Understanding SCBA Parts Diagram for Optimal Safety and Functionality

When it comes to safety in challenging environments, specialized breathing apparatus plays a crucial role. These devices, built with precision and durability, provide a reliable supply of fresh air to those working in hazardous conditions. Their construction involves a range of interconnected elements, each designed to enhance functionality and ensure user protection in intense situations.

Each element in these systems serves a specific purpose, from regulating airflow to securing the equipment on the user. Understanding the function and interaction of these different components is essential for proper usage and maintenance. This not only contributes to the longevity of the equipment but also enhances safety protocols for individuals relying on this life-saving gear.

In this overview, we’ll explore the key aspects of these breathing systems, detailing the role of various parts, their design features, and how they

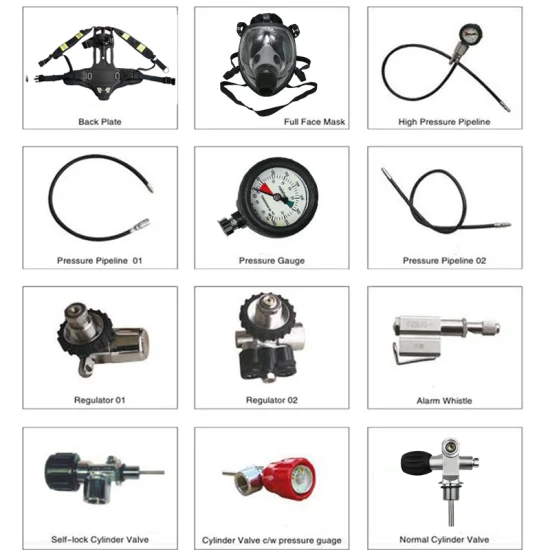

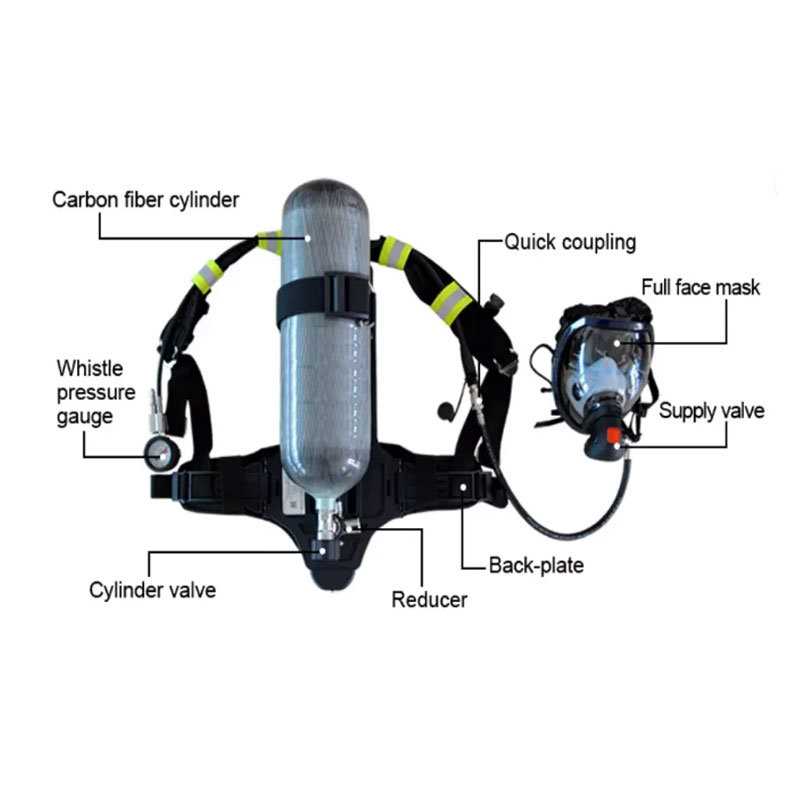

Understanding SCBA Components

Self-contained breathing systems are essential for maintaining air quality in hazardous environments. This section explores the main elements that make up these vital devices, highlighting how each piece works together to ensure a consistent supply of clean air.

