John Deere F525 Mower Parts Diagram

Understanding the structure and functionality of outdoor maintenance machinery is crucial for effective operation and maintenance. With a wide array of models available, each machine has its own specific set of parts that work in harmony to deliver optimal performance. Whether for personal use or professional landscaping, a detailed overview of these components ensures a smoother experience for operators.

When servicing machinery, it is important to identify individual elements that may need attention over time. Regular maintenance can prevent breakdowns and enhance the longevity of the equipment. By exploring the internal configuration and arrangement of each part, users can become more self-sufficient and improve their troubleshooting skills.

This guide aims to provide an in-depth look at the essential components, focusing on their interactions, functions, and the steps needed for maintenance. By familiarizing yourself with the mechanical system, you ensure that your tools stay in peak condition for years to come. From blades to wheels, every detail counts in achieving a smooth operation.

John Deere F525 Mower Overview

This compact, powerful outdoor equipment is designed for precision and efficiency in lawn maintenance. Engineered with a focus on durability and ease of use, it offers a range of features aimed at providing excellent performance. The unique structure combines convenience with functionality, making it a go-to tool for residential and commercial landscaping tasks.

Equipped with a robust engine and innovative design, this machine ensures smooth operation even on challenging terrains. Its user-friendly controls and adjustable components provide flexibility to tackle various mowing conditions. Whether navigating tight spaces or covering larger areas, it offers reliability in both performance and longevity.

Optimized for both comfort and effectiveness, this model incorporates advanced technology to streamline maintenance and reduce operational complexity. With proper care, it continues to deliver consistent results, making it a trusted asset for outdoor professionals and enthusiasts alike.

Key Components of the F525 Mower

The functionality and efficiency of a compact lawn cutting machine are heavily dependent on several core elements working in unison. These vital components ensure smooth operation, allowing users to achieve precise and consistent results with minimal effort. Understanding the essential parts of such equipment is crucial for maintenance and effective usage.

Primary Operational Elements

- Engine – The heart of the system, providing the necessary power for movement and blade rotation.

- Transmission – A crucial mechanism for converting engine power into motion, enabling speed control and maneuverability.

- Deck – Houses the blades and dictates the cutting width, playing a significant role in overall cutting efficiency.

Supporting Structures

- Handlebars – Essential for guiding and controlling the unit, ensuring stability and ease of use during operation.

- Wheels – Providing the necessary traction and movement for the machine, affecting both speed and ease of maneuvering.

- Blade Spindle – Connecting the blades to the motor, this part helps in the rotation and cutting action.

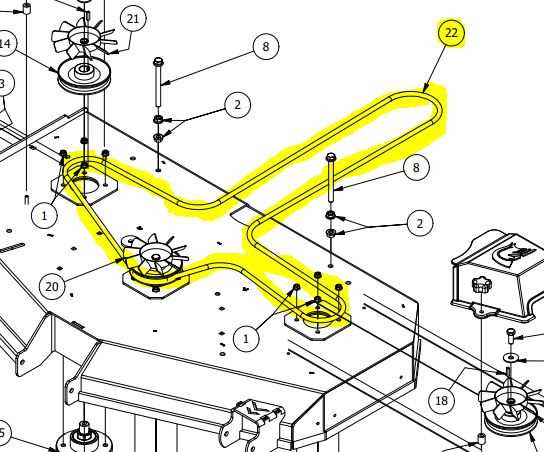

Understanding the Cutting System

The cutting mechanism is one of the most crucial components in any lawn care equipment. It determines the efficiency and precision with which the machine handles grass and other vegetation. This system typically consists of rotating blades, a drive mechanism, and a deck that houses the entire assembly. Proper functioning of this system ensures smooth operation, clean cuts, and uniform results across a variety of terrains.

At the core of this mechanism are the rotating blades, which are driven by a power source. These blades work in conjunction with the deck to direct grass towards the discharge chute. The deck’s design influences the airflow, grass distribution, and overall cutting effectiveness.

| Component | Function |

|---|---|

| Blades | Cut the grass by rotating at high speed, ensuring even trimming. |

| Drive Mechanism | Transfers power from the engine to the blades, enabling rotation. |

| Deck | Encloses the cutting system, directing grass clippings and maintaining airflow. |

| Discharge Chute | Expels cut grass from the deck, preventing clumps and ensuring even distribution. |

Regular maintenance and proper alignment of each component are essential for achieving optimal cutting performance and prolonging the life of the equipment.

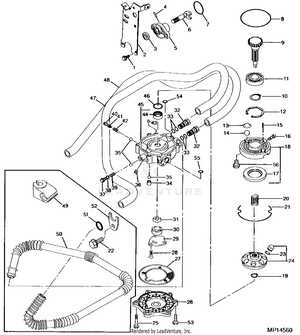

Engine Specifications and Features

The heart of any lawn care equipment is its engine, which drives the machine’s performance. Understanding the engine’s specifications and features is crucial for maintaining efficiency, reliability, and longevity. This section covers key details regarding the power unit that powers this particular model, focusing on its performance, configuration, and unique attributes.

