Complete Guide to Husqvarna 257 Parts Diagram

In the realm of outdoor machinery, having a clear understanding of the various elements that make up your device is essential for maintenance and repair. This knowledge not only aids in troubleshooting but also enhances the overall performance and longevity of the equipment. By familiarizing yourself with the intricate layout of its components, you can ensure that each part functions optimally and contributes to the machine’s efficiency.

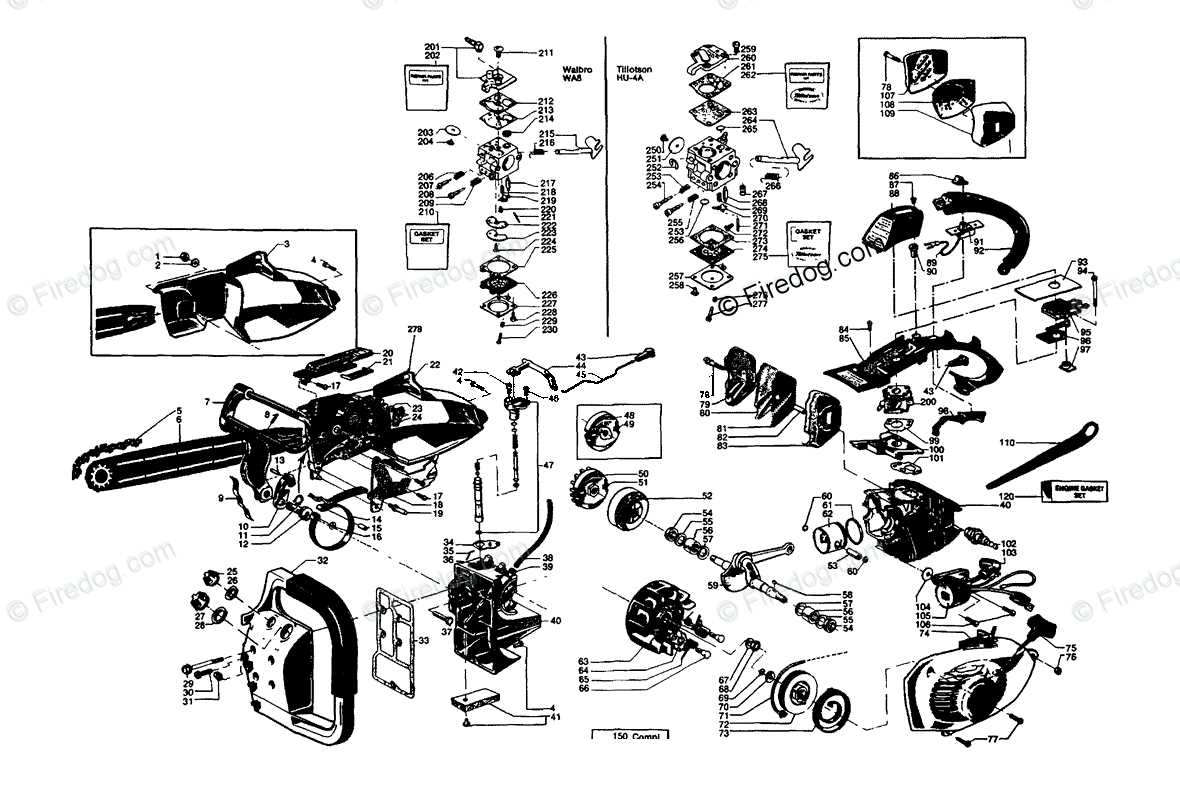

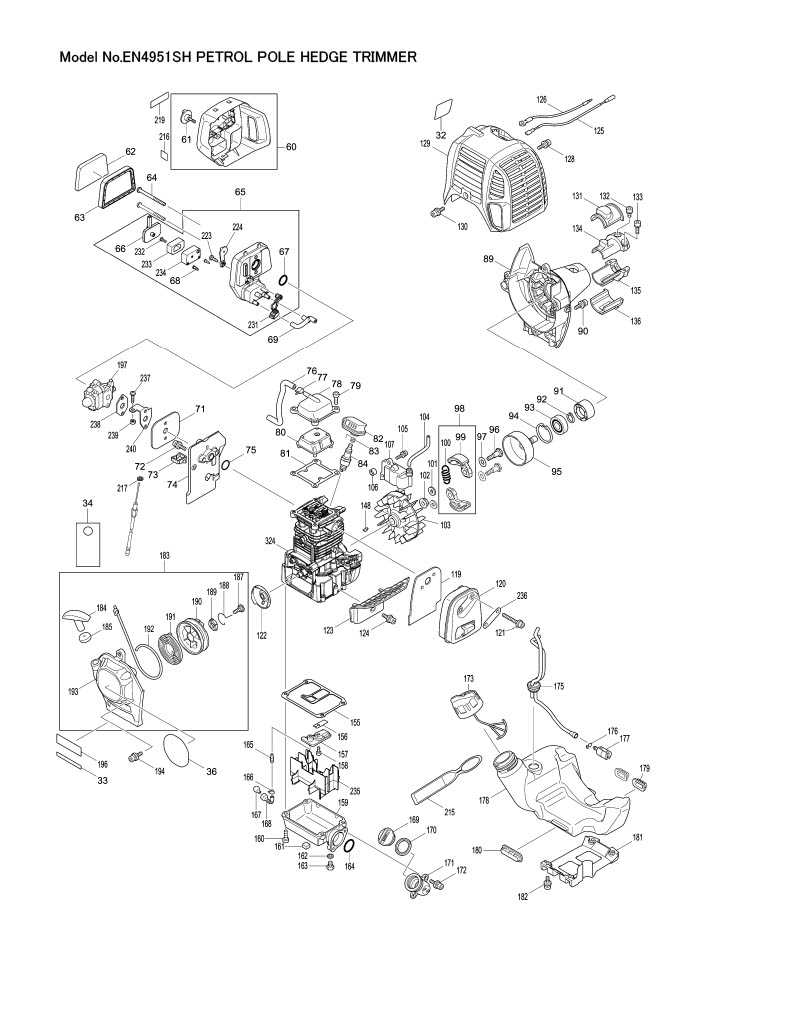

Visual representations of these components serve as invaluable tools for both novice users and seasoned professionals. They provide a comprehensive overview of how each section interacts with others, simplifying the process of identification and replacement. By studying these schematics, one can quickly pinpoint areas that may require attention, whether due to wear, damage, or routine servicing.

Additionally, having access to detailed illustrations can empower users to tackle repairs with confidence. Understanding the arrangement of individual elements allows for a systematic approach, minimizing the risk of errors during reassembly. Ultimately, this knowledge transforms complex tasks into manageable ones, ensuring that your machinery remains in peak condition for years to come.

Understanding the Husqvarna 257 Diagram

Comprehending the layout of components in machinery is essential for effective maintenance and repair. A clear visual representation can aid in identifying each element and its function, ensuring that users can troubleshoot issues efficiently. Familiarity with the arrangement enhances the ability to disassemble and reassemble devices correctly, ultimately extending their lifespan.

Importance of Component Familiarity

