Husqvarna W520 Parts Diagram

When maintaining or repairing outdoor machinery, understanding the layout and connection of its essential elements is crucial. Each part plays a specific role in ensuring optimal performance and longevity. Whether you’re a professional technician or a DIY enthusiast, having a clear overview of these components can significantly improve efficiency and reduce errors during repairs.

Exploring the detailed construction of the equipment helps in identifying where each piece fits and how they work together. Knowledge of the various elements can also assist in troubleshooting problems and determining the right approach for maintenance. A comprehensive breakdown aids in knowing what parts require attention and how they interact within the system.

Familiarity with the design layout provides the confidence needed to handle repairs or upgrades effectively. With the right information, it becomes easier to ensure that everything operates smoothly, avoiding unnecessary replacements or disruptions in function. This approach enhances your understanding of how to care for the equipment and get the best results over time.

Husqvarna W520 Parts Overview

This section provides a comprehensive guide to the essential components of the model, detailing their functions and importance for overall performance. Understanding each element is crucial for proper maintenance and efficient operation. Whether you’re performing routine checks or replacing damaged items, knowing the right pieces can greatly enhance the longevity of your equipment.

Key Components: The heart of the system lies in a few critical items that ensure smooth operation. These include the engine unit, transmission, and cutting mechanism, each of which plays a vital role in functionality. Regular inspection of these elements is recommended to avoid potential failures.

Additional Details: Smaller items, such as fasteners, seals, and filters, although seemingly minor, contribute significantly to maintaining efficiency and preventing wear. Proper knowledge of their placement and condition helps prevent unnecessary disruptions during use.

Understanding the Main Components

Every machine is made up of several key elements that work in harmony to ensure optimal functionality. Each part plays a vital role, contributing to the overall performance, durability, and ease of use. Familiarizing yourself with these components can enhance maintenance efforts and help you make informed decisions when replacements are needed.

The engine serves as the heart of the system, providing the power necessary for operation. Coupled with the transmission, it transfers energy efficiently, allowing for smooth movement and operation. The cutting mechanism, another crucial part, is designed for precision and effectiveness, ensuring that tasks are completed efficiently.

Support systems such as the chassis and frame provide structural integrity and stability, allowing the machine to withstand various pressures and impacts. The control features, including handles and buttons, ensure that the operator can manage the equipment with ease and precision. Lastly, safety components are integrated to protect both the user and the machine from potential hazards during use.

Engine Assembly and Its Parts

The assembly responsible for the mechanical heart of a machine plays a crucial role in its overall functionality and performance. Understanding the individual components that comprise this structure is essential for maintenance, troubleshooting, and enhancement. Each part contributes to the engine’s efficiency, durability, and ability to perform optimally under various conditions.

Key Components of the Engine

Among the vital elements of the assembly are the cylinder block, crankshaft, and piston. The cylinder block serves as the main framework, housing the cylinders where combustion occurs. The crankshaft converts linear motion from the pistons into rotational energy, driving the machine’s operations. The piston moves within the cylinder, creating the necessary pressure for combustion to take place, thereby generating power.

Supporting Elements

In addition to the primary components, several supporting elements are crucial for ensuring smooth operation. These include the camshaft, timing belt, and valves. The camshaft regulates the timing of the engine’s intake and exhaust processes, while the timing belt synchronizes the rotation of the crankshaft and camshaft. Valves open and close at precise intervals to allow air and fuel in and exhaust gases out, optimizing the engine’s performance.

Transmission and Gear Mechanisms

The transmission system plays a crucial role in ensuring the efficient operation of various machinery. It facilitates the transfer of power from the engine to the wheels, enabling movement and enhancing overall performance. Understanding the components and their functions is essential for effective maintenance and repair.

Gear mechanisms are integral to this system, allowing for the adjustment of speed and torque to match different operating conditions. These components work in harmony to optimize functionality, ensuring smooth transitions between different power settings.

| Component | Function |

|---|---|

| Gearbox | Regulates the transmission of power and adjusts speed and torque. |

| Clutch | Enables the engagement and disengagement of the engine from the transmission. |

| Drive Shaft | Transmits torque from the transmission to the wheels. |

| Final Drive | Transfers power to the drive wheels, providing necessary movement. |

Essential Electrical System Elements

The electrical system in any machinery plays a crucial role in ensuring proper functionality and efficiency. Understanding the fundamental components of this system can aid in effective maintenance and troubleshooting, ultimately enhancing performance and longevity.

Key elements of the electrical system include:

- Batteries: Provide the necessary power to start the engine and operate electrical components.

- Alternators: Generate electricity while the engine runs, ensuring that the battery remains charged.

