Ford F350 4×4 Front End Parts Diagram Guide

When it comes to the maintenance and repair of robust trucks, having a clear understanding of their critical systems is essential. Among these systems, the components responsible for steering and suspension play a vital role in ensuring optimal performance and handling. A well-organized overview of these elements can greatly assist both enthusiasts and professionals in navigating the complexities of vehicle upkeep.

Comprehending the layout and function of various assemblies can enhance troubleshooting and replacement processes. Knowing the specific roles of each segment aids in pinpointing issues quickly, minimizing downtime and ensuring safe operation. This knowledge is especially beneficial for those who frequently engage in off-road activities or heavy towing, where reliability is paramount.

In this section, we will explore the essential elements that contribute to the stability and maneuverability of heavy-duty vehicles. By delving into the various assemblies and their interactions, readers will gain valuable insights that can inform both routine maintenance and more extensive repair endeavors.

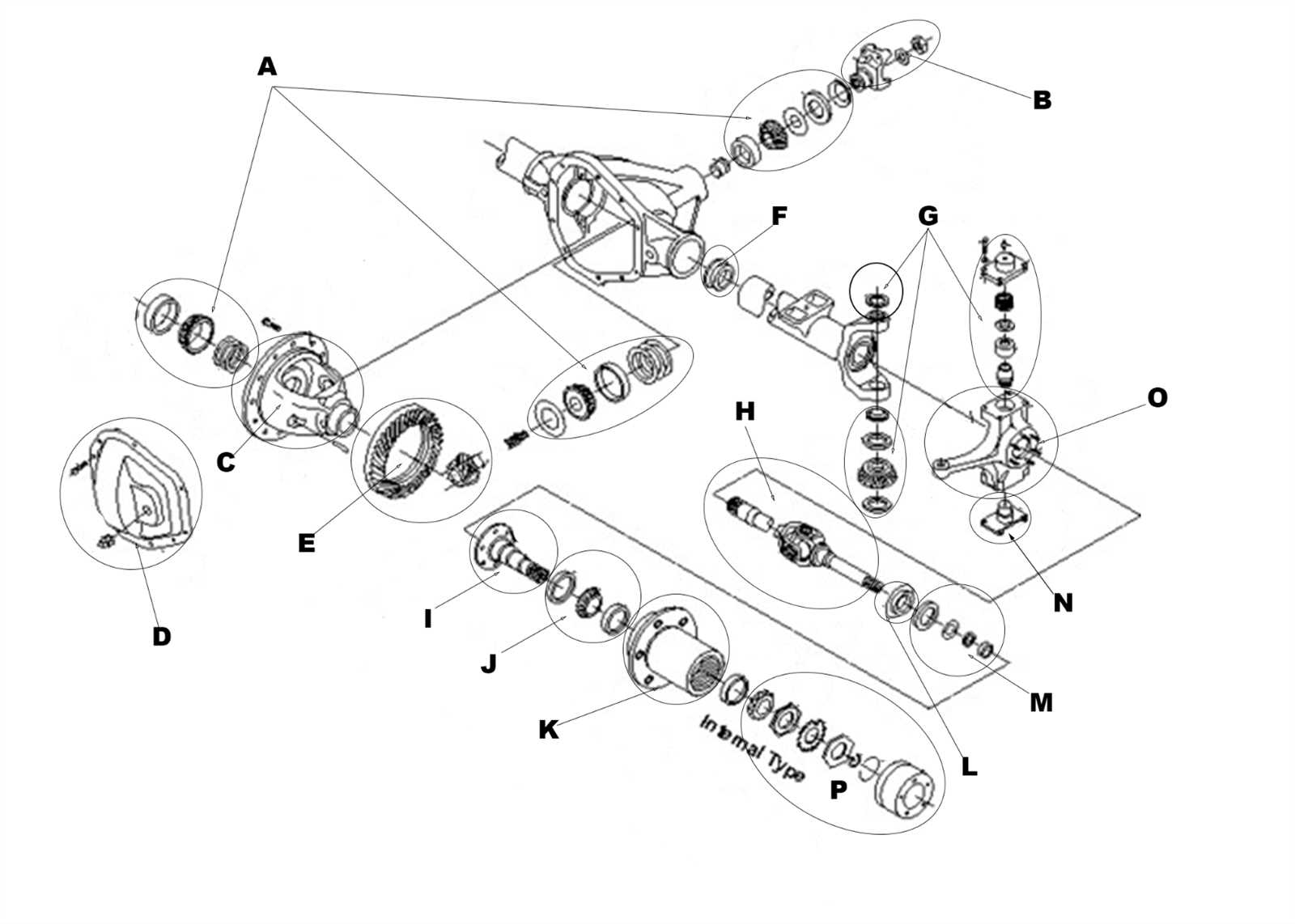

Understanding the Ford F350 Front End

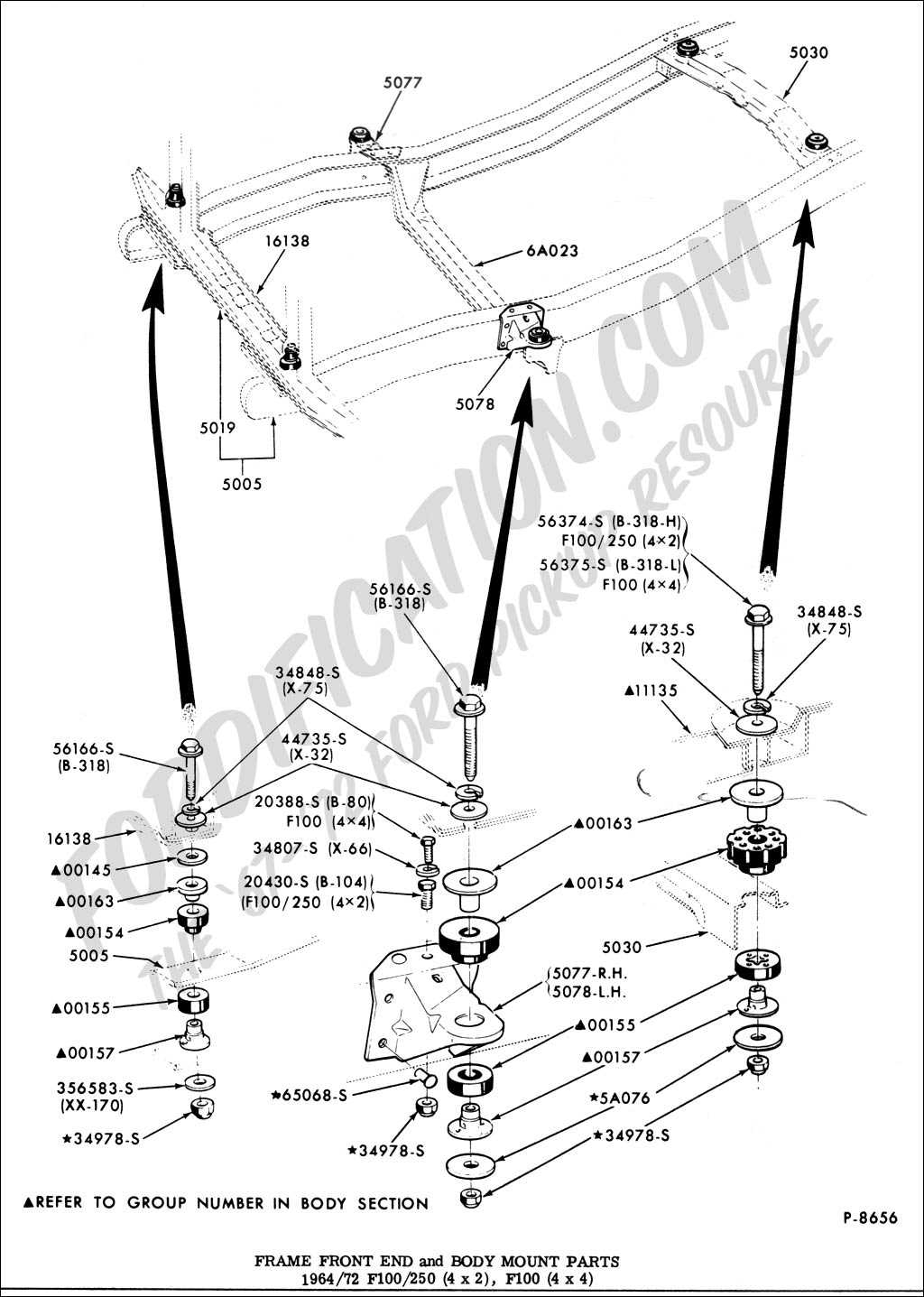

The structure that supports the vehicle’s steering and suspension is crucial for its performance and handling. This assembly plays a significant role in the overall dynamics of the truck, contributing to stability and ride quality. A thorough understanding of this area is essential for anyone involved in maintenance or repair work, as it directly impacts safety and driving experience.

