Understanding the Components of a Semi Truck Fifth Wheel Parts Diagram

The intricate design of heavy-duty transportation vehicles plays a crucial role in their functionality and safety. Each element is meticulously crafted to ensure optimal performance during transit, reflecting the engineering advancements in the field. Gaining insight into these components is essential for both operators and enthusiasts alike.

Among the vital features that facilitate seamless connection and maneuverability, a particular focus lies on the connection mechanisms. These elements not only secure the load but also enhance stability during operation. A comprehensive grasp of these mechanisms can significantly contribute to effective maintenance and operation.

In this exploration, we will delve into the various components involved in the coupling systems, outlining their functions and interrelationships. By understanding the ultimate structure and organization of these systems, one can appreciate the complexity involved in ensuring safe and efficient transportation.

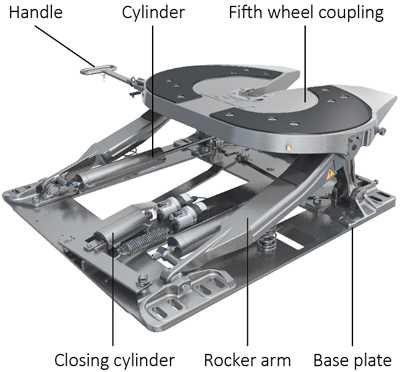

Understanding Fifth Wheel Components

This section explores the essential elements that contribute to the functionality of the coupling mechanism used in heavy vehicles. A thorough understanding of these components is crucial for maintenance, safety, and efficiency in operation.

Main Elements

- Locking Mechanism

- Plate Assembly

- Kingpin Interface

- Support Structure

Functions of Each Component

- The locking mechanism ensures a secure connection between the vehicle and the trailer.

- The plate assembly provides a stable platform for weight distribution.

- The kingpin interface allows for smooth coupling and decoupling.

- The support structure reinforces stability and reduces wear during transit.

Importance of Fifth Wheel in Trucks

The connection between a towing vehicle and a trailer is crucial for ensuring safe and efficient transportation. This component plays a significant role in maintaining stability and control during transit, affecting both the performance and safety of the entire setup.

Key Functions

- Stability: Provides a secure attachment point, minimizing swaying and enhancing handling.

- Weight Distribution: Ensures proper load balancing, reducing wear on both the towing vehicle and the towed unit.

- Ease of Maneuvering: Facilitates sharp turns and navigation in tight spaces, crucial for urban and rural driving.

Safety Considerations

- Regular inspections are vital to ensure the integrity of the connection.

- Proper maintenance helps prevent failures that could lead to accidents.

- Understanding the specifications and compatibility with various trailers enhances overall safety.

In conclusion, the significance of this component cannot be overstated. It is essential for both operational efficiency and safety in transport applications.

