Exploring the Honda EU7000is Parts Layout

Understanding the inner workings of complex machines can be essential for both enthusiasts and professionals. Whether you’re involved in maintenance or simply want to familiarize yourself with the structure of this powerful equipment, a clear visualization of the various elements is invaluable. This section offers an in-depth overview of crucial elements, helping users easily navigate the intricate system.

Each segment has its role and importance, contributing to the overall functionality. Knowing how these different sections fit together and interact can provide insight into their performance and longevity. By exploring the detailed arrangement of these mechanical systems, you’ll gain a better grasp of how to efficiently maintain or repair them.

Understanding the Main Components of the Generator

In any energy-producing unit, various mechanical and electrical elements work together to convert fuel into usable electricity. Each section has a specific role that contributes to the overall function, ensuring stable and reliable performance. This overview focuses on the key areas that make up the core of such a machine, outlining their general function and importance in the operation of the system.

Engine and Power Generation

The heart of the system is the engine, which drives the conversion process. It burns fuel to produce mechanical energy, which is then transformed into electrical output. The engine’s design is critical for ensuring efficiency, noise reduction, and longevity of the unit.

Control and Monitoring Systems

The control unit is responsible for managing various parameters like output levels, fuel usage, and safety protocols. It provides a way to monitor the unit’s performance and

Engine Assembly Overview

The central component of this equipment’s functionality lies in its internal mechanisms, designed to deliver reliable performance. This section covers the various elements responsible for the smooth operation of the machine, highlighting their arrangement and roles in maintaining efficiency and durability.

Core Components

The engine is composed of essential elements that work together harmoniously. Each element, from the fuel system to the air intake, plays a key role in ensuring stable operation. A deep understanding of these components can help in maintaining peak performance and identifying potential issues before they arise.

Integration and Functionality

Within this system, each part is carefully aligned to optimize energy conversion and output. From the ignition system to the

Fuel System and Its Key Elements

The operation of any modern engine relies heavily on the mechanisms responsible for delivering fuel to the internal combustion process. This section explores the vital components that ensure a steady and efficient flow of energy, enabling optimal performance and functionality. A well-maintained delivery system ensures smooth functioning and long-term reliability of the machinery.

Primary Components

The essential parts involved in this system include the reservoir, lines, and regulating mechanisms that work together to transfer energy from storage to the engine. Each of these elements has a crucial role in maintaining flow and pressure, avoiding disruptions, and preventing potential leaks or blockages.

Regulation and Efficiency

Another critical aspect of the system is how it manages flow

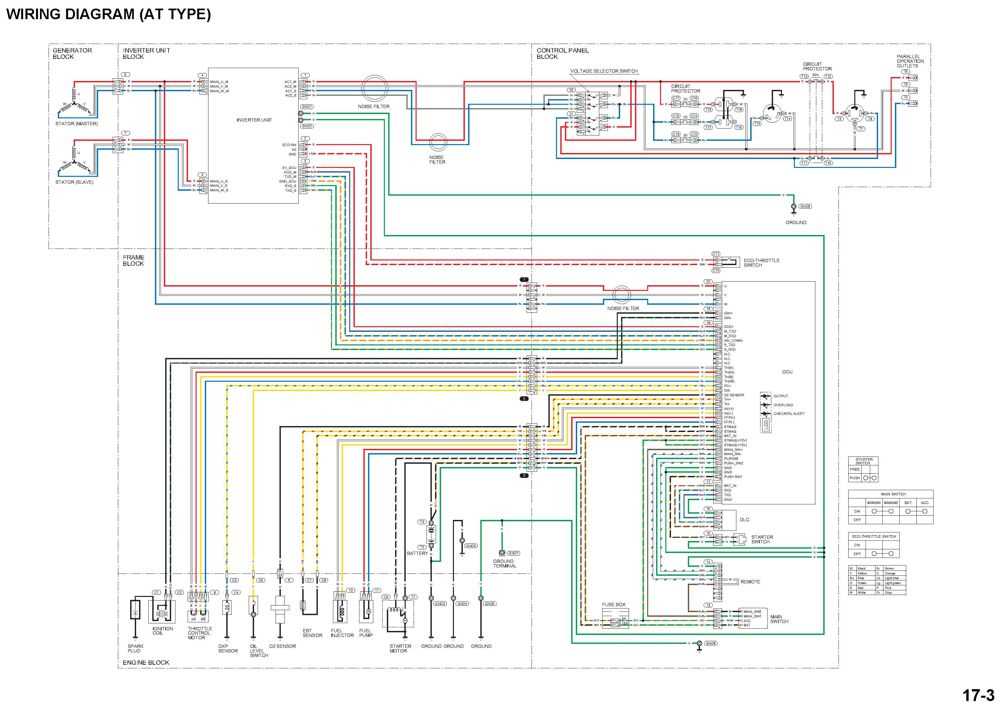

Electrical Components Breakdown

Understanding the internal wiring and key systems within this generator model provides insight into how the essential circuits function together. This section highlights the primary electronic units and their roles, offering a clear understanding of how the different modules interact to ensure reliable operation.