Key components of this assembly include various links, arms, and connectors that work together to ensure smooth operation. Each element serves a specific function, and familiarity with them aids in diagnosing issues and optimizing performance.

| Component | Description |

|---|---|

| Steering Knuckle | Connects the wheel hub to the suspension system and allows for steering movement. |

| A-Arm | Provides support for the suspension system and maintains alignment. |

| Ball Joint | Facilitates movement between the suspension and steering components, allowing for flexibility. |

| Control Arm | Links the chassis to the wheel assembly, helping manage weight distribution and stability. |

| Spindle | Connects the wheel hub to the steering system, enabling rotational movement. |

Understanding these components and their functions is vital for effective troubleshooting and ensuring the longevity of the vehicle. Proper maintenance can prevent potential failures and enhance overall driving experience.

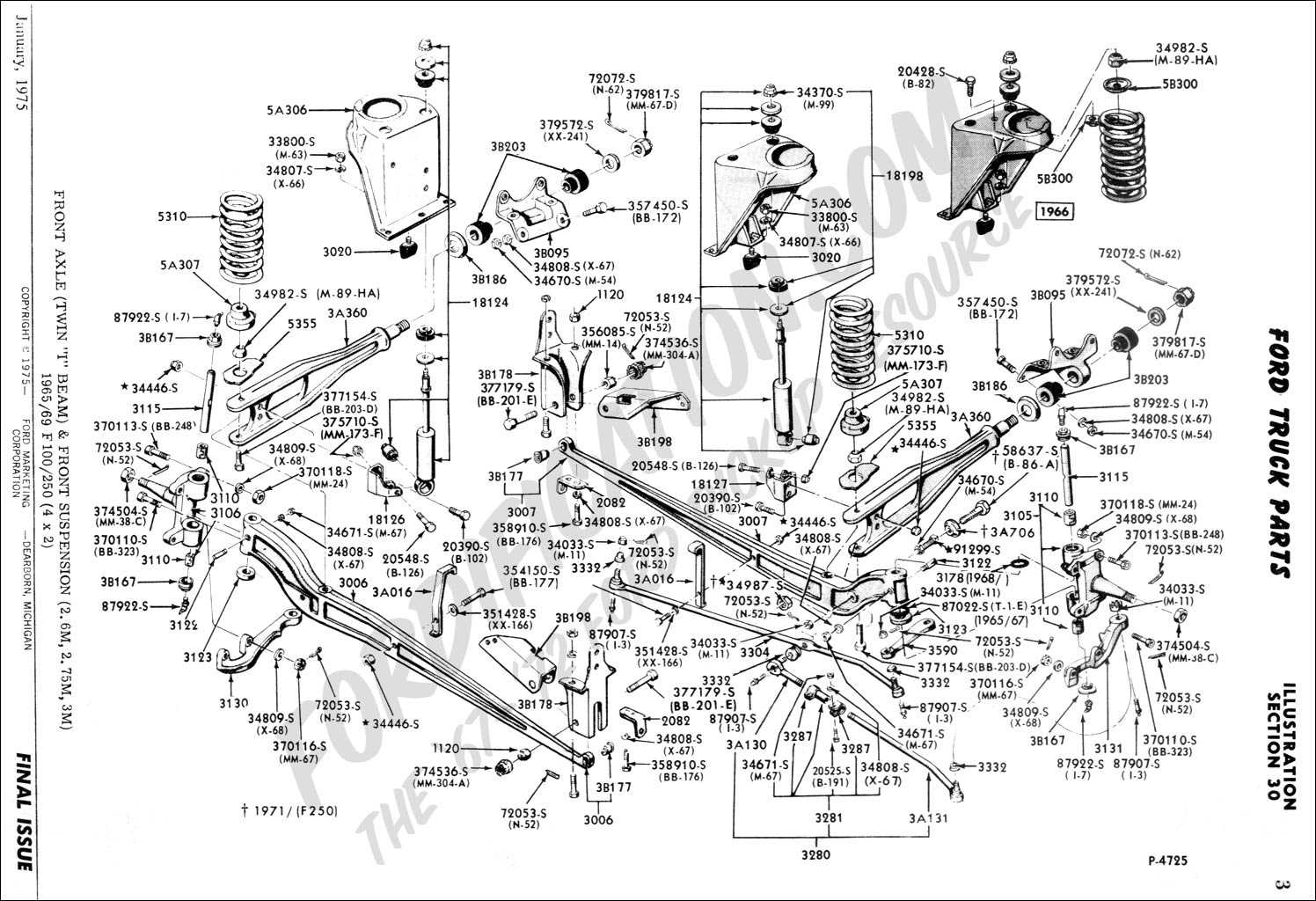

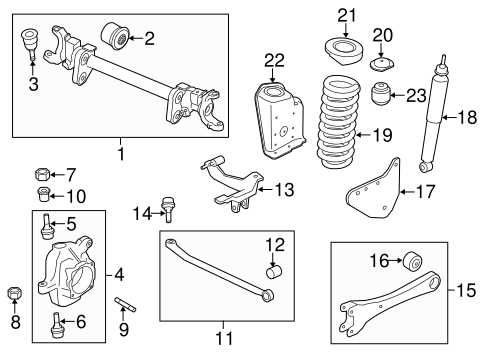

Components of 4×4 Front Suspension

The suspension system at the front of a vehicle plays a crucial role in maintaining stability and control, especially when navigating uneven terrains. It comprises various elements that work together to absorb shocks, support the vehicle’s weight, and ensure a smooth ride. Understanding these components can greatly enhance the performance and handling of a vehicle.

Key Elements of the Suspension System

Among the primary components are the control arms, which connect the chassis to the wheels, allowing for controlled movement. These arms are essential for managing wheel alignment and ensuring that the tires maintain contact with the ground, even over bumpy surfaces. Additionally, coil springs or leaf springs provide the necessary cushioning, absorbing impact from road irregularities and enhancing ride comfort.

Stabilization and Steering Mechanisms

Another critical aspect involves shock absorbers, which dampen the motion of the springs to prevent excessive bouncing. The steering linkage connects the steering wheel to the wheels, enabling precise handling and responsiveness. Together, these components create a cohesive system that not only improves driving dynamics but also contributes to overall safety.