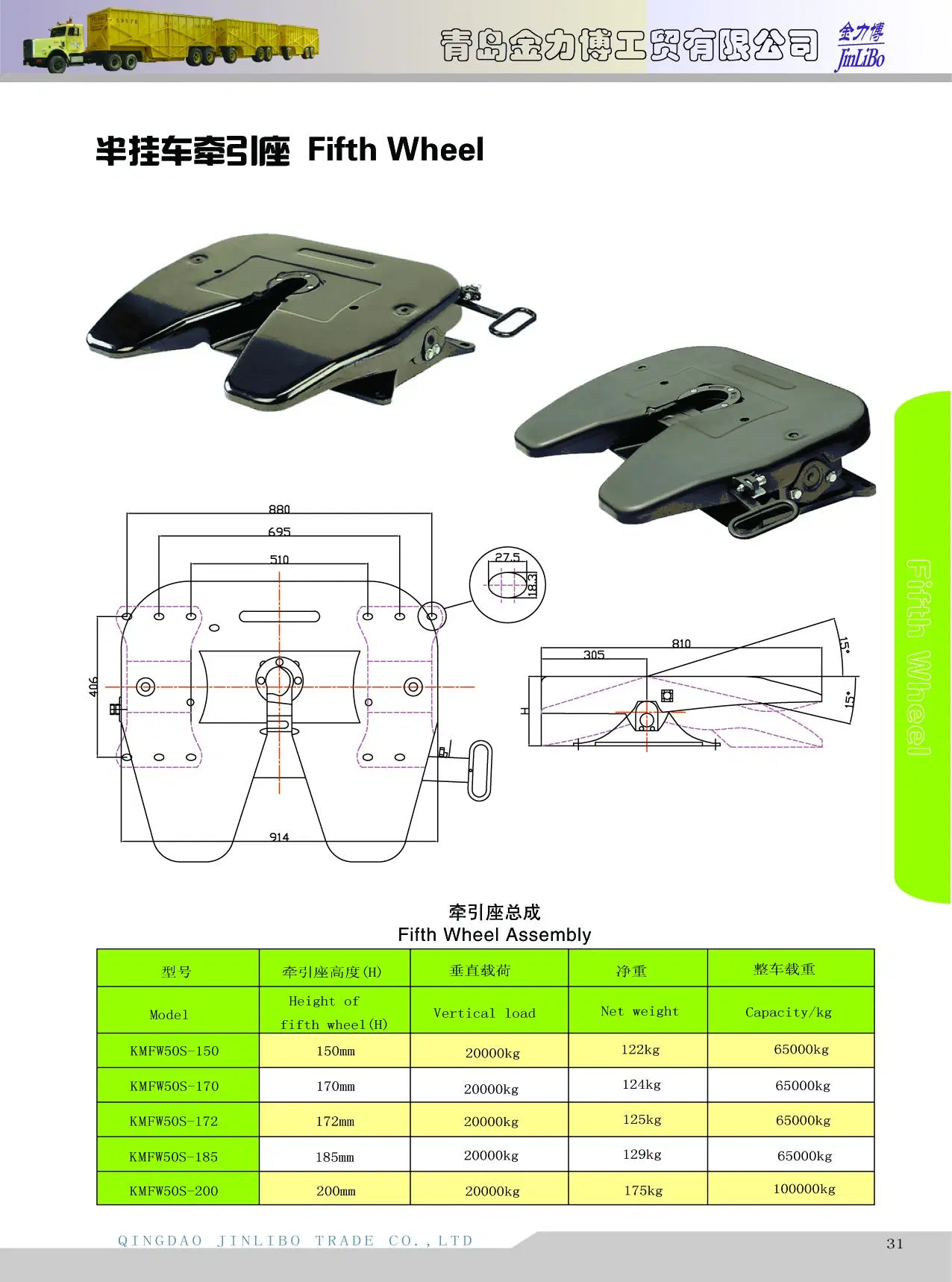

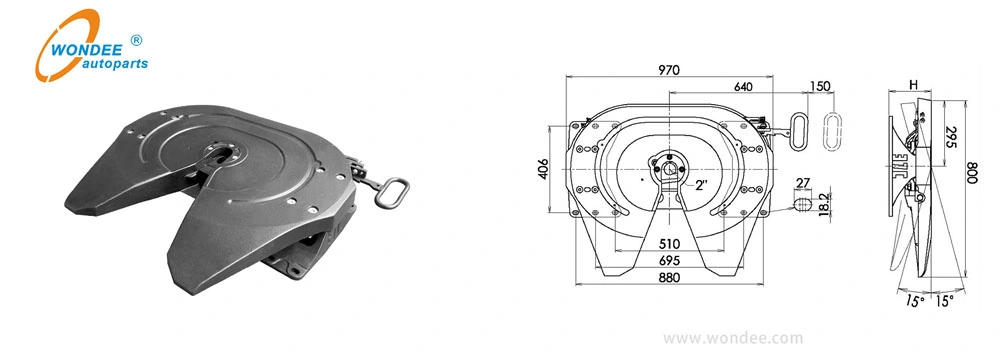

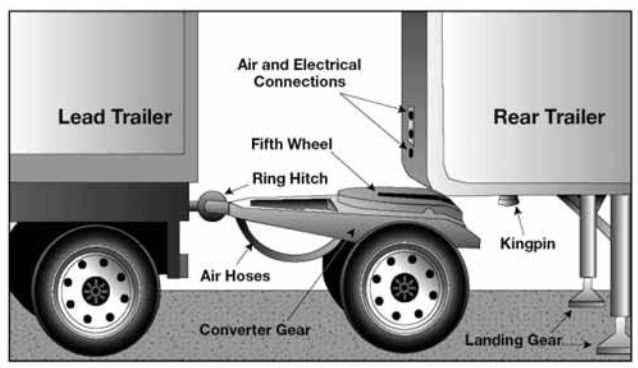

Diagram Overview of Fifth Wheel Parts

This section provides a comprehensive insight into the components that comprise the coupling mechanism used for hauling heavy loads. Understanding these elements is essential for maintenance, troubleshooting, and ensuring optimal performance.

