Comprehensive Guide to Rck60-24b Parts Diagram

The intricate world of mechanical systems often hinges on the seamless integration of various elements. A comprehensive understanding of these configurations is essential for anyone engaged in maintenance or assembly. By visualizing how each piece fits within the larger structure, one can enhance both efficiency and functionality.

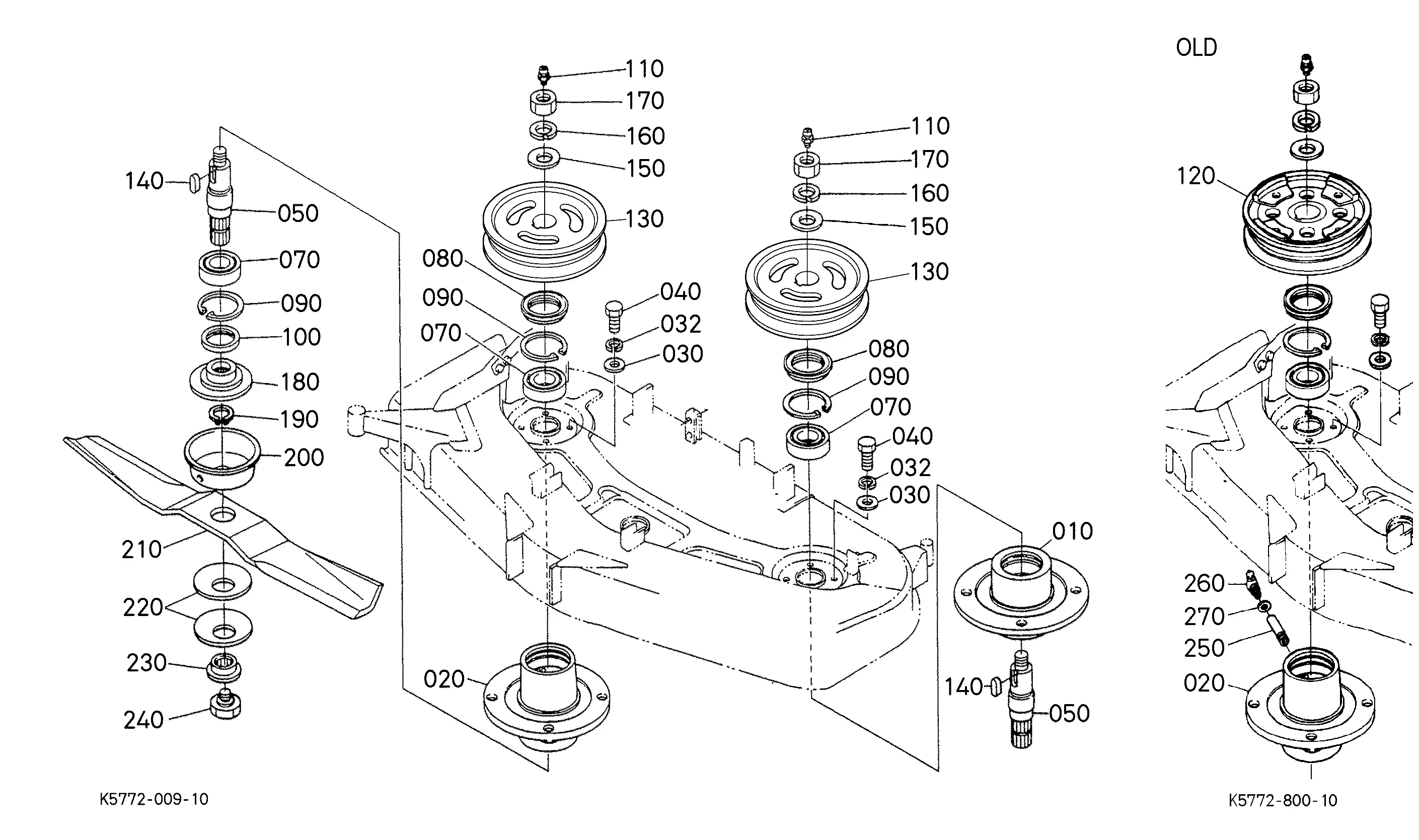

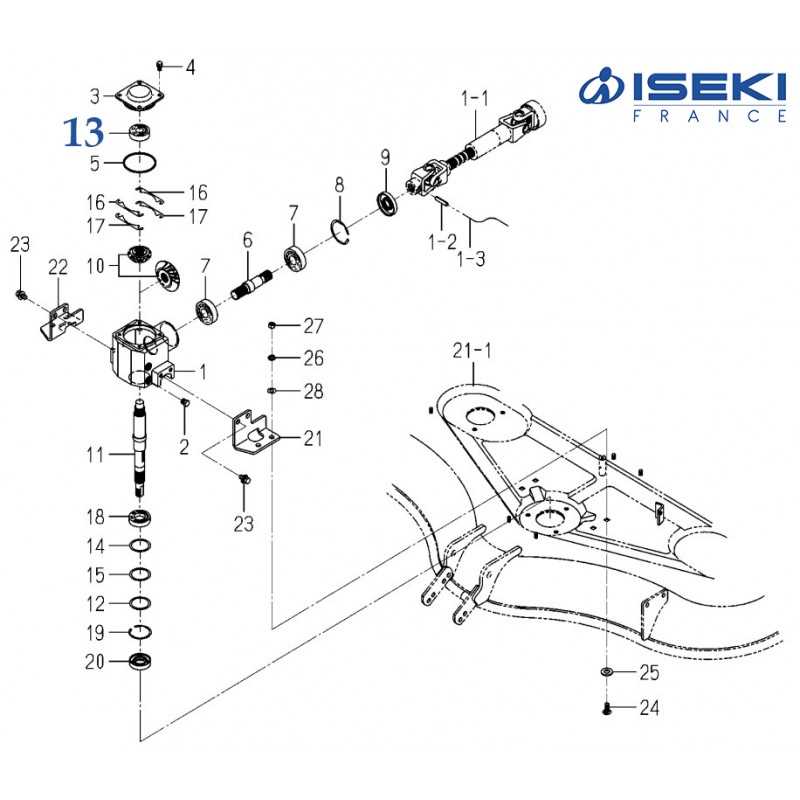

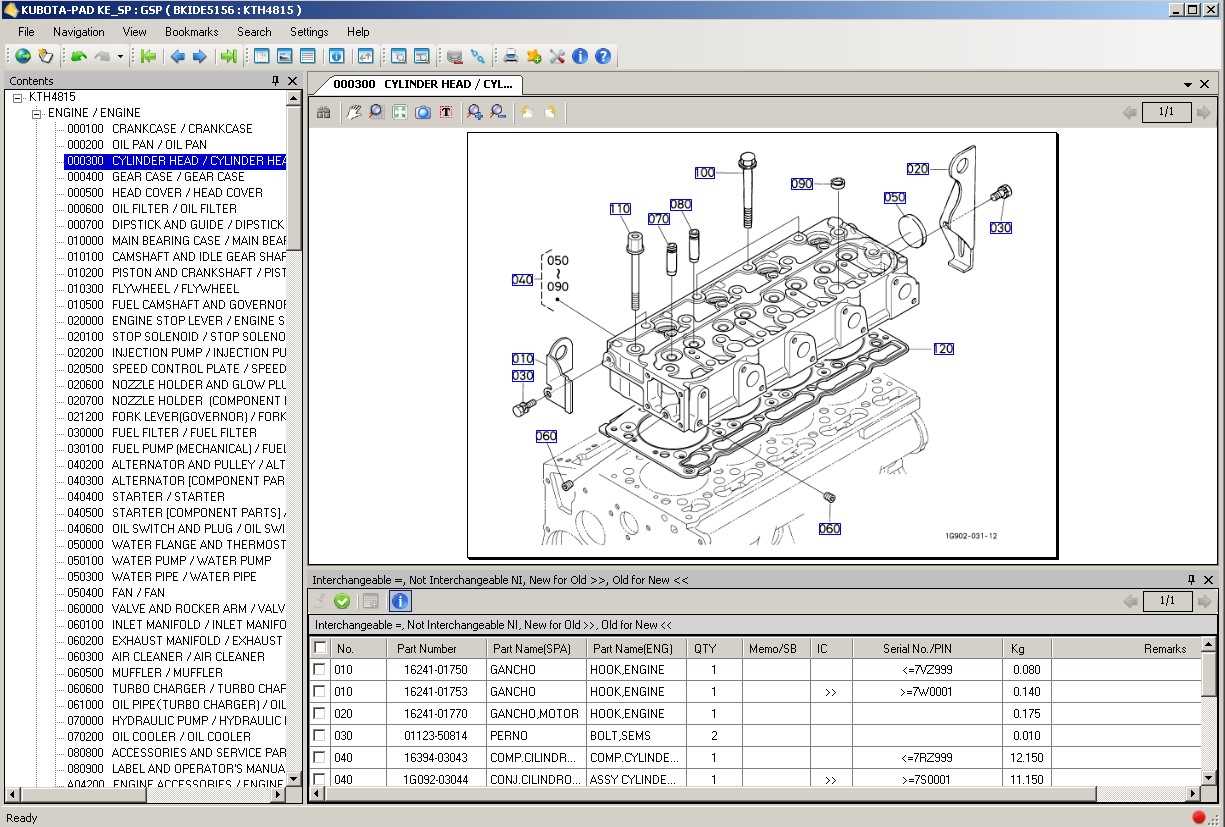

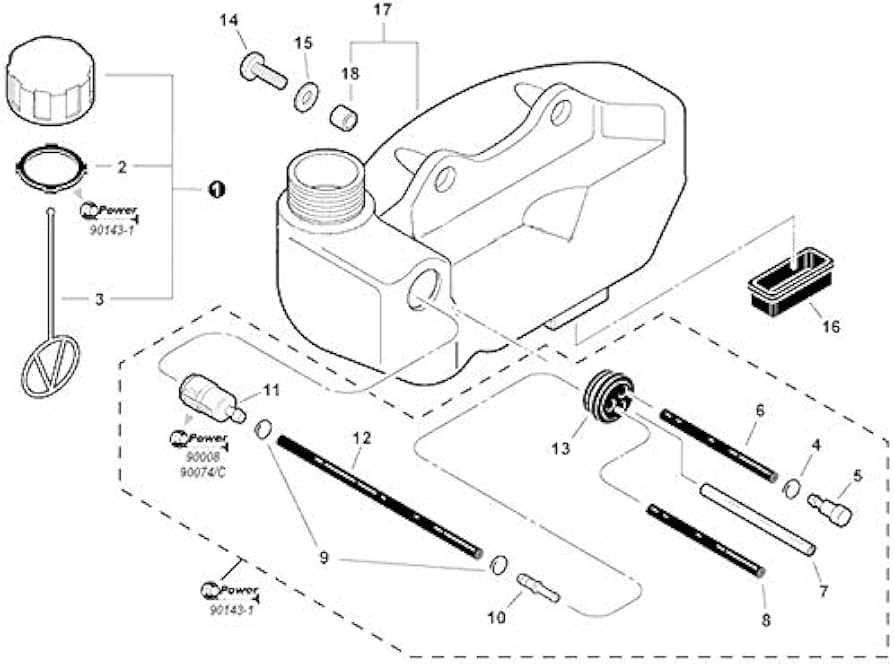

Detailed representations serve as invaluable guides, revealing the relationships and interactions among components. These illustrations not only clarify the positioning of each unit but also highlight critical connections that are vital for optimal performance. Whether you’re troubleshooting an issue or planning an upgrade, these resources are key to informed decision-making.

As technology continues to evolve, so does the complexity of these arrangements. Familiarizing oneself with the specific layout of each system is paramount for professionals in the field. Engaging with these visual aids can lead to a deeper appreciation of the design and engineering that underpin modern machinery.

Understanding the Rck60-24b Parts

This section aims to provide clarity on the components that make up a specific model, emphasizing their functions and interrelations. A thorough understanding of each element is crucial for effective maintenance and operation. Knowledge of these components can enhance both performance and longevity.

Key Components and Their Functions

Each element within the system plays a vital role in ensuring optimal functionality. Familiarity with these components allows users to troubleshoot issues and perform necessary upgrades or repairs efficiently.

