Exploring the Husqvarna 125B Parts Diagram for Ultimate Maintenance

In the realm of outdoor tools, a comprehensive grasp of each component’s functionality is essential for effective maintenance and optimal performance. This knowledge empowers users to identify parts swiftly and resolve issues with confidence.

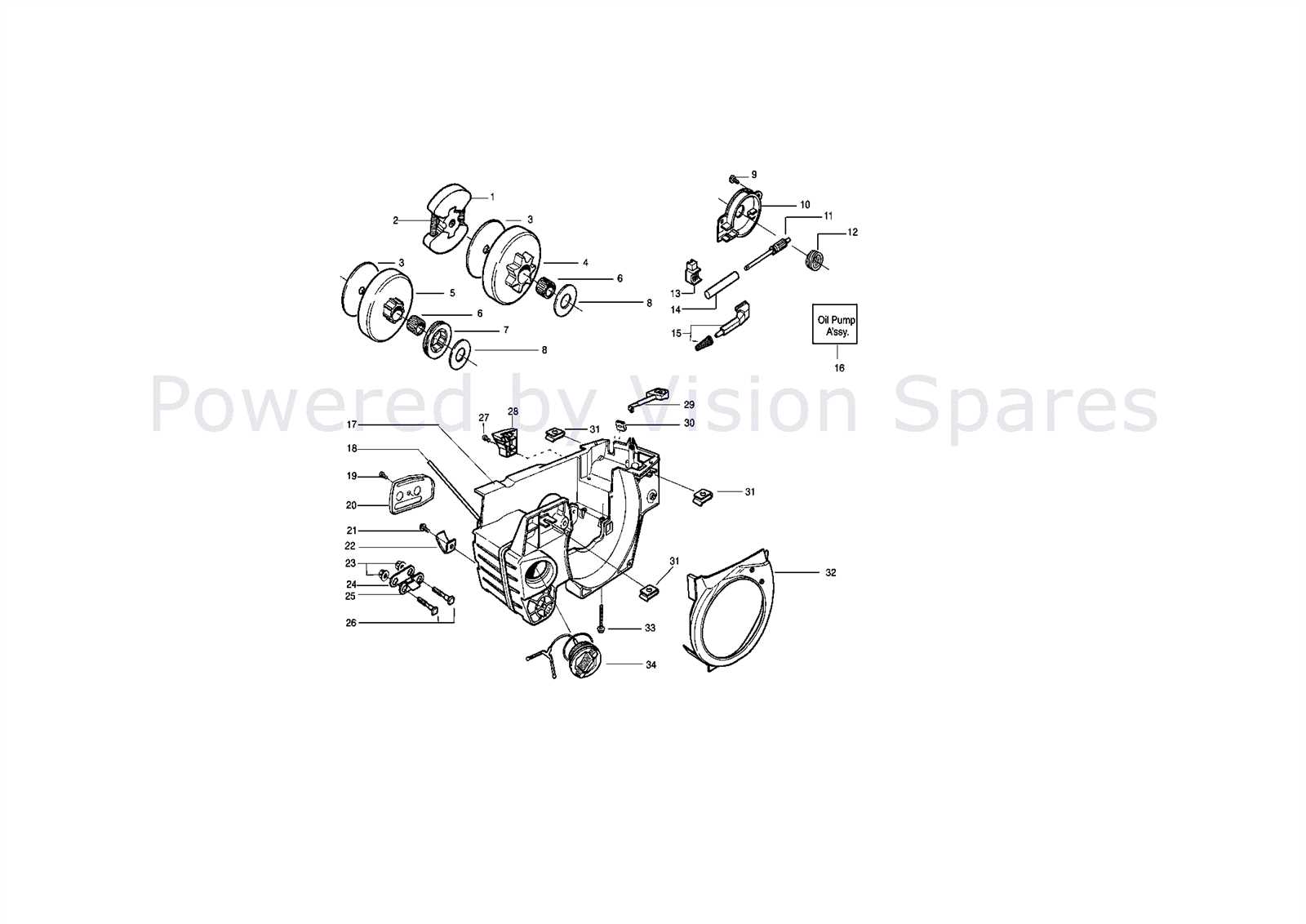

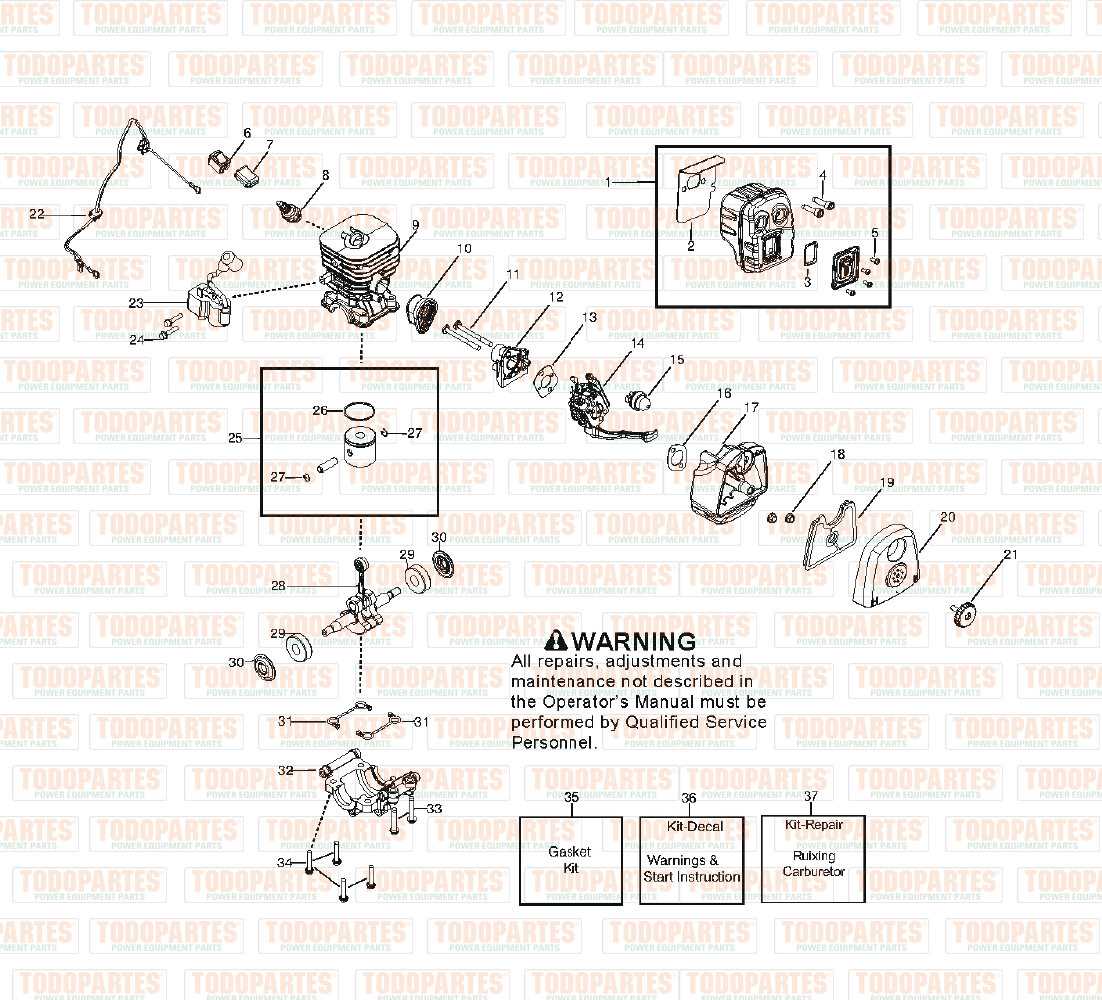

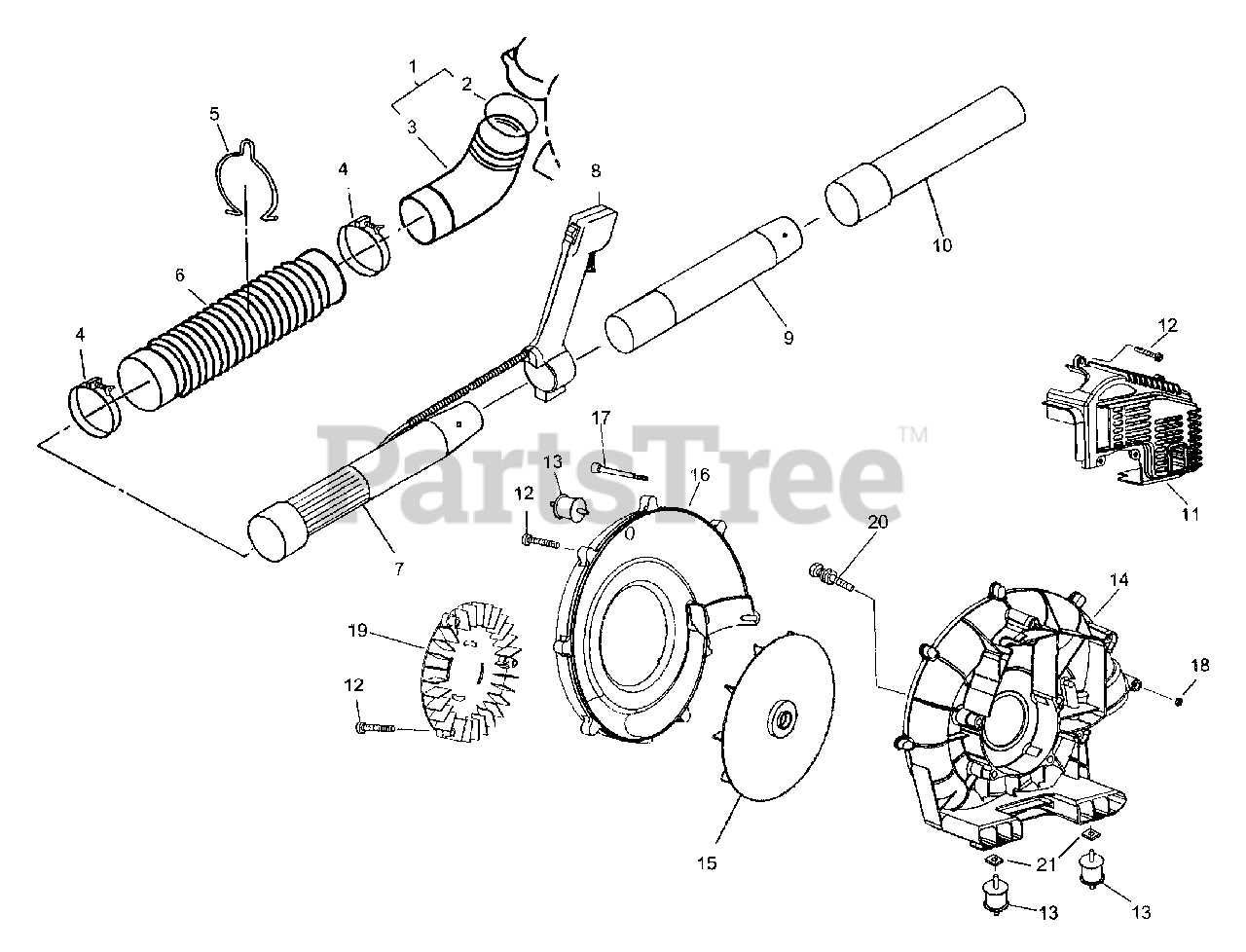

Visual aids can significantly enhance your understanding of how different elements interact within your machine. By examining detailed representations, you can delve into the intricate design and assembly of the device, ensuring you know the role of every piece.

Whether you are a seasoned user or a newcomer, mastering the intricacies of your gear can lead to improved efficiency and longevity. This article serves as an ultimate guide to help you navigate the essential components of your equipment, making repairs and maintenance a more manageable task.

Understanding the Husqvarna 125B