Key Components

- Base Plate: The sturdy foundation that supports the entire assembly.

- Locking Mechanism: Ensures secure attachment between the towing and towed units.

- Kingpin: The pivotal connector that engages with the coupling system.

- Slide Mechanism: Allows for adjustments in positioning to enhance maneuverability.

- Grease Fittings: Essential for lubrication, reducing wear and tear on moving parts.

Functionality Insights

- The locking mechanism engages the kingpin to create a secure connection.

- Movement and adjustments are facilitated by the slide mechanism.

- Regular lubrication via grease fittings helps maintain functionality.

- Periodic inspections ensure all components are in optimal condition for safety.

Key Features of Fifth Wheel Mechanism

The connection mechanism utilized in large vehicles plays a crucial role in ensuring stability and maneuverability during transport. Understanding its fundamental attributes can enhance safety and efficiency in operation.

Essential Attributes

- Durability: Constructed from robust materials, it withstands substantial weight and stress.

- Articulation: Allows for smooth turns and adjustments, facilitating better control.

- Locking Mechanism: Ensures a secure attachment, minimizing the risk of detachment while on the move.

- Adjustability: Can be modified to suit different vehicle heights, enhancing compatibility.

Maintenance Considerations

- Regular inspection for wear and tear.

- Lubrication of moving parts to prevent friction.

- Monitoring for signs of rust or corrosion.

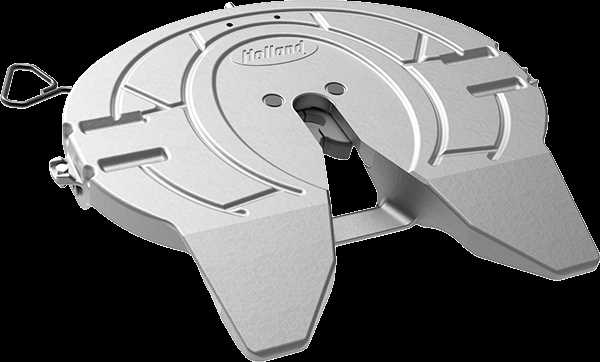

Common Types of Fifth Wheels

Understanding the various types of coupling mechanisms used in heavy-duty towing is essential for ensuring compatibility and safety. Each type is designed to meet specific needs, offering distinct advantages and features tailored for different applications.

| Type | Description | Applications |

|---|---|---|

| Standard | Most commonly used for general towing, featuring a fixed design. | Freight transport, recreational vehicles. |

| Sliding | Allows for movement, providing improved maneuverability in tight spaces. | Urban deliveries, specialized hauling. |

| Gooseneck | Features a ball coupling system for enhanced stability and weight distribution. | Horse trailers, heavy equipment transport. |

| Rotating | Offers a pivoting mechanism that adjusts to the load’s weight and distribution. | Construction sites, uneven terrain transport. |

Maintenance Tips for Fifth Wheel Parts

Regular upkeep is essential for ensuring the longevity and optimal functionality of critical components in heavy-duty hauling setups. Proper attention to these elements not only enhances safety but also improves overall performance.

Routine Inspections

Conduct frequent checks on all mechanisms to identify wear or damage early. Look for cracks, rust, or any signs of deterioration. Addressing issues promptly can prevent costly repairs down the line.

Lubrication Practices

Maintaining adequate lubrication is crucial for smooth operation. Use high-quality grease and follow manufacturer guidelines for application intervals. Properly lubricated components reduce friction and extend the lifespan of the system.

Signs of Fifth Wheel Wear

Understanding the indicators of deterioration in crucial components is essential for maintaining safety and performance. Over time, wear and tear can manifest through various symptoms that signal the need for inspection and potential replacement. Recognizing these signs early can prevent further damage and ensure smooth operations.

