Kubota Z725KH Parts Diagram Explained

In order to maintain a high-performance lawn mower, it’s essential to understand the various elements that contribute to its functionality. Each piece within the machine plays a crucial role in ensuring that the equipment operates smoothly and efficiently. Knowing these components can be invaluable for proper upkeep, enabling owners to tackle any maintenance or repairs with confidence.

With many interconnected parts, a lawn mower relies on a complex structure to deliver the desired results on the field. Learning about the inner workings can offer insights into how to maximize its efficiency and longevity. By familiarizing yourself with the machine’s layout, you can better identify areas for potential upgrades or replacements, ensuring optimal performance over time.

Whether you’re a professional landscaper or a dedicated homeowner, understanding the construction of your equipment can make all the difference. This knowledge not only aids in effective repairs but also empowers users to carry out routine inspections and spot any issues before they become significant problems. Embrace the intricacies of your machine to keep it running at its best for years to come.

Informative Outline on Machine Component Mapping

In this section, we will explore the various elements that make up a typical machine model, breaking down its core assemblies and their roles in overall functionality. Understanding these components is crucial for both maintenance and repair, as each part works together to ensure the machine operates efficiently.

- Key Component Categories – A look at the main categories of essential components and their purposes within the machine’s operation.

- Understanding Mechanical Framework – Exploring the core structural elements and how they support the entire system.

- Fluid and Power Systems – Examining the importance of hydraulic and power systems in supporting performance and durability.

By understanding the function of each group, users can gain a deeper insight into the machine’s structure, which will aid in troubleshooting, regular upkeep, and optimizing the overall performance.

Engine Components and Specifications

The engine system is a complex arrangement of various parts that work together to provide power and efficiency. These components are specifically designed to ensure optimal performance and durability, offering a balance between energy output and fuel consumption. Understanding the engine’s layout and specifications can help with maintenance and troubleshooting, improving the overall lifespan of the machine.

Key Engine Elements

The core elements of the engine include the cylinder block, pistons, and the crankshaft. Each part has a distinct role in the power generation process, contributing to smooth operation. The cylinder block houses the pistons, which move up and down to convert fuel into mechanical energy, while the crankshaft transforms this motion into rotational energy that powers the equipment.

Performance Specifications

The specifications of these engines are tailored for optimal power and efficiency. The design focuses on torque, horsepower, and fuel efficiency to ensure reliable performance under various conditions. These factors are critical when choosing the right engine configuration to meet operational needs effectively.

