Exploring the John Deere 2320 Parts Diagram for Ultimate Maintenance

In the realm of agricultural equipment, having a clear overview of each machine’s layout is essential for maintenance and repairs. Such layouts serve as invaluable resources for operators and technicians alike, providing insights into the intricate assembly of various elements. A well-structured representation helps ensure that every component functions harmoniously, contributing to the overall efficiency of the machinery.

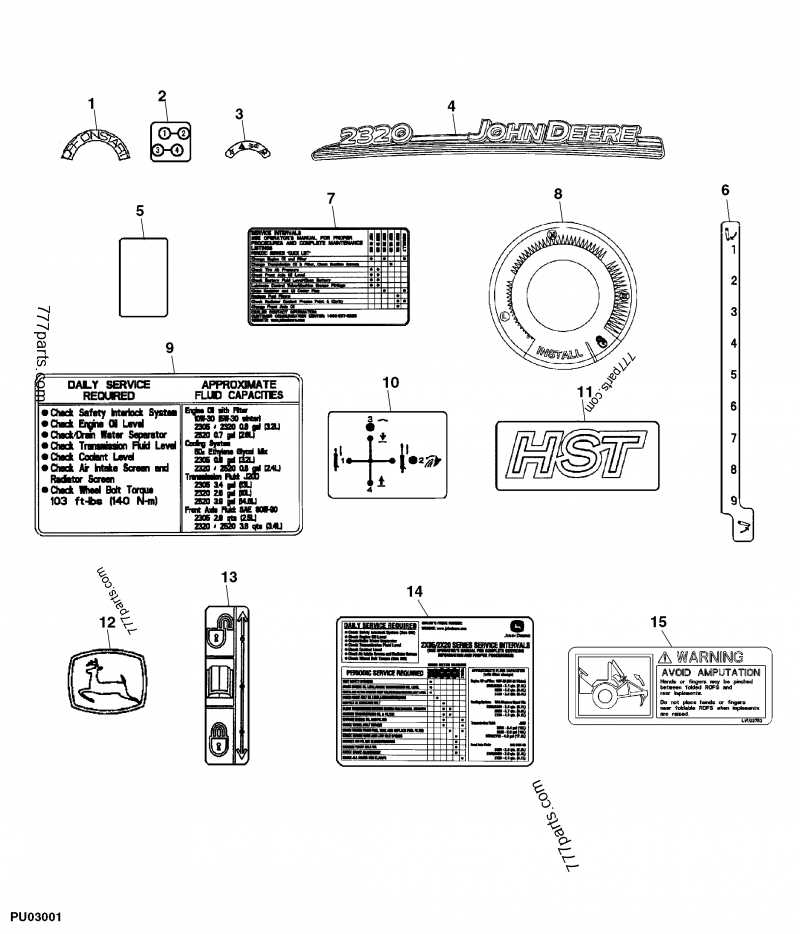

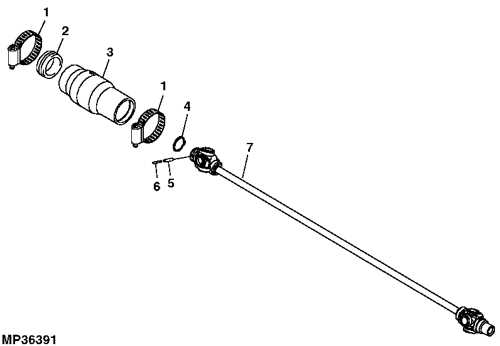

Detailed illustrations offer a visual guide to the organization of vital components, aiding in both identification and troubleshooting. By understanding how each part interrelates, users can make informed decisions regarding upkeep and replacement. This knowledge is crucial for maximizing productivity and minimizing downtime in any farming operation.

Moreover, these visuals facilitate a deeper comprehension of the equipment’s design, allowing for more effective handling during repairs. When operators are equipped with accurate information about the layout, they can approach issues with confidence and precision. Ultimately, such resources not only enhance operational efficiency but also promote a proactive maintenance culture among users.

Understanding John Deere 2320 Components

Grasping the intricacies of machinery requires an appreciation for its individual elements. Each component plays a crucial role in the overall functionality and efficiency of the equipment. A thorough understanding of these parts not only enhances maintenance but also improves performance and longevity.

Key Elements

- Engine: The powerhouse that drives the entire system, responsible for converting fuel into mechanical energy.

- Transmission: This component facilitates the transfer of power from the engine to the wheels, enabling movement and speed regulation.