One of the first symptoms to watch for is excessive play or movement during coupling and uncoupling. If there is noticeable looseness, it may indicate that the mechanism is degrading. Additionally, observe for any unusual noises when navigating turns or bumps; grinding or squeaking sounds often suggest that elements are not functioning as intended.

Another important indicator is visible wear on contact surfaces. Scratches, grooves, or significant discoloration can point to an underlying issue that requires immediate attention. Regularly checking for signs of rust or corrosion is also crucial, as these can weaken the structure and compromise its integrity.

Lastly, monitor for irregular wear patterns on tires, which may suggest misalignment caused by faulty connections. Addressing these indicators promptly will not only enhance safety but also extend the lifespan of the equipment involved.

How to Inspect Fifth Wheel Assembly

Regular evaluation of the coupling system is essential to ensure safe and efficient operation. Proper inspection techniques can help identify wear and potential issues before they lead to significant problems.

Visual Inspection

Begin with a thorough visual examination. Look for signs of wear, cracks, or corrosion on the surface. Ensure that all fasteners are securely tightened and that there are no visible obstructions.

Functional Testing

After the visual check, perform functional tests. Engage the coupling mechanism and observe its operation. Listen for unusual noises and ensure it locks securely in place. Regular maintenance can enhance performance and longevity.

Tools for Fifth Wheel Repair

When it comes to maintaining and fixing the connection system between a vehicle and its load, having the right equipment is crucial. Proper tools not only enhance efficiency but also ensure safety during the repair process. Below are some essential implements that are commonly used in this type of maintenance.

- Socket Set: A comprehensive set is vital for loosening and tightening various bolts and nuts.

- Torque Wrench: This tool ensures that all fasteners are tightened to the manufacturer’s specifications, preventing future issues.

- Grease Gun: Regular lubrication is necessary to keep moving parts functioning smoothly and to extend their lifespan.

- Pry Bar: Useful for aligning components and providing leverage when adjusting positions.

- Impact Wrench: Ideal for quickly removing stubborn fasteners without damaging them.

Additional tools may include a level for ensuring proper alignment, a flashlight for inspecting dark areas, and safety gear such as gloves and goggles. Having a well-rounded toolkit can make a significant difference in the effectiveness and safety of the maintenance performed.

