Comprehensive Guide to Husqvarna 225L Parts Diagram

When it comes to maintaining outdoor machinery, having a clear grasp of its individual elements is essential. Each component plays a crucial role in the overall functionality, ensuring that your device operates efficiently and effectively. Familiarity with these parts allows for informed decisions during repairs and upgrades.

Visualizing the Structure can greatly enhance your comprehension of how everything fits together. A well-organized representation of these components aids in identifying specific areas that may require attention, making the maintenance process more streamlined and manageable.

Moreover, knowing the arrangement of the various elements can lead to improved performance and longevity of your machinery. By exploring the layout, users can delve into troubleshooting and understanding the ultimate intricacies of their equipment, ultimately leading to a more satisfying and productive experience.

Understanding the Husqvarna 225L Parts Diagram

Grasping the assembly of a trimmer can significantly enhance your maintenance and repair capabilities. Familiarizing yourself with the components and their relationships helps in troubleshooting issues effectively. A visual representation of these elements serves as a valuable reference when identifying parts that may require attention or replacement.

Key Components Overview

Each model comprises several essential elements, each playing a unique role in the overall functionality. Here are the primary components you should be aware of:

- Engine: The powerhouse responsible for providing the necessary energy.

- Cutting Head: The part that houses the line or blade, crucial for trimming tasks.

- Shaft: Connects the engine to the cutting head, facilitating power transfer.