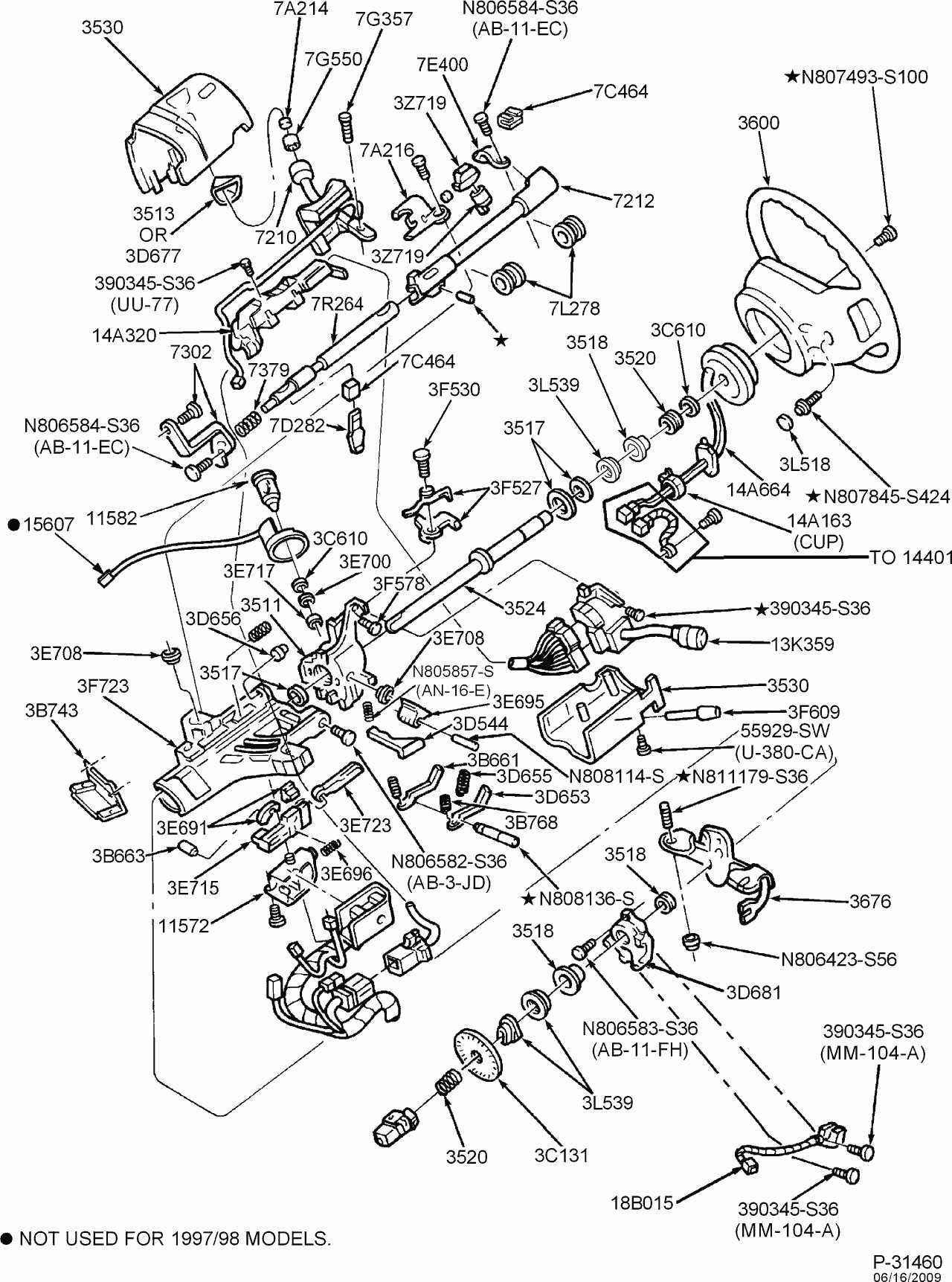

Visual Guide to F350 Front Parts

This section aims to provide an insightful overview of essential components located at the forefront of a vehicle. Understanding these elements can enhance maintenance and repair knowledge, ultimately leading to improved performance and longevity.

- Suspension System:

- Shock Absorbers

- Coil Springs

- Control Arms

- Steering Mechanism:

- Steering Gearbox

- Pitman Arm

- Idler Arm

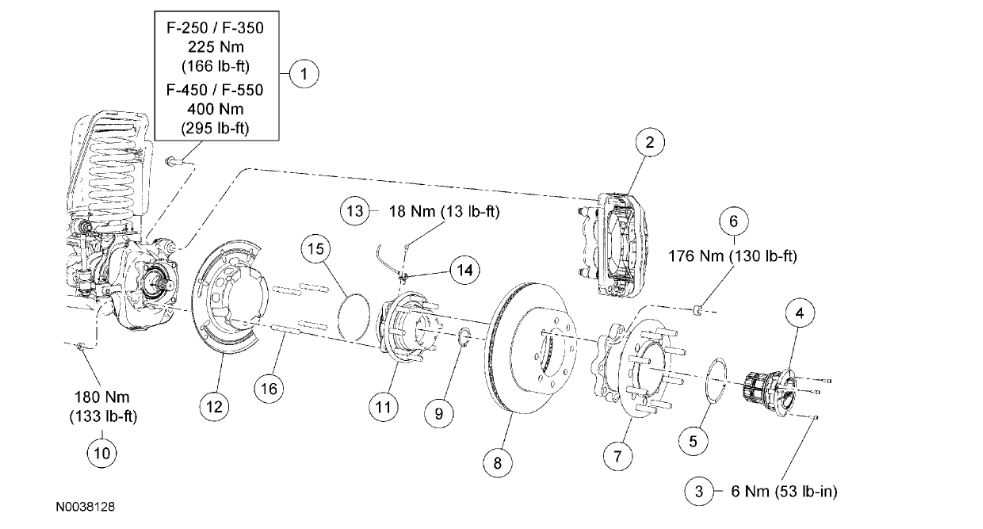

- Braking Components:

- Brake Calipers

- Brake Rotors

- Brake Lines

- Frame Structure:

- Crossmember

- Subframe

- Reinforcement Beams

Familiarizing yourself with these crucial elements will aid in identifying potential issues and enhance your ability to perform necessary repairs or upgrades effectively.

Common Issues with Front End Parts

When it comes to the components that steer and support a vehicle, several challenges can arise over time. Understanding these common problems is essential for maintaining optimal performance and safety. Below are some prevalent issues that drivers may encounter with these crucial assemblies.

- Worn Bushings: Rubber or polyurethane bushings can degrade, leading to poor handling and noise.

- Ball Joint Failure: A worn ball joint can cause instability and uneven tire wear, affecting steering precision.

- Steering Linkage Problems: Issues in the linkage can result in a loose steering feel and misalignment.

- Leaking Shocks: Damaged shock absorbers can impair ride quality and vehicle control, leading to excessive bouncing.

- Alignment Issues: Improper alignment can cause uneven tire wear and affect fuel efficiency.

- CV Joint Wear: Constant velocity joints can wear out, causing clicking noises during turns and affecting drivetrain performance.

Regular inspections and maintenance can help identify these problems early, ensuring a smoother and safer driving experience. Being proactive about these common concerns can significantly extend the lifespan of the vehicle’s steering and support components.