- Wiring Harness: Connects various electrical components, facilitating communication and power distribution.

- Fuses: Protect the electrical circuits by preventing overloads, which could lead to damage.

- Relays: Act as switches to control high-power circuits with lower power signals, enhancing safety and efficiency.

Each of these components serves a distinct function, contributing to the overall effectiveness of the electrical system. Regular inspection and maintenance of these elements can prevent unexpected failures and improve operational reliability.

Fuel System and Related Parts

The fuel delivery mechanism is essential for the efficient operation of any small engine. It comprises various components that work in unison to ensure the proper flow and mixture of fuel and air. Understanding these elements can enhance maintenance and troubleshooting efforts.

Key Components

- Fuel Tank: Stores the gasoline and provides a steady supply.

- Fuel Filter: Cleans the fuel before it reaches the engine, preventing contaminants from causing damage.

- Fuel Pump: Delivers fuel from the tank to the engine at the necessary pressure.

- Carburetor: Mixes air and fuel in the correct proportions for combustion.

- Fuel Lines: Transport fuel between the tank, filter, pump, and carburetor.

Maintenance Tips

- Regularly check and replace the fuel filter to maintain optimal flow.

- Inspect fuel lines for cracks or leaks that could lead to performance issues.

- Ensure the carburetor is clean and properly adjusted to prevent stalling or rough idling.

- Keep the fuel tank filled to avoid sediment buildup at the bottom.

Brake and Steering Components

The efficiency of any machine relies heavily on its control systems, particularly in terms of stopping and navigation. These elements are crucial for ensuring safety and precision during operation. Understanding their functionality and maintenance is essential for optimal performance.

Braking System: The braking mechanism serves as a vital safety feature, allowing the operator to halt the equipment effectively. Key components include the brake pads, which create friction, and the calipers that house these pads. Regular inspection and timely replacement of worn parts are critical for maintaining effectiveness.

Steering Assembly: The steering assembly enables precise directional control. This includes components such as steering links and control arms, which connect to the main body and facilitate movement. Proper adjustment and lubrication are necessary to ensure smooth operation and to prevent wear over time.

