of the visual representation has a specific function and significance. Recognizing these features can lead to informed decisions during servicing. Here are some vital components:

| Component | Description |

|---|---|

| Motor | The driving force behind the system, converting electrical energy into mechanical motion. |

| Impeller | A rotating device that facilitates the movement of fluid within the system. |

| Seal | A protective barrier that prevents leakage and ensures the integrity of the unit. |

| Housing | The outer shell that contains and protects the internal components. |

Importance of Accurate Representation

Having an accurate visual guide not only simplifies the troubleshooting process but also minimizes the risk of errors during assembly or disassembly. Understanding each part’s placement and relationship to others is crucial for optimal functioning and repairs.

Common Issues with XP2 Components

When dealing with components of aquatic systems, several common problems can arise that affect performance and efficiency. Understanding these issues is crucial for effective maintenance and troubleshooting. Here, we outline typical challenges faced by users, as well as potential solutions to enhance system reliability.

| Issue | Description | Solution |

|---|---|---|

| Leakage | Water escaping from joints or connections can lead to reduced efficiency. | Inspect seals and tighten connections; replace worn gaskets. |

| Clogging | Debris accumulation can hinder flow and affect operation. | Regularly clean filters and screens; ensure proper water flow. |

| Noisy Operation | Unusual sounds may indicate mechanical issues or misalignment. | Check for loose parts and realign components as necessary. |

| Overheating | Excessive heat can damage internal components and reduce lifespan. | Ensure adequate ventilation and monitor operating temperatures. |

| Inconsistent Performance | Fluctuations in output may signal underlying problems. | Evaluate electrical connections and inspect for wear. |

Maintenance Tips for Aqua Flo XP2

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances efficiency but also helps prevent potential issues that could lead to costly repairs. Following a structured approach to care can save time and resources in the long run.

1. Routine Inspection: Schedule regular checks to identify any signs of wear or damage. Look for leaks, unusual noises, or vibrations that may indicate underlying problems. Early detection can prevent more significant failures.

2. Cleaning: Keep components clean and free from debris. Accumulation of dirt and buildup can hinder performance. Use a soft brush or cloth to gently remove any residues, and ensure that all vents and filters are clear.

3. Lubrication: Ensure that moving parts are adequately lubricated to minimize friction and wear. Use appropriate lubricants as specified in the manufacturer’s guidelines to maintain smooth operation.

4. Check Seals and Gaskets: Inspect seals and gaskets for cracks or deterioration. Replacing worn seals can prevent leaks and maintain system integrity, ensuring everything operates efficiently.

5. Seasonal Maintenance: Adapt your maintenance routine according to seasonal changes. For instance, if the equipment is exposed to extreme temperatures, additional care may be required to prevent damage.

6. Consult the Manual: Always refer to the user manual for specific maintenance recommendations and schedules. Understanding the manufacturer’s guidance is crucial for proper care and optimal functioning.

By implementing these practices, you can ensure your system remains in excellent condition, reducing the likelihood of unexpected issues and prolonging its lifespan.

How to Replace Faulty Parts

Replacing malfunctioning components in your system is essential for maintaining optimal performance and longevity. Understanding the proper procedures and tools required can help ensure a smooth and efficient process. This guide outlines the necessary steps to identify, remove, and install new elements effectively.

Begin by assessing the unit to pinpoint the specific component that needs attention. Carefully consult the manual for reference, and make sure to gather the appropriate replacement items before proceeding. Having everything on hand will streamline the process and minimize downtime.

Once you’ve identified the faulty element, turn off the power supply to avoid any accidents. Use the right tools to detach the defective component, taking care to note how it is connected for easier reassembly. Handle all parts with caution to prevent damage.

After removal, prepare the area for installation of the new component. Ensure that the surrounding areas are clean and free of debris. Insert the new piece according to the guidelines, making sure it fits securely and is aligned correctly. Follow the same steps in reverse to reconnect everything safely.

Finally, restore power and perform a test to confirm that the replacement was successful. Observing the system’s operation can help verify that everything is functioning as it should. Regular checks and maintenance will further enhance the durability of your equipment.

