Kubota B2710 Parts Diagram for Easy Reference

In the world of machinery maintenance, having a comprehensive understanding of each element is crucial for optimal performance and longevity. Every piece of equipment is made up of numerous intricate parts, each playing a vital role in ensuring seamless operation. A clear visual representation can significantly enhance the efficiency of repairs and upgrades.

Whether you’re a seasoned professional or a novice operator, familiarizing yourself with the configuration of these essential elements will empower you to make informed decisions. By delving into the structure and interconnectivity of the components, you can achieve the ultimate maintenance outcomes and reduce downtime.

In this section, we will explore the various features and arrangements of critical machine elements, providing insights that can aid in troubleshooting and enhancing overall functionality. This knowledge will serve as a valuable resource in your endeavors to maintain and optimize your agricultural assets.

Kubota B2710 Overview

This section provides a comprehensive insight into a specific compact agricultural machine, highlighting its features, specifications, and overall capabilities. The focus is on understanding the essential components and functionalities that make this model a preferred choice among users in various agricultural and landscaping tasks.

Key Features

The machine is designed with a robust structure and advanced technology, offering impressive performance and efficiency. Some of the standout characteristics include:

| Feature | Description |

|---|---|

| Engine Power | Equipped with a powerful engine that ensures reliable operation for various tasks. |

| Compact Design | Offers maneuverability in tight spaces, making it ideal for small to medium-sized farms. |

| Versatility | Compatible with numerous attachments, enhancing its utility for different applications. |

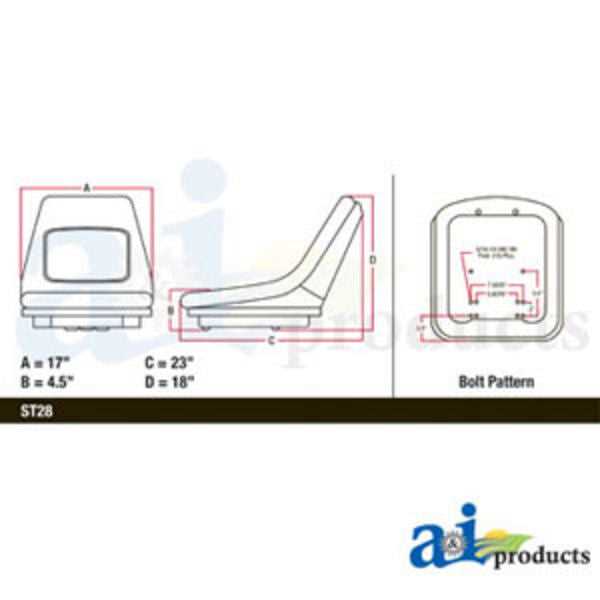

| Operator Comfort | Features a user-friendly cockpit and ergonomic controls for ease of use during prolonged operation. |

Specifications

Understanding the technical specifications helps users make informed decisions about this machine’s suitability for their needs. Here are some critical specifications:

| Specification | Details |

|---|---|

| Weight | Approximately 1,000 kg |

| Width | About 1.2 meters |

| Height | Roughly 2.1 meters |

| Fuel Capacity | 25 liters |

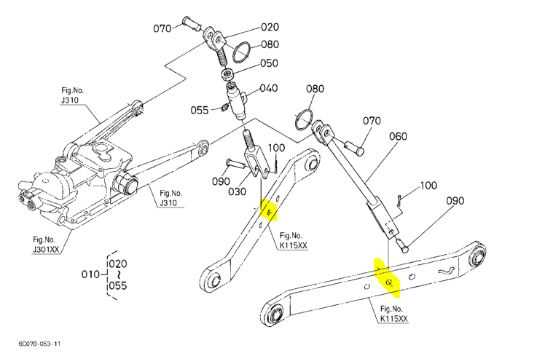

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements play a significant role in simplifying complex structures, making it easier for technicians and enthusiasts to identify and address issues. These illustrations serve not only as a reference but also as a valuable educational tool.

Benefits of Visual References

- Enhances comprehension of intricate assemblies.

- Facilitates accurate identification of specific components.

- Reduces the likelihood of errors during repairs.

- Assists in inventory management by clarifying which parts are needed.

Application in Maintenance

- Streamlines the repair process by providing clear guidance.

- Encourages preventative measures through better understanding of wear and tear.