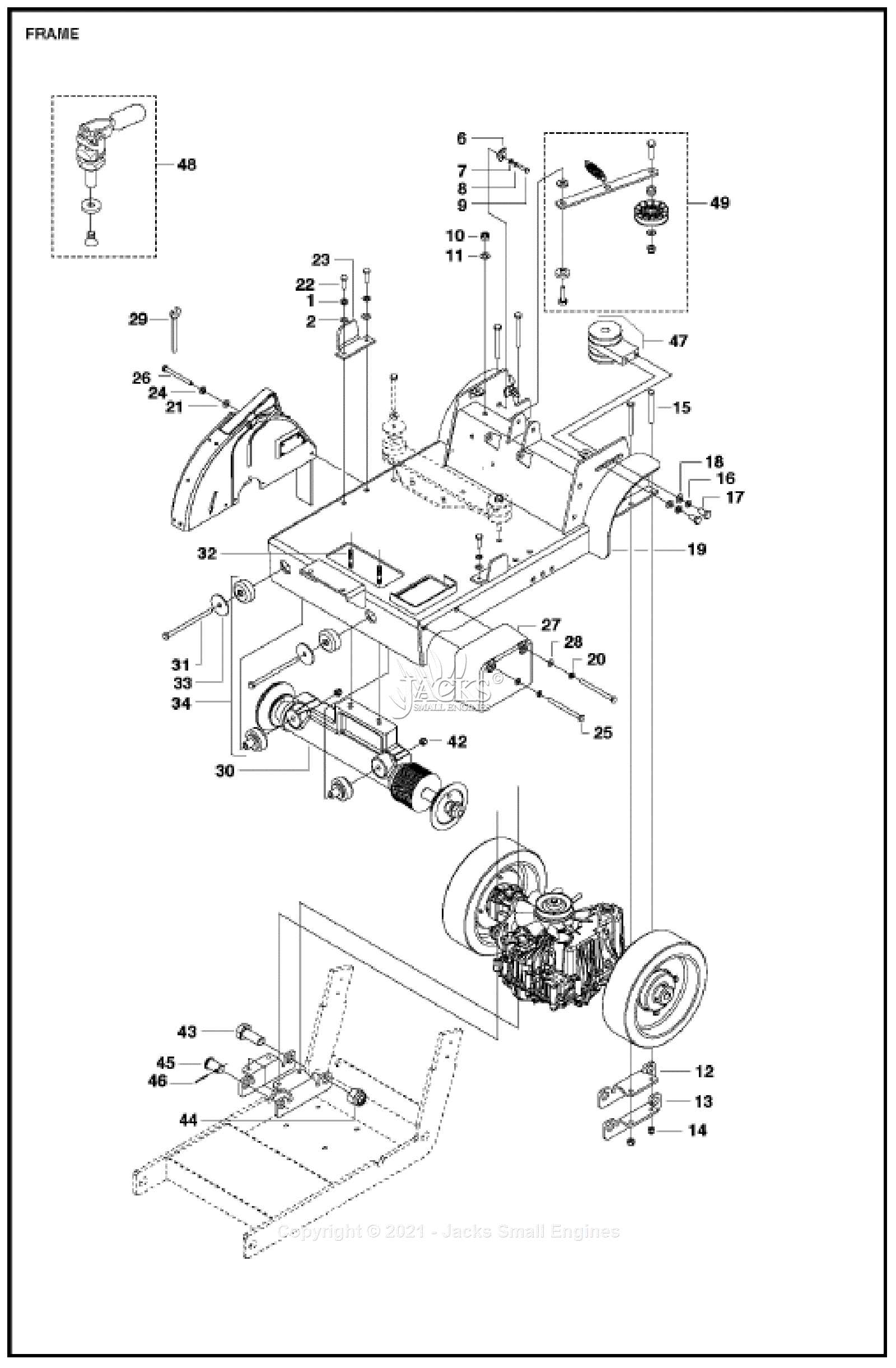

Chassis and Frame Assembly

The foundation of any machinery lies in its structure, which plays a critical role in ensuring stability and durability during operation. A robust chassis and frame assembly provides the necessary support for various components, enabling optimal performance and longevity.

When considering the assembly, attention to detail is paramount. Each part must be carefully aligned and secured to prevent any potential malfunctions. Utilizing quality materials enhances the resilience of the frame, which ultimately contributes to the overall efficiency of the machine.

Incorporating an ergonomic design can also significantly improve user experience. A well-constructed chassis not only supports functionality but also facilitates ease of use and maintenance, making it an essential aspect of machinery design.

