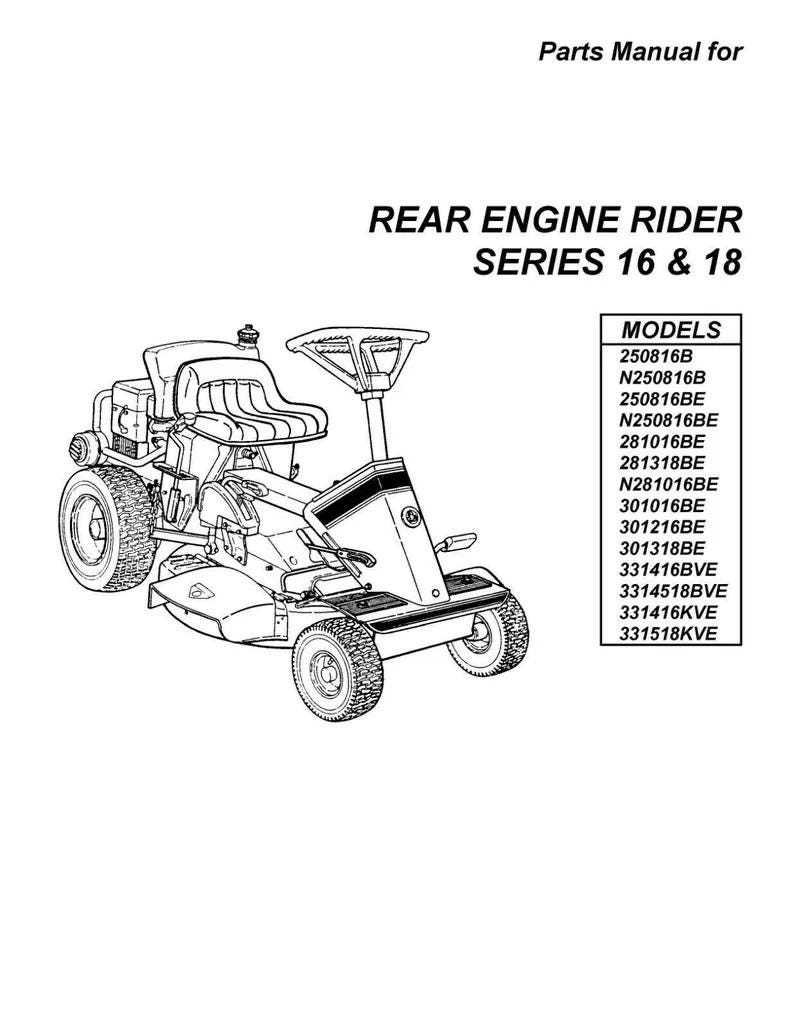

Comprehensive Parts Diagram for Snapper Rear Engine Rider

In the realm of outdoor maintenance equipment, comprehending the intricate details of a machine’s configuration is essential for effective operation and maintenance. Familiarity with the individual elements that contribute to a machine’s functionality allows users to optimize performance and troubleshoot issues efficiently. A well-informed approach not only enhances the longevity of the equipment but also ensures a smoother experience during its use.

When it comes to ensuring the optimal performance of your gardening tool, knowing the arrangement of its various elements plays a critical role. Each component has a specific function, contributing to the overall efficiency and effectiveness of the device. Gaining insights into these crucial features empowers users to make informed decisions, whether it’s for regular upkeep or potential upgrades.

Furthermore, having access to a detailed visual representation of the various mechanisms aids in understanding how they work together harmoniously. By breaking down the composition of the equipment into its individual sections, users can better appreciate the engineering behind it. This understanding can lead to improved maintenance practices and a heightened ability to address any concerns that may arise during use.

Overview of Snapper Rear Engine Riders

This section provides a comprehensive insight into a specific category of lawn maintenance equipment designed for efficient mowing. These machines are characterized by their unique design and functionality, catering to both residential and commercial users.

These models are engineered to deliver enhanced maneuverability and control, allowing users to navigate through various terrains with ease. The innovative layout not only optimizes performance but also contributes to user comfort during operation. With a focus on durability and reliability, this type of mower has become a preferred choice for many who seek efficiency in lawn care.

Understanding the structure and components of these machines is crucial for proper maintenance and operation. Each unit consists of various elements that work together to ensure optimal performance, making it essential for users to familiarize themselves with these features. By doing so, operators can enhance the longevity of their equipment and achieve better mowing results.

Key Components of Snapper Models

This section delves into the essential elements that define the functionality and performance of various lawn maintenance machines. Understanding these core components allows users to appreciate how they contribute to the overall efficiency and reliability of the equipment.