- Enables quicker troubleshooting by isolating problematic areas.

- Promotes informed decision-making regarding replacements or upgrades.

In conclusion, visual aids are indispensable tools for anyone involved in machinery upkeep. They foster efficiency, accuracy, and knowledge, ultimately leading to improved performance and longevity of equipment.

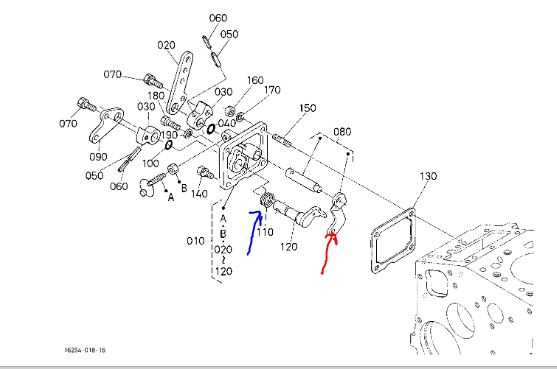

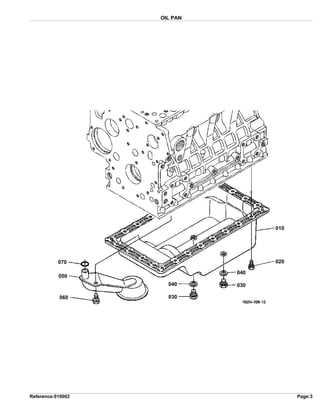

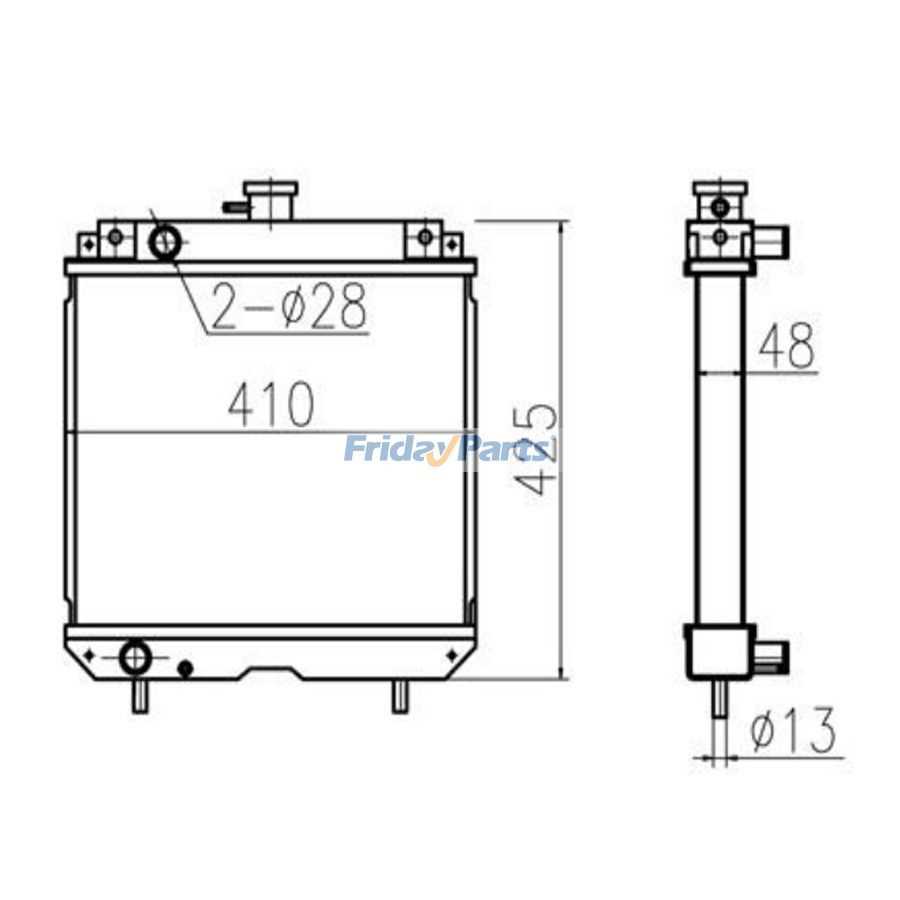

Key Components of B2710

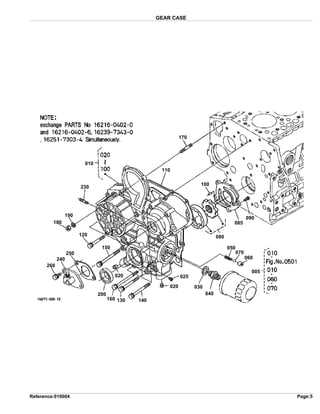

This section explores the essential elements that contribute to the functionality and efficiency of the machine. Understanding these components is crucial for maintenance and optimal performance.