Component Overview Table

| Component | Description |

|---|---|

| Unit A | Responsible for the primary operations and functionality of the system. |

| Unit B | Serves as a support structure, enhancing stability and performance. |

| Unit C | Facilitates connectivity between different elements, ensuring smooth interaction. |

| Unit D | Acts as a control center, managing the overall system activities and responses. |

Components of the Rck60-24b Model

The assembly of any complex system relies on the interplay of various elements that contribute to its overall functionality. Understanding these components is essential for effective maintenance and optimal performance. Each individual part plays a unique role, enhancing the system’s efficiency and reliability.

Moreover, sensors are crucial for monitoring performance and providing real-time feedback, allowing for adjustments to be made as needed. The integration of these various components creates a cohesive unit that not only meets operational demands but also ensures longevity and ease of use.

Importance of Accurate Parts Diagrams

Precise visual representations are essential for understanding complex systems and machinery. They serve as critical references that help users identify components and their relationships within a unit. Such clarity not only aids in maintenance and repairs but also enhances overall efficiency in operations.

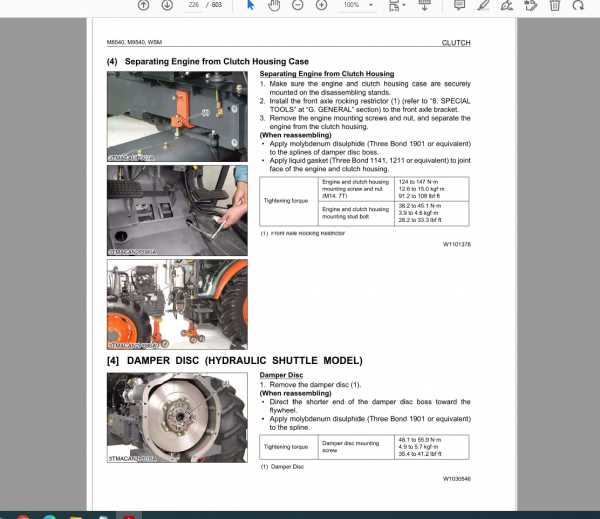

Detailed schematics provide a roadmap for technicians, enabling them to troubleshoot issues swiftly. When components are clearly labeled, it reduces the risk of errors during assembly or disassembly, ultimately leading to improved performance.

Furthermore, accurate visual guides are invaluable for training new personnel. They empower individuals to grasp intricate mechanisms, fostering confidence and competence in handling equipment. The ultimate goal is to minimize downtime and optimize functionality across various applications.

Common Issues with Rck60-24b Parts

When dealing with mechanical components, various challenges can arise that affect functionality and performance. Understanding these common concerns is crucial for effective troubleshooting and maintenance.

Frequent Challenges

- Wear and Tear: Over time, components can degrade, leading to inefficiencies.

- Misalignment: Improper installation can result in parts not fitting correctly, causing operational issues.

- Corrosion: Exposure to moisture can lead to rust and deterioration.

Symptoms to Watch For

- Unusual Noises: Grinding or squeaking sounds may indicate underlying issues.

- Performance Drops: A noticeable decrease in efficiency can signal problems.

- Leakage: Fluid leaks often point to seal or gasket failures.

Where to Find Replacement Parts

Finding the necessary components for maintenance or repair can often feel overwhelming. However, with the right resources and knowledge, you can streamline the process and ensure you obtain quality items efficiently.

Online Retailers

Many online platforms specialize in supplying essential components. Websites such as Amazon or specialized equipment suppliers offer a wide range of options, allowing you to compare prices and availability easily.

Local Distributors

Consider visiting local distributors or authorized service centers. They often stock the required items and can provide expert advice on installation and compatibility, ensuring you make the right choice.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective assembly and maintenance. These illustrations provide a clear overview of individual elements and their relationships, facilitating easier identification and management during repair or construction processes.

Decoding Symbols and Labels

Familiarize yourself with the various symbols and annotations that denote specific items and their functions. Each element typically includes a reference number, which correlates with a list of components, helping you quickly locate the necessary parts. Pay close attention to any special markings that indicate size, orientation, or compatibility.

Interpreting Connections and Layout

Analyze the arrangement of elements to understand how they interact with one another. Arrows or lines may illustrate connections, guiding you on how parts fit together. Recognizing these relationships is crucial for ensuring proper assembly and optimal performance of the entire system.

Maintenance Tips for Rck60-24b

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By implementing systematic care practices, you can prevent common issues and enhance functionality. This guide outlines crucial strategies to maintain efficiency and reliability.