This section delves into the features and functionality of a popular handheld blower, ideal for both professional landscapers and homeowners. By exploring its components and mechanics, users can gain a deeper appreciation for its design and performance capabilities.

Key attributes include:

- Powerful engine for efficient operation

- Lightweight construction for easy handling

- User-friendly controls for seamless use

To maintain optimal performance, understanding the main elements is crucial:

- Engine assembly: The heart of the device that drives airflow.

- Fan system: Designed to maximize blowing efficiency.

- Fuel system: Ensures proper operation and longevity.

- Air filter: Keeps the engine clean and functioning well.

Regular maintenance of these components can significantly enhance the blower’s lifespan and effectiveness, making it an essential tool in any yard care toolkit.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of these elements not only facilitate the identification of individual pieces but also enhance the overall comprehension of how they interact within the system. Such illustrations serve as valuable tools for both professionals and enthusiasts, streamlining the process of troubleshooting and assembly.

Enhanced Efficiency

Utilizing visual guides can significantly improve the efficiency of maintenance tasks. By providing clear information on the placement and function of each component, these resources minimize the time spent searching for parts or deciphering assembly processes. This clarity allows technicians to focus on the task at hand, reducing downtime and ensuring that equipment remains in optimal working condition.

Aid in Troubleshooting

Visual aids are invaluable when diagnosing issues. They help users pinpoint problems more effectively by illustrating how components should fit together and function. When discrepancies arise, referencing these guides enables a quicker resolution, ultimately leading to better performance and reliability of the equipment. Moreover, they empower users to conduct repairs confidently, fostering a deeper understanding of the machinery.