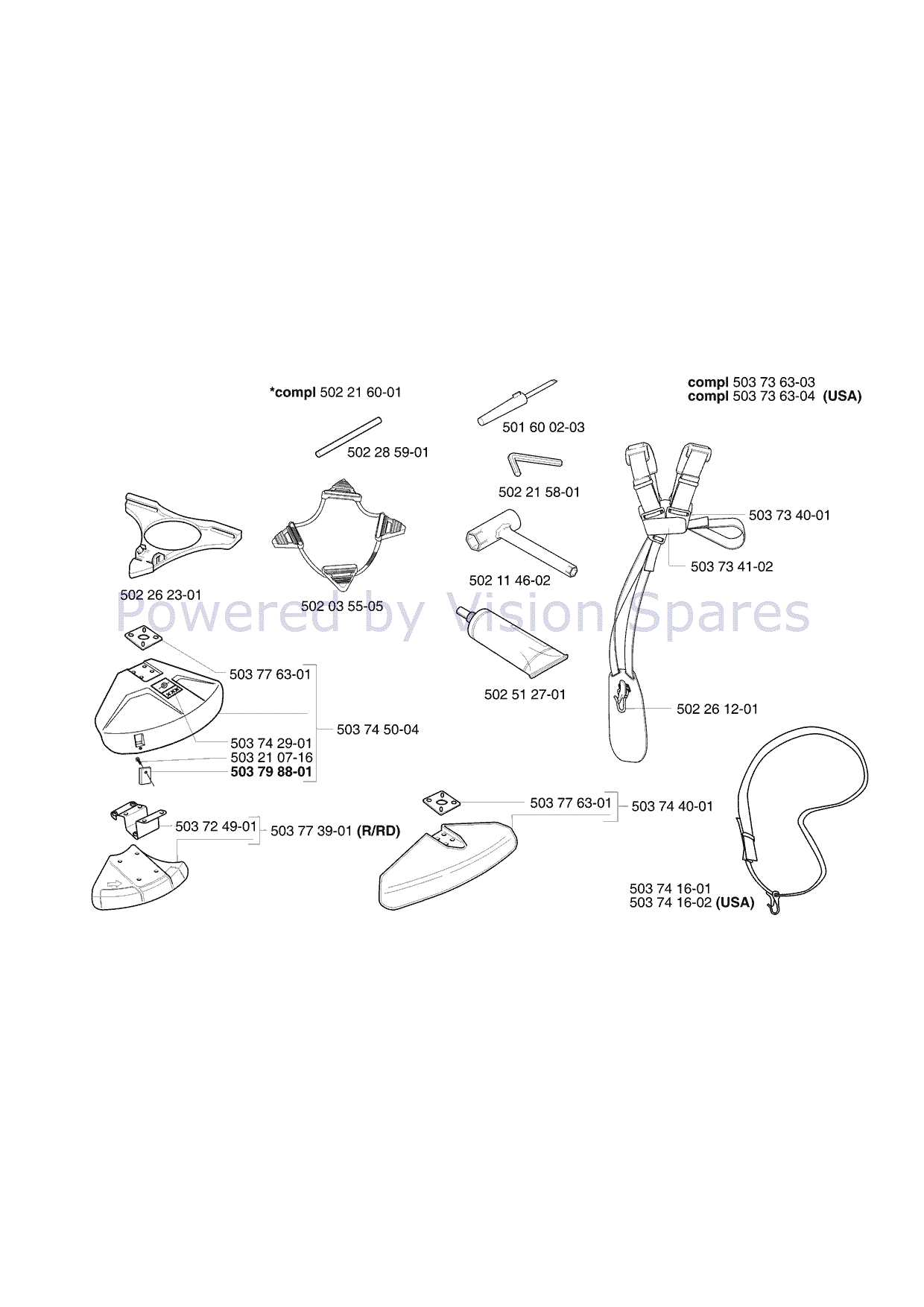

- Handle: Provides control and maneuverability during operation.

