Comprehensive Guide to Burnham Boiler Parts Diagram

In the realm of heating solutions, a comprehensive understanding of system elements is essential for effective maintenance and repair. Each component plays a critical role in ensuring optimal functionality and efficiency, ultimately contributing to a comfortable environment.

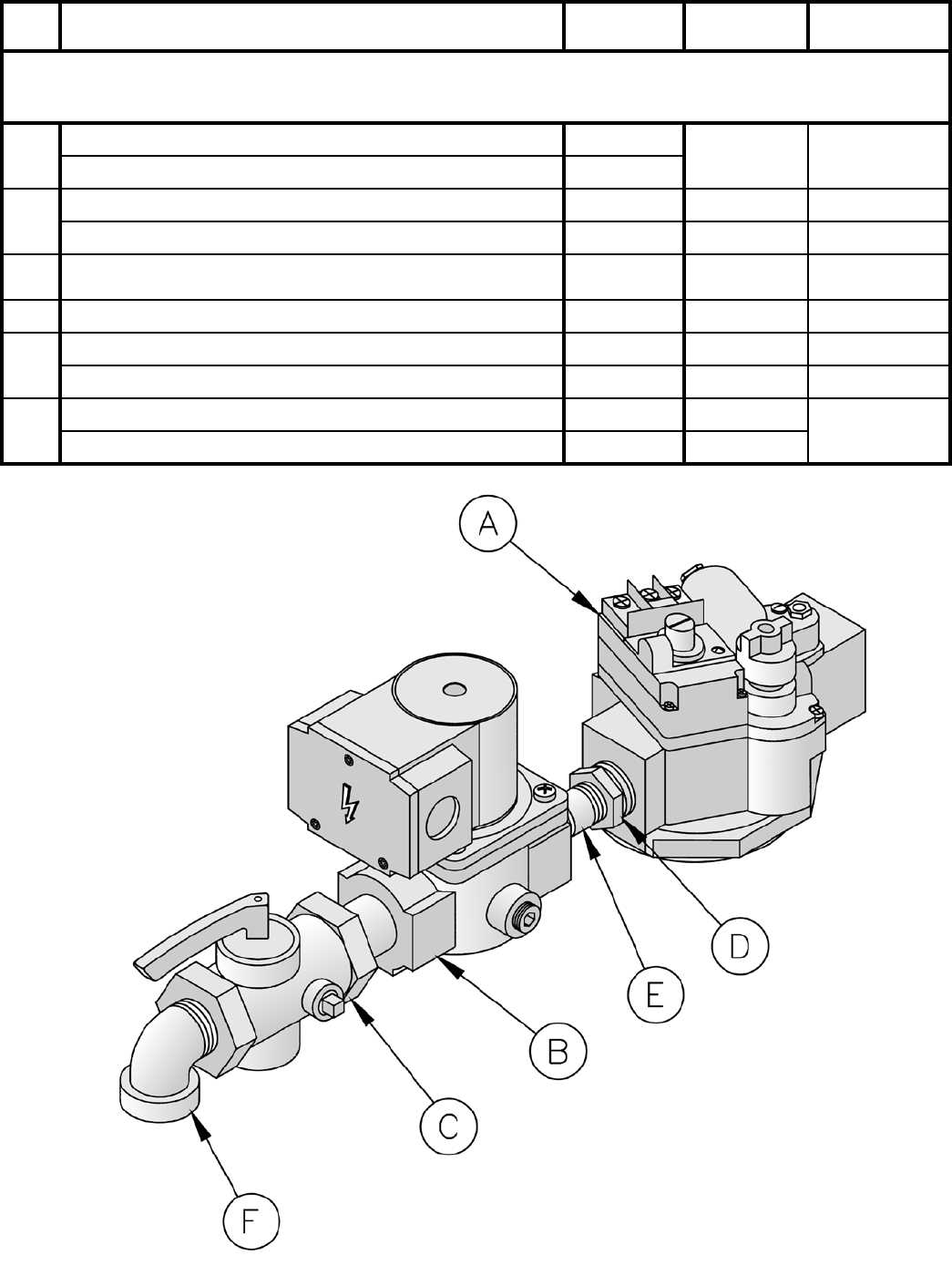

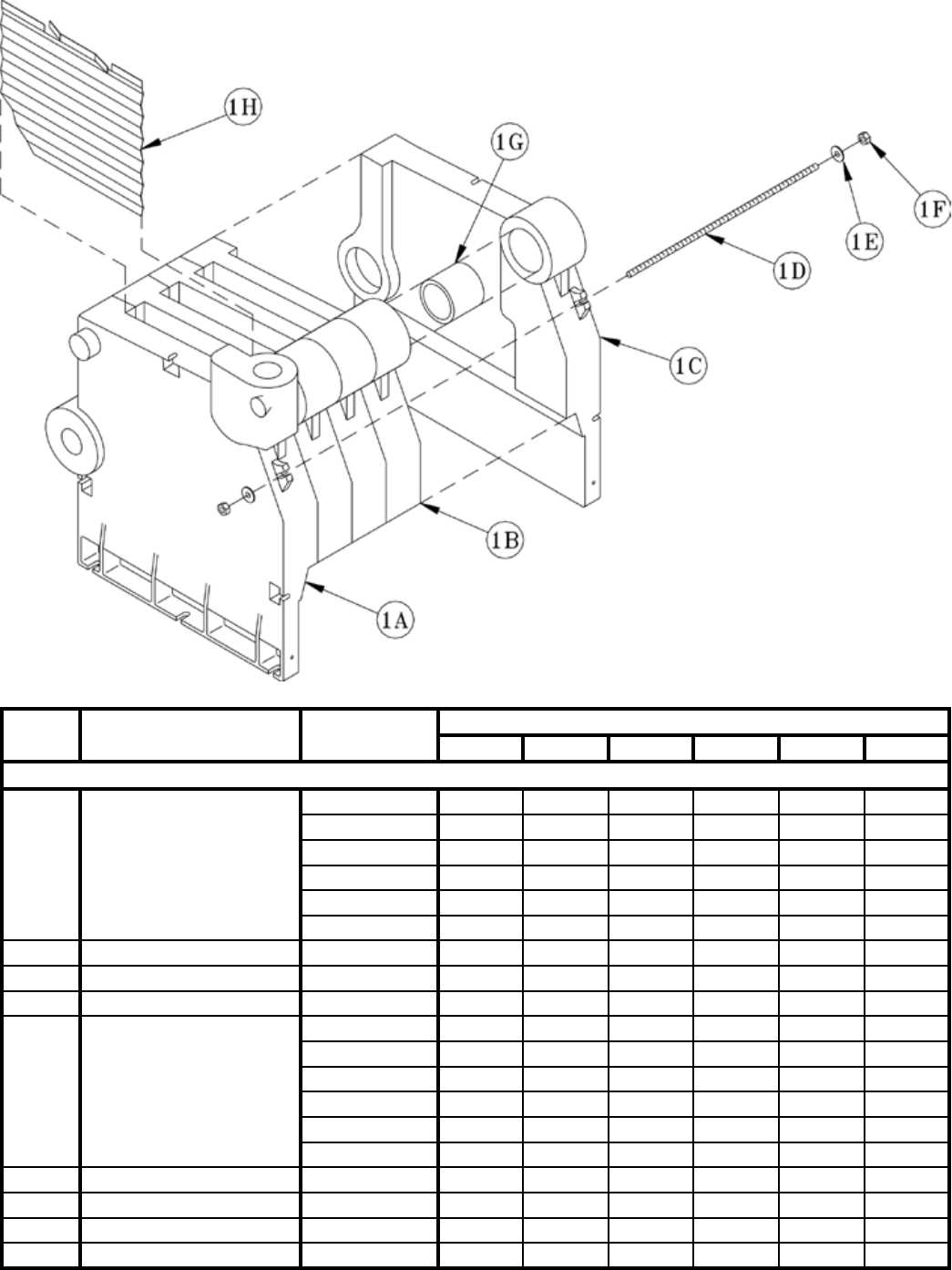

Visual representations of these elements can greatly aid in the identification and troubleshooting of issues. By examining the layout and interconnections, users can better grasp how various parts interact and support overall performance.

Whether you are a seasoned technician or a homeowner seeking to delve into the intricacies of your heating unit, familiarity with the structural arrangement of these mechanisms will enhance your ability to address concerns and ensure longevity.