Air Cylinder: The cylinder serves as the primary reservoir, holding pressurized air for the user. Made from durable materials, it’s designed to withstand high pressure, allowing extended usage in challenging conditions.

Pressure Regulator: This component is critical for managing the air flow, reducing the high-pressure air in the cylinder to a breathable level. By controlling air output, it ensures a steady and safe supply that matches the user’s needs.

Face Mask: The mask forms a sealed connection over the user’s face, safeguarding against harmful substances. Equipped with a clear visor, it pr

Main Features of SCBA Systems

These life-support units are designed to offer vital respiratory protection in hazardous environments. With various integrated components, they provide clean air, allowing users to breathe safely while operating in areas with harmful gases or low oxygen levels.

Air Supply Mechanism: A critical component of these systems is the high-pressure air source, which supplies breathable air to the user. This mechanism ensures that users have a consistent flow of clean air, even in the most demanding environments.

Face Seal and Mask: Equipped with a secure, well-fitted mask, these systems create a barrier between the user and external elements. The mask provides a clear field of vision while maintaining a snug fit to prevent leaks, ensuring full protection during use.

Pressure Regulator: The regulator is responsible for adjusting the air pressure to a comfortable and safe level for the user. By maintaining a steady pressure, it allows smooth and consistent airflow, enhancing the overall experience.

Harness and Support Frame: These systems

How SCBA Cylinders Work

The essential role of compressed air containers in protective breathing equipment is to store a reliable air supply, allowing users to operate in environments with limited oxygen. These containers are meticulously designed to endure high pressure, ensuring the user has ample, breathable air during critical situations.

Construction and Materials

The containers are typically made from durable materials to withstand intense pressures. Many are crafted from lightweight composites or high-grade metals to balance strength and portability. Inside, they are lined to protect against corrosion and other forms of wear, extending their lifespan and reliability.

Air Compression and Release

These containers hold air at very high pressure, usually filled at specialized stations. During operation, the air flows through a regulated system that reduces pressure to a safe, breathable level. This regulation ensures that the user receives a consistent air supply throughout their usage.

- Containers are filled to several thousand pounds per square inch, providing a substantial air reserve.

- They are tested periodically to ensure they can ma

Role of the Regulator in SCBA

The regulator is essential in providing users with a consistent and controlled supply of breathable air during demanding situations. This component is responsible for moderating the pressure of the air, allowing for safe and manageable inhalation throughout its use.

Functions of the Regulator

The regulator performs several crucial functions to ensure the user receives a steady flow of air. It serves to:

- Reduce high-pressure air to a usable level for comfortable breathing

- Maintain a steady flow, adjusting as needed based on the user’s breathing patterns

- Provide a secondary function as a safety feature by controlling airflow in case of emergencies

Regulator Components

The main components that contribute to the regulator’s efficiency and reliability include:

- Inlet Valve: Controls the entry of high-pressure air into the regulator

- Diaphragm: Adjusts airflow in response to the user’s breathing

SCBA Facepiece Essentials

The facepiece is a crucial component that provides a barrier, protecting the user from hazardous environments. This essential element is designed to shield the face while delivering a clear view and enabling comfortable breathing. With precise fittings and durable materials, it creates a secure seal, ensuring optimal functionality and safety in challenging conditions.

Facepieces come in various designs, tailored to different usage needs and user preferences. They often feature adjustable straps for a snug fit and incorporate transparent lenses that resist impact and scratches. The primary objective of this part is to maintain a reliable connection to the breathing apparatus, enabling efficient airflow without compromising visibility or comfort.

Key aspects of these protective items include their material resilience, adaptability for different face shapes, and the integration of safety features like anti-fog coatings or quick-release mechanisms. By prioritizing both safety and comfort, facepieces ensure users can focus on their tasks without distraction, even in high-risk scenarios.