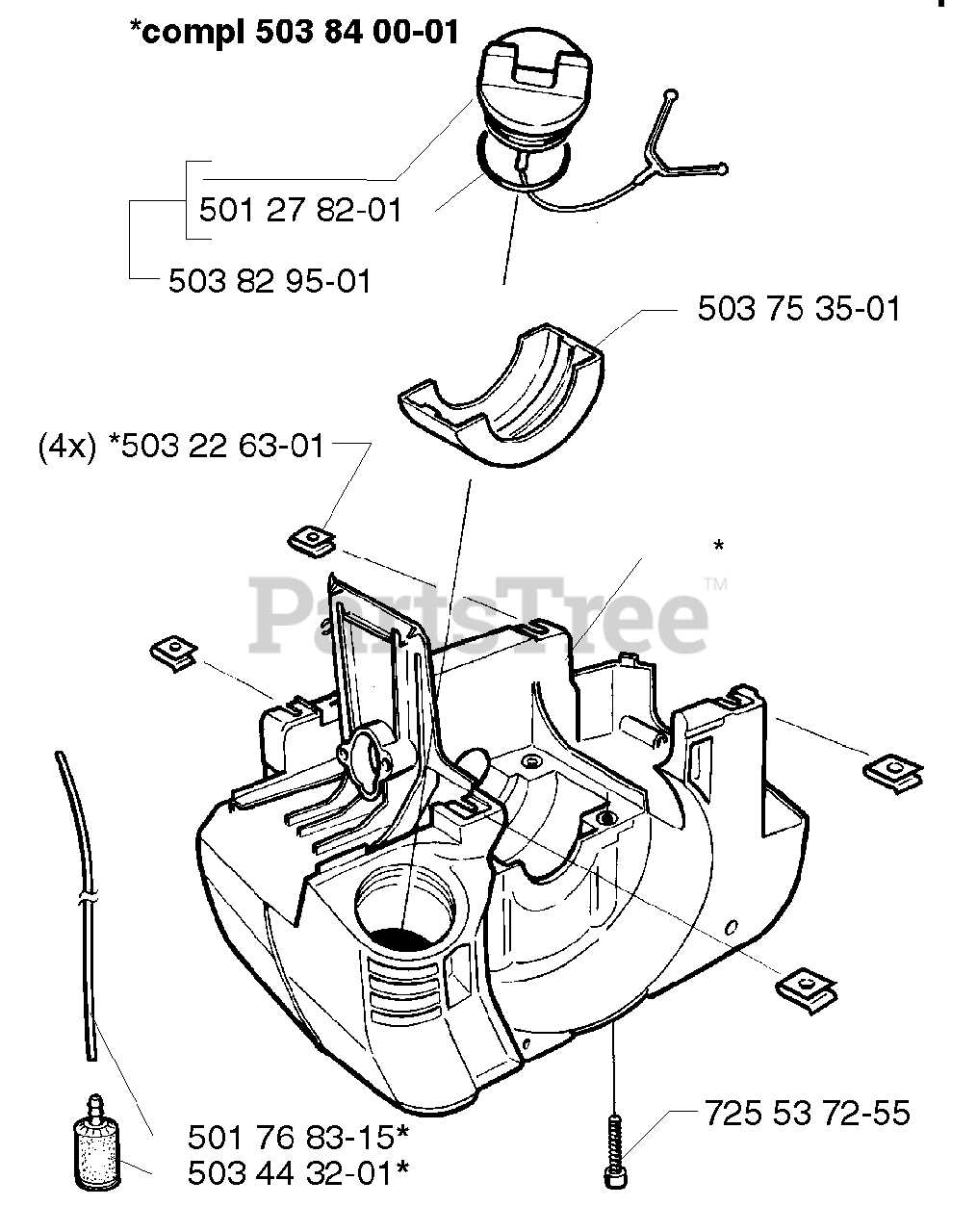

- Fuel Tank: Stores the mixture necessary for the engine to function efficiently.