Chassis and Frame

The chassis serves as the foundational structure of the machinery, providing stability and support. Constructed from durable materials, it is designed to withstand the rigors of outdoor use. A robust frame ensures that all attached components work harmoniously, enhancing the longevity of the unit.

Transmission System

The transmission system plays a crucial role in controlling the movement and speed of the machine. By facilitating smooth gear shifts, this system allows operators to maneuver effortlessly across various terrains. Proper maintenance of the transmission ensures optimal performance, contributing to a seamless user experience.

Understanding Engine Configuration Basics

Grasping the fundamental principles of how propulsion systems are organized is essential for anyone interested in mechanics. Various configurations influence performance, efficiency, and the overall operation of machinery. By examining the arrangements of components and their interactions, one can gain valuable insights into the functionality and maintenance of these systems.

Propulsion systems can be categorized based on several factors, including their layout, the number of cylinders, and the arrangement of those cylinders. Each configuration offers distinct advantages and drawbacks, impacting aspects such as power output, torque, and fuel consumption.

| Configuration Type | Advantages | Disadvantages |

|---|---|---|

| Inline | Compact design, smooth operation | Limited power in larger sizes |

| V-Type | Higher power output, better balance | More complex, requires more space |

| Flat | Lower center of gravity, excellent balance | Wider design, potentially heavier |

Understanding these configurations not only aids in appreciating the technology behind various systems but also enhances the ability to troubleshoot and optimize performance. Familiarity with the inherent characteristics of each layout equips individuals with the knowledge necessary for effective maintenance and improvements.

Importance of Maintenance and Repair

Regular upkeep and timely repairs are essential for ensuring the longevity and optimal performance of machinery. Neglecting these aspects can lead to reduced efficiency, increased wear and tear, and ultimately, costly replacements. By prioritizing maintenance, users can prevent minor issues from escalating into significant problems, thus safeguarding their investment.

Enhancing Performance

Routine check-ups and servicing contribute to the smooth operation of equipment. When components are kept in good condition, they work together effectively, resulting in better productivity. Regular inspections help identify potential malfunctions before they affect performance, allowing for prompt corrective actions.

Cost-Effectiveness

Investing time and resources in maintenance can lead to significant savings in the long run. Properly maintained equipment requires fewer repairs and experiences fewer breakdowns, reducing operational costs. Additionally, maintaining machinery can prolong its lifespan, maximizing return on investment.