SCBA Harness and Frame Structure

The harness and frame assembly serves as the backbone of any respiratory protection system, providing essential support and stability. Its design is crucial for ensuring comfort and efficiency, enabling users to carry the system effectively during operations. The combination of materials and structural elements plays a significant role in the overall functionality and reliability of the apparatus.

Frame: The framework is engineered to distribute weight evenly across the user’s body, minimizing fatigue during prolonged use. Constructed from durable materials, it offers both strength and flexibility. The design may include various attachment points for additional equipment, enhancing the versatility of the unit.

Harness: This component is designed to securely hold the assembly in place while allowing for a full range of motion. Its adjustable straps ensure a snug fit, accommodating various body sizes and shapes. The use of breathable fabrics enhances comfort, especially in demanding environments.

Overall, the integration of the harness and frame not only improves safety but also facilitates ease of use, allowing operators to focus on their tasks without being hindered by discomfort or instability.

Air Supply Valves in SCBA

The air supply mechanisms play a crucial role in ensuring a continuous flow of breathable atmosphere for users operating in hazardous environments. Understanding these components is essential for maintaining safety and efficiency during use.

Air supply valves are integral to the functioning of these breathing systems. They regulate the flow of air from the storage cylinders to the mask, allowing users to control their air intake as needed. Here are some key functions and features:

- Flow Regulation: These valves manage the amount of air delivered, adjusting it based on the user’s requirements.

- Emergency Release: In critical situations, they provide a mechanism for rapid air release, ensuring user safety.

- Pressure Monitoring: Many valves include gauges that indicate the remaining air pressure, helping users plan their operations effectively.

- Durability: Designed to withstand extreme conditions, these mechanisms are made from robust materials to ensure reliability.

Proper maintenance and regular inspections of these valves are essential for optimal performance. Users should be trained to recognize potential issues, such as leaks or malfunctioning components, to guarantee a secure and efficient operation.

In summary, understanding the role of air supply mechanisms enhances safety and effectiveness, allowing users to focus on their tasks without compromising their well-being.

Importance of the Pressure Gauge

The pressure gauge is a crucial component that ensures safe and efficient operation within various systems. Its primary function is to monitor the pressure levels, providing vital information that helps in maintaining optimal performance. By continuously displaying pressure readings, this instrument plays a significant role in the overall functionality and safety of the equipment.

Critical Role in Safety

Monitoring pressure levels is essential for preventing hazardous situations. Anomalies in pressure can lead to catastrophic failures, potentially putting users at risk. The pressure gauge serves as an early warning system, allowing for timely interventions to address any irregularities. This proactive approach helps in safeguarding both the equipment and its operators.

Enhancing Operational Efficiency

Accurate pressure readings contribute to the efficient operation of the system. By providing real-time data, the gauge allows users to make informed decisions regarding the functioning of the equipment. Maintaining the correct pressure levels not only enhances performance but also prolongs the lifespan of the machinery, ultimately leading to reduced maintenance costs.

Feature Benefit Real-time Monitoring Ensures immediate awareness of pressure levels Safety Alerts Prevents dangerous situations through early detection Operational Insights Facilitates optimal functioning and maintenance SCBA Alarm Mechanisms Explained

In the realm of respiratory protection systems, monitoring user safety is of utmost importance. Various alerting devices play a critical role in ensuring that individuals are promptly notified of potential dangers, such as low air supply or equipment malfunction. Understanding these alarm mechanisms enhances user awareness and reinforces safe practices in hazardous environments.

Types of Alert Systems

Different alert systems are employed to provide immediate warnings. The most common types include auditory signals and visual indicators. Auditory alarms emit distinct sounds, drawing attention to any urgent situation. In contrast, visual alerts often utilize flashing lights or indicators to signal when attention is required. Both systems are designed to be easily recognizable, allowing users to respond quickly.