- Hydraulic System: Essential for operating attachments and lifting mechanisms, this system harnesses fluid power to perform various tasks.

- Chassis: The structural framework that supports all other components and ensures stability during operation.

Maintenance Tips

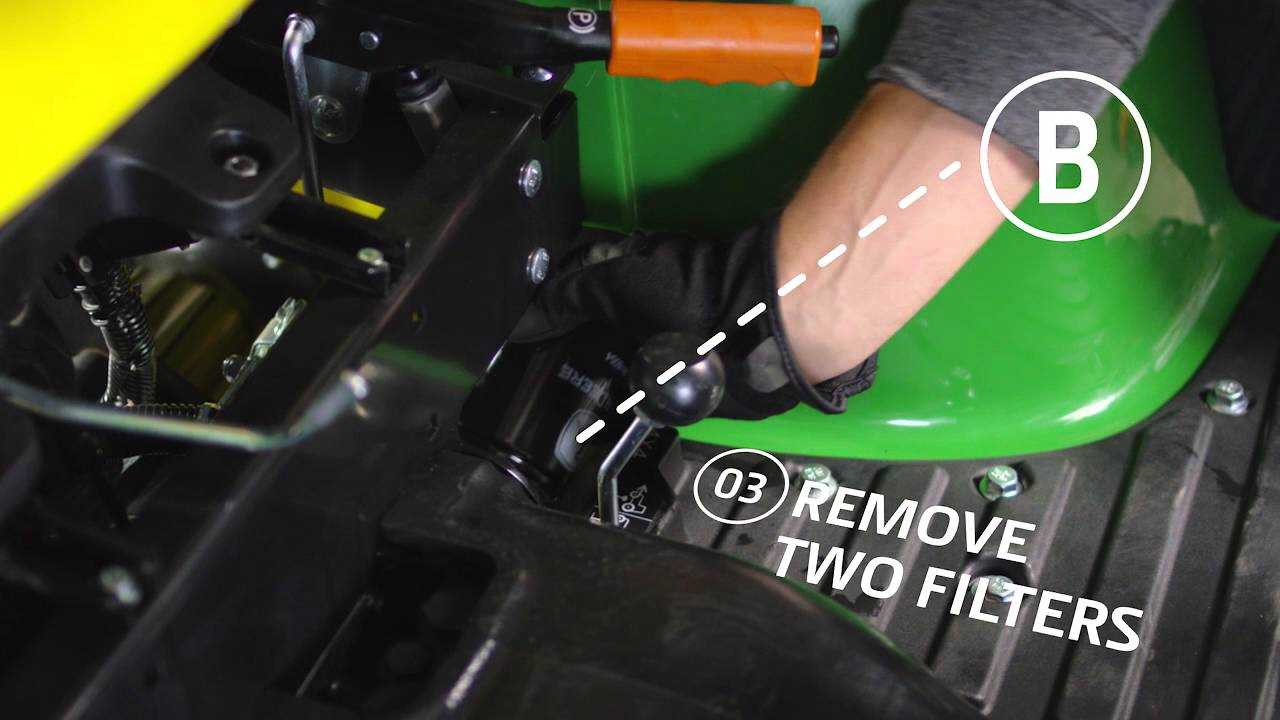

- Regularly inspect the engine and replace filters as needed to ensure optimal performance.

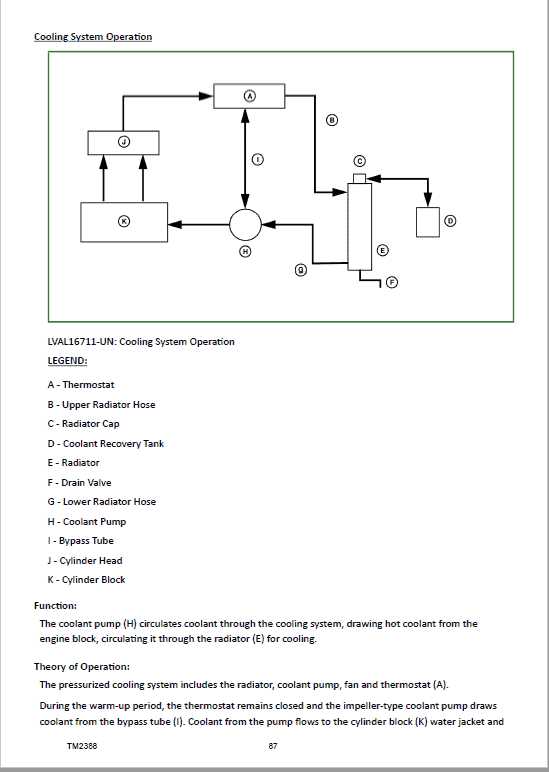

- Check fluid levels in the hydraulic system to prevent overheating and mechanical failure.