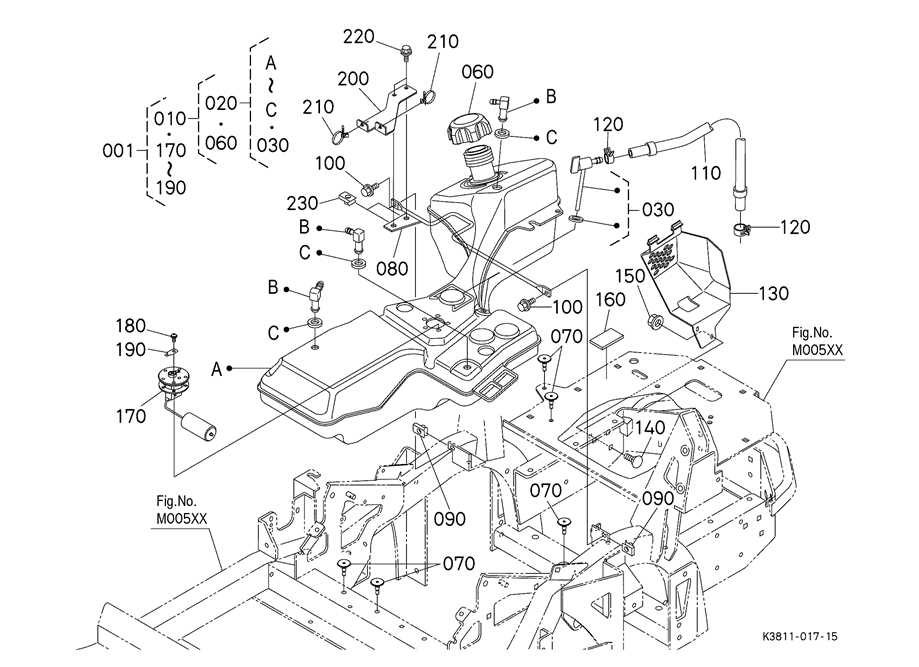

Fuel System Details and Parts

The fuel system plays a crucial role in delivering energy to the engine by ensuring an efficient flow of gasoline or diesel. Proper functioning of this system is essential for optimal performance and longevity of the equipment. Understanding each component and its function helps in maintaining the overall health of the system and ensuring a steady fuel supply.

In the fuel system, key components include the tank, lines, filter, and pump, each playing a specific role in managing the flow. The fuel tank stores the gasoline or diesel and is connected to the engine through fuel lines, which carry the fuel with minimal loss. A filter removes impurities before reaching the pump, where pressure is applied to send the fuel to the engine. This process ensures that only clean and pressurized fuel reaches the combustion chamber.

Regular inspection and timely replacement of these components can prevent common issues such as fuel leaks, clogged filters, and pump failures. By understanding the roles of each part, you can effectively troubleshoot and maintain a fuel system, ensuring efficient engine performance.