How to Identify Front End Wear

Recognizing signs of deterioration in the steering and suspension components of your vehicle is essential for maintaining optimal performance and safety. Various symptoms can indicate that certain elements may be worn or damaged, which can lead to handling issues or increased tire wear. Observing these indicators early can save you time and money on repairs.

Common Symptoms of Wear

Several noticeable signs can help you determine if your vehicle’s steering and suspension system is experiencing wear:

| Symptom | Description |

|---|---|

| Uneven Tire Wear | Irregular patterns on tires can signal alignment issues or failing components. |

| Loose Steering | Excessive play in the steering wheel may indicate worn tie rods or bushings. |

| Vibration | Unusual shaking during driving can point to issues with the shocks or struts. |

| Noisy Ride | Clunking or popping noises while turning might suggest damaged joints or bearings. |

| Pulling to One Side | If the vehicle veers left or right while driving straight, it may need alignment or component replacement. |

Inspection Tips

To effectively assess the condition of your vehicle’s steering and suspension, perform routine checks. Begin by visually inspecting for cracks or signs of rust on the components. Additionally, lift the vehicle and wiggle the wheels to check for excessive movement. Regular maintenance and prompt attention to these symptoms can significantly extend the lifespan of your vehicle’s system.

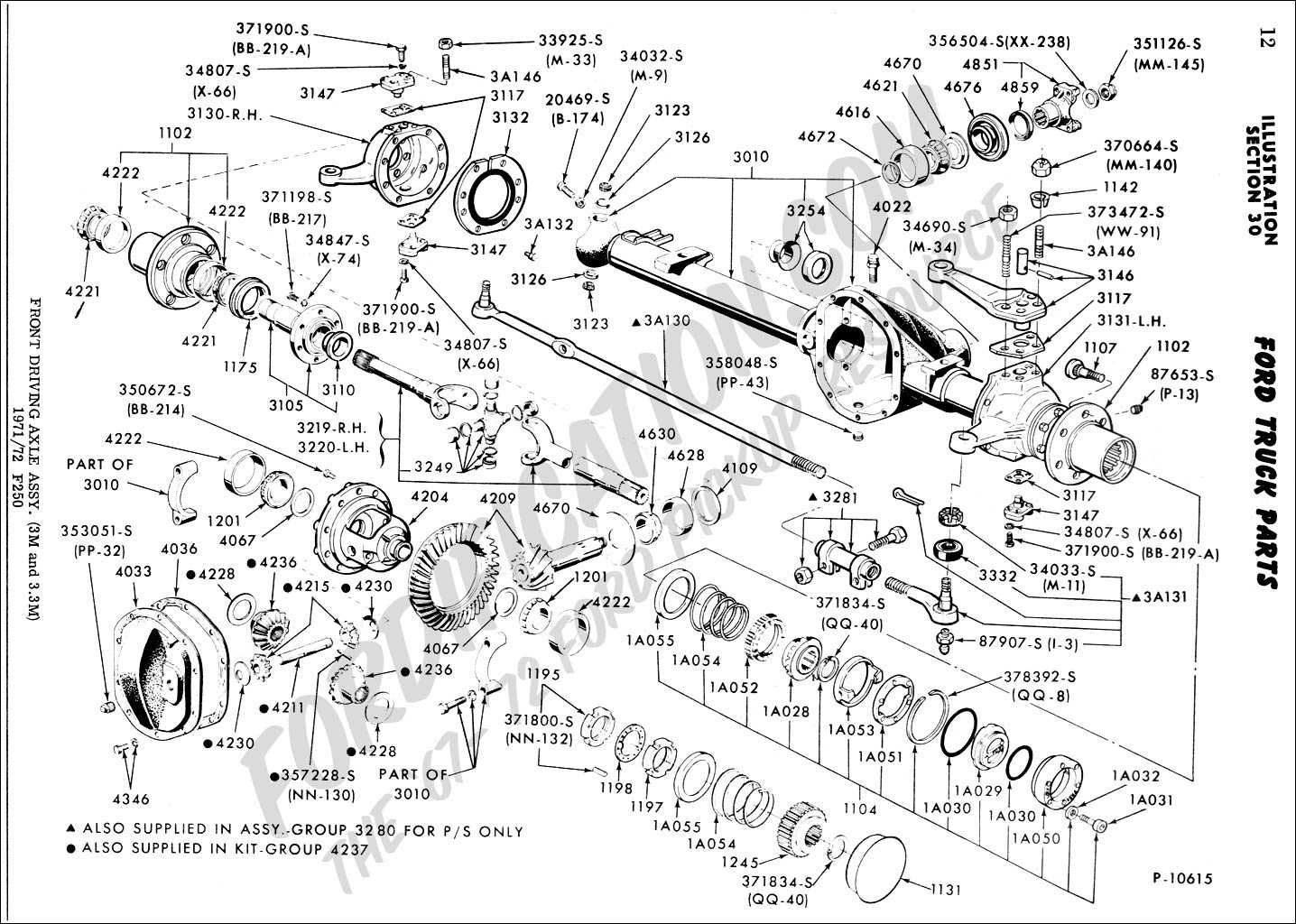

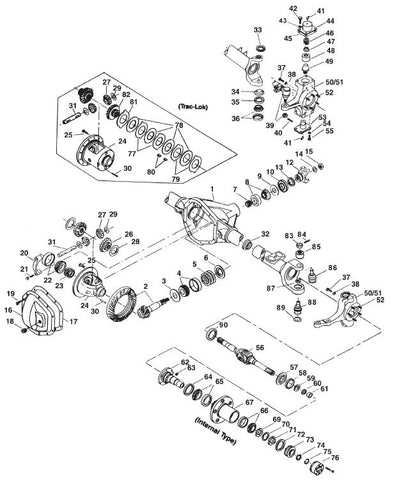

Replacement Parts for Ford F350

Maintaining the performance and safety of your vehicle often requires the timely replacement of various components. Understanding the available options and their specifications can help ensure optimal functionality and longevity. This section delves into essential elements that may need attention over time, offering insights into suitable alternatives and enhancements.

| Component | Description | Replacement Options |

|---|---|---|

| Suspension System | Crucial for stability and ride quality. | Coil springs, shock absorbers, control arms |

| Steering Mechanism | Ensures responsive handling and control. | Steering gears, tie rods, power steering pumps |

| Braking System | Vital for safety and stopping power. | Brake pads, rotors, calipers |

| Transmission | Essential for power transfer and performance. | Clutch kits, transmission filters, gaskets |

Choosing the right replacements not only enhances performance but also contributes to the overall driving experience. Regular inspections and timely updates can prevent further complications and ensure reliability on the road.

Benefits of Upgrading Front Components

