Understanding the Jari Mower Parts Diagram for Efficient Maintenance

In the world of outdoor maintenance, the functionality of your essential tools greatly relies on the intricate design and arrangement of their individual elements. Gaining insight into how these components interact and contribute to overall performance can enhance your ability to troubleshoot and maintain your equipment effectively.

Identifying the various segments within your machinery not only aids in recognizing potential issues but also empowers you to execute repairs with confidence. Each section plays a vital role in the seamless operation of the device, ensuring that it performs at its best during those critical maintenance tasks.

By familiarizing yourself with these components, you position yourself for success in keeping your tools in optimal condition. This knowledge will prove invaluable, whether you’re conducting routine maintenance or tackling more complex repairs. Understanding the structure of your equipment lays the foundation for a long-lasting and efficient outdoor experience.

Understanding Jari Mower Mechanics

The inner workings of a cutting machine are intricate and fascinating. By exploring the various components and their functions, one can gain valuable insights into how these devices operate efficiently. A solid grasp of the mechanics not only enhances maintenance but also improves performance and longevity.

Key Components

- Engine: The heart of the machine, responsible for generating power.

- Transmission: This system transfers power from the engine to the cutting elements.

- Blades: The sharp implements that perform the actual cutting, designed for precision.

- Deck: The housing that holds the blades and influences cutting height.

- Wheels: These provide mobility and stability, essential for maneuvering across different terrains.

Maintenance Tips

- Regularly check and change the oil to ensure optimal engine performance.

- Inspect the blades for dullness or damage and sharpen or replace as necessary.

- Keep the deck clean to prevent debris buildup that can affect cutting efficiency.

- Check tire pressure to maintain proper traction and handling.

- Perform seasonal inspections to address any wear and tear before heavy usage.

Understanding these elements contributes significantly to effective operation, ensuring that the cutting process is both smooth and efficient. Regular maintenance and awareness of component functionality lead to a better overall experience.

Key Components of Jari Mowers

Understanding the essential elements of these innovative machines is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance, durability, and ease of use. This section will explore the vital elements that contribute to the functionality of these versatile gardening tools.

Core Elements

The primary structure consists of several key items that facilitate movement and cutting efficiency. Recognizing their importance helps in troubleshooting and enhancing performance.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing the necessary energy for operation. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Cutting Deck | Houses the blades, responsible for the actual cutting of grass or foliage. |

| Blades | Sharp instruments that slice through vegetation with precision. |

| Chassis | The frame that supports all other components and provides stability. |

Maintenance Considerations

Benefits of Using Jari Mowers

Employing high-quality equipment for lawn maintenance can significantly enhance efficiency and results. Such tools are designed for optimal performance, ensuring that tasks are completed swiftly and effectively.

Enhanced Efficiency

- Faster cutting speed reduces time spent on landscaping.

- Adjustable settings allow for tailored performance according to specific needs.

- Durable construction minimizes downtime and maintenance requirements.

Improved Results

- Precision cutting delivers a cleaner finish.

- Versatile designs accommodate various terrains and conditions.

- Ergonomic features enhance user comfort during operation.

Common Issues with Jari Parts

When maintaining equipment, users often encounter a variety of challenges related to components. Recognizing these common problems can enhance performance and prolong the lifespan of the machinery.

Frequent Problems

- Worn or damaged components leading to inefficient operation.

- Incompatibility issues with replacement items.

- Rust and corrosion affecting durability.

Solutions and Tips

- Regularly inspect items for wear and replace them as needed.

- Ensure compatibility when sourcing new components.

- Utilize protective coatings to prevent rust.

Maintenance Tips for Jari Equipment

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention to maintenance not only enhances functionality but also helps prevent costly repairs and downtime. Here are some practical tips to ensure your machinery remains in excellent condition.

1. Regular Inspection: Conduct frequent checks on all components to identify any signs of wear or damage. Look for loose bolts, frayed belts, and any unusual noises during operation.

2. Cleanliness is Key: Keep the equipment clean by removing debris, grass clippings, and dirt. A clean machine not only operates better but also reduces the risk of corrosion and rust.

3. Lubrication: Apply lubricant to moving parts as recommended by the manufacturer. This reduces friction and prevents premature wear, ensuring smooth operation.

4. Blade Maintenance: Regularly sharpen blades to maintain cutting efficiency. Dull blades can strain the engine and lead to uneven cuts.

5. Fuel Care: Use high-quality fuel and replace it regularly to prevent issues with the engine. Stale fuel can cause starting problems and affect performance.

6. Storage Practices: When not in use, store the machinery in a dry, sheltered area. Proper storage protects it from the elements and extends its lifespan.

7. Follow the Manual: Always refer to the user manual for specific maintenance recommendations and schedules. Adhering to the guidelines will help you avoid common pitfalls and keep your equipment running smoothly.

By implementing these maintenance practices, you can ensure that your equipment performs efficiently and lasts for many seasons to come.