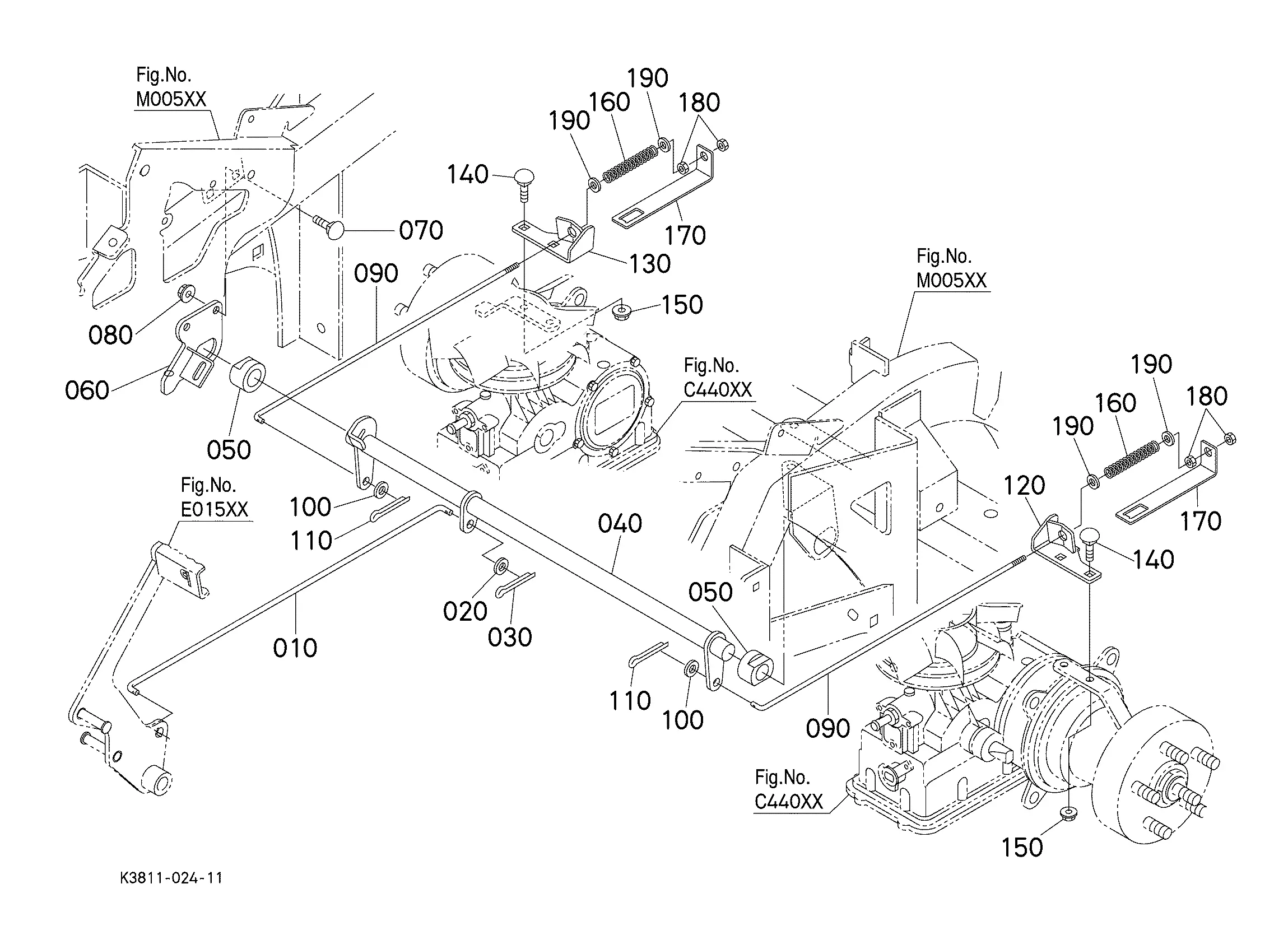

Transmission Components for Kubota Z725KH

The transmission system is a critical part of any high-performance mower, allowing for smooth power transfer and precise control. Understanding the different elements within this mechanism can help with maintenance and troubleshooting, ensuring efficient operation and extending the lifespan of the equipment.

Key Elements of the Transmission System

One of the primary components includes the hydraulic pumps, which are responsible for creating the necessary pressure to drive the wheels. These pumps work in tandem with gear assemblies to control speed and maneuverability, offering both stability and responsiveness during operation.

Hydrostatic Drive and Belt Systems

The hydrostatic drive allows for variable speed adjustments, giving operators full control over the mower’s pace. Additionally, belt systems connect various parts of the transmission, facilitating efficient power transfer from the engine to the wheels. Proper maintenance of these belts and fluid levels is essential for optimal functionality.