Enhancing the components at the forefront of your vehicle can lead to significant improvements in performance, safety, and overall driving experience. Upgraded elements not only contribute to better handling and responsiveness but also extend the lifespan of your vehicle. Investing in higher-quality materials and designs can yield both immediate and long-term benefits.

One of the primary advantages of upgrading these elements is the enhancement of stability and control. Improved design can minimize body roll and enhance traction, particularly in challenging driving conditions. This results in a more confident driving experience, whether navigating rough terrains or cruising on highways.

Another benefit is the potential for increased durability. Upgraded components are often crafted from superior materials that can withstand wear and tear, thereby reducing the frequency of replacements. This not only saves money over time but also ensures that your vehicle remains reliable and performs optimally.

| Benefit | Description |

|---|---|

| Improved Handling | Better response and control during maneuvers. |

| Enhanced Safety | Increased stability reduces the risk of accidents. |

| Durability | Longer lifespan reduces the need for frequent replacements. |

| Performance Boost | Optimized design enhances overall driving dynamics. |

Ultimately, upgrading these components is a proactive step towards ensuring that your vehicle meets both current and future demands, providing a smoother and safer ride for years to come.

Essential Tools for Front End Repair

When undertaking repairs on the steering and suspension components of a vehicle, having the right equipment is crucial for achieving optimal results. The tools not only enhance efficiency but also ensure safety during the maintenance process. Understanding which implements are necessary can make a significant difference in the outcome of the job.

First and foremost, a comprehensive set of wrenches and sockets is indispensable. These allow for the loosening and tightening of various bolts and nuts throughout the assembly. A torque wrench is particularly important, as it ensures that fasteners are secured to the manufacturer’s specifications, preventing future issues.

Pneumatic or hydraulic jacks facilitate lifting the vehicle safely, providing necessary clearance for working beneath it. Coupled with jack stands, these tools help maintain stability during repairs. Additionally, a quality impact wrench can greatly reduce the time needed to remove stubborn fasteners.

For precise adjustments and measurements, a reliable alignment tool is essential. This equipment aids in ensuring that all components are correctly positioned, which is vital for proper handling and tire wear. Furthermore, ball joint separators and tie rod pullers simplify the disassembly process, making it easier to replace worn parts.