- Keep the transmission system clean and free of debris to maintain smooth operation.

- Monitor the condition of the chassis and other structural components for signs of wear and tear.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians, offering clarity and facilitating efficient troubleshooting. They break down complex systems into manageable sections, ensuring that every element is easily identifiable.

These visual aids enhance communication between team members and streamline the repair process. By providing detailed insights, they help prevent errors and ensure that replacements are accurately executed. Moreover, they contribute to improved training for new personnel, making it easier to grasp intricate mechanical systems.

Ultimately, having access to clear visual guides can significantly reduce downtime and enhance overall operational efficiency. In the world of machinery maintenance, such resources are invaluable for ensuring that every component functions optimally.

Key Features of the John Deere 2320

This compact utility machine is designed to deliver exceptional performance and versatility for various tasks. It combines power and efficiency, making it an ideal choice for both professional landscapers and homeowners alike. The innovative engineering provides users with reliability and ease of operation, ensuring that every project is completed smoothly.

Performance and Power

The engine is engineered to provide robust power while maintaining fuel efficiency. Its advanced design allows for smooth operation across a range of conditions, whether mowing, tilling, or hauling materials. This capability ensures that users can tackle demanding jobs with confidence.

Versatile Attachments

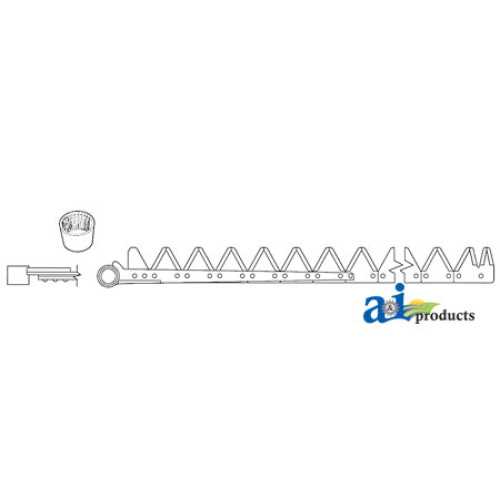

This machine supports a wide array of implements and accessories, enhancing its functionality. From loaders to tillers, the ability to switch between tools effortlessly allows for a more productive workflow. This adaptability makes it suitable for various applications, from agricultural tasks to landscaping projects.

Commonly Replaced Parts Explained

In the realm of machinery maintenance, certain components tend to wear out more frequently due to their vital roles in functionality. Understanding these elements can significantly enhance the upkeep process and prolong the lifespan of equipment. This section delves into the key components that often require attention, ensuring optimal performance and reliability.

Key Components

- Filters: Regularly changing filters is essential to maintain fluid cleanliness and prevent engine damage.

- Batteries: Over time, batteries can lose their ability to hold a charge, necessitating replacement to ensure smooth operation.

- Tires: Wear and tear on tires can impact traction and stability, making timely replacements crucial.

Additional Considerations

- Check belts and hoses for signs of cracking or fraying, as these can lead to larger issues if neglected.

- Monitor hydraulic fluid levels and consider changing hoses to maintain system efficiency.

- Regularly inspect the electrical system to identify any faulty wiring or connections that may require servicing.