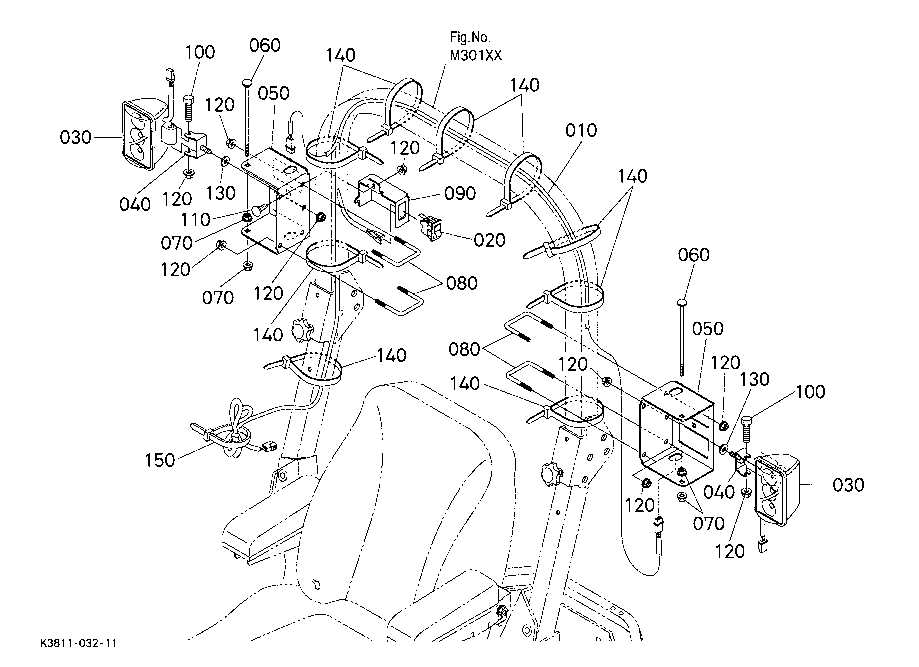

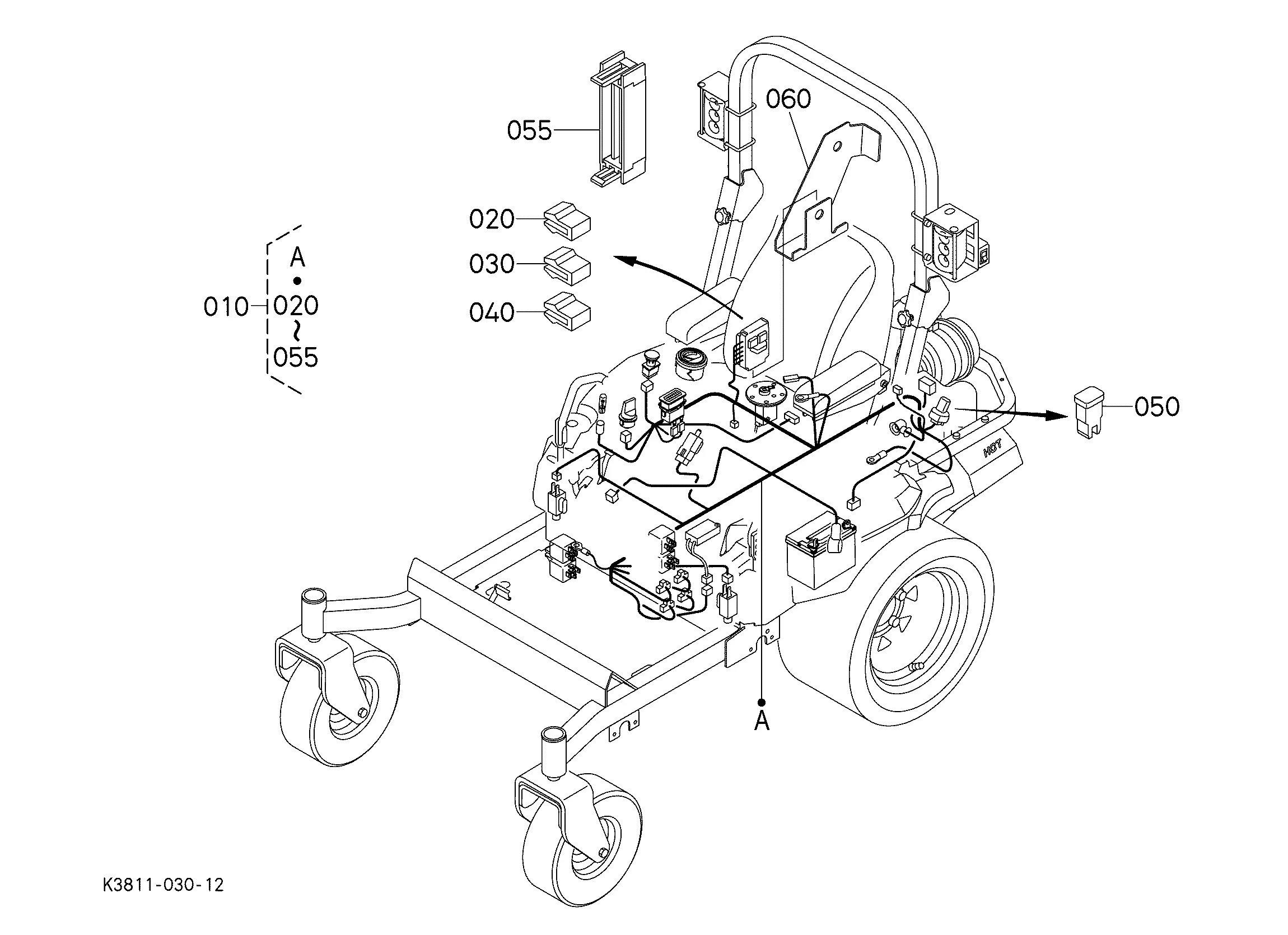

Electrical System Parts Breakdown

The electrical system is essential for ensuring smooth operation and proper functionality. It consists of various interconnected components that contribute to the overall performance and reliability of the equipment. This section offers an in-depth look at the core elements of the electrical framework, highlighting their roles and how they interconnect to support the machine’s operation. Understanding these elements is crucial for maintaining efficiency and addressing potential issues effectively.

