Comprehensive Guide to Deere Parts Diagrams

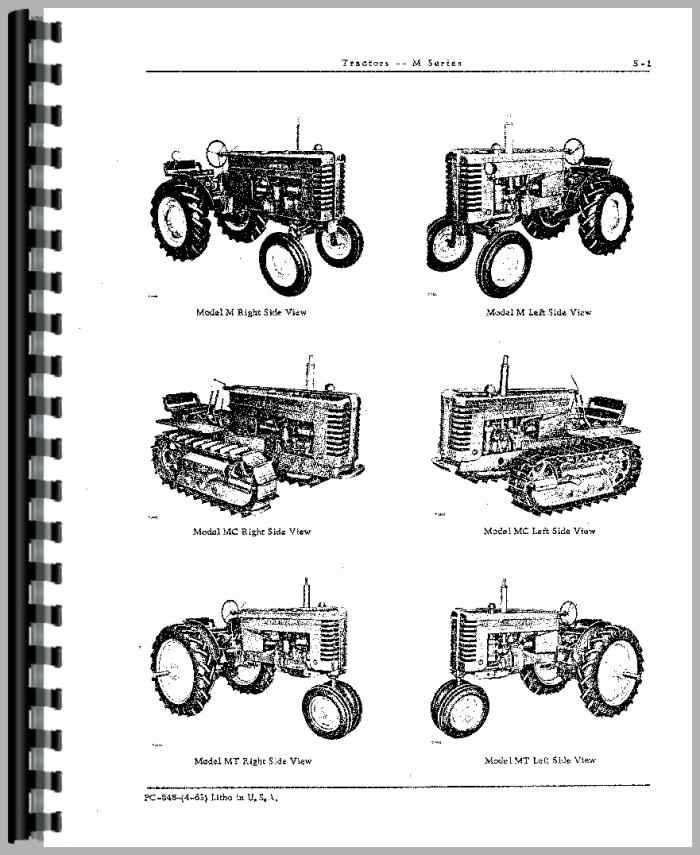

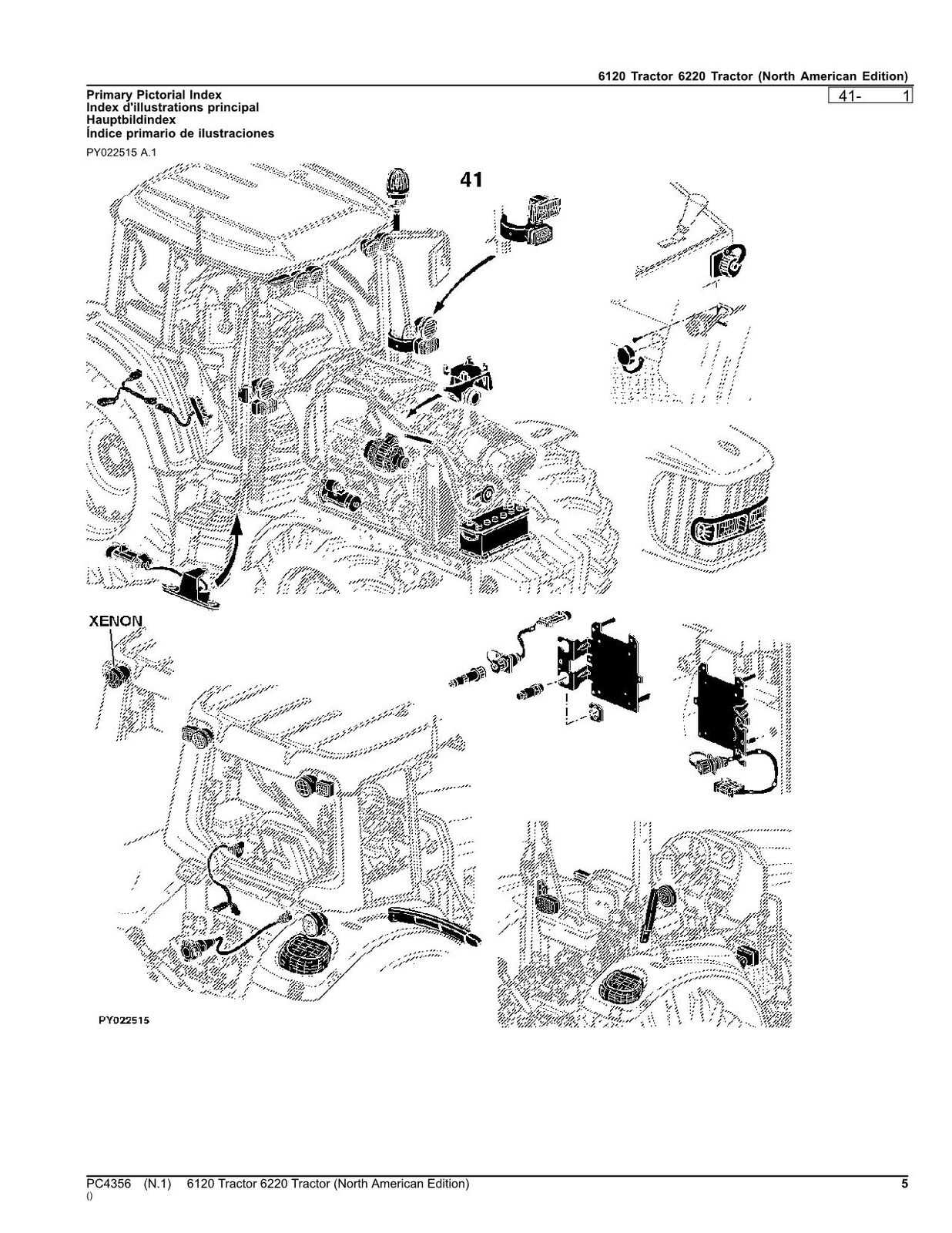

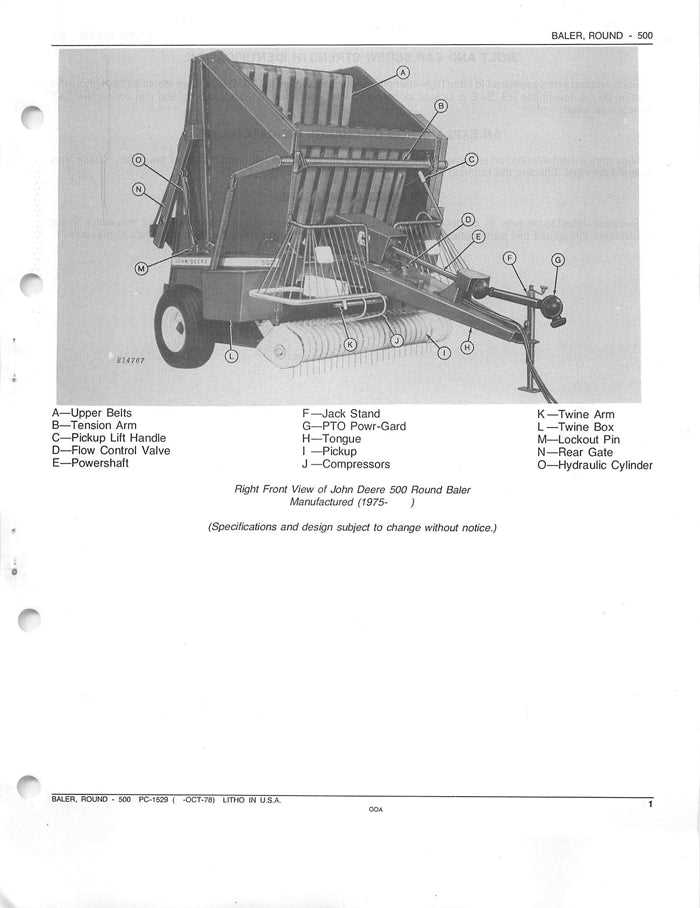

When it comes to maintaining heavy equipment, a clear visualization of its elements is essential. A well-structured representation serves as a guide, helping users identify and understand the various components involved in the machinery’s operation.

These illustrations are invaluable tools for technicians and operators alike, facilitating efficient repairs and replacements. By allowing individuals to pinpoint specific pieces and their functions, the visuals ultimately streamline the maintenance process.