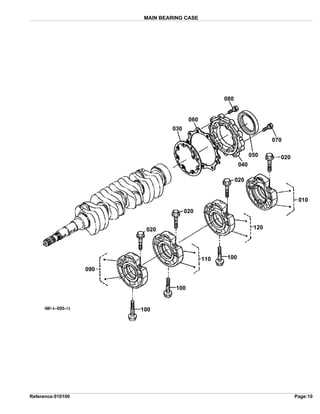

Engine: The powerhouse of the equipment, providing the necessary torque and horsepower to perform various tasks.

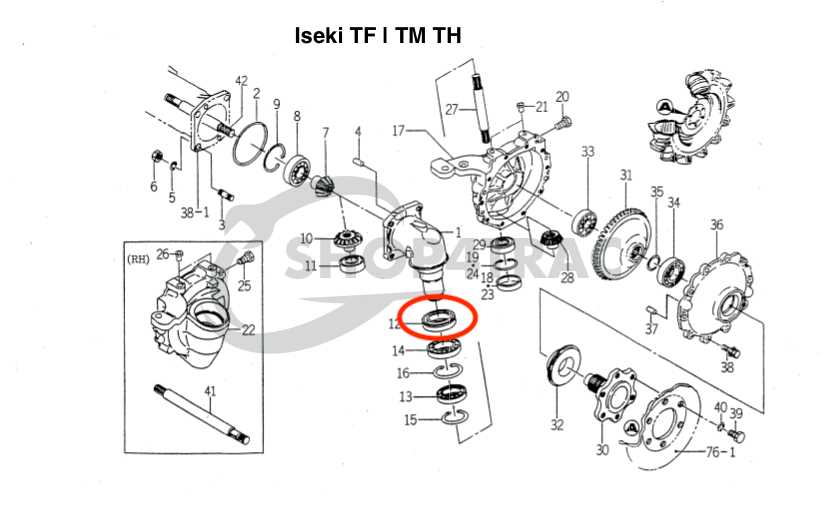

Transmission: This system facilitates smooth gear shifts and effective power distribution, enhancing maneuverability.