Functionality of Alarms

The primary function of these alert mechanisms is to provide real-time feedback regarding the operational status of the breathing apparatus. When a user’s air supply diminishes to a predetermined level, the alarm system activates, ensuring that individuals are aware of the need to exit or recharge the device. Additionally, these systems can detect malfunctions within the equipment, offering another layer of safety by alerting users to issues that may compromise their protection. Such proactive measures are essential in environments where safety cannot be compromised.

Functions of the Second Stage Regulator

The second stage regulator plays a crucial role in ensuring optimal performance and safety during breathing operations in demanding environments. It is responsible for delivering air at a pressure that is comfortable and usable for the individual. This component enhances the overall efficiency of the breathing apparatus, allowing for better control and adaptability to varying conditions.

Pressure Regulation: One of the primary functions of this regulator is to reduce the high-pressure air supplied from the primary tank to a manageable level. By doing so, it maintains a consistent and safe airflow, which is essential for the user’s comfort and functionality.

Flow Adjustment: The second stage also regulates the flow of air based on the user’s inhalation needs. It ensures that the right amount of air is available without excessive force, promoting a more natural breathing pattern. This dynamic adjustment is vital for efficient air consumption during extended usage.

Safety Features: Additionally, this component incorporates safety mechanisms that prevent excessive pressure from reaching the user. In the event of a malfunction, it is designed to fail safely, ensuring that the individual still has access to breathable air.

Performance Monitoring: Some advanced models include features that monitor air flow and pressure, providing real-time feedback to the user. This functionality allows for better planning and management of air supply, critical in emergency situations.

In summary, the second stage regulator is an essential element that significantly enhances the usability, safety, and effectiveness of the overall system, ensuring users can operate efficiently and securely in their respective environments.

SCBA Backplate and Mounting

The backplate serves as a fundamental component in ensuring stability and comfort while utilizing respiratory protection systems. It is designed to securely hold various elements in place, providing a reliable foundation for optimal functionality. Understanding the construction and features of this element is essential for effective usage and maintenance.

Key Features of the Backplate

- Material: Typically constructed from durable and lightweight materials for enhanced mobility.

- Ergonomics: Designed to conform to the user’s back, minimizing pressure points during extended use.

- Attachment Points: Equipped with various mounting locations to secure additional equipment or accessories.

- Adjustability: Features adjustable straps to accommodate different body sizes and preferences.

Mounting Options

Mounting mechanisms are crucial for integrating the essential components into the system efficiently. Different methods can be employed, depending on the intended application and user preferences.

- Quick-Release Buckles: Allow for fast detachment and reattachment, facilitating easy access.

- Hook and Loop Straps: Provide adjustable tension, ensuring a snug fit.

- Clamp Systems: Offer robust support for securely fastening additional apparatus.

- Customizable Mounts: Enable users to tailor their setup according to specific operational requirements.

Incorporating these elements effectively enhances the overall performance and usability of respiratory protection equipment, ensuring safety and comfort in critical situations.

SCBA Mask Seal and Safety

The integrity of a respiratory protective device is crucial for ensuring the safety of the user in hazardous environments. A reliable seal plays a vital role in maintaining the effectiveness of the breathing apparatus. Any compromise in this area can lead to potential exposure to harmful substances, making it essential to prioritize the quality of the fit and the condition of the sealing components.

Importance of a Proper Seal

Achieving a secure and effective fit is paramount for optimal performance. A well-fitted mask ensures that the user receives uncontaminated air while preventing external pollutants from entering the breathing zone. Regular inspection of the sealing edges and materials can identify wear and tear that might compromise safety. Proper training on how to adjust and test the fit of the equipment can further enhance user protection.

Maintenance Practices

Routine maintenance of the sealing mechanism is essential for long-term reliability. Users should regularly clean and inspect the sealing surfaces to prevent degradation from environmental factors or chemical exposure. Replacing worn components and adhering to manufacturer guidelines can significantly enhance the lifespan and effectiveness of the apparatus. Furthermore, conducting fit tests before each use helps ensure that the equipment functions as intended, providing peace of mind to the wearer.