Knowing the specific roles of various parts helps in diagnosing problems quickly. When users can visualize where each piece fits, they can make informed decisions during repairs or replacements. This understanding not only streamlines the repair process but also minimizes the risk of errors that could lead to further damage.

Enhancing Maintenance Skills

With a solid grasp of the layout, individuals can develop their skills in equipment upkeep. Whether it’s routine cleaning, part replacement, or deeper repairs, recognizing how elements interact fosters confidence. A detailed illustration serves as a valuable reference, allowing users to perform tasks more effectively and safely.

Overview of Husqvarna 257 Components

This section provides a comprehensive look at the essential elements that make up a popular outdoor power tool. Understanding these components is crucial for maintenance, repair, and ensuring optimal performance. Each part plays a significant role in the overall functionality, contributing to the efficiency and durability of the equipment.

Engine: The heart of the machine, this component generates the necessary power for operation. It typically features a two-stroke or four-stroke design, impacting fuel efficiency and emissions.

Bar and Chain: These elements work together to cut through various materials. The bar supports the chain, which has sharpened links designed for slicing efficiently.

Air Filter: This part is essential for maintaining engine performance by preventing dirt and debris from entering. Regular cleaning or replacement is necessary for longevity.

Fuel System: Comprising the fuel tank, lines, and carburetor, this system is vital for delivering the right mixture of air and fuel to the engine. Proper maintenance ensures reliable starts and optimal performance.