Lastly, keeping a variety of hand tools, such as pliers and screwdrivers, on hand ensures readiness for any unforeseen tasks that may arise during the repair process. By equipping oneself with these essential tools, the complexity of vehicle maintenance can be significantly reduced, leading to a more successful and efficient repair experience.

Maintenance Tips for F350 Front End

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s steering and suspension components. Attention to detail can prevent larger issues down the line and enhance driving comfort.

- Check for Wear: Inspect bushings and joints for signs of deterioration or play.

- Fluid Levels: Regularly monitor and top off steering fluid to maintain system efficiency.

- Alignment: Schedule alignments periodically to ensure proper handling and tire longevity.

- Tire Inspection: Rotate tires regularly and check for uneven wear patterns.

Implementing these practices will ultimately lead to a smoother ride and a more reliable vehicle.

DIY vs. Professional Repairs

When it comes to maintaining and fixing vehicles, enthusiasts often face the choice between tackling repairs themselves or hiring a skilled technician. Each approach carries its own benefits and challenges, influencing both the quality of work and overall cost. Understanding these aspects can help individuals make informed decisions about their vehicle maintenance needs.

Advantages of DIY Repairs

Engaging in self-repairs can provide a profound sense of accomplishment. It often allows for greater flexibility with time and can be more economical, especially for those who already possess the necessary tools and knowledge. Additionally, tackling repairs personally can deepen one’s understanding of the vehicle’s mechanics, fostering a stronger connection to the machine.

Benefits of Professional Assistance

Opting for expert services can yield quicker and potentially more reliable results, particularly for complex issues. Professionals come equipped with specialized tools and extensive experience, which can ultimately save time and prevent costly mistakes. Moreover, many services offer warranties on their work, providing peace of mind for the vehicle owner.

Cost Analysis of Front End Parts

Evaluating the expenses associated with various components of the vehicle’s front assembly is essential for both maintenance and budgeting. Understanding these costs can help owners make informed decisions when repairs or upgrades are necessary.

Factors Influencing Costs

- Quality of Materials: Higher-quality materials typically lead to increased durability and performance, affecting overall pricing.

- Brand Reputation: Established brands may charge a premium, while lesser-known manufacturers might offer lower prices.

- Type of Component: Different components, such as suspensions or steering systems, have varying price ranges based on complexity and functionality.

- Labor Costs: Professional installation can significantly impact total expenses, particularly for intricate assemblies.

Typical Expense Breakdown

- Ball Joints: $50 – $200

- Control Arms: $100 – $400

- Steering Linkage: $70 – $300

- Sway Bar Links: $30 – $100

By analyzing these components and their associated costs, vehicle owners can plan effectively for both immediate repairs and long-term maintenance, ensuring optimal performance and safety on the road.

Impact of Terrain on Front End Parts

The type of landscape encountered during driving can significantly affect various components of a vehicle’s steering and suspension system. Different environments, from rugged mountains to smooth highways, impose unique stresses and challenges that can lead to varying degrees of wear and tear. Understanding these impacts is crucial for maintaining optimal performance and longevity of these crucial systems.

Rugged Terrain Challenges

In off-road conditions, vehicles often face obstacles such as rocks, mud, and steep inclines. These factors can lead to increased strain on suspension elements and steering mechanisms. For instance, frequent impacts from uneven surfaces can cause misalignment and premature wear, necessitating more frequent maintenance and potential replacements.

Smooth Surfaces and Their Effects

Conversely, traveling on well-maintained roads presents a different scenario. While the wear is generally less severe, prolonged exposure to high speeds can still affect components due to heat buildup and vibration. Regular checks and adjustments are essential to ensure that the vehicle remains responsive and safe, even in less challenging environments.

Finding Quality Parts Suppliers

When it comes to maintaining and upgrading your vehicle, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Identifying reliable vendors can significantly impact both the functionality and safety of your machine. Here are some essential tips for locating reputable suppliers.

- Research and Reviews: Start by looking for customer feedback and ratings. Online forums and review sites can provide insights into the experiences of other buyers.

- Industry Reputation: Choose suppliers known for their credibility in the market. Companies with a longstanding history often have established quality standards.

- Product Range: A wide selection of components indicates a supplier’s capability to meet various needs, making them a more versatile choice.

- Warranty and Return Policies: Check the warranty options and return policies offered. Reliable suppliers often stand behind their products.

Engaging with knowledgeable staff can also enhance your purchasing experience. Look for vendors who are willing to share expertise and assist in selecting the right items for your needs.

Finally, consider local versus online options. While online shopping provides convenience, local suppliers may offer personalized service and quicker access to items.