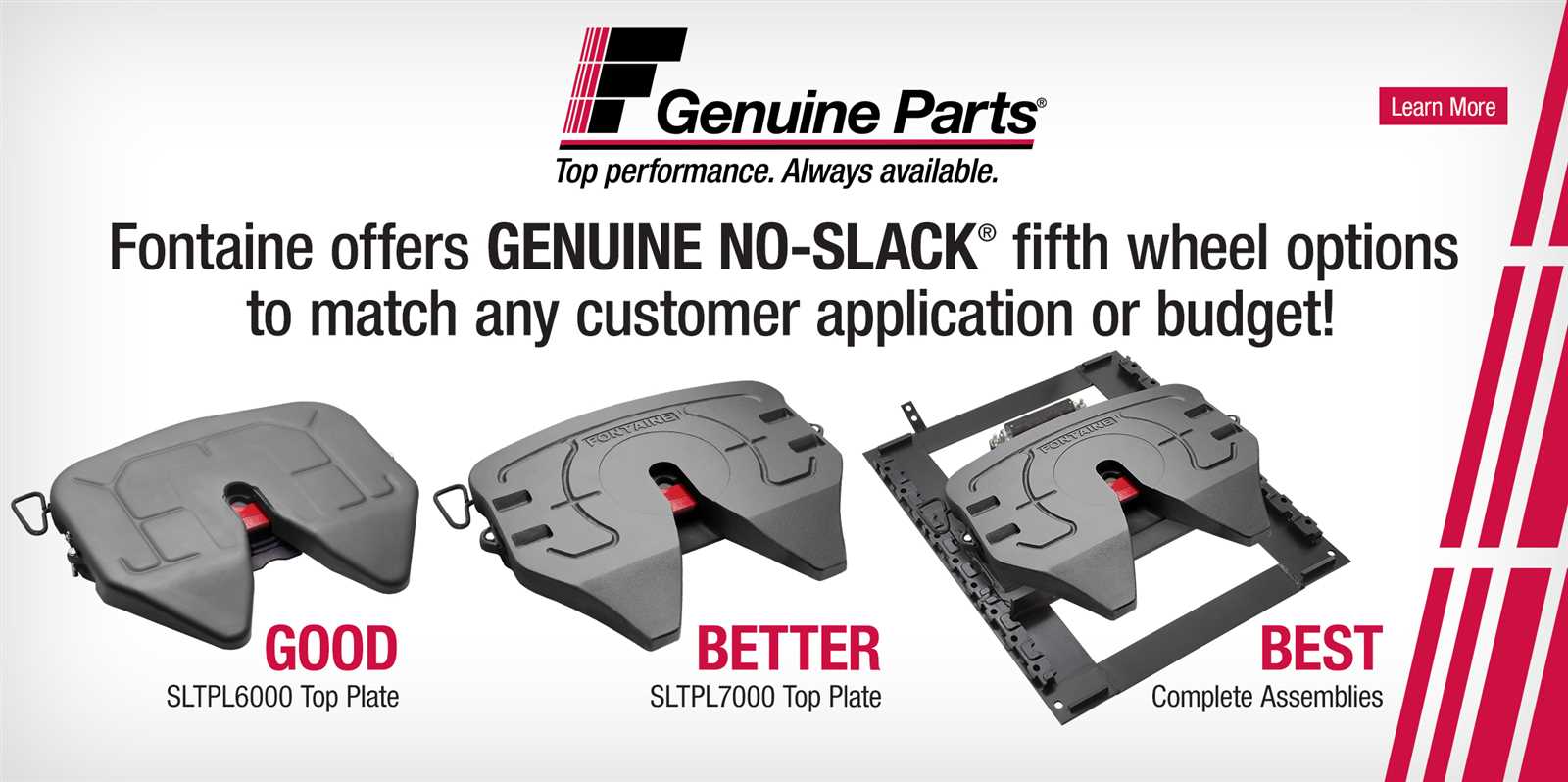

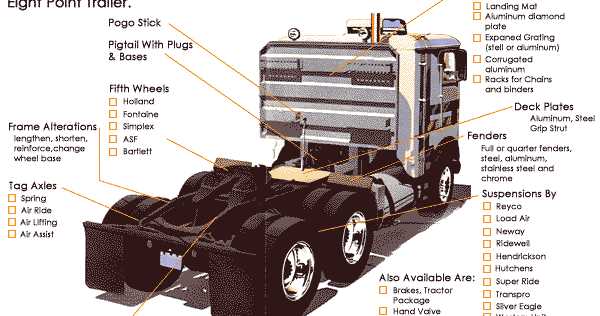

Upgrading Your Fifth Wheel Setup

Enhancing your towing configuration can significantly improve your overall experience and safety on the road. By focusing on key components and making strategic upgrades, you can ensure a more stable and efficient connection between your vehicle and trailer. This section will explore the benefits of upgrading various elements of your coupling setup.

Benefits of Enhanced Components

Upgrading to high-quality connection hardware can provide better durability and performance. Improved couplings and hitches can lead to smoother handling and reduced wear on both your vehicle and trailer. Additionally, investing in advanced technology such as air-ride systems can dramatically enhance ride comfort, minimizing the impact of bumps and road imperfections.

Choosing the Right Upgrades

When considering upgrades, evaluate your specific needs and usage patterns. Whether it’s increasing weight capacity or enhancing maneuverability, selecting components that align with your requirements is essential. Researching reputable brands and consulting with experts can help you make informed decisions that enhance your overall towing setup.

Safety Considerations for Fifth Wheels

Ensuring the security and functionality of coupling mechanisms is vital for safe transportation. Understanding key aspects of these connectors can significantly reduce the risk of accidents and enhance overall safety on the road.

Inspection and Maintenance

Regular checks are essential for optimal performance. Inspect the locking mechanism, ensure proper lubrication, and look for signs of wear or damage. Timely maintenance can prevent failures during operation.

Proper Loading Techniques

Distributing weight evenly is crucial for stability. Uneven loads can lead to hazardous situations. Always follow guidelines to maintain balance and enhance safety during transit.

| Safety Aspect | Recommendation |

|---|---|

| Inspection Frequency | Every trip |

| Weight Distribution | Evenly across the platform |

| Lubrication | As per manufacturer guidelines |

| Damage Check | Before and after use |