As one explores these detailed layouts, the intricate relationships between different elements become apparent, enhancing comprehension. This insight not only aids in troubleshooting but also empowers users to take proactive measures in their equipment care.

Understanding Deere Parts Diagrams

Comprehending technical illustrations is essential for effective maintenance and repair of machinery. These visual aids serve as vital resources, enabling users to identify components and their relationships within complex systems.

Key benefits of mastering these visuals include:

- Improved troubleshooting efficiency

- Enhanced understanding of assembly and disassembly processes

- Better communication with service professionals

To fully grasp these illustrations, consider the following steps:

- Familiarize yourself with common symbols used in these resources.

- Study the layout to understand how various elements connect.

- Refer to the accompanying manuals for detailed explanations.

By delving into this knowledge, you can ultimately optimize the functionality and longevity of your equipment.

Importance of Accurate Parts Identification

Identifying components with precision is crucial in various industries, ensuring efficiency and reliability in maintenance and repairs. Misidentification can lead to operational disruptions and increased costs, making it essential to have a clear understanding of each element involved.

Benefits of Accurate Identification

- Enhanced Operational Efficiency

- Reduced Downtime

- Cost Savings

- Improved Safety Standards

Consequences of Misidentification

- Increased Repair Costs

- Potential Damage to Equipment

- Extended Project Timelines

- Safety Hazards for Operators

How to Read Deere Diagrams

Understanding technical illustrations related to machinery can significantly enhance your ability to perform maintenance and repairs. These visuals provide crucial insights into the assembly and components of equipment, helping users identify parts and their functions with ease.

Identifying Components

The first step in deciphering these illustrations is to familiarize yourself with the symbols and notations used. Each element typically represents a specific component or assembly, with distinct markings indicating their roles. Pay close attention to the legend, which will guide you through the meanings of various symbols.

| Symbol | Description |

|---|---|

| Circle | Indicates a connection point |

| Square | Represents a component housing |

| Arrow | Shows direction of flow or movement |

Understanding Assembly Flow

After recognizing individual components, the next step is to analyze how they fit together. Look for arrows and lines that illustrate the flow of operations or connections between different parts. This understanding helps in visualizing the overall structure and function of the machinery, enabling effective troubleshooting and assembly.

Common Components in Deere Machinery

The effectiveness of agricultural equipment relies heavily on its fundamental elements, which work in harmony to ensure optimal performance. Understanding these key components is essential for maintenance and operational efficiency.

Engines serve as the heart of the machinery, providing the necessary power for various tasks. The transmission system plays a critical role in transferring this power to the wheels or tracks, enabling mobility across different terrains.

Hydraulic systems are vital for lifting and controlling attachments, enhancing versatility. Additionally, the chassis provides structural support and stability, ensuring that the equipment can withstand heavy loads and harsh conditions.

Regular attention to these integral components can prolong the lifespan of the machinery and improve overall productivity in the field.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can significantly enhance repair and maintenance efforts. Understanding where to access these resources is essential for anyone looking to ensure their equipment operates smoothly and efficiently.

Online Resources

Many manufacturers provide comprehensive digital catalogs on their official websites. These platforms often feature searchable databases, allowing users to explore various models and corresponding components with ease.

Community Forums and User Groups

Engaging with online communities can yield valuable insights. Enthusiasts and professionals alike often share their expertise, including links to resources where detailed illustrations can be found.

Tips for Using Diagrams Effectively

Utilizing visual representations can significantly enhance understanding and efficiency when working on machinery. To maximize their potential, it is essential to approach them with clear strategies that promote clarity and effectiveness.

Understanding the Layout

Familiarize yourself with the overall structure before diving into specifics. Recognizing how various components interact can provide a holistic view that aids in troubleshooting and maintenance.

