Understanding Yamaha Outboard Parts Diagram for Ultimate Maintenance

When it comes to maintaining aquatic machinery, having a comprehensive grasp of its essential elements is vital. This knowledge not only enhances performance but also extends the lifespan of the equipment. Enthusiasts and professionals alike benefit from exploring the intricate connections and functionalities within these mechanical systems.

In this section, we will delve into the specific elements that make up marine propulsion systems, providing an ultimate resource for those looking to troubleshoot or upgrade their vessels. By examining various configurations and components, users can gain insight into optimal performance and maintenance strategies.

Moreover, a thorough understanding of these components empowers boat owners to make informed decisions regarding repairs and replacements. Whether you are a novice or an experienced sailor, having access to clear visual representations will facilitate your learning process and improve your hands-on skills.

Understanding Yamaha Outboard Motor Components

Grasping the intricacies of marine propulsion systems is essential for enthusiasts and professionals alike. Familiarity with the individual elements that contribute to overall functionality can enhance maintenance, repair, and performance optimization.

Core Elements

The primary components play a pivotal role in ensuring smooth operation. These elements include the power unit, transmission assembly, and cooling mechanisms, each designed to work in harmony. A comprehensive understanding of their interactions is vital for troubleshooting and enhancing efficiency.

Maintenance and Troubleshooting

Regular examination of these key components is crucial. Identifying wear and tear early can prevent more significant issues down the line. Proper upkeep not only prolongs lifespan but also maximizes performance, allowing for an enjoyable experience on the water.