Engine Performance

This engine is designed to deliver consistent power for various turf management tasks. Key elements influencing its performance include displacement, horsepower, and operational efficiency. The following are the main features that define its power output:

- Horsepower: This engine is equipped with sufficient horsepower to handle demanding tasks without compromising speed or reliability.

- Displacement: The engine’s displacement ensures a balance between fuel efficiency and power delivery for longer operating periods.

- Cooling system: An advanced cooling system helps maintain optimal engine temperature, reducing the risk of overheating during extended use.

- Fuel system: Features a carburetor designed for smooth fuel delivery, ensuring consistent operation even in varying conditions.

Engine Configuration

The engine’s configuration is designed for durability and easy maintenance. Its layout and components are optimized for quick troubleshooting and simple repairs. Key configuration features include:

- Cylinder arrangement: The engine uses a vertical arrangement to optimize space and reduce vibration.

- Air filter: An efficient air filtration system ensures that the engine operates with clean air, improving both performance and longevity.

- Starting system: Equipped with an easy-start system, allowing for quick engine ignition with minimal effort.

Maintenance and Replacement Parts

Proper upkeep and timely component replacements are essential for ensuring the longevity and efficient operation of your outdoor equipment. Regular inspection and servicing of key elements help in preventing breakdowns and maximizing performance. Identifying the right replacements for worn-out components is crucial for maintaining smooth functionality.

- Engine and Transmission: Check for fluid levels and signs of wear regularly.

- Belts and Cables: Ensure all belts are tight and free from cracks or damage.

- Blades and Cutting Mechanism: Replace dull or chipped blades to maintain cutting efficiency.

- Air Filter: Clean or replace the air filter to ensure optimal airflow and engine performance.

- Wheels and Tires: Inspect for wear and proper inflation to avoid uneven operation.

To avoid downtime, always use high-quality components that are compatible with your equipment model. Regularly consult the maintenance manual for guidance on when and how to replace specific parts to prevent costly repairs in the future.

Transmission and Drive Mechanism

The transmission system plays a crucial role in transferring power from the engine to the wheels, enabling efficient movement of the machine. This complex mechanism ensures that the vehicle operates smoothly, providing the necessary force for different speeds and tasks. The drive system, working in tandem with the transmission, ensures that the motion is delivered consistently, regardless of terrain or load conditions.

Key Components

The key components of the transmission and drive system include belts, pulleys, gears, and shafts. Each of these parts is essential in managing the flow of power and ensuring the proper function of the machine. Regular maintenance of these components is vital to prevent wear and tear, which could lead to system failure.

System Overview

The drive system typically uses a combination of mechanical and hydraulic components to achieve efficient power distribution. Belts and pulleys work together to adjust speed, while gears control the force transmitted to the wheels. The system is designed to adapt to different operational conditions, from slow and steady to fast and powerful performance.

| Component | Function |

|---|---|

| Transmission Belt | Transmits power from the engine to the drive system |

| Pulley | Adjusts the speed and direction of power flow |

| Gearbox | Regulates the speed and torque delivered to the wheels |

| Drive Shaft | Transfers power from the gearbox to the wheels |

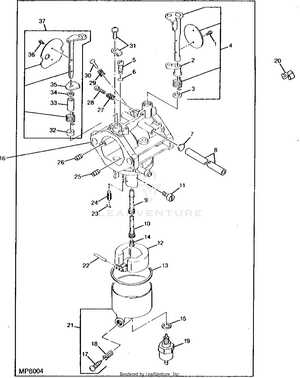

Fuel System and Tank Details

The fuel system plays a critical role in providing the necessary power for the engine. Proper functionality ensures smooth operation and efficient fuel consumption. This section covers the key components that make up the fuel delivery system, including the fuel tank, lines, and associated mechanisms that maintain flow and pressure. A reliable fuel system guarantees that the engine runs effectively, avoiding power loss or breakdowns.

Fuel Tank Configuration

The fuel tank is designed to store fuel securely, preventing leaks and ensuring a constant supply to the engine. It is typically made from durable materials that resist corrosion and damage. Inside the tank, a fuel filter may be included to prevent contaminants from entering the fuel lines, ensuring that only clean fuel reaches the engine.

Fuel Delivery Mechanism

Fuel is transported from the tank to the engine through a network of fuel lines and filters. The fuel pump maintains proper pressure, allowing the engine to receive the required amount of fuel under varying conditions. Maintaining the fuel system involves regular checks for clogs, leaks, or damage to the fuel lines. Proper maintenance of this system ensures optimal engine performance and longevity.

Electrical Components in the F525

Understanding the electrical system in garden equipment is crucial for its performance and longevity. The system consists of various components that work together to provide the necessary power and control functions. Each part plays a specific role in the efficient operation of the machine, ensuring that it runs smoothly and reliably during usage. Below is a breakdown of the key electrical components found in these machines.