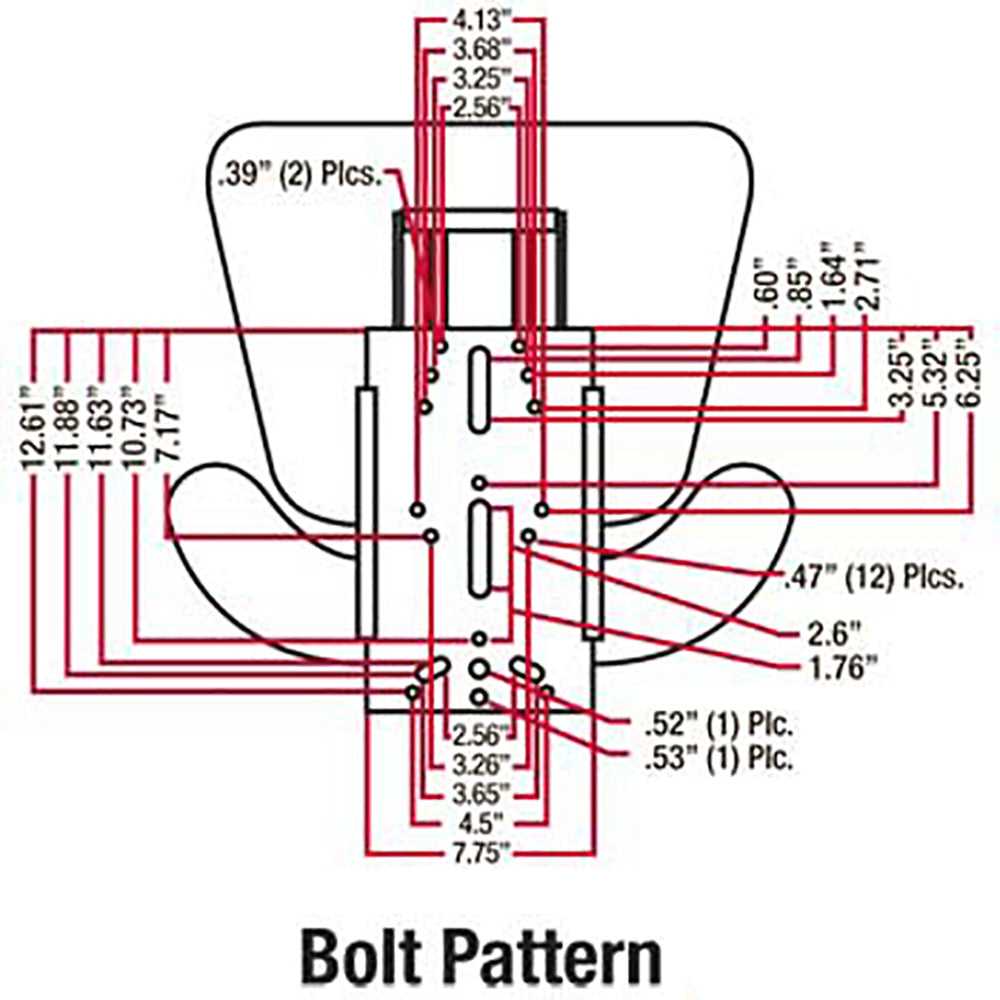

How to Interpret Parts Diagrams

Understanding visual representations of mechanical components is crucial for effective maintenance and repair. These illustrations provide a comprehensive overview of each element, allowing users to identify, locate, and understand the function of various parts within a system.

Start with the Legend: Every schematic usually includes a legend or key that explains the symbols and notations used. Familiarizing yourself with these indicators can significantly enhance your ability to navigate the illustration efficiently.

Break it Down: Focus on one section at a time. Large visuals can be overwhelming; by isolating specific areas, you can better grasp the relationships between components and their respective roles.