Steering and Control Components

The steering and control mechanisms are essential for ensuring precise handling and efficient maneuverability. These components allow for smooth direction changes and effective operation control, contributing significantly to overall performance. Understanding the function and arrangement of each element within the system is key to maintaining optimal responsiveness.

Steering Linkage: The linkage is a series of interconnected parts that transmits movement from the steering wheel to the wheels. It ensures accuracy in steering, translating operator input into directional adjustments.

Control Levers and Pedals: These components provide operators with the ability to adjust speed, direction, and various other functions seamlessly. Properly maintained levers and pedals allow for smoother operation and improved safety.

Control Panel: The panel houses essential controls and displays, allowing for easy monitoring of key functions. With a well-organized layout, the panel enhances operational efficiency and allows for quick adjustments on the go.

Hydraulic System and Key Elements

The hydraulic system plays a vital role in ensuring efficient operation and smooth control. Its components work together to manage the fluid pressure required for various functions, providing the necessary power to drive multiple systems.

Main Components of the Hydraulic System

- Pump: Responsible for generating the fluid pressure that powers the hydraulic system, converting mechanical energy into hydraulic energy.

- Hydraulic Fluid: A specialized fluid that transmits power and lubricates the components to reduce wear and tear.

- Valves: These regulate the flow and direction of the hydraulic fluid, ensuring proper pressure distribution throughout the system.

- Cylinders: Convert hydraulic energy into mechanical force, driving the movement of various parts and components.

Additional Elements and Functionality

- Reservoir: Stores the hydraulic fluid, providing a steady supply while helping to dissipate heat and remove air from the system.

- Filters: Keep the hydraulic fluid clean by trapping contaminants, which helps maintain system efficiency and prolongs component life.

- Hoses and Pipes: Facilitate the transfer of hydraulic fluid between components, designed to withstand high pressure and prevent leaks.

Deck Assembly Parts Overview

The deck assembly is a crucial component that ensures effective cutting and maintenance of grass. It comprises various elements that work together to deliver a smooth and even cut, adapting to different lawn conditions. Understanding these elements can help with proper maintenance and timely replacements, ensuring efficient operation.

- Blades: The blades are designed to deliver a clean and precise cut, typically made of durable materials to withstand frequent use.

- Spindle Assembly: This part connects the blades to the deck, providing stability and proper rotation. It supports the smooth movement of the blades during mowing.

- Deck Shell: The shell serves as the framework that holds the entire assembly together. It offers protection and supports the other components securely.

- Belt System: A series of belts drive the rotation of the blades. These belts transfer power and maintain tension for optimal performance.

- Idler Pulley: The pulley helps maintain the right belt tension, which is essential for the blades’ efficient movement. It also reduces wear on the belt system.

Regular checks and maintenance of these components ensure longevity and consistent performance. By keeping these parts in good condition, you can achieve an even and professional-looking cut on your lawn.

Blades and Cutting Mechanism Parts

The efficiency of a mowing system relies heavily on its cutting components. These elements are designed to work together to ensure a clean and precise cut, which is essential for maintaining a well-groomed lawn or field. Understanding the various components involved in the cutting mechanism can enhance performance and longevity.

Key components of the cutting system include:

- Blades: The sharp edges that perform the cutting action. They come in different shapes and sizes, tailored for specific tasks.

- Blade Holders: These fixtures secure the blades in place, allowing them to function effectively while minimizing vibrations.

- Spindles: Rotational elements that facilitate the movement of the blades. They are crucial for the cutting mechanism’s operation.

- Bearings: Components that reduce friction between moving parts, ensuring smooth operation and extending the life of the system.

- Deck: The housing that supports the blades and other cutting components, providing stability and protection.

Regular maintenance and timely replacement of these components are essential for optimal performance. Neglecting any part of the cutting mechanism can lead to diminished cutting quality and potential damage to the mower.