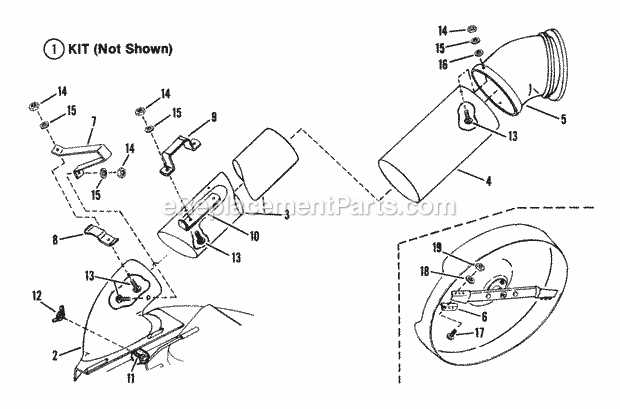

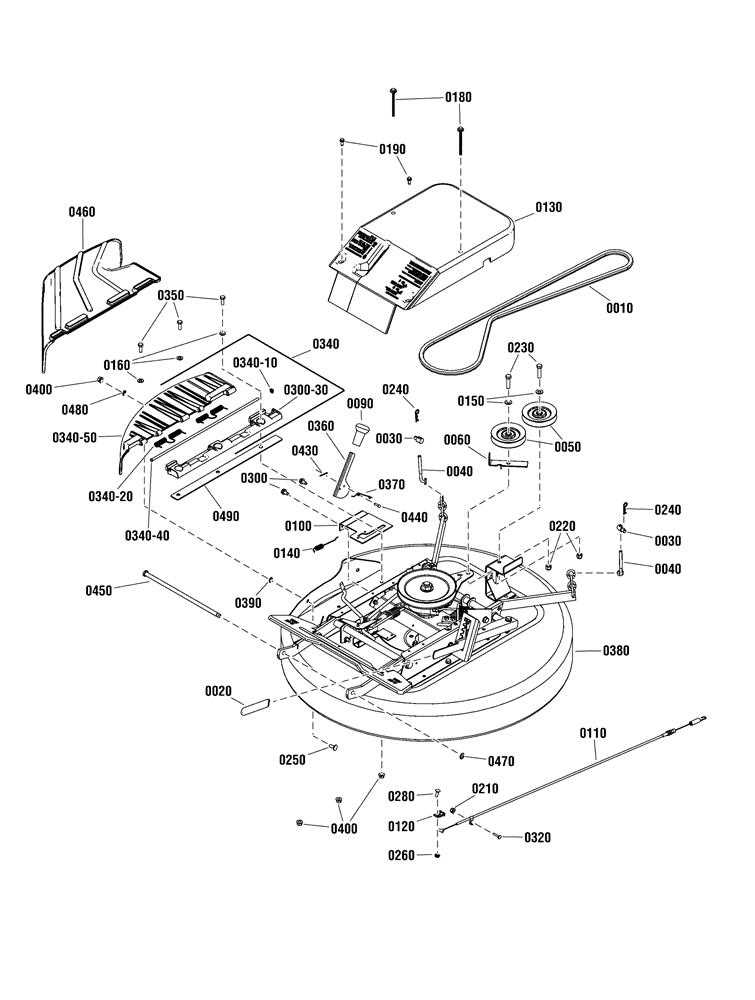

Identifying Common Parts in Diagrams

Understanding the various components illustrated in technical schematics is essential for effective maintenance and repair. Recognizing these elements enables users to navigate the complexities of machinery with confidence, ensuring that they can troubleshoot and resolve issues efficiently.

Common Components: Among the most frequently encountered elements are belts, blades, and housings. Each of these plays a crucial role in the overall functionality of the equipment. Belts typically facilitate motion transfer, while blades are essential for cutting operations. Housings provide structural integrity, protecting internal mechanisms from external damage.

Furthermore, understanding the relationships between these components can significantly enhance one’s ability to perform repairs. For instance, knowing how to identify and replace worn-out belts can prevent more severe mechanical failures down the line. Thus, familiarizing oneself with these basic elements is a key step in mastering equipment operation and maintenance.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides, showcasing the various elements of a machine and their relationships to one another. By mastering the skill of interpreting these visuals, one can identify necessary components and ensure the proper functioning of the equipment.

To begin, familiarize yourself with the overall layout of the illustration. Each section is typically labeled, indicating specific areas or groups of components. Pay close attention to the accompanying numbers or letters, which correspond to detailed descriptions found in the associated documentation. This method allows for a clear understanding of how individual parts interact within the system.

Next, note any symbols or color codes present in the illustration. These can provide valuable information about the type of components and their functions. For instance, different colors might signify various categories of elements, such as electrical or mechanical parts. Recognizing these distinctions aids in locating the right components quickly.

Additionally, it is beneficial to compare the visual representation with the physical equipment. This practice reinforces your understanding of how each part fits into the overall assembly. By aligning the illustration with the actual machine, you can effectively troubleshoot issues and replace or repair components as needed.

In conclusion, mastering the interpretation of visual representations of components is a valuable skill for anyone involved in maintenance or repair work. With practice, the ability to read these guides will lead to more efficient repairs and an enhanced understanding of equipment functionality.

Essential Tools for Repairs

Having the right instruments is crucial for conducting effective maintenance and repairs on machinery. A well-equipped toolkit not only facilitates the repair process but also ensures that tasks are completed efficiently and safely. Here is a selection of essential tools that every repair enthusiast should consider having on hand.

- Wrenches: Adjustable and socket wrenches are vital for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers is necessary for handling different types of screws.

- Pliers: Needle-nose and slip-joint pliers assist in gripping and manipulating components effectively.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues and measuring voltage, current, and resistance.

- Diagnostic Tools: Specialized devices can help identify problems within the system quickly.

With these tools, you can confidently approach repairs, ensuring that you are well-prepared to tackle any challenges that may arise during the maintenance process.

Ordering Replacement Parts Online

In today’s digital age, acquiring necessary components for your outdoor machinery has become more straightforward than ever. The convenience of online shopping allows users to browse through a wide selection of items, ensuring they can find exactly what they need without the hassle of visiting multiple physical stores.

When purchasing components online, it’s essential to prioritize a few key factors. First, always verify the reliability of the retailer. Look for customer reviews and ratings to gauge the trustworthiness of the site. Additionally, confirm that the seller provides detailed descriptions and specifications for each item, ensuring compatibility with your equipment.