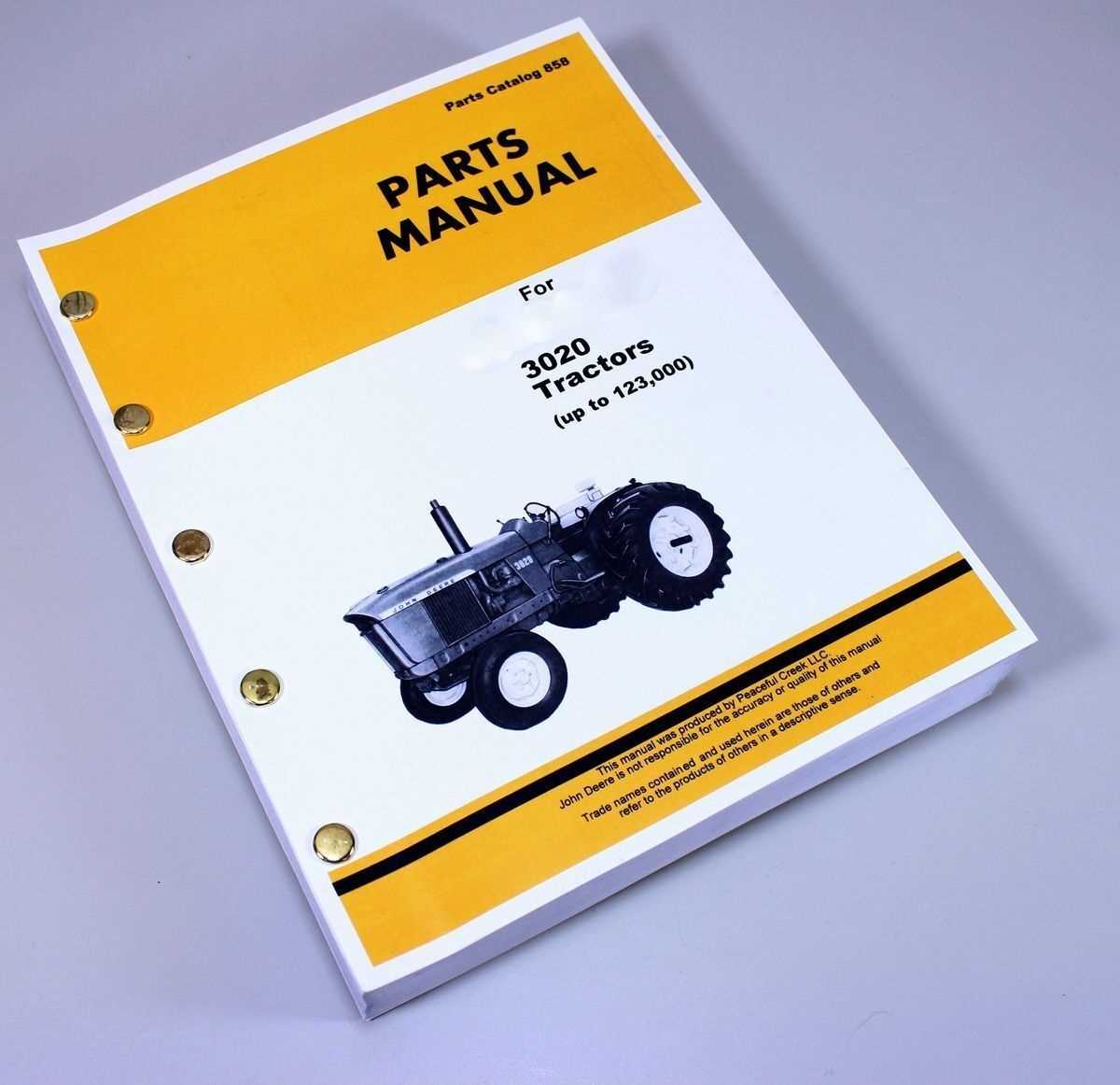

Refer to the Manual: Complement your understanding by consulting the accompanying documentation. Manuals often provide detailed descriptions that can clarify the purpose of individual elements shown in the visual guide.

Practice Makes Perfect: The more you engage with these representations, the easier it will become to interpret them. Regularly studying various visuals will enhance your familiarity with the layout and symbols commonly used.

By mastering these techniques, you’ll be well-equipped to utilize visual references for efficient maintenance and repair tasks.

Finding Genuine John Deere Parts

Ensuring the longevity and performance of your equipment requires using authentic components. Sourcing these essential items not only enhances efficiency but also safeguards your investment. Recognizing the value of genuine replacements is crucial for optimal operation and maintenance.

When searching for original components, consider the following strategies:

| Method | Description |

|---|---|

| Authorized Dealers | Visit certified retailers to access a comprehensive selection of authentic components backed by manufacturer warranties. |

| Official Websites | Explore the manufacturer’s official site for catalogs and options tailored to your equipment’s specifications. |

| Online Marketplaces | Utilize reputable e-commerce platforms that specialize in original components, ensuring authenticity through customer reviews and ratings. |

| Community Forums | Engage with fellow equipment owners in online communities to gather recommendations and insights on sourcing genuine replacements. |

By following these approaches, you can confidently acquire the components needed to maintain and enhance your machinery’s performance, ensuring reliable and efficient operation for years to come.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires consistent upkeep and attention to detail. By following a few essential maintenance practices, you can optimize performance and prevent costly repairs.

Regular Inspections

Routine checks are vital for identifying wear and tear before they escalate into serious issues. Consider the following:

- Inspect fluid levels regularly, including oil, coolant, and hydraulic fluids.

- Check for any leaks or unusual noises during operation.

- Examine belts and hoses for signs of deterioration.

Scheduled Maintenance

Adhering to a maintenance schedule can significantly enhance equipment reliability. Keep these practices in mind:

- Change oil and filters according to manufacturer recommendations.

- Clean or replace air filters to ensure proper airflow.

- Sharpen and maintain cutting tools for efficiency.