Main Components of the 125B

Understanding the essential elements of this equipment is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality and efficiency, contributing to its performance.

Key Elements

- Engine: Powers the unit and provides necessary energy for operation.

- Air Filter: Ensures clean air intake for optimal performance.

- Fuel Tank: Stores the fuel required for engine operation.

- Blower Housing: Houses the motor and directs airflow.

- Handle: Provides control and maneuverability during use.

Additional Features

- Throttle Control: Allows for speed regulation.

- Choke: Facilitates easier starting in various conditions.

- Exhaust System: Manages emissions and noise output.

Common Issues with 125B Parts

When dealing with outdoor equipment, users often encounter various challenges related to components. Understanding these common problems can enhance maintenance efforts and improve overall performance.

| Issue | Description |

|---|---|

| Clogged Filters | Debris buildup can hinder airflow, leading to reduced efficiency and performance. |

| Worn Seals | Over time, seals may deteriorate, resulting in leaks and compromised functionality. |

| Faulty Spark Plug | A malfunctioning spark plug can cause starting issues and poor combustion. |

| Damaged Cables | Frayed or broken cables can interrupt power delivery, affecting operation. |

How to Read the Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair of any equipment. This guide will help you interpret the layout and function of various elements, ensuring you can easily identify and address any issues.

Follow these steps to enhance your comprehension:

- Familiarize Yourself with the Symbols:

- Identify common symbols used to represent specific parts.

- Learn the meaning of each icon to avoid confusion.

- Understand the Layout:

- Recognize how components are arranged in relation to one another.

- Pay attention to connections and pathways illustrated in the image.

- Refer to the Key:

- Look for a legend that explains the symbols and lines.

- Use the key as a reference to decode the visual information accurately.

- Identify Groupings:

- Notice how components are grouped based on their functions.

- Understand the relationship between different sections of the layout.

- Cross-Reference with Documentation:

- Utilize manuals or online resources for additional context.

- Compare the visual with written descriptions for clarity.

By following these guidelines, you’ll be equipped to effectively read and utilize the visual representation, leading to more efficient repairs and maintenance tasks.

Replacement Parts for Efficiency

Ensuring optimal performance of your equipment requires the timely replacement of worn components. Regularly updating these elements not only enhances functionality but also prolongs the lifespan of your machine. Understanding which pieces to replace can lead to significant improvements in efficiency and reliability.

Benefits of Using Quality Components

- Improved Performance: Quality replacements maintain the equipment’s original efficiency.

- Increased Lifespan: Durable parts reduce the frequency of replacements.

- Cost-Effectiveness: Investing in quality can save money in the long run.

- Enhanced Safety: Reliable components minimize the risk of accidents.

Key Components to Monitor

- Filters: Regular replacement ensures optimal airflow and performance.

- Blades: Dull or damaged blades can hinder operation and reduce effectiveness.

- Hoses: Worn hoses can lead to leaks and decreased performance.

- Spark Plugs: These should be changed to ensure proper ignition and fuel efficiency.

By focusing on these critical areas, you can ensure your equipment runs smoothly and efficiently, ultimately achieving better results in your tasks.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. By following a few essential practices, you can extend the life of your tools and maintain their efficiency over time.

- Regular Cleaning: Remove debris, dust, and dirt after each use to prevent buildup that can affect performance.

- Check Filters: Inspect and clean air filters regularly to ensure optimal airflow and prevent engine strain.

- Inspect Fuel System: Use fresh fuel and check for leaks or clogs in the fuel lines to maintain proper functionality.

- Sharpen Blades: Keep cutting components sharp for efficient operation, reducing the strain on the engine.

- Routine Lubrication: Apply lubricant to moving parts to minimize wear and tear, ensuring smooth operation.

Adopting these practices not only improves performance but also enhances safety and reliability during use.

- Perform regular inspections to catch issues early.

- Store equipment in a dry, sheltered place to protect it from environmental damage.

- Follow manufacturer guidelines for maintenance schedules.

By committing to these maintenance tips, you will ensure that your outdoor equipment serves you well for years to come.

Where to Find Authentic Parts

Locating genuine components for your equipment can significantly enhance its performance and longevity. It’s essential to ensure that replacements are reliable and compatible with your machine.

Here are several avenues to explore:

- Manufacturer’s Website: Always a top choice for original items.

- Authorized Dealers: They provide certified options and can offer expert advice.

- Specialty Retailers: Look for stores that focus on outdoor equipment for a curated selection.

- Online Marketplaces: Websites dedicated to machinery often have a range of new and refurbished components.