Benefits of Using Quality Replacement Parts

Utilizing high-quality components for repairs and upgrades offers numerous advantages that significantly enhance the performance and longevity of equipment. Selecting superior alternatives ensures that the functionality remains consistent with original specifications, minimizing the risk of failure and enhancing overall efficiency.

One of the primary benefits is improved reliability. Quality replacements are typically manufactured to stringent standards, which means they are less likely to malfunction or wear out prematurely. This reliability translates into reduced downtime, allowing users to focus on their tasks without frequent interruptions for maintenance.

Another important aspect is the cost-effectiveness of using durable alternatives. While the initial investment may be higher, the long-term savings become apparent as the need for replacements diminishes. High-quality components often come with warranties, providing peace of mind and protecting against unexpected expenses.

Furthermore, opting for superior materials contributes to enhanced safety. Reliable components reduce the likelihood of accidents caused by equipment failure, ensuring a safer working environment. This is particularly crucial in settings where safety regulations are paramount.

Lastly, choosing top-notch replacements can lead to improved performance. These components are designed to work seamlessly with existing systems, enhancing efficiency and productivity. By prioritizing quality, users can ensure their equipment operates at its best for years to come.

Identifying Genuine Aqua Flo Components

Recognizing authentic elements in a specific product line is crucial for ensuring optimal performance and longevity. Counterfeit components may seem similar at first glance but often lack the quality and reliability of their genuine counterparts. This section aims to equip users with the knowledge needed to distinguish between authentic and imitation items.

Visual Inspection

Begin with a thorough examination of the components. Genuine items typically feature precise manufacturing details, including logos and model numbers. Look for signs of craftsmanship such as smooth edges and consistent colors. High-quality materials are often more durable and have a distinct feel compared to subpar alternatives.

Documentation and Packaging

Authentic products usually come with detailed documentation and branded packaging. Check for certificates of authenticity and warranty information. Reputable manufacturers take pride in their packaging, ensuring that it reflects their brand’s integrity.

Comparing XP2 to Other Models

When evaluating the performance and features of different pump systems, it’s essential to consider how each model stacks up against others in the market. This section aims to highlight the distinctions and similarities between various options, focusing on efficiency, durability, and user-friendliness.

Performance Metrics

- Flow Rate: Assessing the maximum flow capabilities can reveal which models are better suited for larger pools or water features.

- Energy Consumption: Comparing the power usage helps determine long-term operational costs and environmental impact.

- Noise Levels: Evaluating sound output during operation can affect user satisfaction and suitability for residential areas.

Durability and Maintenance

- Material Quality: Different constructions can influence longevity and resistance to wear and tear.

- Ease of Maintenance: Models that are simpler to service can reduce downtime and improve user experience.

- Warranty and Support: Comparing coverage options provides insight into manufacturer confidence and customer support.

By examining these key aspects, potential users can make informed decisions based on their specific needs and preferences, ensuring they select the most suitable system for their requirements.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your aquatic system can significantly elevate its overall performance. Implementing strategic enhancements not only optimizes water circulation but also boosts energy efficiency, ensuring that the setup operates at its best. Whether you are a hobbyist or a professional, exploring various upgrade options can lead to remarkable benefits.

One effective approach is to invest in advanced filtration systems. High-quality filters can drastically improve water clarity and quality, reducing the frequency of maintenance. Additionally, consider incorporating energy-efficient pumps that offer better flow rates while consuming less electricity. This transition not only helps the environment but also reduces operating costs over time.

Moreover, the integration of smart technology can greatly enhance user experience. Automated monitoring systems can track water parameters and adjust settings in real-time, ensuring optimal conditions for aquatic life. These innovations allow for greater control and peace of mind, making maintenance easier and more efficient.

Finally, enhancing your setup with better lighting solutions can have profound effects on the overall ecosystem. LED lighting, for example, provides efficient illumination while promoting healthy growth in aquatic plants. These upgrades contribute to a balanced environment, ultimately leading to a thriving habitat.