Key Electrical Components

- Battery: Powers the system and ensures proper ignition and electrical functions.

- Ignition Switch: Allows the operator to start and stop the engine by controlling the electrical flow.

- Wiring Harness: Connects all electrical components, enabling communication between them.

- Solenoid: Engages the starter motor to initiate engine operation when activated by the ignition switch.

- Fuses: Protect the electrical system from overloads and short circuits by breaking the circuit in case of a fault.

Maintaining Electrical Integrity

Regular maintenance of the electrical system is essential to prevent malfunctions. Checking the battery for proper charge, inspecting wires for wear, and replacing blown fuses are simple tasks that can prevent costly repairs. Ensuring that all electrical connections are clean and secure is key to maintaining the overall function of the equipment.

Chassis and Frame Construction

The chassis and frame are crucial components of any vehicle or machine designed for heavy-duty tasks. They provide the structural integrity and durability necessary to withstand various mechanical stresses. The design and materials used in the construction of these elements directly influence the overall performance, stability, and longevity of the machine. A robust chassis ensures the efficient transfer of power, while a well-engineered frame supports the overall weight and balance, enhancing maneuverability and ease of use.

Material Selection

Choosing the right materials for the frame and chassis is essential for optimizing strength and reducing weight. Steel alloys are often favored for their resilience and ability to resist deformation under pressure. In some cases, lightweight metals like aluminum may be incorporated to enhance the machine’s maneuverability without compromising durability. The combination of materials is strategically chosen based on the intended workload and environmental conditions the machine will operate in.

Structural Design

Structural design plays a key role in how well the chassis and frame distribute forces during operation. Engineers focus on creating a layout that balances strength with flexibility, ensuring that the machine can handle impacts and rough terrain without losing performance. The frame’s geometry, including cross members and reinforcements, is carefully planned to provide maximum support without unnecessary weight. The design process takes into account vibration dampening, load-bearing capacities, and ease of maintenance, contributing to the overall longevity of the machine.

Wheel and Tire Setup

The setup of the wheels and tires is crucial for ensuring optimal performance and stability during operation. Proper selection and installation contribute to better maneuverability, comfort, and safety. Understanding the correct specifications for size, inflation, and alignment is essential to maximize the effectiveness of the equipment.

Choosing the Right Tires involves considering the terrain, load capacity, and traction requirements. Tires with suitable tread patterns and durability are vital for handling various ground conditions, from smooth lawns to uneven surfaces.

Wheel Alignment is another key aspect, ensuring that all wheels are properly aligned to avoid uneven wear and enhance stability. Proper alignment can also prevent unnecessary strain on the drive system and improve overall efficiency.

Regular Maintenance of tires and wheels is essential for long-term reliability. Checking for wear, maintaining appropriate tire pressure, and replacing damaged components help to extend the lifespan of the equipment and ensure it runs smoothly.

Attachments for John Deere Mower

Various accessories can enhance the functionality and versatility of lawn equipment. These additions allow for a broader range of tasks, making it easier to adapt to different conditions and needs. Whether it’s for clearing debris, maintaining your lawn, or even handling snow, the right attachments can significantly improve efficiency and performance.

Front-Mounted Tools are designed to attach to the front of the machine, offering precise control over operations. These include tools like blades, snow plows, and brush cutters, which are ideal for specific tasks such as clearing roads or cutting through thick underbrush.

Rear-Mounted Attachments provide additional power for larger tasks, like trailers for hauling materials or tillers for soil preparation. They are designed to be easy to attach and detach, giving users the flexibility to switch between different functions with minimal effort.

Additionally, mid-mount implements allow for tasks that require close precision, such as aerating the soil or adding fertilizer to the lawn. These attachments are often equipped with adjustable settings to cater to different types of terrains.

Overall, a variety of implements can be selected to match specific needs, enhancing the capabilities of your equipment and ensuring long-term productivity in any outdoor task.

Common Repair Issues and Solutions

Repairing small engine machines often involves addressing a few recurring problems that affect their performance. Recognizing these issues early can help in taking preventive measures and ensure the longevity of the equipment. Below, you’ll find some of the most common mechanical failures and effective solutions to keep your machine running smoothly.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine Not Starting | Dirty spark plug, low fuel, clogged carburetor | Clean or replace the spark plug, check and refill the fuel, clean or replace the carburetor |

| Uneven Cutting | Worn-out blades, unbalanced deck, low tire pressure | Sharpen or replace blades, adjust deck height, inflate tires to recommended pressure |

| Overheating | Blocked air vents, old engine oil, dirty cooling fins | Clean air vents, change engine oil, remove debris from cooling fins |

| Vibration During Operation | Loose or damaged components, unbalanced blades | Tighten bolts, inspect for damage, balance or replace blades |

| Poor Traction | Worn-out tires, low tire pressure, damaged drive belt | Replace tires, inflate to proper pressure, inspect and replace drive belt if needed |