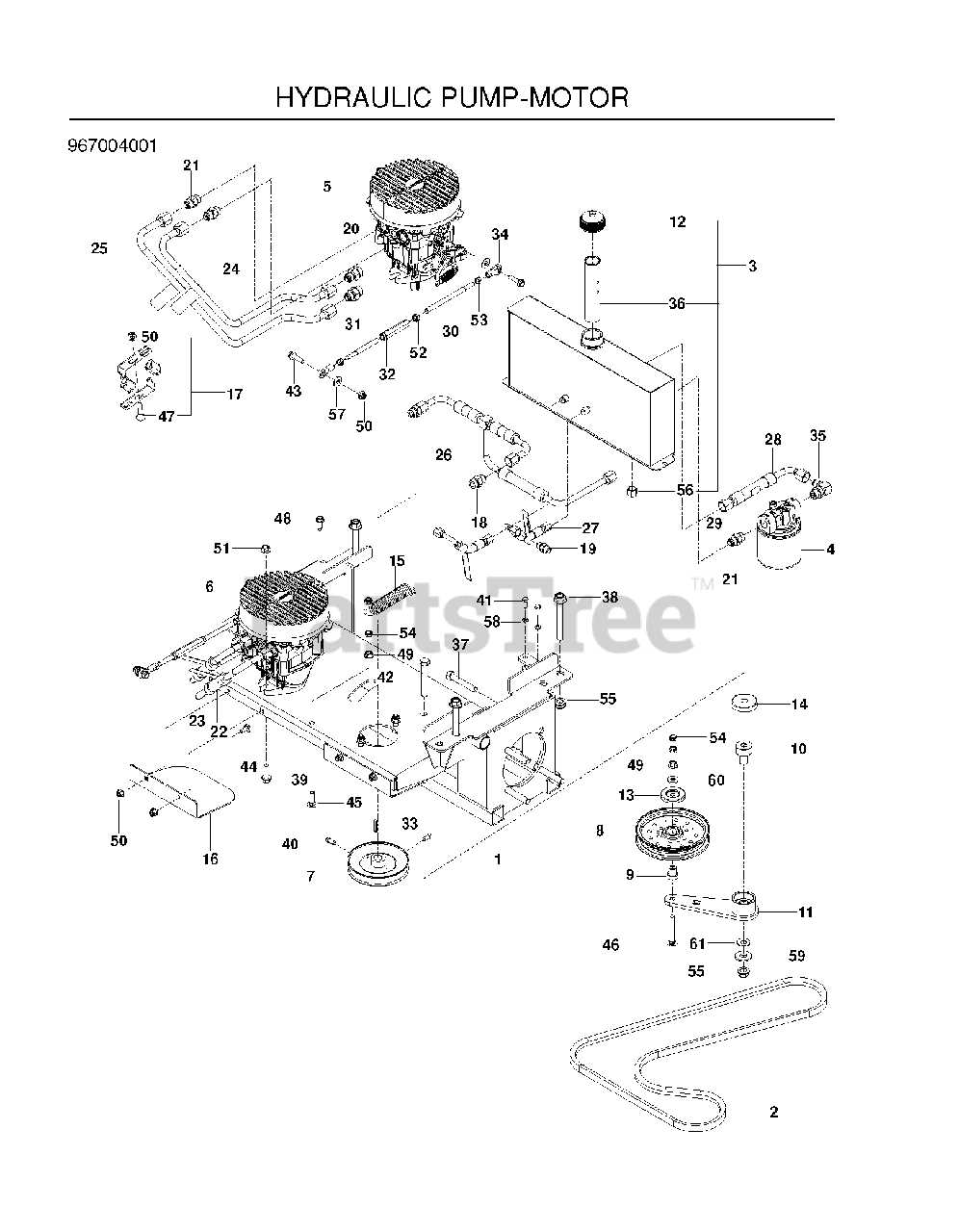

Hydraulic System and Components

The hydraulic system is crucial for the effective operation of machinery, utilizing fluid power to enable various functions. This system comprises multiple components that work in harmony to generate force and facilitate movement, making it an essential aspect of mechanical engineering.

Key Components

- Hydraulic Pump

- Actuators

- Valves

- Hydraulic Reservoir

- Hoses and Fittings

Functionality

- The hydraulic pump generates flow by converting mechanical energy into hydraulic energy.

- Actuators convert hydraulic energy back into mechanical energy to perform tasks.

- Valves control the direction and flow of the hydraulic fluid.

- The reservoir stores hydraulic fluid, ensuring a constant supply.

- Hoses and fittings connect components, allowing fluid to circulate efficiently.

Wheel and Tire Specifications

This section delves into the essential characteristics of wheels and tires, which are crucial for ensuring optimal performance and safety in various applications. Understanding these specifications helps users make informed choices when selecting components for their machines.

- Wheel Diameter: The diameter of the wheel directly influences stability and handling. Common sizes vary depending on the model and intended use.

- Tire Width: Wider tires provide better traction and stability, while narrower options can enhance maneuverability.

- Tread Pattern: The design of the tire tread affects grip and performance on different surfaces, ranging from smooth to rugged terrains.

- Load Capacity: Each tire and wheel combination has a maximum load rating that must be adhered to for safe operation.

When selecting wheels and tires, consider the following factors:

- Intended Use: Different applications require specific specifications to maximize efficiency and safety.

- Surface Conditions: The type of terrain influences tire selection, with options available for both soft and hard surfaces.

- Weather Conditions: Choosing the right tread pattern can enhance performance in wet or dry environments.

- Maintenance Needs: Regular inspection and maintenance of tires and wheels are vital for prolonging their lifespan and ensuring safe operation.

Maintenance and Repair Tips

Proper upkeep and timely repairs are essential for the longevity and optimal performance of any machinery. Regular attention to these aspects can prevent minor issues from escalating into significant problems, ensuring that your equipment runs smoothly and efficiently over time.

Regular Inspections

Frequent examinations of your device are vital. Look for signs of wear and tear, such as cracks, rust, or loose components. Pay close attention to the operating parts; even a small malfunction can disrupt functionality. Establish a routine to check filters, belts, and lubricants, as these are crucial for seamless operation.

Cleaning and Lubrication

Keeping your equipment clean is paramount. Remove debris and dirt that may accumulate in and around the moving parts. Use appropriate cleaning solutions to avoid damage. Additionally, ensure that all moving elements are properly lubricated to reduce friction, enhance performance, and extend the life of your machinery.

By following these simple yet effective maintenance tips, you can significantly improve the reliability and efficiency of your equipment.

Where to Find Replacement Parts

Finding components for your equipment can be a straightforward process if you know where to look. Several resources provide access to essential items, ensuring your machine runs smoothly.

Online Retailers

- Dedicated websites specializing in outdoor machinery often have a vast selection.

- General e-commerce platforms can offer competitive prices and quick shipping.

- Manufacturer’s official site usually provides accurate specifications and authenticity.

Local Stores

- Hardware stores often stock common components and can order specific ones for you.

- Specialty shops may offer a tailored selection for various brands and models.

- Service centers often have access to parts and can assist in repairs.