Another vital aspect is understanding the return policy. In case the wrong component is ordered or does not meet expectations, a flexible return policy can save time and frustration. Be sure to check shipping costs and delivery times, as these can vary significantly between retailers. By taking these steps, you can enhance your online shopping experience and ensure you receive high-quality items promptly.

Comparing Snapper Models and Features

This section explores various models and their distinctive characteristics within a specific brand of lawn care equipment. Understanding the differences can help users choose the most suitable option for their landscaping needs. Each design offers unique functionalities that cater to diverse preferences and requirements.

Key Features of Different Models

When evaluating different models, it is essential to consider several factors, including cutting width, engine performance, and ease of use. For instance, some options may boast wider cutting decks, allowing for quicker lawn maintenance, while others may focus on enhanced maneuverability in tight spaces. Additionally, engine specifications can significantly affect overall efficiency and reliability.

Benefits of Upgrading

Upgrading to a more advanced model often results in improved performance and user experience. Newer designs typically incorporate innovative technology, leading to better fuel efficiency and reduced maintenance requirements. Furthermore, the availability of various attachments and accessories expands the functionality of modern machines, making them versatile tools for any gardening enthusiast.

Tips for Efficient Lawn Care

Maintaining a lush and healthy lawn requires a strategic approach that combines proper techniques and regular attention. Implementing effective methods can greatly enhance the overall appearance and health of your outdoor space. This section will explore valuable insights to optimize your lawn care routine.

Regular Mowing Practices

Consistent cutting is essential for a vibrant lawn. Aim to mow at a height of around three inches to encourage deep root growth and reduce weed development. Ensure your blades are sharp; dull blades can tear grass, making it susceptible to disease. Additionally, vary your mowing pattern to prevent soil compaction and encourage upright growth.

Effective Watering Techniques

Proper hydration is crucial for sustaining your lawn’s vitality. Water deeply and infrequently to promote strong roots. Early morning is the best time for irrigation, as it allows the grass to absorb moisture before the heat of the day. Utilizing mulch can also help retain moisture in the soil, reducing the frequency of watering.

Common Issues with Rear Engine Riders

Many users encounter various challenges when operating this type of lawn equipment. Understanding these common problems can help in maintaining performance and ensuring longevity. By recognizing potential issues, owners can take proactive measures to avoid costly repairs and improve overall efficiency.

Frequent Mechanical Problems

- Difficulty starting the machine due to battery or ignition issues.

- Inconsistent cutting height resulting from improper adjustments.

- Loss of power while in use, often linked to fuel supply or carburetor complications.

- Excessive vibration indicating potential wear on blades or engine mounts.

Maintenance Challenges

- Regular checks of the fuel system to prevent clogs and leaks.

- Ensuring the blades are sharpened to promote clean cuts.

- Monitoring tire pressure to maintain proper traction and maneuverability.

- Inspecting belts for signs of wear or fraying to avoid failures.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance or repairs on outdoor machinery is paramount. Proper precautions can help prevent accidents and injuries, fostering a secure environment for the technician and the equipment. By adhering to recommended guidelines, one can effectively minimize risks associated with mechanical work.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and steel-toed boots.

- Ensure the work area is clean and free from hazards to prevent slips and falls.

- Disconnect the power source before commencing any repairs to eliminate electrical hazards.

- Use tools and equipment that are in good condition and suitable for the task at hand.

- Read the manufacturer’s manual thoroughly to understand the machinery’s specific safety protocols.

Emergency Preparedness

It is crucial to be prepared for emergencies that may arise during repair activities. This includes:

- Having a first aid kit readily available in the workspace.

- Knowing the location of emergency shut-off switches or valves.

- Being familiar with the emergency contact numbers for quick assistance.

- Conducting regular safety drills to ensure readiness for potential incidents.

By implementing these safety measures, technicians can effectively safeguard themselves and others while maintaining or repairing machinery.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionality within various lawn care machines. Understanding these elements can enhance the maintenance experience and improve overall performance.

What are the signs that a component needs replacement? It’s essential to monitor for unusual sounds, vibrations, or decreased efficiency, as these may indicate wear or damage.

How can I ensure I purchase the correct component? Always refer to the machine’s manual or consult a knowledgeable professional to confirm compatibility before making a purchase.

Are there benefits to using original components versus aftermarket options? Original components are typically designed to meet specific standards, ensuring optimal performance and longevity, while aftermarket options may vary in quality.

What maintenance practices can prolong the lifespan of components? Regular cleaning, lubrication, and timely inspections can significantly extend the life of various machine elements.

Where can I find reliable resources for component information? Reputable websites, user manuals, and dedicated forums can provide valuable insights and guidance on component care and troubleshooting.