Understanding Burnham Boilers

Efficient heating systems play a crucial role in maintaining comfortable environments in residential and commercial settings. A comprehensive grasp of these mechanisms enhances their longevity and effectiveness. This section explores the essential components that contribute to the functionality and reliability of these heating units.

Key Features: Numerous elements work in harmony to ensure optimal performance. Understanding how these components interact is vital for troubleshooting and maintenance.

System Efficiency: Properly configured systems maximize energy use, leading to cost savings and reduced environmental impact. Awareness of each element’s role can help in achieving the ultimate efficiency.

Essential Components of Burnham Systems

The efficiency and reliability of heating systems hinge on a variety of critical elements that work in harmony to deliver optimal performance. Understanding these fundamental components is vital for anyone involved in maintenance, repair, or installation. Each piece plays a unique role, contributing to the overall functionality and safety of the system.

| Component | Function |

|---|---|

| Heat Exchanger | Transfers heat from the combustion process to the water or air being heated. |

| Burner | Mixes fuel and air to create a controlled flame for heating. |

| Control System | Regulates the operation of the entire unit, ensuring efficiency and safety. |

| Pump | Circulates water or fluid through the system to distribute heat effectively. |

| Flue | Exhausts combustion gases safely outside the building. |

| Pressure Relief Valve | Prevents excessive pressure buildup, ensuring safe operation. |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the maintenance and repair of complex systems. They serve as essential guides for technicians, enabling them to understand the relationships and functionalities of various components. Without these detailed representations, the risk of errors during installation or troubleshooting significantly increases.

Accurate visual references not only enhance the efficiency of repair processes but also contribute to safety. When technicians can easily identify parts and their connections, they can work more confidently and effectively, reducing the likelihood of accidents or further damage. Moreover, having reliable schematics aids in training new personnel, ensuring that knowledge transfer is both effective and consistent.

| Benefit | Description |

|---|---|

| Clarity | Visual aids simplify complex information, making it easier to comprehend. |

| Efficiency | Streamlined processes lead to faster repairs and maintenance tasks. |

| Safety | Reduces the likelihood of accidents by clearly outlining procedures and connections. |

| Training | Facilitates the onboarding of new staff by providing clear reference materials. |

How to Read Boiler Schematics

Understanding technical illustrations is essential for effective maintenance and troubleshooting of heating systems. These visuals provide a detailed representation of components and their interconnections, allowing users to grasp the system’s functionality. By familiarizing yourself with common symbols and layouts, you can interpret the information accurately and identify issues more efficiently.

Start by recognizing the key symbols used in these illustrations. Each element typically corresponds to a specific component, such as pumps, valves, and sensors. Familiarizing yourself with these symbols can streamline your understanding and enable you to follow the flow of the system seamlessly.

Next, pay attention to the lines that connect the symbols. Different line styles often indicate various types of connections, such as electrical wiring or fluid pathways. Understanding these distinctions can help you pinpoint potential areas of concern, whether they relate to power supply or fluid movement.

It’s also important to note any annotations or legends that accompany the illustration. These notes often provide additional context, such as specifications or operational guidelines, which can be crucial for proper interpretation. By consulting these details, you enhance your comprehension and ensure accurate assessment of the system’s condition.

Lastly, practice is key. Regularly reviewing and analyzing schematics will build your confidence and proficiency. Over time, you will find it easier to navigate these visuals, leading to more effective problem-solving and maintenance strategies.

Common Parts and Their Functions

This section explores essential components found within heating systems, highlighting their roles and significance in maintaining efficiency and safety. Understanding these elements is crucial for effective operation and troubleshooting.

Heat Exchanger: This vital component transfers thermal energy from the combustion process to the water, ensuring optimal heating.

Pump: Responsible for circulating water throughout the system, the pump plays a key role in maintaining consistent temperatures and flow.

Thermostat: This device monitors and regulates the temperature, allowing for precise control over the heating environment.

Expansion Tank: It accommodates the increase in water volume as it heats, preventing pressure buildup and potential damage.

Control Valve: This mechanism regulates the flow of fluid, ensuring that the system operates efficiently and safely.

Maintenance Tips for Burnham Boilers

Regular upkeep is essential for optimal performance and longevity of your heating system. By following some basic guidelines, you can ensure efficient operation and prevent costly breakdowns. Consistent attention to details will help maintain a comfortable environment in your space.