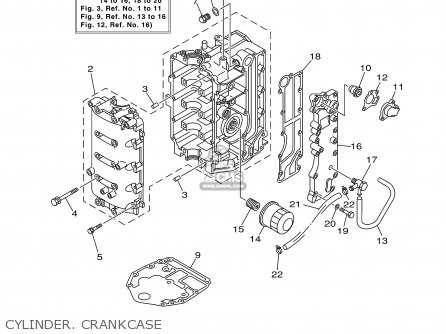

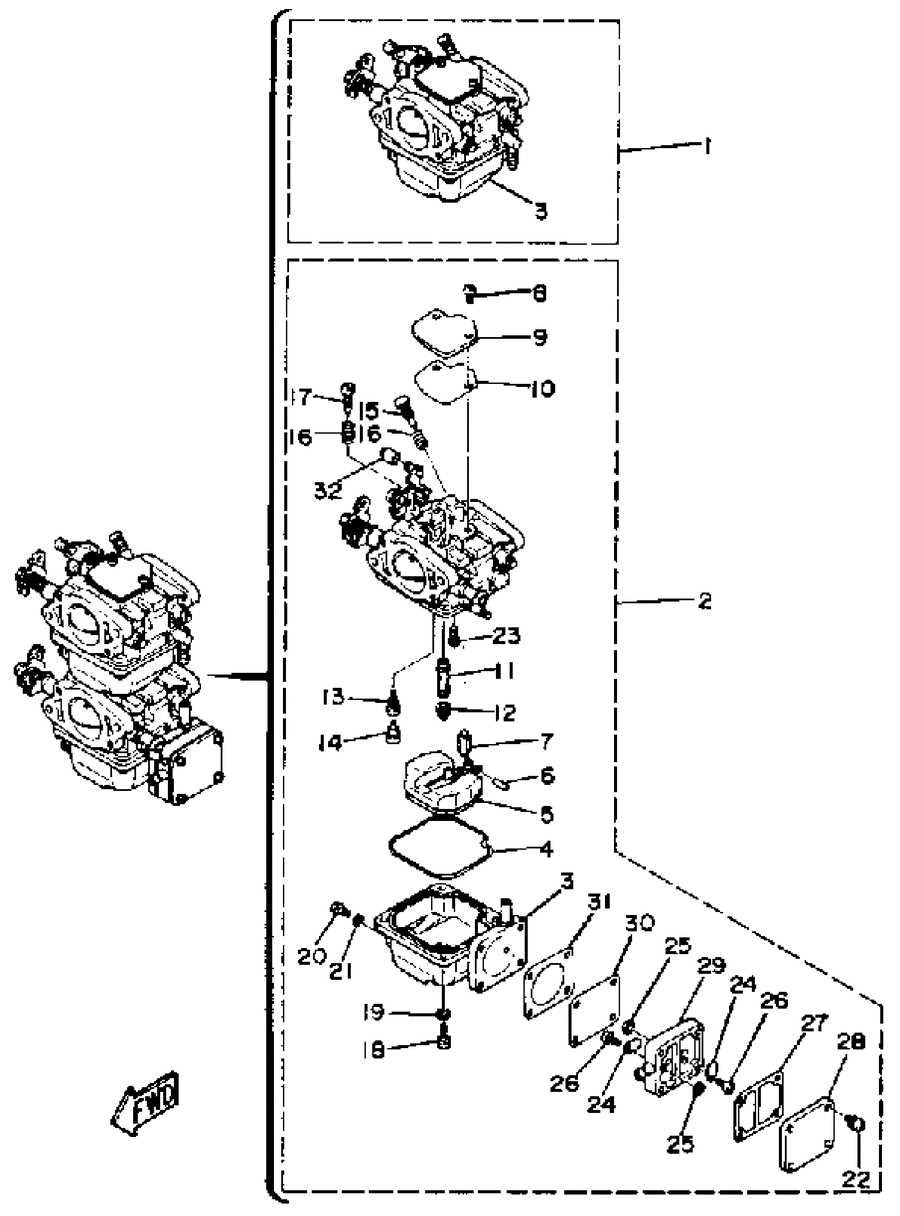

Importance of Accurate Parts Diagrams

Having precise visual representations of components is crucial for effective maintenance and repair. These illustrations serve as essential tools for technicians and enthusiasts alike, enabling them to identify and source the necessary elements efficiently. Without clarity in these visual aids, the risk of errors during assembly or replacement increases significantly.

Enhancing Efficiency

Accurate visuals streamline the troubleshooting process. They allow users to quickly pinpoint issues and understand the arrangement of various elements, ultimately saving time and reducing frustration.

Ensuring Compatibility

When dealing with numerous models and variations, clarity in illustrations ensures that the correct items are selected for replacements. This minimizes the likelihood of incompatible components being used, which could lead to further complications.

Identifying Common Yamaha Outboard Issues

Recognizing typical problems in marine engines is crucial for maintaining optimal performance and ensuring longevity. By understanding these common issues, boaters can take proactive measures to prevent more significant damages and costly repairs.

Engine Performance Issues

Many users experience a decline in engine efficiency, which can manifest as reduced power or stalling. These symptoms often point to fuel supply problems, electrical malfunctions, or clogged filters.

Cooling System Failures

A malfunctioning cooling system can lead to overheating and severe engine damage. Regular inspections are essential to catch signs of blockages or leaks early.

| Issue | Symptoms | Potential Causes |

|---|---|---|

| Power Loss | Slow acceleration, stalling | Fuel issues, electrical problems |

| Overheating | Temperature warnings, steam | Blocked cooling passages, leaks |

Essential Maintenance for Longevity

Regular upkeep is crucial for ensuring the durability and efficiency of any marine equipment. By implementing a consistent maintenance routine, you can prevent potential issues and enhance the performance of your vessel. This proactive approach not only saves time and money but also provides peace of mind on the water.

Key Practices to Consider

Routine Inspections: Conduct frequent checks on vital components to identify wear and tear early. Regularly examining the condition of the engine, fuel system, and electrical connections can prevent unexpected breakdowns.

Lubrication and Cleaning

Proper Lubrication: Ensuring all moving parts are well-lubricated minimizes friction and wear. Cleaning is equally important; removing debris and salt buildup protects surfaces and prolongs the lifespan of critical elements.

How to Use Parts Diagrams Effectively

Understanding visual representations of components can significantly enhance your maintenance and repair tasks. These illustrations serve as essential tools for identifying each element, ensuring that you can locate and procure the correct items needed for any job.

1. Familiarize Yourself with the Layout

Begin by studying the overall layout of the illustration. Recognizing the structure and arrangement of different sections allows for quicker navigation and understanding of how various elements interconnect.

2. Cross-Reference with Manuals

Utilize the visual guides in conjunction with your user manuals. This combination provides a comprehensive understanding, helping you make informed decisions when replacing or repairing components.

Top Tools for Outboard Repairs

When it comes to maintaining and fixing marine engines, having the right equipment is essential for ensuring optimal performance and longevity. The right tools not only simplify the repair process but also enhance the quality of the work done, making every task more efficient and effective.