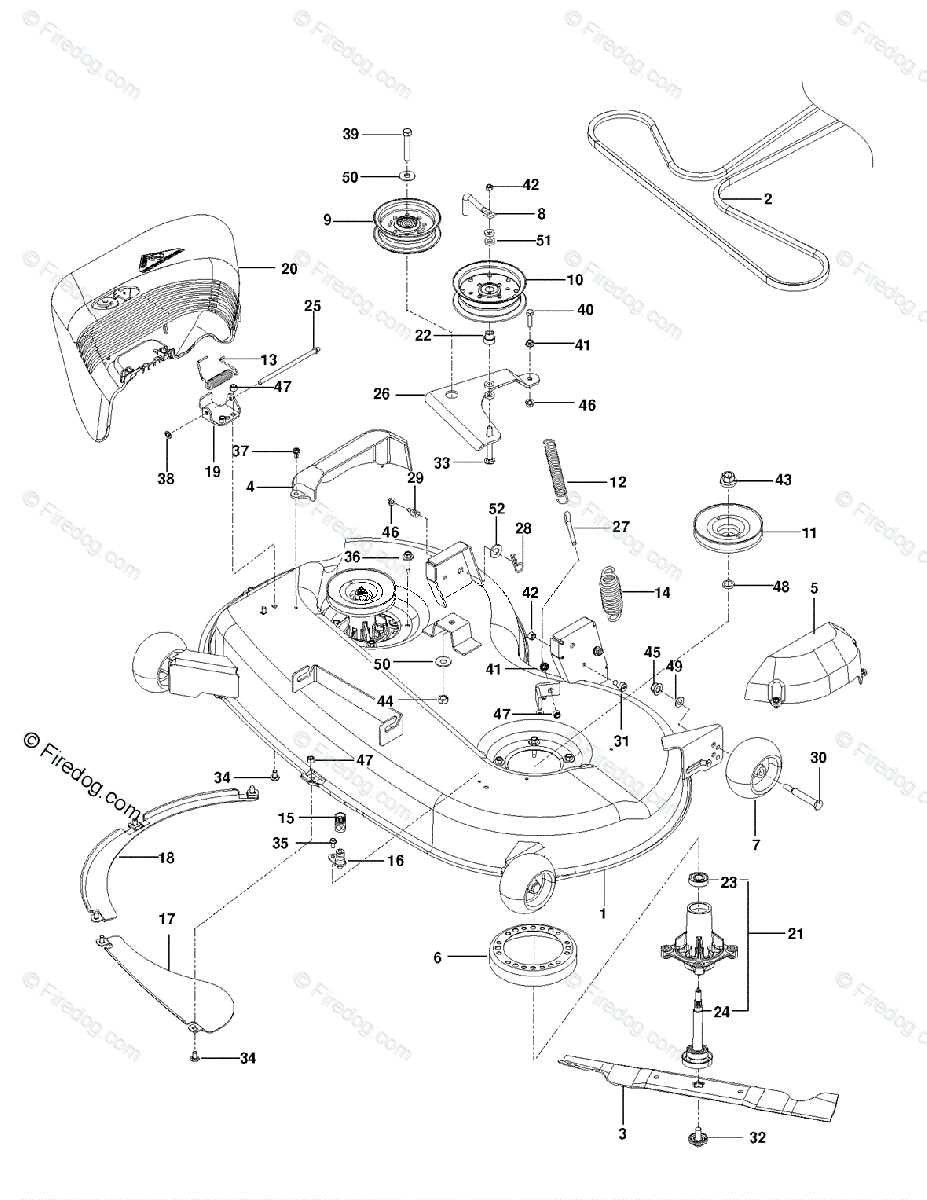

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repairs. These illustrations provide a comprehensive overview of components, their functions, and how they fit together. Familiarity with these visuals can save time and enhance efficiency when tackling any project.

Key Components of Visual Schematics

- Labels: Each part is usually accompanied by a number or letter for easy identification.

- Connections: Arrows often indicate how parts interact or connect with one another.

- Legend: A guide explaining symbols or abbreviations used within the illustration.

Steps to Analyze the Illustration

- Start by examining the legend to understand the symbols.

- Identify the key components using the labels provided.

- Trace the connections to comprehend how parts work together.

- Refer to the accompanying text or manual for additional context.

Finding Replacement Parts Online

In today’s digital age, sourcing components for your equipment has become remarkably convenient. With a wealth of online platforms available, you can easily locate the necessary items to keep your machinery running smoothly. Whether you need a specific component or a general accessory, the internet offers a plethora of options to ensure you find what you’re looking for.

To begin your search, it’s essential to know the make and model of your device. This information will guide you to the right online retailers that specialize in the specific items you need. Many websites provide detailed catalogs, making it easier to navigate through various categories and quickly identify compatible components.

Additionally, online marketplaces often feature user reviews and ratings, which can help you gauge the quality of the components before making a purchase. This feedback can be invaluable in determining whether a particular supplier is trustworthy and if the items meet your expectations.