Regular Inspections

Conduct routine checks to identify potential issues early. Look for signs of wear or damage, and ensure all components are functioning properly. Scheduling professional evaluations annually can also provide insights into system health.

Cleaning and Servicing

Keep the unit clean by removing dust and debris from surrounding areas. Ensure that filters are replaced or cleaned regularly to maintain airflow. Regular servicing by a qualified technician is crucial for thorough maintenance and performance optimization.

Troubleshooting Common Issues

When dealing with heating systems, it’s essential to address potential malfunctions effectively. Various challenges can arise, often leading to inefficient operation or complete failure. Understanding these issues can help maintain optimal performance and extend the lifespan of your equipment.

Below is a table outlining some frequent problems, their possible causes, and suggested solutions:

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| No heat | Thermostat malfunction, low water level | Check thermostat settings, inspect water levels |

| Unusual noises | Air trapped in the system, loose components | Bleed the system, tighten connections |

| Leaks | Worn seals, corrosion | Inspect for damage, replace seals or parts |

| Increased energy bills | Poor insulation, system inefficiency | Improve insulation, schedule regular maintenance |

By identifying and addressing these common challenges promptly, you can ensure a more reliable and efficient heating system. Regular inspections and maintenance are key to preventing larger issues down the line.

Upgrading Your Boiler Parts

Enhancing your heating system is essential for improving efficiency and performance. By selecting superior components, you can ensure reliable operation and reduce energy costs. This section outlines the benefits and considerations when choosing new elements for your heating unit.

| Component | Benefits | Considerations |

|---|---|---|

| Heat Exchanger | Improved heat transfer efficiency | Compatibility with existing setup |

| Circulator Pump | Enhanced flow rate | Power requirements |

| Thermostat | Increased control and accuracy | Integration with current system |

| Expansion Tank | Prevention of pressure issues | Proper sizing for your system |

Investing in upgraded components can significantly enhance your system’s efficiency and longevity. Careful consideration of compatibility and performance will yield the ultimate benefits.

Safety Considerations for Repairs

When undertaking maintenance or repairs on heating systems, it is essential to prioritize safety to prevent accidents and ensure efficient operation. Proper precautions help mitigate risks associated with electrical and mechanical components.

Always disconnect power before beginning any work. This simple step prevents accidental shocks and injuries. Additionally, use appropriate personal protective equipment such as gloves and safety goggles to protect yourself from potential hazards.

It is crucial to follow manufacturer guidelines closely, as they provide specific safety measures and recommendations for your particular model. Ensuring adequate ventilation during repairs can also minimize the risk of harmful gas buildup.

Finally, consider consulting a professional if the repair involves complex systems or if you feel uncertain about the process. This not only ensures safety but can also save time and resources in the long run.

Finding Replacement Parts Easily

Locating suitable components for your heating system can be a straightforward task with the right approach. Whether you’re dealing with a minor repair or a significant upgrade, having a clear understanding of where to search and what to look for can save both time and effort.

Utilizing Online Resources

The internet is a treasure trove of information and resources. Numerous websites specialize in providing detailed catalogs of components, complete with specifications and compatibility information. By using specific model numbers or descriptions, you can quickly narrow down your options. Online forums and communities dedicated to home maintenance can also offer valuable insights and recommendations for trusted suppliers.

Consulting Professionals

If you’re unsure about what you need, don’t hesitate to reach out to professionals in the field. Technicians and specialists often have access to exclusive suppliers and can assist in identifying the correct items. Additionally, they can provide advice on installation and maintenance, ensuring that your system runs efficiently. Investing in expert guidance can prevent costly mistakes and enhance the longevity of your equipment.

Resources for Further Learning

Exploring additional materials can greatly enhance your understanding of heating systems and their components. A variety of educational resources, including manuals, online courses, and expert forums, provide valuable insights and practical knowledge for enthusiasts and professionals alike.

Online Courses

Several platforms offer specialized courses on thermal systems and maintenance practices. These structured programs are designed to equip learners with both theoretical knowledge and hands-on skills. Consider enrolling in courses that delve into system efficiency and troubleshooting techniques.

Expert Forums and Communities

Engaging with communities focused on heating technology can be beneficial. These forums allow users to share experiences, seek advice, and gain tips from seasoned professionals. Participating in discussions can lead to a deeper understanding of the intricacies involved in system operation.