Benefits of Understanding Component Layout

Being knowledgeable about the layout and functionality of each part offers numerous advantages:

- Enhanced Troubleshooting: Quickly identify issues based on the visual layout.

- Informed Maintenance: Schedule repairs and replacements proactively.

- Improved Efficiency: Ensure optimal performance by understanding each element’s role.

- Cost-Effective Repairs: Reduce reliance on professional services by handling minor repairs yourself.

With a clear understanding of the components, you’ll be better equipped to maintain your equipment and ensure its longevity.

Key Components of the 225L Model

This section explores the essential elements of a popular outdoor power tool, highlighting their significance in ensuring optimal performance and longevity. Understanding these key components can enhance maintenance practices and improve overall functionality.

Major Elements

Several crucial parts contribute to the effective operation of this tool. Each element plays a vital role in ensuring smooth functionality, durability, and user satisfaction.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the machine, providing necessary energy for operation. |

| Fuel System | Includes the tank and delivery components that supply the engine with fuel efficiently. |

| Cutter Head | The attachment responsible for cutting, featuring different configurations based on user needs. |

| Handle Assembly | Designed for ergonomic use, offering comfort and control during operation. |

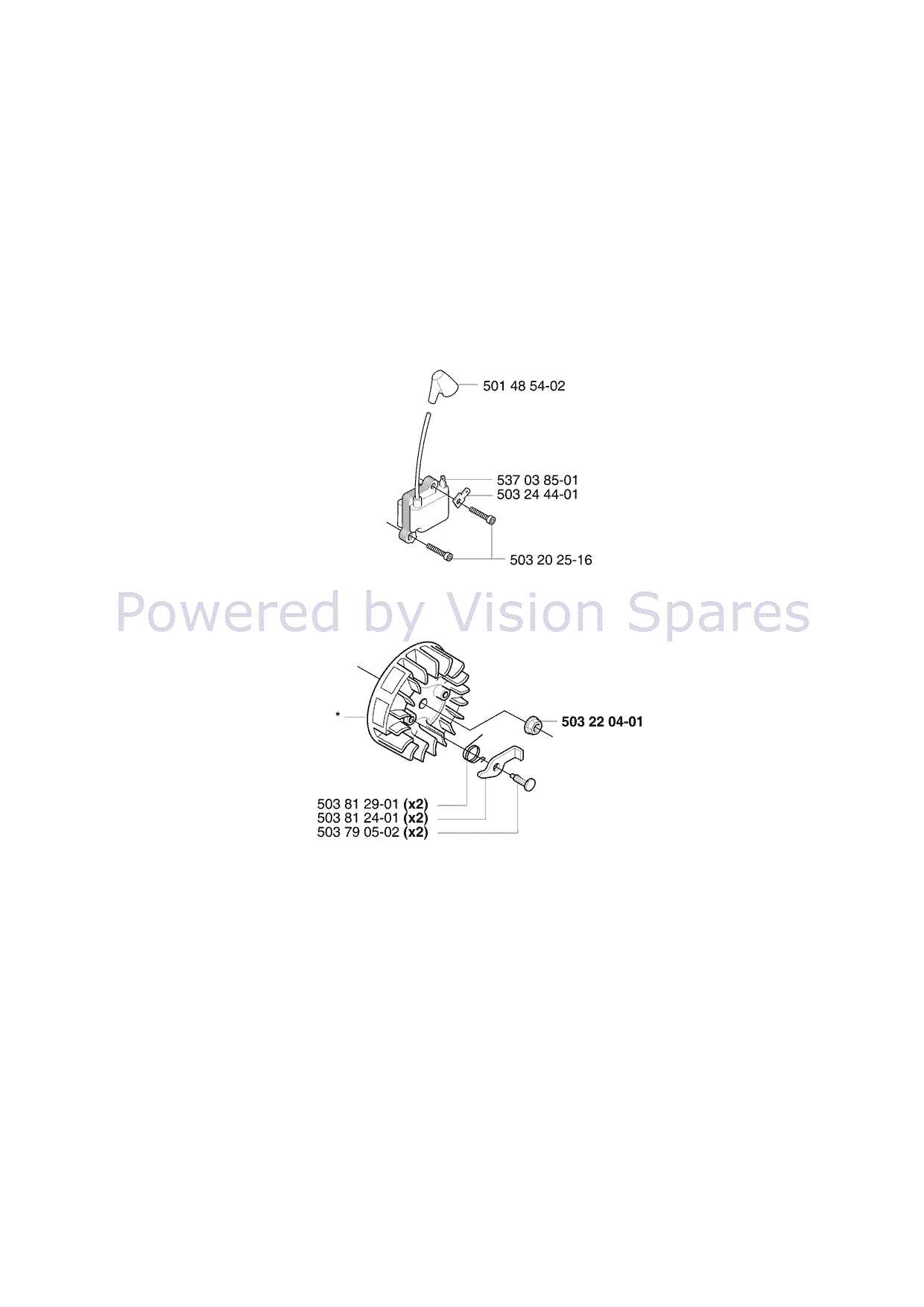

| Ignition System | Ensures reliable starting and smooth engine performance through effective spark generation. |

Maintenance and Care

Regular upkeep of these essential parts is crucial for maintaining the efficiency and longevity of the equipment. Users are encouraged to familiarize themselves with each component to facilitate proper maintenance routines.

Benefits of Knowing Parts Layout

Understanding the configuration of components in a machine is crucial for effective maintenance and repair. Familiarity with how parts are organized not only enhances efficiency but also simplifies troubleshooting and enhances overall user experience.

First and foremost, having a clear grasp of component arrangement allows users to identify issues swiftly. When problems arise, knowing where each element is located can save valuable time and effort during diagnostics.

Additionally, this knowledge aids in preventing potential damage. Recognizing the relationships between different parts helps in making informed decisions about adjustments or replacements, thus minimizing the risk of further complications.

Moreover, an understanding of layout can improve safety. Many machines require specific procedures to handle components correctly; awareness of where each part is situated can reduce the likelihood of accidents during maintenance tasks.

Lastly, being well-versed in the structure of a device can foster confidence in users. This familiarity empowers individuals to perform routine checks and repairs independently, promoting a sense of ownership and proficiency.

Common Issues with 225L Parts

When dealing with outdoor power equipment, users often encounter various challenges related to components and their functionality. Understanding these issues can enhance maintenance and improve performance.

- Wear and Tear: Regular use can lead to deterioration of essential components, affecting overall efficiency.

- Fuel System Problems: Clogs in fuel lines or issues with the carburetor can cause engine performance to suffer.

- Starting Difficulties: Problems with ignition systems or batteries can prevent the device from starting reliably.

- Overheating: Insufficient cooling or airflow can lead to excessive heat, potentially damaging the engine.

- Vibration and Noise: Loose fittings or worn parts can result in increased vibration and unwanted noise during operation.

Regular inspections and proactive replacements can help mitigate these issues, ensuring a longer lifespan and optimal performance of your equipment.