Ignition System: Responsible for starting the engine, this system includes components such as the spark plug and coil. Troubleshooting ignition issues is key to keeping the equipment operational.

Safety Features: Built-in mechanisms ensure user safety, such as chain brakes and throttle lockouts. Familiarity with these features enhances safe operation and reduces the risk of accidents.

Importance of Accurate Parts Identification

Understanding the precise components of machinery is crucial for maintaining optimal performance and ensuring longevity. Identifying the right elements allows users to make informed decisions regarding repairs and replacements, ultimately enhancing the efficiency of the equipment.

Accurate identification minimizes the risk of errors during maintenance, which can lead to costly downtime or further damage. When users can delve into specifics, they are more likely to find the ultimate solutions tailored to their needs.

Furthermore, knowing the correct components aids in sourcing quality replacements, ensuring compatibility and functionality. This knowledge fosters confidence in handling machinery, empowering users to tackle challenges effectively.

Common Issues with Husqvarna 257 Parts

When it comes to maintenance of outdoor power equipment, certain components often face recurring challenges that can affect performance. Understanding these common problems can help users take proactive steps to ensure longevity and efficiency.

Frequent Problems

- Wear and tear due to regular use.

- Clogs in fuel lines leading to poor performance.

- Electrical issues caused by faulty wiring.

- Overheating of the engine from inadequate cooling.

Preventive Measures

- Regularly inspect and replace worn components.

- Clean fuel systems to prevent blockages.

- Check wiring and connections for damage.

- Ensure proper ventilation around the engine.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring a machinery unit, ensuring efficient operation and longevity. By following a systematic method, you can tackle any issues with clarity and precision.

Preparation

- Gather necessary tools and materials.

- Consult the manual for specifications and safety guidelines.

- Find a clean, organized workspace to avoid misplacing parts.

Disassembly

- Turn off and disconnect the power source.

- Carefully remove outer casing and access panels.

- Document the location of each component for reassembly.

By following these steps, you will establish a solid foundation for successful repairs, leading to ultimate efficiency and functionality.

Where to Find Replacement Parts

Finding components for your outdoor equipment can often be a daunting task, yet it’s essential for maintaining optimal performance. Fortunately, there are several reliable sources to explore that offer a wide range of options to meet your needs.

Online retailers are one of the most convenient avenues for sourcing necessary items. Websites specializing in outdoor machinery frequently provide an extensive catalog of available components, complete with specifications and compatibility details. These platforms often feature customer reviews, which can help guide your selection.

Local hardware stores and authorized service centers also represent valuable resources. Staffed by knowledgeable personnel, these establishments can offer expert advice and may have the specific items you require in stock. Additionally, they can assist with identifying compatible alternatives if certain components are unavailable.

For those seeking more personalized options, online marketplaces allow users to connect directly with individual sellers. This can lead to discovering rare or discontinued components that may not be easily found through traditional channels.

Lastly, participating in forums and community groups dedicated to outdoor equipment can yield fruitful leads. Fellow enthusiasts often share recommendations and experiences regarding where to locate specific items, enhancing your chances of finding exactly what you need.

Comparing Original vs. Aftermarket Parts

When considering components for machinery, it’s essential to evaluate the differences between genuine and alternative options. Each category offers distinct advantages and potential drawbacks, influencing both performance and longevity.

Original components are often manufactured by the brand itself, ensuring compatibility and adherence to quality standards. This can lead to enhanced reliability and optimal functionality over time.

On the other hand, aftermarket alternatives typically provide cost-effective solutions. These options may vary in quality and can sometimes deliver improved performance or unique features that appeal to specific needs.

Ultimately, the decision hinges on individual priorities, whether that be budget constraints, performance expectations, or the desire for warranty coverage. By carefully examining both types, one can make an informed choice that aligns with their requirements.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your outdoor power equipment requires regular upkeep and attention. Implementing effective maintenance practices can significantly extend the lifespan of your machinery, helping you avoid costly repairs and replacements. Below are essential tips to keep your equipment running smoothly.

Regular Cleaning

Keeping your tools clean is fundamental to their longevity. After each use, remove any debris, grass clippings, or dirt that may accumulate. This not only prevents corrosion but also ensures proper airflow and functionality. Use a soft brush or compressed air to reach tight areas, ensuring that every part is free of obstructions.