Referencing Specific Sections

When searching for particular elements, focus on specific sections rather than scanning the entire illustration. This targeted approach saves time and reduces confusion.

| Tip | Description |

|---|---|

| Highlight Key Areas | Use markers or notes to emphasize critical components for quicker reference. |

| Keep a Legend | Maintain a key that explains symbols and notations for clarity. |

| Take Notes | Document observations directly on the visual aid for future reference. |

Benefits of Using Official Resources

Utilizing authorized materials for equipment maintenance offers significant advantages that enhance efficiency and longevity. Accessing verified information ensures compatibility and reliability, which is crucial for optimal performance. Official resources are designed to streamline repair processes, reduce errors, and ultimately save time and money.

Accuracy and Reliability

One of the primary benefits of official resources is the assurance of accuracy. These documents provide detailed and precise information that aligns perfectly with the equipment specifications, minimizing the risk of mishaps during repairs.

Comprehensive Support

Official channels often offer extensive support, including customer service and technical assistance. This level of backing can prove invaluable when tackling complex issues, ensuring users can address challenges efficiently and effectively.

Comparing Aftermarket and OEM Parts

The choice between alternative components and original manufacturer offerings is a crucial decision for many equipment owners. Each option presents distinct advantages and potential drawbacks, impacting performance, longevity, and cost-effectiveness. Understanding these differences helps ensure informed purchasing choices that align with individual needs and priorities.

Quality and Reliability

Original manufacturer offerings are typically designed to meet stringent quality standards, ensuring a perfect fit and optimal performance. These components often come with warranties that reflect their durability and reliability. In contrast, alternative components can vary significantly in quality. While some may offer comparable performance at a lower price, others might fall short, leading to potential issues down the line.

Cost Considerations

Price is often a deciding factor when selecting between these two options. Alternative components generally provide a more budget-friendly choice, appealing to those looking to minimize expenses. However, the initial savings might be offset by shorter lifespans or increased maintenance needs. On the other hand, investing in original offerings may entail higher upfront costs but can lead to better long-term value through enhanced reliability and reduced frequency of replacements.

Maintenance Tips from Parts Diagrams

Understanding the layout of machinery components is crucial for effective upkeep. These illustrations serve as a valuable resource, enabling operators to identify essential elements and ensure optimal functionality.

- Regular Inspections: Frequently examine your machinery based on the visual guide to catch wear and tear early.

- Replacement Timing: Refer to the schematic to determine the lifespan of critical components and schedule replacements proactively.

- Proper Lubrication: Use the diagram to locate lubrication points and maintain smooth operation.

- Assembly Guidance: Utilize the visual aids for accurate reassembly after repairs to prevent future issues.

By leveraging these illustrations, operators can enhance the longevity and efficiency of their equipment.

Troubleshooting Using Diagrams

Visual aids play a crucial role in diagnosing mechanical issues. They provide a clear representation of components and their relationships, allowing technicians to pinpoint problems efficiently. Utilizing such resources can streamline the troubleshooting process, reducing downtime and enhancing repair accuracy.

Identifying Components

One of the primary benefits of visual representations is the ease of identifying individual elements within a complex system. By referring to these visuals, technicians can quickly locate and assess the condition of specific parts that may be causing operational issues.

Systematic Approach to Diagnosis

Employing a structured method while using these visual tools can lead to more effective troubleshooting. Following a systematic approach ensures that all potential issues are considered, minimizing the risk of overlooking critical faults.

| Step | Description |

|---|---|

| 1 | Review the visual representation to understand the system layout. |

| 2 | Identify the components that are suspected to be malfunctioning. |

| 3 | Check for visible signs of wear or damage. |

| 4 | Consult manufacturer specifications for performance standards. |

| 5 | Perform necessary tests to confirm suspicions. |

Updating Your Knowledge on Parts

Staying informed about components is essential for effective maintenance and optimal performance of your equipment. Understanding the intricacies of each element can significantly enhance your ability to troubleshoot issues and make informed decisions when repairs are necessary.

Regularly reviewing manuals, attending workshops, and engaging with online communities can provide valuable insights. Additionally, exploring resources that offer detailed breakdowns can help you familiarize yourself with various features and functionalities.

By continuously expanding your knowledge base, you empower yourself to tackle challenges confidently, ensuring longevity and reliability in your machinery. This commitment to learning will ultimately lead to better performance and reduced downtime.