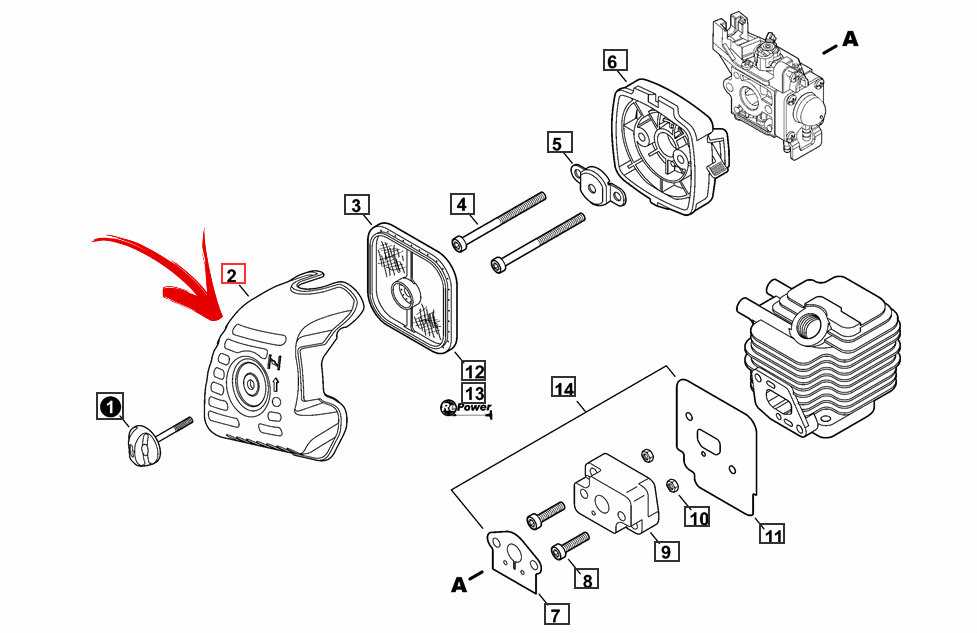

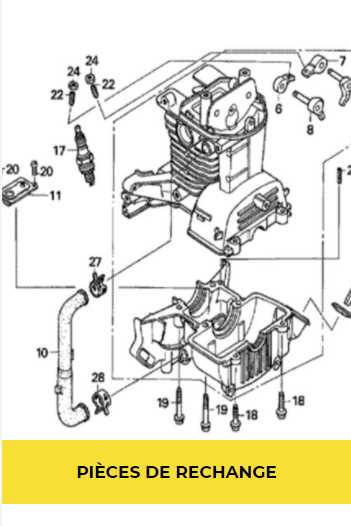

How to Use the Parts Diagram

Understanding a schematic can greatly enhance your ability to maintain and repair equipment effectively. It serves as a visual guide, helping you identify each component and its relationship to others within the system. Here’s how to navigate this essential resource.

- Familiarize Yourself with the Layout:

- Observe the overall structure of the illustration.

- Note the organization of parts, often categorized by function or location.

- Identify Components:

- Locate the specific element you need information on.

- Refer to accompanying labels or numbers that correspond to parts lists.

- Cross-Reference with Documentation:

- Use the visual aid in conjunction with manuals or guides.

- Ensure you understand the specifications and assembly requirements for each part.

- Plan Your Maintenance or Repair:

- Use the information gathered to create a checklist of needed items.

- Determine the tools required for the task based on the components involved.

- Consult Experts if Needed:

- If unsure about any aspect, seek advice from professionals or forums.

- Sharing insights can provide additional clarity on complex systems.

By effectively utilizing this visual resource, you can simplify your maintenance tasks and ensure your equipment remains in optimal condition.

Where to Find Replacement Parts

When seeking components for your outdoor equipment, various reliable sources are available. Understanding where to look can save time and ensure you receive quality replacements.

Online Retailers: Numerous websites specialize in outdoor machinery accessories, offering a wide selection. Websites like e-commerce giants often provide detailed catalogs, allowing users to search for specific items with ease.

Local Dealerships: Authorized dealers often carry genuine items tailored for specific models. Visiting a dealership can also provide the added benefit of expert advice on the right replacements.

Second-hand Markets: Auctions and classified ads can be treasure troves for those seeking budget-friendly options. However, always verify the condition and compatibility before purchasing.

Manufacturer’s Website: The official site of your equipment’s maker usually has a dedicated section for obtaining replacements, ensuring authenticity and compatibility.

By exploring these avenues, you can confidently find the necessary components to keep your machinery in optimal condition.

Tools Needed for Repairs

When undertaking maintenance or fixing equipment, having the right instruments is crucial for efficiency and effectiveness. Proper tools not only simplify the process but also enhance safety and precision during the repair tasks. This section outlines the essential equipment that will facilitate smooth and successful repairs.

Essential Hand Tools

Basic hand tools such as screwdrivers, wrenches, and pliers are indispensable for any repair project. These tools allow for easy disassembly and reassembly of components. A socket set can also be invaluable for dealing with various fasteners, ensuring that you can tackle different tasks with ease.

Power Tools and Safety Gear

In addition to hand tools, power tools like drills and impact wrenches can significantly speed up the repair process. However, safety should always be a priority. Using gloves, goggles, and ear protection will help prevent accidents while working, ensuring a safer repair environment.

Maintenance Tips for Longevity

Proper care is essential for extending the lifespan of your equipment. Regular maintenance not only ensures optimal performance but also helps prevent costly repairs down the line. Here are some effective strategies to keep your machine running smoothly:

- Perform regular cleaning to remove debris and dirt.

- Check and replace air filters as needed to maintain airflow.

- Inspect the fuel system regularly to avoid clogs and leaks.