By implementing these maintenance tips, you can maximize the performance and durability of your equipment, ensuring it serves you well for years to come.

DIY Repairs: Tools Needed

Undertaking repairs on machinery can be a rewarding experience, offering both cost savings and a sense of accomplishment. To ensure success in your endeavors, it’s essential to have the right tools at your disposal. This section outlines the necessary equipment that will facilitate effective maintenance and repair tasks.

Essential Tools

When preparing for DIY repairs, consider investing in the following essential tools:

| Tool | Description |

|---|---|

| Wrenches | Used for tightening and loosening nuts and bolts. |

| Screwdrivers | Essential for assembling and disassembling various components. |

| Socket Set | Allows for efficient fastening of fasteners in tight spaces. |

| Pliers | Great for gripping, twisting, and cutting wire. |

| Jack Stands | Provide stability and safety when working underneath equipment. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

Safety Equipment

In addition to the primary tools, safety equipment is crucial to protect yourself during repairs:

| Equipment | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and harmful substances. |

| Gloves | Prevents cuts and improves grip while handling parts. |

| Steel-Toed Boots | Offers foot protection from heavy objects and equipment. |

| Ear Protection | Reduces the risk of hearing damage in noisy environments. |

Identifying Wear and Tear Issues

Understanding the signs of deterioration in machinery is crucial for maintaining optimal performance and extending lifespan. Regular inspections can help detect subtle changes that may indicate underlying problems, allowing for timely interventions.

Common Signs of Deterioration

Components may exhibit several indicators of wear, such as unusual noises, vibrations, or reduced efficiency. Visual inspections can reveal cracks, rust, or unusual wear patterns. Checking fluid levels and quality is also essential, as contaminated fluids can significantly impact functionality.

Importance of Timely Maintenance

Addressing wear and tear promptly can prevent more severe issues from developing. Implementing a regular maintenance schedule and using diagnostic tools will aid in early detection. Keeping an eye on performance metrics ensures that any decline can be managed before it leads to costly repairs.

Aftermarket vs. Original Parts

When it comes to maintaining machinery, the choice between aftermarket and original components is crucial. Each option presents unique advantages and disadvantages that can significantly impact performance and cost-effectiveness. Understanding these differences helps in making informed decisions that best suit individual needs.

Advantages of Original Components

Original components are typically designed specifically for the machinery, ensuring a perfect fit and optimal performance. Durability is often guaranteed, as these parts undergo rigorous testing. Additionally, using genuine parts can maintain the warranty and resale value of the equipment.

Benefits of Aftermarket Options

Aftermarket options often come at a lower cost, making them appealing for budget-conscious users. Many manufacturers produce high-quality alternatives that may even enhance performance. Flexibility in sourcing these components allows for greater accessibility, especially in remote areas.

Resources for Parts Diagram Access

Finding the right resources for visual breakdowns of equipment components is crucial for maintenance and repairs. Accessing these visuals can streamline your workflow and enhance your understanding of various machinery systems.

Online Platforms

Numerous websites offer detailed schematics and illustrations. Manufacturer sites often provide official resources, while third-party platforms can supplement with user-generated content and forums for shared insights.

Printed Manuals

Physical handbooks are invaluable for hands-on reference. These manuals typically include comprehensive visuals and descriptions, allowing users to delve into specifics whenever necessary.

Safety Precautions During Repairs

Ensuring safety during maintenance and repairs is crucial to prevent accidents and injuries. Adopting proper precautions not only protects the individual performing the work but also safeguards the machinery and surrounding environment. Familiarity with safety protocols can greatly enhance the overall efficiency of repair tasks.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential when undertaking any repair activities. This equipment serves as the first line of defense against potential hazards. The following table outlines the recommended PPE for repair work:

| Type of Equipment | Purpose |

|---|---|

| Safety Glasses | Protect eyes from debris and chemicals. |

| Gloves | Provide hand protection from sharp edges and chemicals. |

| Steel-Toed Boots | Prevent foot injuries from heavy objects. |

| Hearing Protection | Protect against loud noises that can cause hearing damage. |

| Dust Mask or Respirator | Filter out harmful dust and fumes. |

Workspace Safety

In addition to wearing the right protective gear, maintaining a safe workspace is vital. An organized and clutter-free area reduces the risk of accidents. Ensure that tools are stored properly and that spills are cleaned up immediately. Adequate lighting is also necessary to enhance visibility, allowing for safer and more precise work.