Understanding the Key Components of a Pressure Washer

In the realm of outdoor maintenance, various machines play crucial roles in ensuring surfaces remain pristine. These devices, designed to facilitate efficient cleaning, consist of numerous elements that work harmoniously together. A comprehensive exploration of these components can enhance one’s grasp of their functionality and maintenance.

Each segment of this equipment serves a specific purpose, contributing to its overall efficiency. Recognizing the importance of these elements enables users to troubleshoot issues, optimize performance, and ultimately extend the lifespan of the machine. By examining the intricacies of these mechanisms, one can delve into the ultimate potential of their cleaning tasks.

Whether you are a novice or a seasoned user, understanding these essential elements can significantly impact your cleaning experience. Grasping how each part interacts not only boosts effectiveness but also empowers users to make informed decisions regarding repairs and upgrades.

Understanding Pressure Washer Components

The inner workings of a high-efficiency cleaning device are fascinating and essential for its functionality. Grasping the various elements can significantly enhance your understanding of how it operates and aids in effective maintenance. This knowledge empowers users to troubleshoot and optimize their equipment for better performance.

Key Components

At the heart of this device lies the motor, which powers the entire system, converting energy into mechanical action. Coupled with this is the pump, responsible for generating the necessary force to propel the cleaning solution. Understanding these core elements is crucial for maximizing effectiveness.