Essential Hand Tools

Investing in a set of high-quality hand tools is crucial. A combination of wrenches, screwdrivers, and pliers should be at the top of your list. These tools enable you to tackle a variety of tasks, from tightening screws to adjusting fittings. A well-organized toolkit allows for quick access and efficient workflow.

Power Tools for Efficiency

For more complex repairs, power tools such as drills and impact wrenches can significantly reduce time and effort. These devices are designed to handle tough jobs, making them invaluable for tasks like removing stubborn bolts or drilling precise holes. Selecting the right power tools can elevate your repair experience.

Finding Authentic Yamaha Parts Online

When it comes to maintaining your watercraft, sourcing genuine components is crucial for performance and longevity. With a plethora of options available online, distinguishing between authentic items and counterfeit alternatives can be a daunting task. This guide aims to streamline your search and ensure that you acquire high-quality elements for your vessel.

Tips for Identifying Genuine Components

First and foremost, always purchase from reputable dealers. Look for authorized retailers or well-established online platforms that specialize in marine supplies. Check customer reviews and ratings to gauge their reliability. Furthermore, scrutinize the product descriptions and images; authentic items typically have detailed specifications and clear branding.

Understanding the Importance of Quality

Investing in high-quality components ensures not only optimal performance but also safety while navigating. Counterfeit or subpar alternatives may lead to malfunction, potentially causing damage to your craft or even posing a risk to your safety. Therefore, taking the time to find the right source for genuine components is essential for any watercraft enthusiast.

Differences Between 2-Stroke and 4-Stroke

The choice between two distinct engine types often influences performance, efficiency, and maintenance requirements. Understanding their fundamental characteristics can help in selecting the most suitable option for specific needs.

Two-stroke engines complete a power cycle with every two strokes of the piston, resulting in a simpler design and lighter weight. They tend to provide higher power output for their size, making them popular in applications requiring quick acceleration. However, their fuel efficiency is generally lower, and they may produce more emissions due to incomplete combustion.

In contrast, four-stroke engines operate with a more complex cycle that requires four strokes of the piston to complete one power cycle. This design allows for better fuel efficiency and lower emissions, contributing to a cleaner operation. They typically offer more torque at lower RPMs, making them suitable for applications where sustained power is necessary.

Maintenance also differs between the two types. Two-stroke engines usually require more frequent servicing due to their design, while four-stroke engines tend to have longer intervals between maintenance tasks. Ultimately, the choice between these engines depends on the specific requirements of the task at hand and personal preferences regarding performance and upkeep.

Upgrading vs. Replacing Outboard Parts

When it comes to enhancing the performance of your marine engine, two primary approaches often emerge: upgrading existing components or replacing them entirely. Each option presents unique benefits and considerations that can significantly impact your vessel’s efficiency and longevity.

Benefits of Upgrading

Upgrading allows for improved performance without the need for a complete overhaul. This method often focuses on enhancing specific functionalities, such as boosting speed or fuel efficiency, while retaining much of the original system.

When to Replace

Replacement may become necessary when components are worn out or fail to meet modern standards. Newer models often come with advancements that enhance reliability and reduce maintenance costs in the long run.

| Criteria | Upgrading | Replacing |

|---|---|---|

| Cost | Generally lower initial expense | Higher upfront investment |

| Performance | Improvement in specific areas | Potential for overall enhancement |

| Longevity | Can extend life of components | Fresh start with new technology |

Seasonal Checklists for Outboard Owners

Maintaining your marine engine throughout the year is essential for optimal performance and longevity. A well-structured seasonal checklist can help ensure that your equipment is always ready for the water, regardless of the time of year. Below, you’ll find vital tasks to keep in mind as you prepare for each season.

Spring Checklist:

- Inspect fuel lines and replace if necessary.

- Change the oil and oil filter.

- Check the battery charge and connections.

- Examine the propeller for any signs of wear or damage.

Summer Checklist:

- Monitor coolant levels and top off if needed.

- Inspect the hull for any cracks or blisters.

- Test all electrical systems and lights.

- Ensure the safety equipment is up to date.

Fall Checklist:

- Flush the cooling system with fresh water.

- Remove and clean the spark plugs.

- Store the battery properly for the winter.

- Cover the engine to protect it from elements.

Winter Checklist:

- Thoroughly clean and dry the unit.

- Inspect all seals and gaskets for wear.

- Store in a climate-controlled environment if possible.

- Check for any signs of corrosion.

Following these checklists will help ensure your equipment is always in peak condition, ready for the ultimate adventure on the water.