Control Module: The central element that manages various functions, from starting sequences to automatic shutdown. It ensures optimal performance by constantly monitoring the machine’s status and reacting accordingly.

Voltage Regulator: This critical piece maintains consistent energy output, preventing fluctuations that could damage connected devices. It adjusts the levels to match the demand, ensuring a stable supply.

Ignition System: Responsible for initiating the power cycle, this subsystem ensures a smooth start by providing the necessary spark at the right moment. Proper maintenance is key to reliable operation.

Each of these elements works in unison, allowing the machine to perform efficiently while safeguarding connected equipment and

Cooling Mechanism Explained

Efficient temperature regulation is crucial for maintaining optimal performance and ensuring longevity of any machinery. The design focuses on controlling heat dissipation, preventing overheating, and ensuring smooth operation even under heavy workloads.

The cooling process involves various components working together to achieve consistent airflow and effective heat management. Below is an overview of the system’s key elements:

- Airflow Circulation: A fan directs the air through critical areas, helping to carry away excess heat generated during operation.

- Heat Sink Design: The heat exchange surfaces are specifically designed to absorb and dissipate thermal energy efficiently.

- Ventilation Pathways: The system includes strategic vent placements that

Handle and Frame Structure

The configuration of the handle and framework is crucial for the functionality and usability of portable power generators. A well-designed structure not only ensures stability but also enhances maneuverability, making it easier to transport the device across various terrains.

In this section, we will explore the key components and characteristics that contribute to the overall efficiency and durability of the structure:

- Handle Design: The ergonomics of the handle play a significant role in user comfort. A comfortable grip allows for easy lifting and repositioning.

- Material Composition: The materials used in constructing the frame must be robust yet lightweight, providing a balance between strength and portability.

- Frame Configuration: The geometry of the frame impacts the generator’s stability during operation, ensuring it remains secure and reduces vibrations.

- Connection Points: Reinforced joints and connections between the handle and frame enhance overall structural integrity, allowing for better handling during transport.

Understanding these elements is essential for evaluating the reliability and convenience of a portable power solution.

Exhaust and Muffler Design

The design of the exhaust system and its associated components plays a crucial role in enhancing performance and ensuring efficient operation. This system is responsible for directing exhaust gases away from the engine, reducing noise, and optimizing emissions. Understanding the intricacies of its construction can lead to improved functionality and longevity.

The muffler, a vital component of this system, is engineered to minimize sound produced by the engine while maintaining optimal exhaust flow. Its structure typically includes a series of chambers and perforated tubes that facilitate sound wave cancellation, thereby reducing noise levels significantly. The choice of materials and configuration also influences durability and performance.

Component Function Material Muffler Reduces engine noise and directs exhaust flow Stainless steel, aluminized steel Exhaust Pipe Transports exhaust gases from the engine Stainless steel, mild steel Resonator Tunes the exhaust sound for a desired tone Aluminized steel, fiberglass Effective exhaust and muffler design not only contributes to a quieter operation but also enhances overall efficiency. By optimizing exhaust flow and minimizing back pressure, these components aid in achieving better fuel economy and engine performance.

Carburetor and Air Filter Details

This section focuses on the essential components responsible for fuel and air management within a specific model of portable generator. Understanding the intricacies of these elements can enhance performance and efficiency, ensuring optimal operation during use.

Functionality of the Fuel Delivery System

The fuel delivery system plays a crucial role in mixing air and fuel in the appropriate ratio for combustion. This component’s design influences how effectively the engine operates, impacting both power output and fuel efficiency. Regular maintenance, such as cleaning and adjustment, is vital to prevent clogging and ensure smooth operation.

Importance of the Air Filtration System

The air filtration system is equally important as it protects the engine from dust and debris, allowing for clean air intake. A well-maintained filter enhances engine longevity and performance. Periodic inspection and replacement of the air filter are recommended to maintain optimal airflow and prevent potential damage.

Starting System Components

The mechanism responsible for initiating the operation of the generator is comprised of several crucial elements that work in harmony. Each component plays a significant role in ensuring reliable ignition and efficient performance. Understanding these parts can enhance troubleshooting and maintenance efforts, leading to improved longevity and functionality.

Key Elements of the Starting Mechanism

Ignition Coil: This device is essential for generating the high voltage required to ignite the fuel-air mixture within the engine. Its proper functioning is vital for starting efficiency and overall engine performance.

Starter Motor

Starter Motor: Acting as the powerhouse of the starting system, this component is responsible for turning the engine over during the initial start-up. A well-functioning starter motor is critical for quick and reliable ignition.

Maintenance Parts and Replacement Tips

Proper upkeep of equipment is crucial for ensuring longevity and optimal performance. Understanding the essential components that require regular attention can significantly enhance the functionality and reliability of your machine. This section focuses on common replacement items and valuable advice for maintaining your generator.

