Understanding Efco Chainsaw Parts Diagram for Efficient Repairs

The intricate design of outdoor power tools requires a comprehensive grasp of their various elements. By exploring the structural composition, one can enhance performance and ensure longevity. This knowledge serves as a foundation for effective maintenance and troubleshooting.

Each machine is a symphony of interconnected mechanisms, each fulfilling a specific role. Familiarity with these components not only aids in efficient operation but also fosters a deeper appreciation for engineering marvels. When you delve into this topic, you will uncover the ultimate insights necessary for optimal functionality.

As you navigate through the complexities of these devices, understanding the visual representation of their assembly becomes paramount. This exploration will equip you with the expertise to tackle repairs and modifications with confidence, ensuring your equipment remains in peak condition.

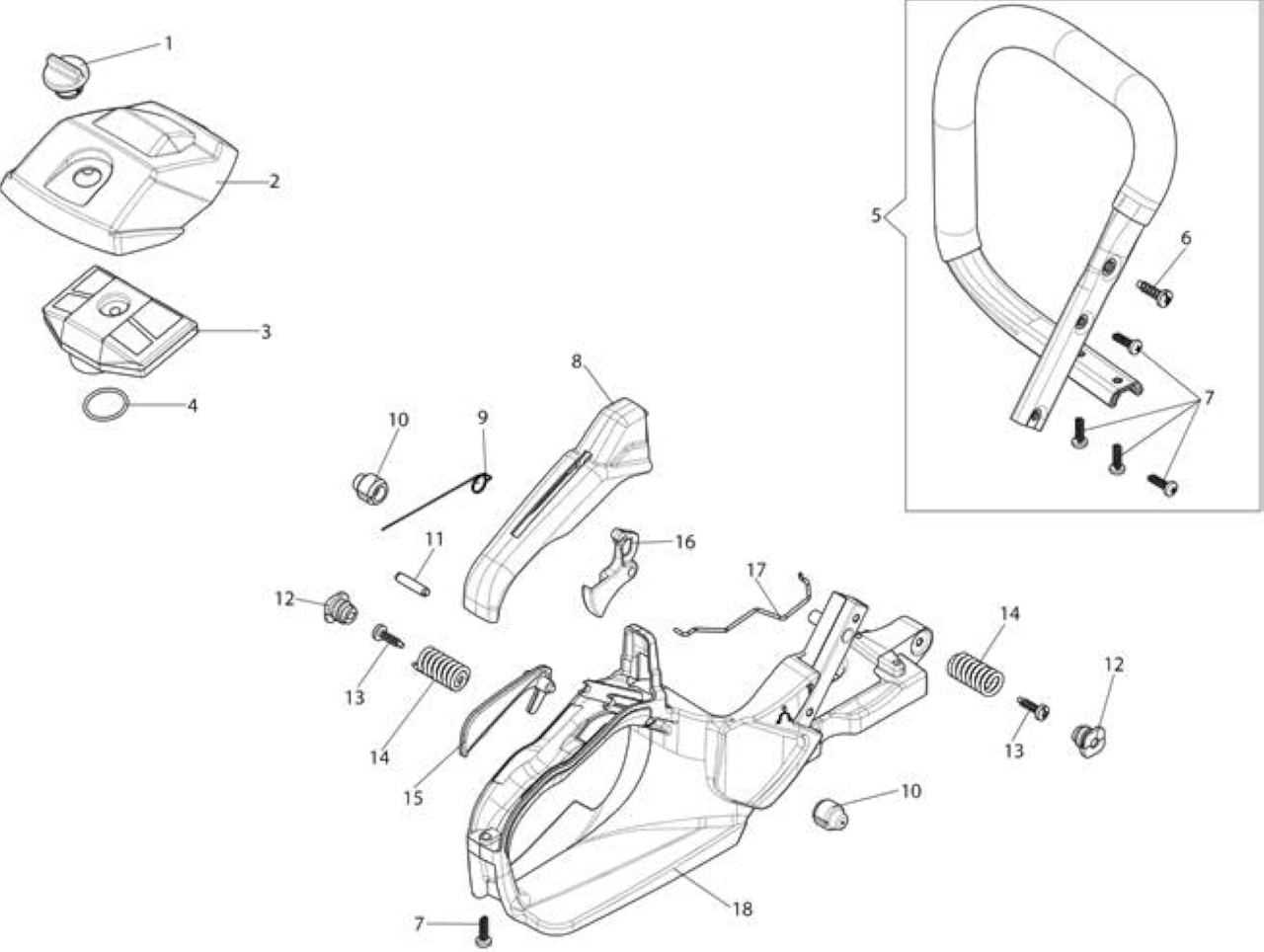

Understanding Efco Chainsaw Components

When it comes to the mechanics of cutting equipment, familiarity with its various elements is crucial for optimal performance and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the tool. Grasping the interrelationship between these parts can enhance the user experience and prolong the lifespan of the equipment.