Additional Features

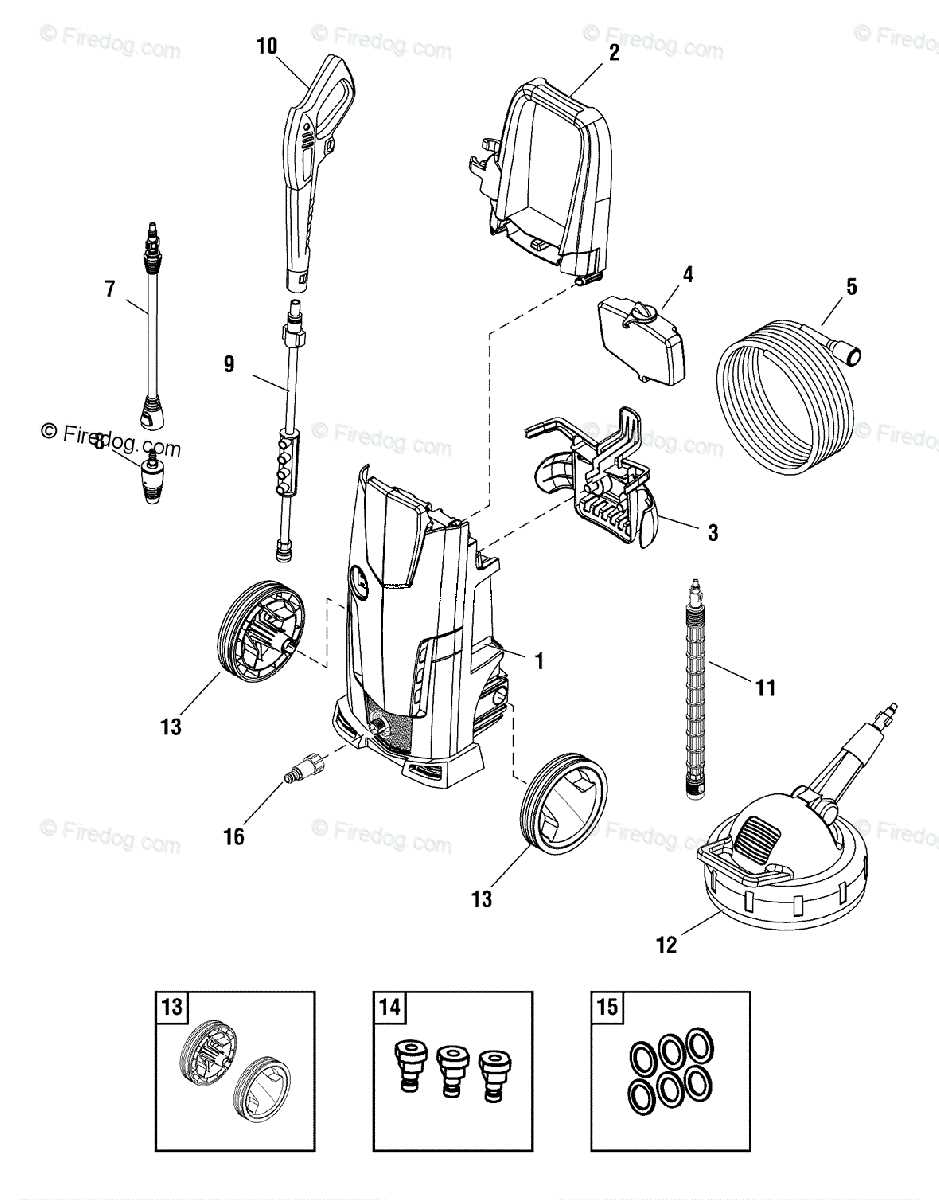

Moreover, various accessories enhance functionality, including different nozzles that adjust the intensity and spread of the cleaning spray. The hose and wand play vital roles in directing the flow and reach, making them indispensable in achieving thorough results.

In summary, a comprehensive grasp of these components can lead to informed decisions regarding maintenance, usage, and upgrades, ensuring the ultimate performance of your cleaning tool.

Essential Parts of a Pressure Washer

Understanding the key components of a cleaning machine is crucial for effective usage and maintenance. Each element plays a specific role in ensuring optimal performance and durability, allowing users to achieve outstanding results in various cleaning tasks.

| Component | Description |

|---|---|

| Motor | Drives the pump, providing the necessary power for operation. |

| Pump | Generates high-pressure water flow for efficient cleaning. |

| Nozzle | Controls the spray pattern and intensity of the water stream. |

| Hose | Transports water from the unit to the nozzle. |

| Trigger Gun | Allows the user to control the flow of water easily. |

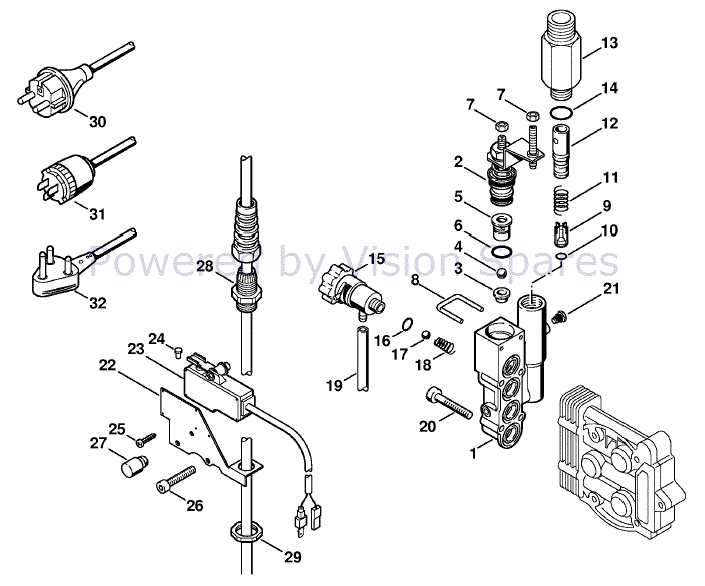

Functionality of the Pump System

The pump system serves as the heart of the cleaning mechanism, playing a crucial role in generating the necessary force to expel water effectively. By converting energy into kinetic movement, it ensures that the fluid is delivered at high speeds, enhancing the overall cleaning efficiency.

Components and Their Roles

Key elements of the pump assembly include the motor, impeller, and valves. The motor provides the initial power, while the impeller propels the liquid through the system. Valves regulate the flow, ensuring that the right amount of water is directed towards the nozzle for optimal results.

Importance of Maintenance

Regular upkeep of the pump system is essential for longevity and performance. Neglecting this vital component can lead to reduced efficiency and increased wear. Ensuring clean filters and checking for leaks are simple yet effective ways to keep the system running smoothly.