- Local Repair Shops: Professionals may have access to authentic replacements or can direct you to reliable sources.

Investing time in sourcing the right components can lead to the ultimate performance of your device.

DIY Repairs and Resources

Engaging in self-repair can be a rewarding experience, empowering individuals to address mechanical issues effectively. Access to reliable resources and clear guidance can significantly enhance this process, allowing for a deeper understanding of equipment maintenance and functionality.

Finding the Right Guides

Numerous online platforms offer comprehensive manuals and instructional videos tailored to specific models. These resources often include troubleshooting tips and step-by-step procedures, making it easier to tackle repairs confidently. Utilize forums and community groups where enthusiasts share their experiences and insights.

Essential Tools for Repairs

Having the proper tools is crucial for successful repairs. Invest in high-quality screwdrivers, wrenches, and specialty tools designed for your specific equipment. Additionally, consider acquiring a repair kit that includes essential components, ensuring you’re prepared for any maintenance task.

Comparing Parts with Other Models

When examining components across various models, it becomes essential to identify both similarities and differences that can influence functionality and performance. Each device may share certain features, yet subtle distinctions can significantly affect user experience and maintenance requirements.

Compatibility plays a crucial role when selecting components for repair or upgrade. By analyzing how specific elements correspond to those found in similar machines, users can make informed decisions regarding replacements. This process not only enhances efficiency but also prolongs the lifespan of the equipment.

Moreover, performance optimization can often be achieved by integrating elements from other designs. Understanding which parts are interchangeable allows enthusiasts and professionals alike to enhance their machines, ensuring they operate at peak efficiency while potentially reducing costs.

In summary, a thorough comparison of components across different models provides valuable insights into compatibility and performance enhancements, empowering users to maximize the utility of their devices.

Tools Needed for Assembly

Proper assembly of outdoor equipment requires specific instruments to ensure efficiency and safety. Utilizing the right tools not only simplifies the process but also enhances the overall performance of the machine.

Essential Hand Tools

A variety of hand tools are crucial for the assembly process. Commonly needed items include screwdrivers, wrenches, and pliers, which help in securing components tightly and effectively. Having a set of metric and standard sizes available can prevent delays and ensure a smooth workflow.

Power Tools and Accessories

In addition to hand tools, power tools can significantly speed up assembly. A cordless drill is particularly useful for driving screws quickly. Safety goggles and gloves are also essential accessories to protect the user during the assembly process.

Understanding Part Numbers and Codes

In the world of machinery and equipment, every component is assigned a unique identifier. These codes are essential for ensuring that the right elements are sourced for maintenance and repair. Understanding how these identifiers work can streamline the process of identifying and ordering the correct replacements.

Importance of Unique Identifiers

Unique identifiers serve multiple purposes. They not only simplify inventory management but also facilitate clear communication between manufacturers, suppliers, and consumers. With a consistent coding system, users can easily locate specifications and compatibility details for each item, reducing the risk of errors during procurement.

Decoding the Numbers and Letters

The format of these identifiers often combines letters and numbers, each segment conveying specific information about the item. Here’s a brief overview of a typical coding structure:

| Segment | Meaning |

|---|---|

| First Letter | Indicates the category of the component |

| Numbers | Specifies the model or series |

| Last Letters | Denotes variations or specific features |

By familiarizing yourself with these codes, you can enhance your ability to navigate through catalogs and online resources, making the process of finding the right elements more efficient.

Customer Reviews on Replacement Parts

Feedback from users plays a vital role in understanding the quality and reliability of components available for various equipment. Consumers often share their experiences regarding durability, ease of installation, and overall satisfaction, providing valuable insights for potential buyers. This section highlights customer opinions on alternative components and their performance in real-world applications.

Common Themes in User Feedback

- Durability: Many customers emphasize the longevity of certain replacements, noting that they outperform the originals.

- Ease of Installation: Reviews frequently mention how straightforward the installation process is, which can save time and frustration.

- Performance Improvement: Some users report noticeable enhancements in functionality after switching to specific alternatives.

- Cost-Effectiveness: Customers often highlight the value of choosing replacements that offer comparable quality at a lower price.

Highlighted Customer Experiences

- One user praised a particular alternative for lasting twice as long as the original, significantly reducing their maintenance costs.

- Another customer noted that the installation was so simple that they managed to complete it without professional assistance.

- Several reviews discussed improved efficiency, with users experiencing a smoother operation after the upgrade.

- A number of customers commented on their surprise at the affordability of high-quality replacements, making them a popular choice.