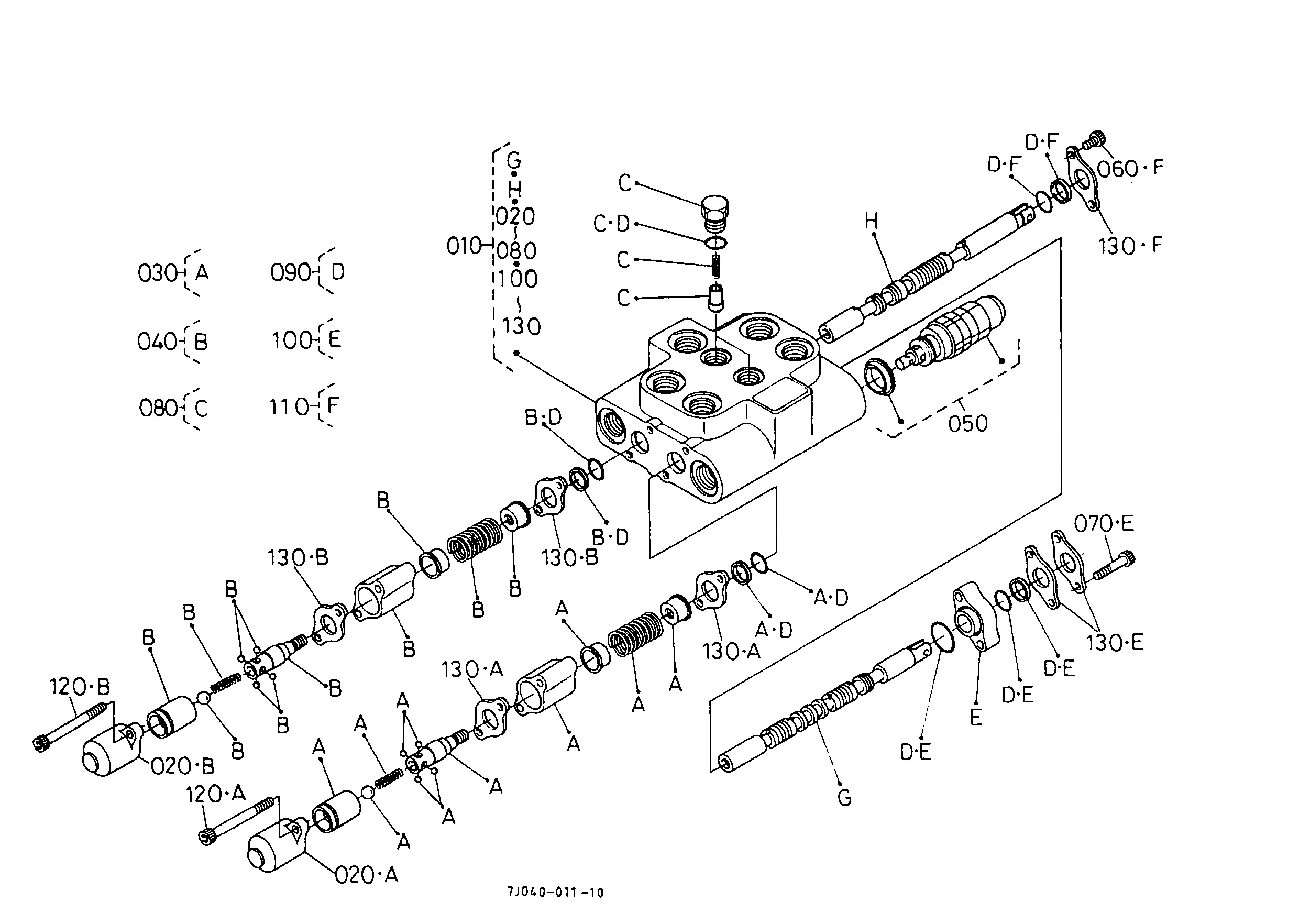

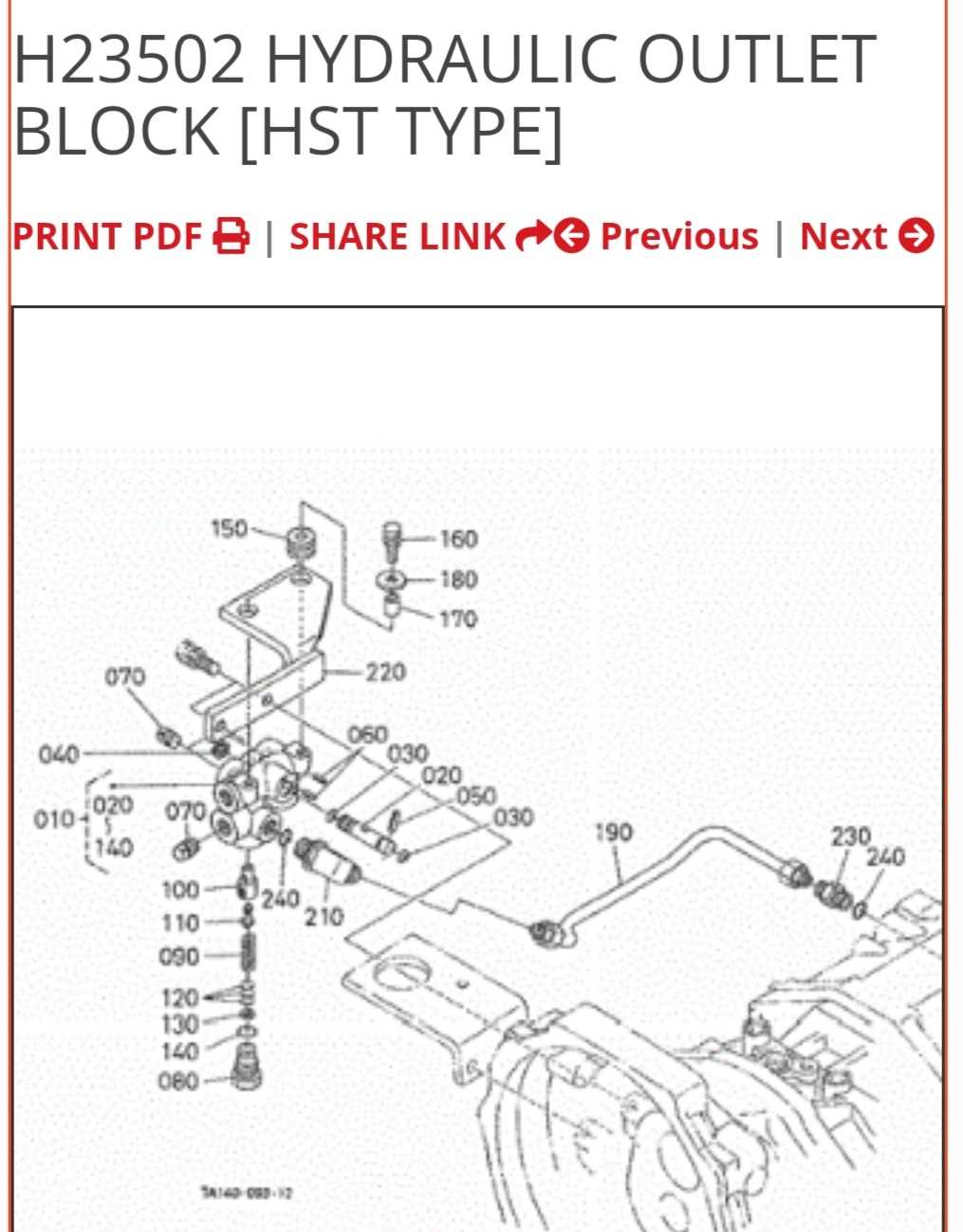

Hydraulic System: An integral part that enables the operation of attachments and implements, allowing for versatile usage.

Chassis: The frame structure supports all other components, ensuring stability and durability during operation.