Lastly, don’t forget to compare prices across different platforms. Some sites might offer discounts or promotions that can save you money. By doing a bit of research, you can ensure you’re getting the best deal while securing the necessary components for your equipment.

Jari Mower Assembly Instructions

Assembling outdoor machinery requires a clear understanding of the components and their relationships. This section will guide you through the essential steps to efficiently piece together your equipment, ensuring optimal functionality and performance.

Step 1: Begin by laying out all components in an organized manner. This helps in identifying each part and reduces the chance of missing items during assembly.

Step 2: Consult the provided manual for specific instructions related to your model. Pay attention to diagrams that illustrate the assembly process, focusing on the sequence of connections.

Step 3: Use the appropriate tools for each connection. Tighten bolts and screws securely, but avoid over-tightening, which could damage components.

Step 4: Once assembled, conduct a thorough inspection to ensure all parts are in place and functioning correctly. This step is crucial for safe operation.

Step 5: Finally, perform a test run to verify that everything operates smoothly. Make any necessary adjustments before regular use.

Safety Tips for Operating Mowers

Ensuring a secure environment while using lawn care equipment is essential for both the operator and bystanders. Following specific guidelines can significantly reduce the risk of accidents and injuries.

- Wear appropriate personal protective equipment, including goggles, gloves, and sturdy footwear.

- Inspect the machine before each use for any signs of damage or wear.

- Keep the work area clear of debris, obstacles, and children or pets.

- Read and understand the manufacturer’s instructions before operating the equipment.

- Never bypass safety features or operate machinery with missing guards.

By adhering to these practices, operators can enhance their safety and ultimately ensure a more effective and enjoyable experience.

Comparing Jari with Other Brands

When evaluating various options in the landscaping equipment sector, it’s crucial to understand the unique attributes that distinguish one manufacturer from another. Each brand offers a different blend of quality, performance, and innovation, influencing consumer choices. This section delves into how one prominent name stacks up against its competitors, focusing on aspects such as reliability, ease of use, and customer support.

Key Features and Performance

- Durability: The longevity of the equipment varies among brands, with some designed to withstand harsher conditions.

- Efficiency: Performance in terms of speed and fuel consumption is often a deciding factor.

- Technology: Advanced features such as automated systems can enhance usability and productivity.

Customer Satisfaction and Support

- Warranty: The length and coverage of warranties can indicate a brand’s confidence in its products.

- Service Network: Accessibility to service centers and parts availability can significantly affect user experience.

- User Reviews: Feedback from current owners often reveals insights into reliability and overall satisfaction.

By assessing these factors, potential buyers can make informed decisions that best meet their specific needs, ensuring a productive investment in landscaping tools.

Upgrading Jari Mower Features

Enhancing the capabilities of your equipment can significantly improve efficiency and overall performance. By focusing on key components and implementing modern technologies, users can achieve a more effective and user-friendly experience. This section explores various enhancements that can be applied to optimize functionality.

Incorporating Advanced Technology

Integrating state-of-the-art technology can revolutionize operations. For instance, adding smart sensors can provide real-time feedback on performance metrics. These sensors not only help in monitoring efficiency but also alert operators to potential issues before they escalate, ensuring seamless functioning.

Improving User Comfort and Control

Enhancements aimed at user comfort can greatly impact productivity. Upgrading the seating and controls can lead to a more ergonomic experience, allowing for extended periods of operation without fatigue. Furthermore, implementing intuitive control systems can simplify navigation and handling, making it easier for operators to focus on their tasks.

Investing in these upgrades not only enhances performance but also extends the lifespan of the equipment, making it a wise choice for any user looking to maximize their investment.

Expert Recommendations for Jari Users

For those who rely on specialized equipment for landscaping and maintenance tasks, understanding the nuances of operation and upkeep is crucial. This section offers valuable insights to enhance performance, longevity, and efficiency, ensuring a seamless experience for enthusiasts and professionals alike.

Regular Maintenance: Establish a routine for checking the condition of key components. Routine inspections help identify wear and tear early, preventing costly repairs. Regularly clean and lubricate moving parts to maintain optimal functionality.

Utilize Quality Accessories: Invest in high-quality attachments and enhancements that are compatible with your equipment. Using subpar alternatives can lead to malfunctions and reduce overall efficiency.

Stay Informed: Keep abreast of the latest updates, modifications, and best practices within the community. Engaging with user forums and expert blogs can provide insights that improve your operational techniques and equipment handling.

Proper Storage: Ensure that equipment is stored in a dry, sheltered area to protect it from harsh weather conditions. Covering machinery when not in use can significantly extend its lifespan and performance.

Follow the Manufacturer’s Guidelines: Adhering to the provided instructions for use and maintenance is essential. These guidelines are designed to maximize efficiency and ensure safety while operating the machinery.

By integrating these recommendations into your routine, users can enhance their experience, ensuring reliable and effective performance for years to come.