Essential Components for Upkeep

Several key elements must be monitored and replaced as needed to keep your generator running smoothly. Regular inspection and timely replacement of these components can prevent costly repairs and extend the life of the equipment.

Component Replacement Frequency Maintenance Tips Air Filter Every 100 hours of operation Clean or replace the filter to ensure proper airflow and efficiency. Oil Filter Every 100 hours of operation or annually Replace the filter during oil changes to maintain clean lubrication. Spark Plug Every 200 hours of operation or as needed Inspect regularly; replace if worn to ensure smooth ignition. Fuel Filter Every 200 hours of operation or annually Check for clogs and replace to maintain fuel flow. Battery Every 2-3 years Keep terminals clean and check charge regularly. Tips for Effective Maintenance

In addition to regular replacements, following best practices for maintenance can greatly enhance the lifespan of your generator. Always consult the manufacturer’s guidelines for specific recommendations, and consider keeping a maintenance log to track inspections and replacements.

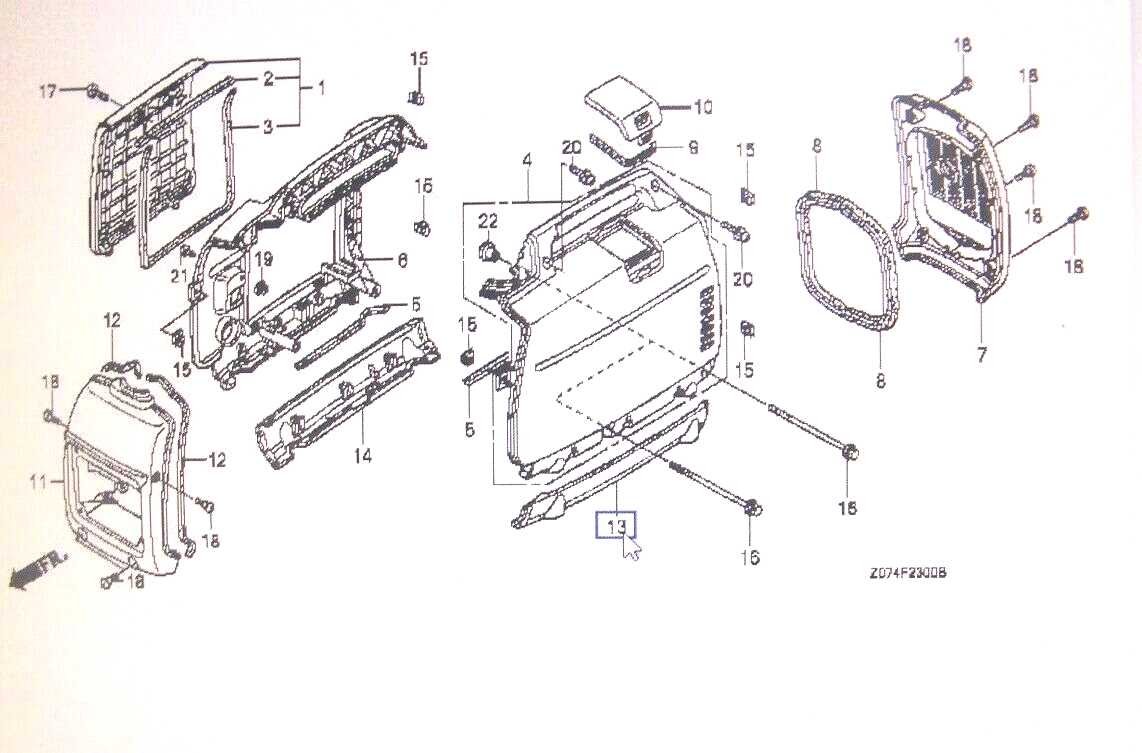

Diagram Interpretation for Effective Repairs

Understanding the visual representation of components is crucial for successful maintenance and troubleshooting. A well-structured illustration provides insights into the relationships between various elements, enabling users to identify issues quickly and efficiently. This knowledge empowers technicians to make informed decisions during repairs, ultimately enhancing the longevity and performance of the equipment.

Key Elements to Analyze

- Labels and Symbols: Familiarize yourself with the terminology and icons used within the illustration. These indicators often denote specific functionalities or connections.

- Component Layout: Examine how each piece fits within the assembly. Recognizing the arrangement aids in understanding how different parts interact.

- Connections: Pay attention to the pathways and junctions that facilitate communication between elements. This knowledge is vital for troubleshooting connectivity issues.

Steps for Effective Interpretation

- Begin by reviewing the legend or key, which clarifies any unfamiliar symbols.

- Identify major sections of the representation and categorize components based on their functions.

- Trace potential issues by focusing on connections that might be causing malfunctions.

- Document any findings to streamline future maintenance efforts.