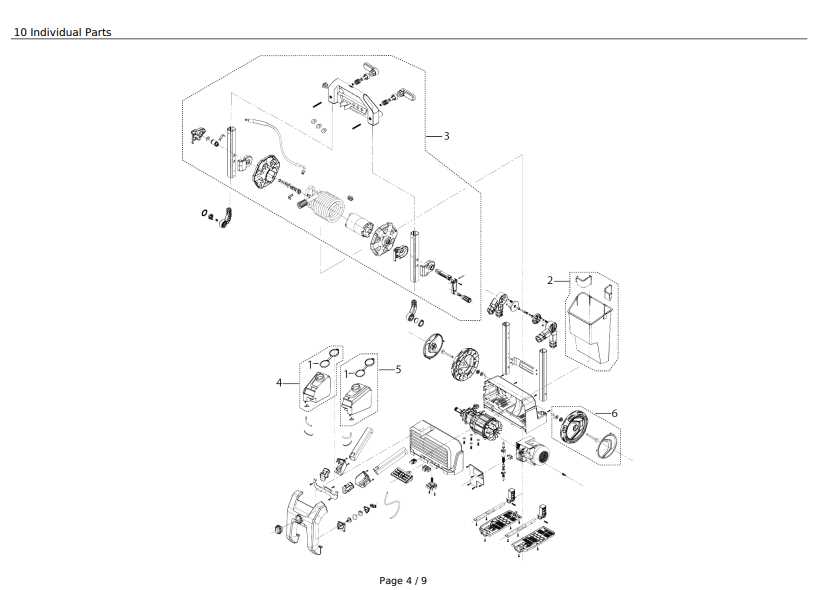

Role of the Electric Motor

The electric motor serves as the driving force behind many cleaning devices, transforming electrical energy into mechanical motion. This vital component plays a key role in ensuring efficiency and effectiveness in the operation of various cleaning equipment.

Functionality and Operation

In essence, the electric motor is responsible for powering the mechanism that generates high-velocity fluid movement. It operates by converting electrical input into rotational energy, which in turn propels the cleaning solution through the system. This process is essential for achieving optimal results in tasks that require thorough removal of dirt and grime.

Key Specifications

| Specification | Description |

|---|---|

| Power Rating | Indicates the strength of the motor, typically measured in horsepower (HP) or watts. |

| Voltage | Refers to the electrical input required for the motor to function efficiently. |

| RPM | Stands for revolutions per minute, indicating the speed at which the motor operates. |

| Durability | Describes the motor’s ability to withstand prolonged use and various environmental conditions. |

Understanding the electric motor’s specifications can help users select the appropriate device for their specific cleaning needs, ensuring both performance and longevity in operation.