Start with routine inspections to identify wear and tear. Check for any loose components and ensure all connections are secure. Lubricate moving parts periodically to reduce friction and prevent overheating.

Cleaning is vital; remove dust and debris to maintain airflow and cooling efficiency. Pay attention to filters and replace them as needed to ensure proper operation.

Monitor performance metrics regularly to catch any irregularities early. Keeping a maintenance log can help track changes over time and facilitate timely interventions.

Finally, always refer to the manufacturer’s guidelines for specific recommendations on care and upkeep. Following these tips will contribute to the ultimate reliability of your machinery.

Comparing Rck60-24b to Other Models

This section examines the nuances between a specific model and its counterparts in the same category, focusing on key features, performance metrics, and user experiences. Understanding these differences helps potential buyers make informed decisions tailored to their needs.

Key Features Comparison

| Model | Feature 1 | Feature 2 | Feature 3 |

|---|---|---|---|

| Model A | Detail 1 | Detail 2 | Detail 3 |

| Model B | Detail 1 | Detail 2 | Detail 3 |

| Model C | Detail 1 | Detail 2 | Detail 3 |

User Feedback Overview

Feedback from users highlights the strengths and weaknesses of various models, showcasing preferences in usability and efficiency. Insights into customer satisfaction can ultimately guide choices in selecting the best option available.

Expert Recommendations for Repairs

When it comes to maintenance and restoration of complex equipment, having a clear strategy is essential. Experts advise approaching repairs with a structured plan that ensures efficiency and longevity. This section outlines key recommendations to facilitate successful interventions.

Assessment and Planning

Before commencing any repair work, a thorough evaluation of the system’s condition is crucial. Understanding the specific issues and potential complications will guide the repair process. Here are some steps to consider:

| Step | Description |

|---|---|

| 1. Inspection | Conduct a detailed examination to identify wear, damage, or malfunction. |

| 2. Documentation | Keep a record of findings to track performance over time. |

| 3. Strategy Development | Create a repair plan that outlines necessary tools and parts needed. |

Execution and Follow-Up

Once the planning phase is complete, executing the repair with precision is vital. Adhering to manufacturer guidelines can prevent further issues. After repairs are completed, follow-up checks should be performed to ensure everything is functioning correctly. Regular maintenance routines can enhance the lifespan of the equipment and mitigate future problems.

Upgrading Components for Better Performance

Enhancing the efficiency and capability of machinery often involves the thoughtful selection and replacement of specific elements. By strategically upgrading individual components, users can experience improved functionality and longevity. This process not only boosts performance but also contributes to overall operational excellence.

When considering enhancements, it is essential to evaluate several key areas:

- Compatibility: Ensure that new components are compatible with existing systems to avoid operational disruptions.

- Quality: Opt for high-quality alternatives that offer durability and reliability under various conditions.

- Technological Advancements: Stay updated with the latest innovations that can provide significant advantages over older versions.

Before proceeding with upgrades, it is advisable to conduct a thorough analysis of current performance metrics. This helps in identifying the most beneficial areas for improvement.

- Identify Weak Points: Determine which components are underperforming or causing inefficiencies.

- Research Alternatives: Look for superior products or technologies that can replace the existing parts.

- Implement Changes: Carefully install the new components, ensuring that all specifications and guidelines are followed.

- Test Performance: After installation, assess the system to gauge improvements and fine-tune as necessary.

Investing time and resources into upgrading specific elements can lead to significant gains in productivity and effectiveness. A well-planned approach ensures that each enhancement contributes positively to the overall performance of the system.

Frequently Asked Questions About Rck60-24b

This section addresses common inquiries related to a specific model’s components and their functionalities. Understanding these elements can enhance user experience and maintenance efficiency.

- What are the key features of this model?

Key features include durability, efficiency, and compatibility with various systems.

- How can I obtain replacement components?

Replacement items can typically be acquired through authorized dealers or online marketplaces.

- Is there a warranty available?

Yes, most manufacturers offer a warranty that covers defects in materials and workmanship.

- What is the recommended maintenance schedule?

A regular maintenance schedule should include inspections every few months and thorough cleaning as needed.

- Are there any common issues to be aware of?

Some users report minor issues like wear and tear, which can often be resolved with simple adjustments.