- Sharpen blades frequently for efficient cutting.

- Keep all moving parts lubricated to reduce friction.

- Store your equipment in a dry place to prevent rust and corrosion.

By following these guidelines, you can delve into effective maintenance practices that will ensure your equipment remains reliable and efficient for years to come.

Identifying Original vs. Aftermarket Parts

When maintaining outdoor equipment, distinguishing between genuine components and alternatives is crucial for performance and longevity. Understanding the differences can help users make informed decisions and ensure the reliability of their machinery.

Here are some key factors to consider when identifying original and aftermarket components:

- Quality and Durability: Original components are often made from higher-quality materials, ensuring better performance and longevity compared to their aftermarket counterparts.

- Compatibility: Genuine parts are specifically designed for certain models, providing a perfect fit, while aftermarket options may not always align correctly.

- Price: While original components tend to be more expensive, the initial cost can be offset by reduced maintenance and repair expenses in the long run.

- Brand Reputation: Researching the manufacturer’s reputation can provide insight into the reliability and performance of both original and alternative options.

- Warranty and Support: Original components usually come with warranties, ensuring support in case of issues, whereas aftermarket options may lack such guarantees.

By considering these factors, users can effectively evaluate their choices and select components that best suit their needs, ultimately leading to better equipment performance and satisfaction.

Ordering Parts: Best Practices

When seeking replacement components for your equipment, following effective strategies can ensure a smooth purchasing experience. Understanding the nuances of sourcing these items can help in making informed decisions, saving both time and resources.

Consider the following guidelines to streamline your ordering process:

| Practice | Description |

|---|---|

| Research | Gather information about the specific components required, including model numbers and specifications. |

| Compare Suppliers | Evaluate different vendors for quality, pricing, and delivery times to ensure the best deal. |

| Verify Compatibility | Ensure that the selected items are compatible with your equipment to avoid unnecessary returns. |

| Check Reviews | Look for customer feedback to gauge the reliability of the supplier and the quality of the products. |

| Order in Advance | Place orders ahead of time to account for potential delays in shipping or availability. |

Assembly Instructions from the Diagram

Understanding how to assemble components effectively is crucial for ensuring optimal performance of your equipment. This section provides clear guidance derived from the visual representation of the assembly, highlighting the necessary steps to follow for a seamless setup.

Step 1: Begin by gathering all required components. Ensure that you have the necessary tools at hand for an efficient assembly process.

Step 2: Refer to the provided visual reference to identify each part’s position. This will help you understand how components fit together and the sequence in which they should be assembled.

Step 3: Start with the base unit, securing it firmly. Proceed to attach the various elements as indicated, ensuring each connection is snug and aligned according to the visual guide.

Step 4: After assembling the main structure, double-check all connections. Make any adjustments as needed to ensure stability and proper function.

Step 5: Finally, perform a test run to confirm that everything operates smoothly. If any issues arise, refer back to the visual representation for troubleshooting tips.

By following these steps meticulously, you can achieve a successful assembly that enhances the efficiency and longevity of your equipment.

Cost Analysis of Replacement Parts

Understanding the financial implications of component replacements is crucial for maintaining efficiency and performance. Evaluating the costs associated with various components can provide insights into budget allocation and long-term savings. By analyzing pricing trends and the impact of quality on durability, one can make informed decisions when sourcing replacements.

When assessing expenses, consider both original and aftermarket options. Original components often promise better compatibility and longevity, but they come at a higher price. In contrast, aftermarket alternatives may be more affordable but could compromise performance or lifespan. Conducting a thorough comparison can help in identifying the ultimate balance between cost and quality.

Additionally, it’s important to factor in labor costs if professional installation is required. DIY approaches can save money, yet they demand a certain level of expertise. Overall, a comprehensive analysis can lead to smarter choices and enhance the overall value of maintenance investments.

Frequently Asked Questions on Parts

This section aims to address common inquiries regarding components and their maintenance, providing essential information for effective use and longevity.

- What should I check regularly?

- Inspect for wear and tear.

- Ensure proper lubrication.

- Clean any debris or buildup.

- Where can I find replacements?

- Authorized dealers.

- Online retailers.

- Local repair shops.

- How can I identify the correct component?

- Refer to the user manual.

- Check model specifications.

- Consult online resources or forums.

- What are the signs of faulty components?

- Unusual noises during operation.

- Decreased performance.

- Visible damage or corrosion.