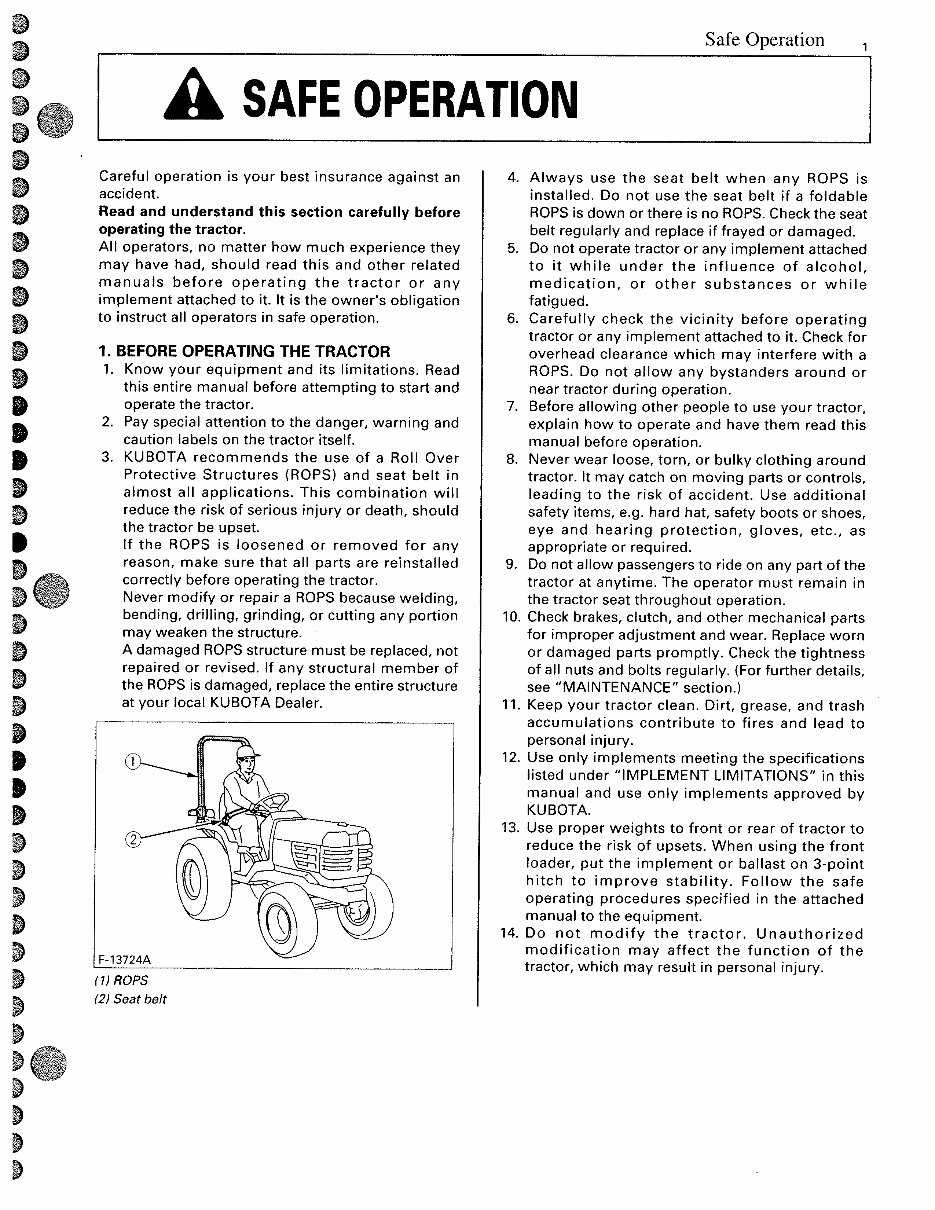

Steering Mechanism: Critical for navigation, this system allows for precise control and responsiveness while driving.

Electrical System: Powers lights, instruments, and starter systems, essential for functionality and operator awareness.

Each of these parts plays a vital role in the overall performance and reliability of the machine, making knowledge of them essential for any operator or technician.

Common Issues with Kubota B2710

Understanding the frequent challenges faced by operators of compact tractors is essential for effective maintenance and optimal performance. Addressing these concerns not only prolongs the machine’s lifespan but also enhances its efficiency in various tasks.

Engine Performance Problems

One of the most prevalent issues is related to engine performance. Symptoms may include difficulty starting or irregular idling. These problems often stem from fuel delivery issues or clogged filters, which can impede the flow of fuel and air necessary for smooth operation.

Hydraulic System Failures

Another common area of concern is the hydraulic system. Operators may notice reduced lifting capacity or slow response times. These symptoms might indicate leaks in hoses or issues with the hydraulic fluid, making it crucial to regularly check fluid levels and maintain system integrity.

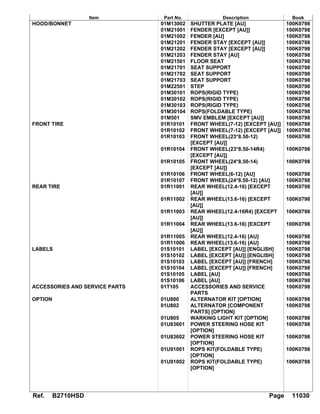

Finding Replacement Parts

When it comes to maintaining machinery, sourcing suitable components is crucial for ensuring optimal performance and longevity. Whether you are looking to replace a worn-out piece or upgrade functionality, understanding where to find reliable options can make all the difference.

Here are several avenues to consider when searching for the right components:

- Authorized Dealers: Visiting a certified dealer can provide access to genuine items that meet manufacturer specifications.

- Online Retailers: Numerous e-commerce platforms specialize in machinery components, often offering competitive pricing and user reviews to guide your choice.

- Local Auto Parts Stores: Many local shops carry a selection of universal items that may be compatible with your equipment.

- Aftermarket Suppliers: Consider checking out aftermarket options, which can provide cost-effective alternatives without compromising quality.

Before making a purchase, it’s essential to gather as much information as possible about the required component. This includes:

- Identifying the specific model and make of your equipment.

- Reviewing the owner’s manual for compatibility details.

- Consulting online forums or communities for recommendations based on user experiences.

By exploring these resources and gathering necessary information, you can confidently locate suitable components that will enhance the functionality and reliability of your machinery.

Using the Parts Diagram Effectively

Understanding how to navigate a visual representation of components can significantly enhance maintenance and repair efforts. By leveraging this tool, users can easily identify specific elements, ensuring accurate replacement and efficient troubleshooting. This approach not only streamlines the process but also minimizes the risk of errors.