Scheduled Inspections

Conducting periodic inspections is vital for early detection of wear and tear. Check essential components such as the blades, filters, and belts regularly. Replace any damaged parts promptly to prevent further issues. Keeping an eye on fuel lines and connections can also help avert leaks and ensure safety during operation.

Emphasizing the importance of these practices will lead to a more reliable performance and enhance the overall efficiency of your outdoor tools. Consistent attention to maintenance will ultimately reward you with a smoother and more enjoyable experience in your yard work.

Tools Needed for Repairs

When it comes to maintenance and fixing equipment, having the right tools is essential for achieving optimal results. A well-equipped toolbox not only facilitates smoother repairs but also ensures safety and efficiency during the process.

Essential Tools

- Wrenches: Adjustable and fixed sizes to handle various bolts and nuts.

- Screwdrivers: A set including flathead and Phillips for different screw types.

- Pliers: Needle-nose and slip-joint pliers for gripping and bending tasks.

- Torque Wrench: For applying precise torque to fasteners.

- Hex Keys: Often needed for hexagonal screws and bolts.

Additional Equipment

- Safety Gear: Gloves and goggles to protect against injuries.

- Cleaning Supplies: Rags and solvents to maintain cleanliness during repairs.

- Lubricants: Essential for ensuring moving parts operate smoothly.

- Measuring Tools: Rulers or calipers for accurate measurements.

- Work Light: To illuminate dark areas during inspections and repairs.

Having these tools on hand will make the repair process more efficient and effective, allowing for a thorough and safe approach to any maintenance task.

Exploring Parts Compatibility Options

Understanding the various components that make up your machinery is essential for effective maintenance and repair. Compatibility among different models and brands can significantly impact functionality and performance. By delving into the available alternatives, you can ensure that replacements not only fit properly but also enhance the overall efficiency of your equipment.

When considering substitutes, it’s crucial to evaluate specifications and design features. Many manufacturers provide compatibility charts that outline which elements can be interchanged without compromising quality. This exploration can lead to finding the ultimate solutions that meet both budgetary and operational needs.

Additionally, consulting with experts or utilizing online forums can provide valuable insights into potential matches. Engaging with communities can help you discover recommended alternatives that others have successfully implemented, further broadening your options.

Visual Guide to the Parts Diagram

This section provides an illustrative overview of the components that make up a specific model, offering clarity and insight into each element’s function and placement. Understanding these elements is crucial for maintenance and repair tasks.

Component Breakdown

- Engine Assembly

- Chassis Structure

- Control Mechanisms

- Fuel System

- Cutting Equipment

Maintenance Tips

- Regularly check the engine for wear and tear.

- Ensure the chassis is free of debris.

- Inspect control mechanisms for responsiveness.

- Monitor fuel system for leaks.

- Sharpen cutting equipment as needed.

DIY vs. Professional Repairs

When it comes to maintaining machinery, the choice between tackling repairs independently or hiring an expert can significantly impact both time and cost. Each approach has its own set of advantages and challenges, making it essential to evaluate which path aligns best with your skills and needs.

Advantages of DIY Repairs

- Cost-effective: Save on labor costs by handling repairs yourself.

- Learning experience: Gain valuable knowledge about the equipment.

- Flexibility: Work on your own schedule without waiting for a professional.

Benefits of Professional Services

- Expertise: Access to specialized knowledge and experience.

- Time-saving: Quick resolution of complex issues.

- Warranty protection: Ensure that repairs are done correctly to maintain warranty status.

Ultimately, weighing these factors will help you decide the best route for keeping your equipment in top shape.

Frequently Asked Questions About Husqvarna 257

This section addresses common inquiries related to a specific outdoor equipment model, focusing on its maintenance, functionality, and available components. Understanding these aspects can enhance user experience and prolong the life of the machinery.

General Maintenance

Regular upkeep is essential for optimal performance. Users often wonder how frequently they should perform routine checks and replacements to ensure longevity.

Available Components

Many users seek information about where to find replacements and upgrades for their machinery. Identifying compatible parts can be crucial for repairs.

| Question | Answer |

|---|---|

| How often should I service my equipment? | It is recommended to service it at least once a year or after a significant number of hours of use. |

| Where can I find replacement components? | Check authorized dealers, online retailers, and specialty shops for compatible options. |

| What maintenance tasks should I prioritize? | Focus on cleaning, sharpening, and replacing worn-out items to maintain efficiency. |