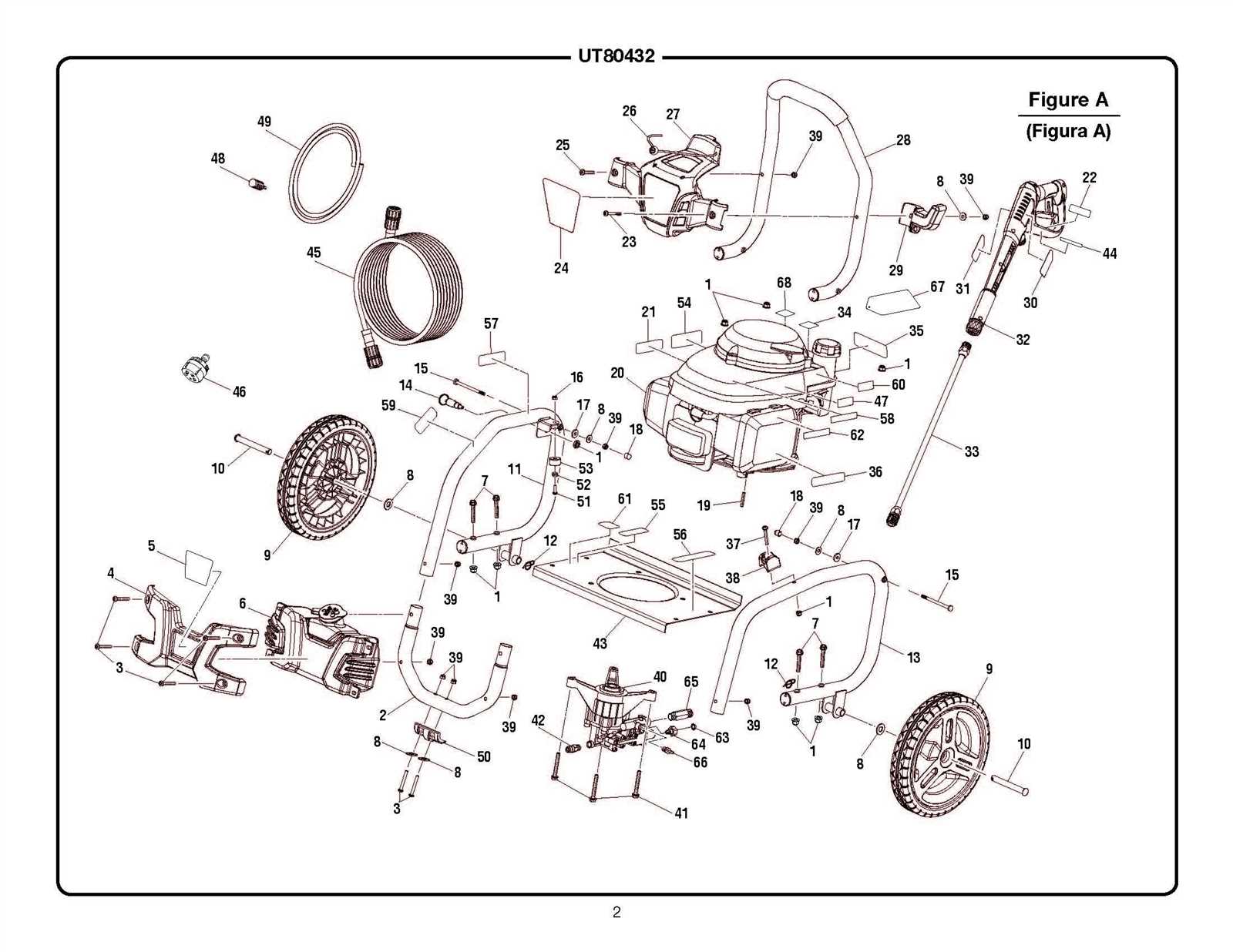

How the Hose Works

The hose plays a vital role in the efficient transfer of fluid, ensuring that it reaches its intended destination with precision and power. By channeling water from a source to a nozzle, it enables effective cleaning and maintenance tasks, making it an essential component in various applications.

Constructed from durable materials, the hose is designed to withstand high levels of force while maintaining flexibility. Its design not only allows for easy maneuverability but also ensures a consistent flow, maximizing the effectiveness of the system.

| Feature | Description |

|---|---|

| Material | Typically made from reinforced rubber or synthetic substances to prevent wear and tear. |

| Diameter | Varies to accommodate different flow rates, impacting the overall performance. |

| Connection Type | Equipped with fittings that secure the hose to both the source and the nozzle, ensuring no leaks. |

| Length | Available in various lengths, providing flexibility and reach for diverse tasks. |

Understanding the mechanics behind the hose helps users appreciate its significance in achieving optimal results. Proper maintenance and care of the hose are crucial to prolonging its lifespan and enhancing overall performance in tasks where effective fluid transfer is needed.

Importance of Nozzles in Cleaning

Nozzles play a crucial role in achieving effective cleaning results. Their design and functionality significantly influence how surfaces are treated, ensuring that dirt and grime are removed efficiently. Understanding the various types can help in selecting the right tool for specific tasks.

| Type of Nozzle | Function | Best For |

|---|---|---|

| Flat Fan | Even distribution of water | Large surfaces like driveways |

| Turbo Nozzle | Rotating jet for tough stains | Concrete and heavy-duty cleaning |

| Soap Nozzle | Mixes detergent for deeper cleaning | Pre-treating surfaces |

| Wide Angle | Gentle spray for delicate surfaces | Wood or painted surfaces |

Features of the Spray Gun

The spray gun is an essential tool that significantly enhances the efficiency of various cleaning tasks. Its design allows for the effective application of water, ensuring that surfaces are treated with precision and power. This section delves into the distinctive characteristics that make the spray gun an indispensable component in cleaning operations.

Ergonomic Design: One of the standout features of the spray gun is its ergonomic construction. This design ensures comfort during prolonged use, reducing fatigue and allowing for better control. The handle is often crafted to fit naturally in the hand, making it easier to maneuver while working.

Adjustable Nozzle: Many models come equipped with an adjustable nozzle, which offers versatility in the intensity and pattern of the spray. Users can easily switch between a fine mist for delicate surfaces and a concentrated jet for tougher grime, enhancing overall functionality.

Durability: The materials used in the construction of the spray gun are typically chosen for their resilience. High-quality plastics and metals can withstand various environmental conditions, ensuring longevity and reliable performance even under demanding circumstances.

Quick Connect Feature: The convenience of a quick connect feature allows for swift attachment and detachment from hoses or other equipment. This saves valuable time during setup and transitions between different tasks, making the cleaning process more efficient.

Safety Mechanisms: Many spray guns incorporate safety features such as a trigger lock to prevent accidental discharge. This adds an extra layer of protection for users, especially in environments where safety is paramount.

Overall, the spray gun is designed not only for effectiveness but also for user convenience, making it a key tool in achieving optimal cleaning results.