Benefits of Utilizing Visual Representations

Utilizing visual representations provides clarity, helping users quickly locate and understand the interconnections between various components. This can lead to more informed decisions regarding maintenance and part selection.

Tips for Maximizing Effectiveness

To make the most of these visuals, familiarize yourself with the layout and symbols used. Refer to the accompanying documentation for detailed descriptions, and consider creating a checklist based on the visual to ensure nothing is overlooked during repairs.

| Component | Description | Replacement Tips |

|---|---|---|

| Engine | Main power source | Check for leaks and wear |

| Transmission | Power transfer unit | Inspect fluid levels regularly |

| Hydraulic System | Fluid-driven mechanism | Ensure seals are intact |

Benefits of Original Kubota Parts

Using authentic components for your machinery offers numerous advantages that enhance performance and longevity. These original elements are designed specifically for your equipment, ensuring optimal functionality and reliability.

- Quality Assurance: Authentic components undergo rigorous testing to meet high standards, guaranteeing durability.

- Perfect Fit: Designed to match your machine precisely, they reduce the risk of malfunctions and improve efficiency.

- Warranty Protection: Using genuine parts helps maintain warranty coverage, safeguarding your investment.

- Support Availability: Original manufacturers provide ongoing support and resources, ensuring you have access to expert advice.

- Resale Value: Machinery maintained with authentic components typically retains higher resale value, appealing to future buyers.

Investing in original components ultimately ensures your equipment runs smoothly, providing peace of mind and enhancing productivity.

Aftermarket vs. OEM Parts

When it comes to vehicle maintenance, choosing between alternative and original components is crucial. Each option offers distinct advantages and considerations that can significantly impact performance and longevity.

Benefits of OEM Components

- Designed specifically for compatibility.

- Typically backed by manufacturer warranties.

- Assured quality and reliability standards.

Advantages of Alternative Components

- Often more affordable than original options.

- Variety of choices available to suit different needs.

- Potential for enhanced features or performance upgrades.

Ultimately, the decision depends on individual priorities, such as budget constraints and performance expectations. Delve into each option to determine which best aligns with your requirements.

Maintenance Tips for B2710 Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your machinery. Regular attention to maintenance tasks can prevent costly repairs and keep your equipment running smoothly. Here are some essential practices to consider for optimal performance.

Regular Inspections

Conduct frequent checks on all major components, including the engine, hydraulic systems, and tires. Look for signs of wear and tear, and address any issues promptly to avoid bigger problems down the line.

Fluid Management

Maintain proper fluid levels for oil, coolant, and hydraulic fluid. Regularly change filters and fluids as recommended to ensure your machinery operates at its best and to extend its lifespan.

Resources for Parts Identification

Identifying components for machinery can be a daunting task, but numerous resources can simplify the process. These tools assist users in finding the right elements needed for maintenance or repairs.

- Manufacturer Manuals: Official guides often contain detailed information about various elements, including specifications and installation instructions.

- Online Forums: Community discussions provide insights from experienced users who share tips and resources for locating specific items.

- Parts Retailer Websites: Many retailers offer searchable databases where users can find components based on model numbers and descriptions.

- Videos and Tutorials: Visual guides can be beneficial for understanding how to identify and replace components effectively.

Utilizing these resources can lead to more efficient repairs and maintenance, ensuring optimal performance of your machinery.

Understanding the Warranty Information

When purchasing machinery, comprehending the coverage provided is essential for safeguarding your investment. Warranty details outline the responsibilities of the manufacturer and the rights of the consumer, ensuring that any potential issues are addressed within a specified period. A thorough understanding of these terms can save time, money, and frustration in the long run.

Key Aspects of Warranty Coverage

- Duration: The length of time the warranty remains valid is crucial. It typically begins from the date of purchase.

- Scope: Understanding what components are covered and which are excluded can prevent surprises later.

- Conditions: Most warranties include specific conditions that must be met for the coverage to remain valid, such as regular maintenance.

Claim Process

Filing a warranty claim can be straightforward if you follow the outlined procedures. Here are the steps generally involved:

- Gather all necessary documentation, including proof of purchase and any service records.

- Contact the manufacturer or authorized dealer to report the issue.

- Submit a claim with detailed information about the problem.

- Follow any additional instructions provided by the manufacturer for inspection or repair.

Understanding these elements can enhance your ownership experience and ensure that you are adequately protected should any complications arise.