Identifying the Water Inlet

Understanding the various components of a cleaning device is essential for effective operation and maintenance. One of the crucial elements in this setup is the entry point for water, which plays a significant role in ensuring optimal performance. Recognizing this component helps users to connect their equipment correctly and troubleshoot any potential issues related to water flow.

The water inlet is typically located at the back or side of the unit, designed for easy access. It is usually marked with a symbol or label indicating its purpose, which aids in quick identification. This component connects to a standard garden hose, allowing for a steady supply of water during operation. Ensuring that this entry point is free from obstructions and securely attached is vital for maintaining efficient functionality.

In some models, the water inlet may feature filters to prevent debris from entering the system, highlighting its importance in preserving the integrity of internal components. Regular inspection and cleaning of this area can significantly extend the life of the device and enhance its cleaning capabilities. Users should familiarize themselves with this essential part to ensure they are using their equipment safely and effectively.

Functions of the Pressure Regulator

The pressure regulator plays a crucial role in ensuring that the flow of fluid is controlled and maintained at optimal levels. Its primary function revolves around managing the force exerted by the fluid, allowing for efficient operation and safety during use. Understanding these functions is essential for effective utilization and maintenance.

Key Functions

- Maintaining Consistent Flow: It ensures that the flow remains steady, preventing fluctuations that can disrupt operations.

- Safety Management: By regulating force, it protects equipment from damage caused by excessive pressure.

- Enhancing Efficiency: It optimizes performance by ensuring the right amount of force is delivered for various tasks.

Operational Benefits

- Facilitates diverse applications by allowing adjustments based on specific requirements.

- Extends the lifespan of the equipment by minimizing wear and tear from extreme forces.

- Promotes user safety by reducing the risk of accidents related to high pressure.

Understanding the Detergent Tank

The detergent tank plays a crucial role in enhancing the cleaning efficiency of your equipment. By allowing for the application of specialized cleaning solutions, it ensures that surfaces are not just cleaned, but also treated for better results. Understanding its function can significantly improve your cleaning outcomes.

Functionality of the Detergent Tank

The primary function of the tank is to store and dispense cleaning agents. These solutions can target various types of dirt and stains, making them essential for tackling challenging tasks. The tank typically connects to the main unit, allowing for seamless mixing with water as it is applied.

Maintenance Tips

Regular maintenance of the tank is vital for optimal performance. Ensure it is cleaned after each use to prevent residue buildup, which can hinder functionality. Inspecting for leaks or clogs will help maintain the efficiency of your cleaning process, ultimately leading to better results.

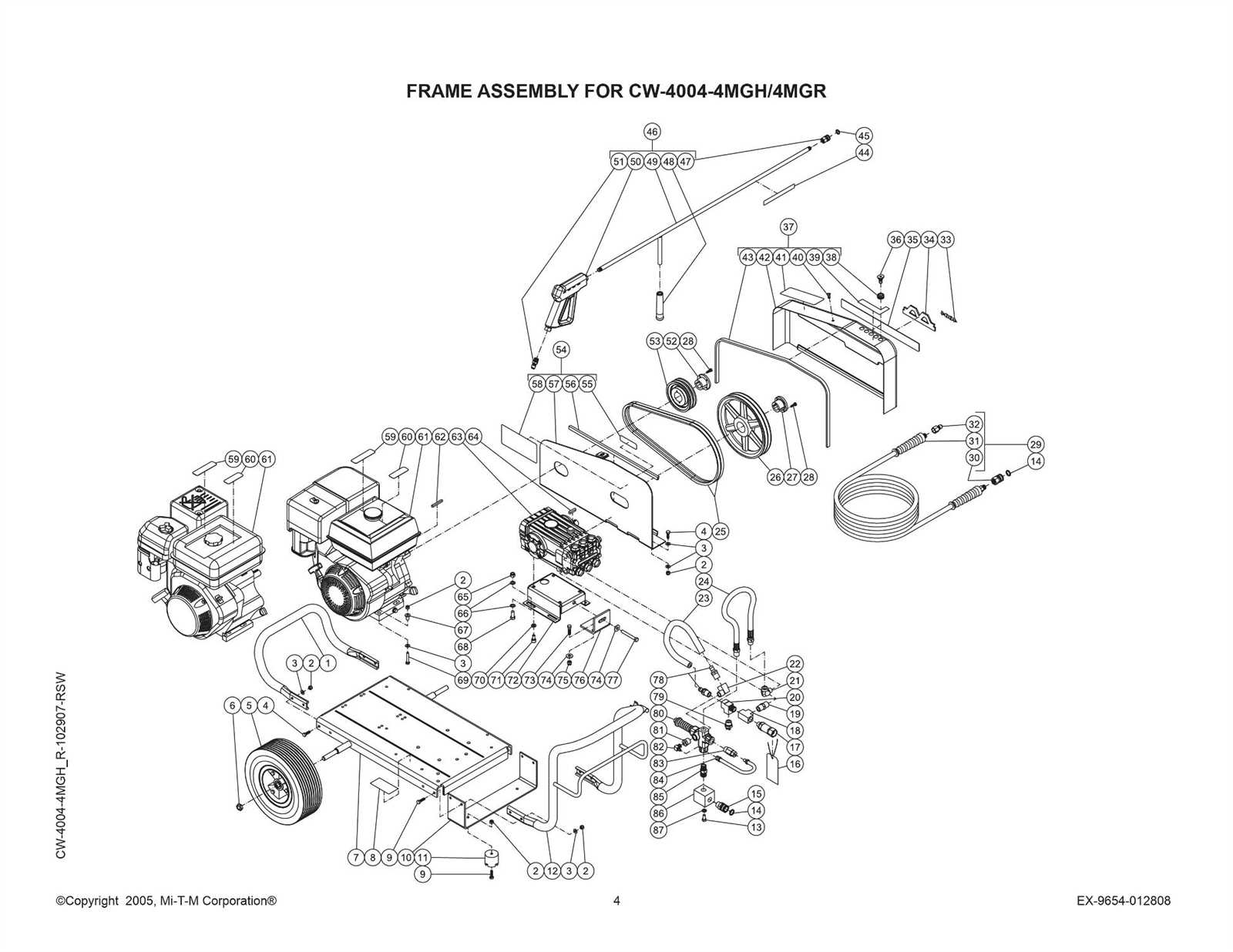

Exploring the Frame and Wheels

The structural components of cleaning equipment play a crucial role in its overall functionality and maneuverability. Among these, the framework and mobility elements significantly influence how effectively the device can be transported and utilized. Understanding these components can enhance both the user experience and the device’s longevity.

The frame serves as the backbone of the equipment, providing stability and support for all other elements. A well-designed structure ensures that the device can withstand rigorous use while maintaining balance during operation. Materials used in the construction of the frame often include durable metals or high-quality plastics, contributing to both strength and weight considerations.

Wheels are equally vital, as they facilitate movement across various surfaces. The size, material, and design of the wheels can greatly affect how easily the equipment can be maneuvered. Larger wheels typically offer better navigation on uneven terrain, while smaller ones may provide more precision in tight spaces. Additionally, some models feature wheels with locking mechanisms, allowing for stability during use.

By examining the interplay between the framework and mobility features, users can gain insights into how these elements enhance operational efficiency and ease of use. A solid understanding of these components is essential for making informed choices when selecting equipment for specific tasks.

Common Maintenance Parts

Regular upkeep is essential for ensuring optimal performance and longevity of cleaning equipment. Understanding the key components that require attention can help users maintain their tools effectively and avoid costly repairs.

- Filters: These components trap debris and impurities, ensuring a clean flow of liquid.

- Seals: Seals prevent leaks and maintain pressure, making them vital for efficient operation.

- Hoses: Durable and flexible hoses are crucial for transporting fluids without wear or damage.

- Nozzles: Various nozzles allow for different spray patterns, and they should be checked for clogs or damage.

- Pumps: Regular inspection of pumps is necessary to ensure they function smoothly and do not lose efficiency.

Addressing the maintenance needs of these components will enhance the overall performance and reliability of your cleaning equipment.

Safety Features in Pressure Washers

Ensuring user protection while operating high-powered cleaning equipment is paramount. These machines are designed with various safety mechanisms that prevent accidents and enhance overall user experience. Understanding these features can significantly reduce risks during usage.

Automatic Shut-off Systems

Many models come equipped with automatic shut-off systems that activate when the trigger is released. This feature not only conserves energy but also minimizes the potential for unwanted spray, ensuring a safer environment for the operator and bystanders.

Safety Lock Mechanisms

Safety lock mechanisms are essential in preventing accidental activation. These locks require deliberate action to engage the trigger, which helps avoid unexpected operation, making the equipment safer to handle during transport or storage.