Power Source: At the heart of any cutting tool lies its power unit, responsible for generating the energy needed for operation. This component typically comprises an engine or motor that converts fuel or electrical energy into mechanical power.

Cutting Mechanism: The cutting apparatus is where the actual action happens. This part usually includes a guide bar and a cutting chain that work together to slice through various materials with precision. Understanding the tension and sharpness of this mechanism is essential for effective performance.

Control Features: Safety and usability are significantly influenced by the control elements of the tool. These include switches and triggers that allow the user to manage speed and activation, ensuring a smooth and safe operation.

Support Structure: The chassis or frame provides stability and support, housing all the vital components securely. This structure is designed to withstand vibrations and impacts, making it an integral part of the equipment’s durability.

By delving into these components, users can gain insights into maintenance practices, troubleshoot issues, and ultimately enhance their overall experience with the tool.

Importance of Parts Diagrams

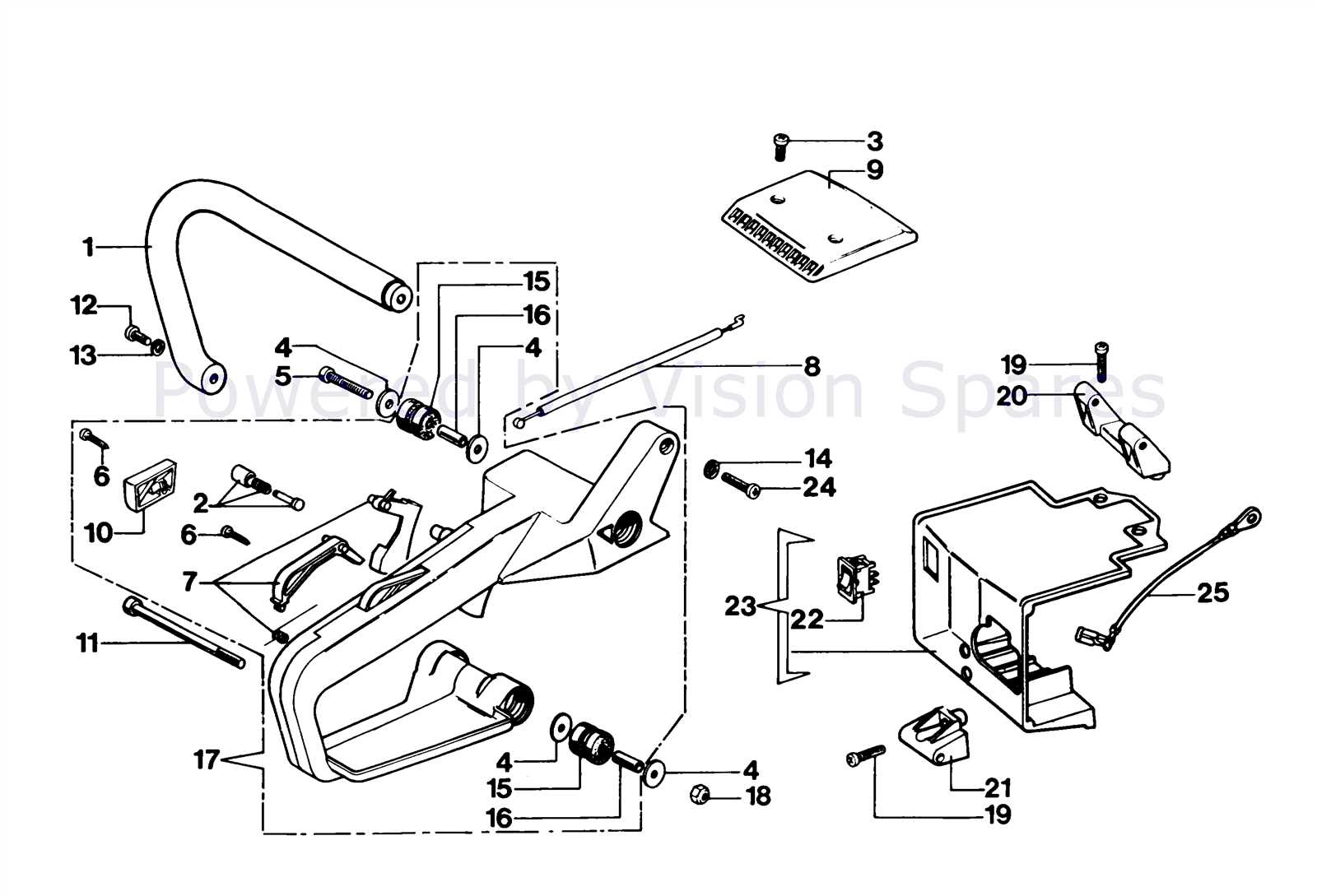

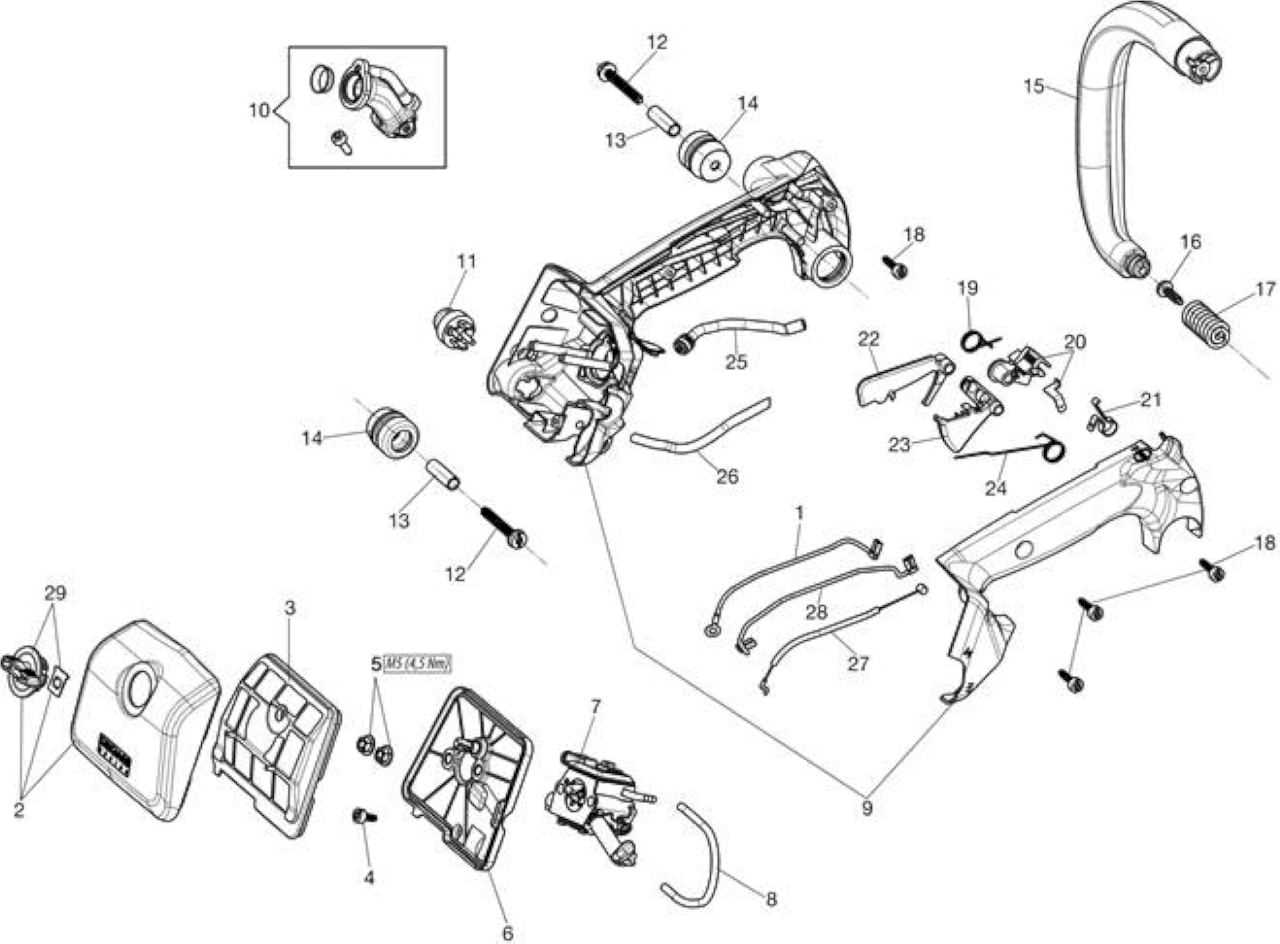

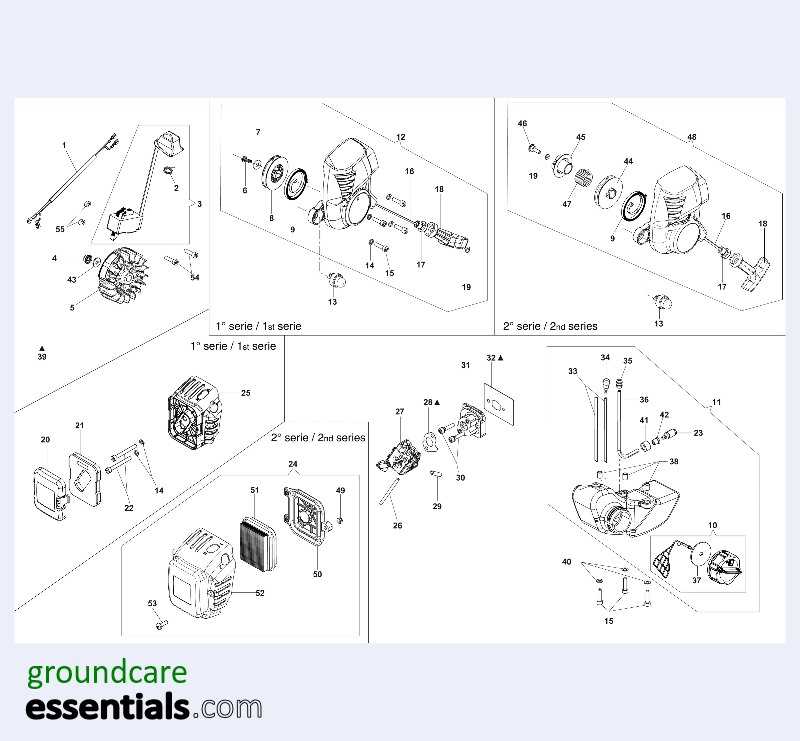

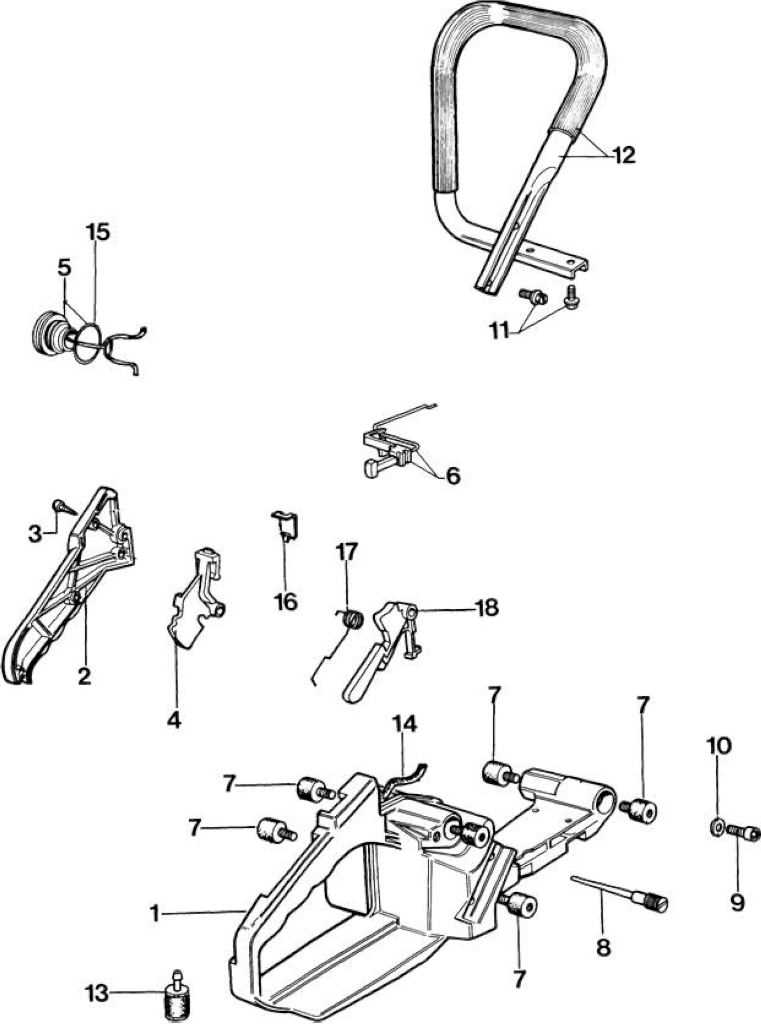

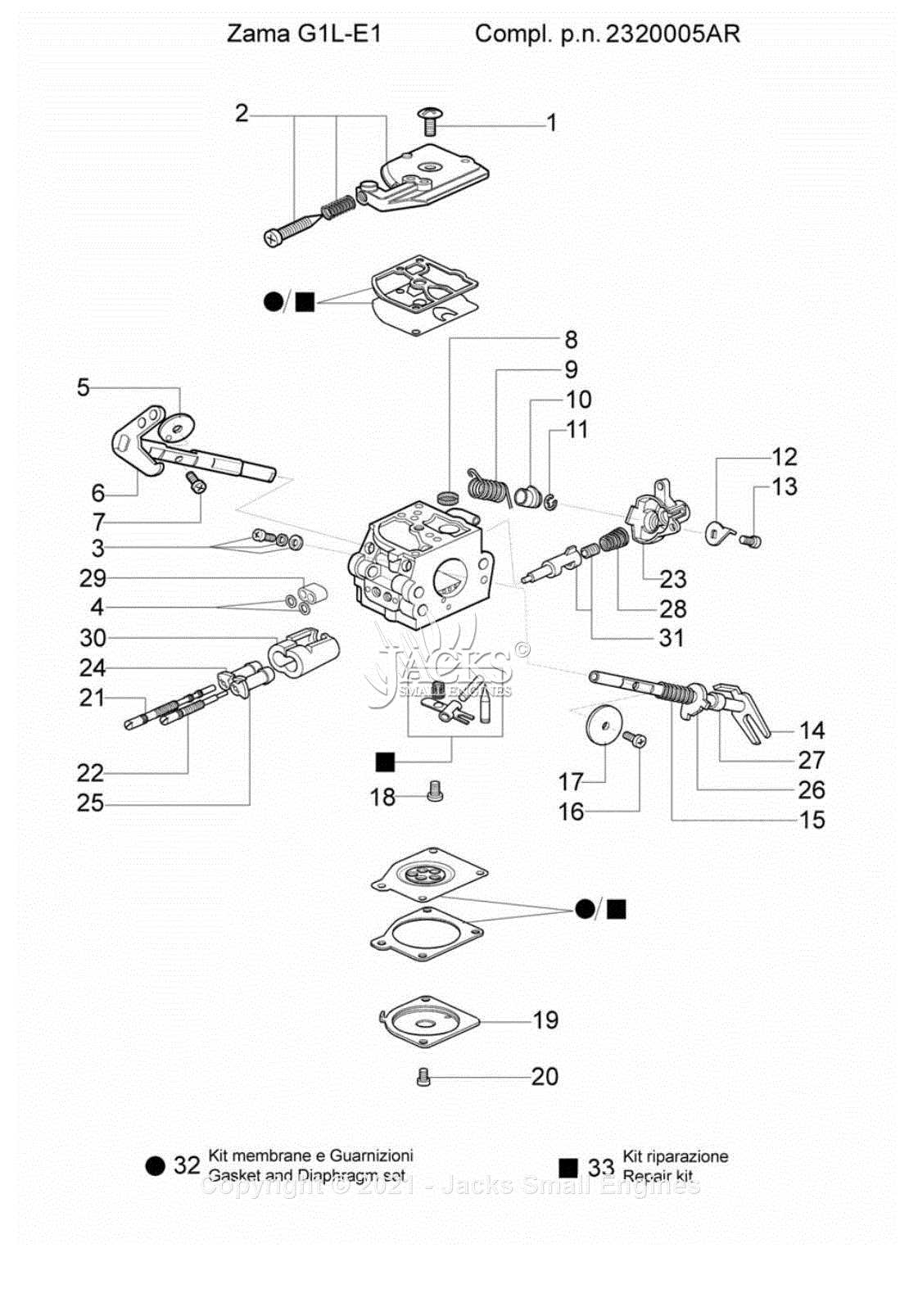

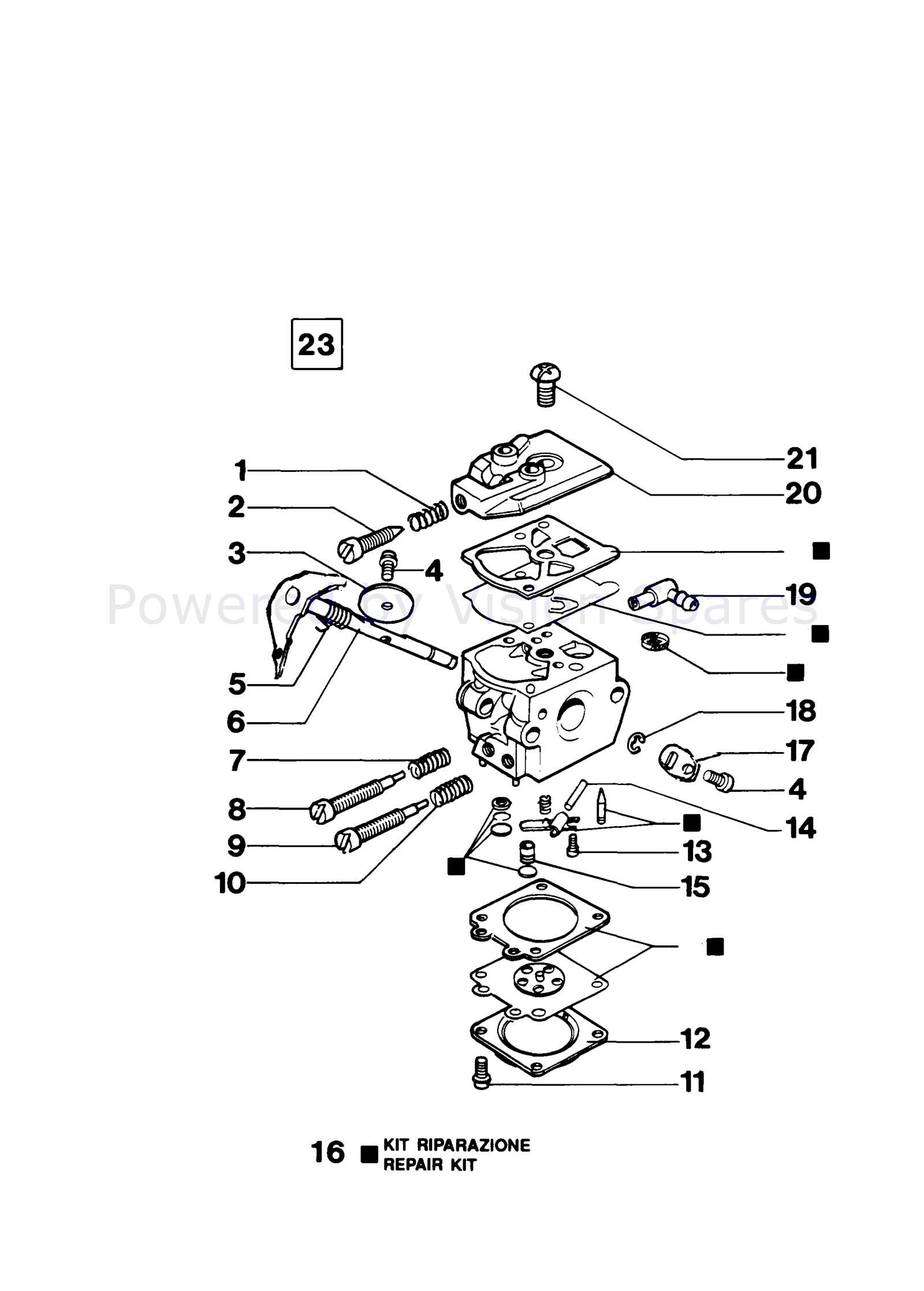

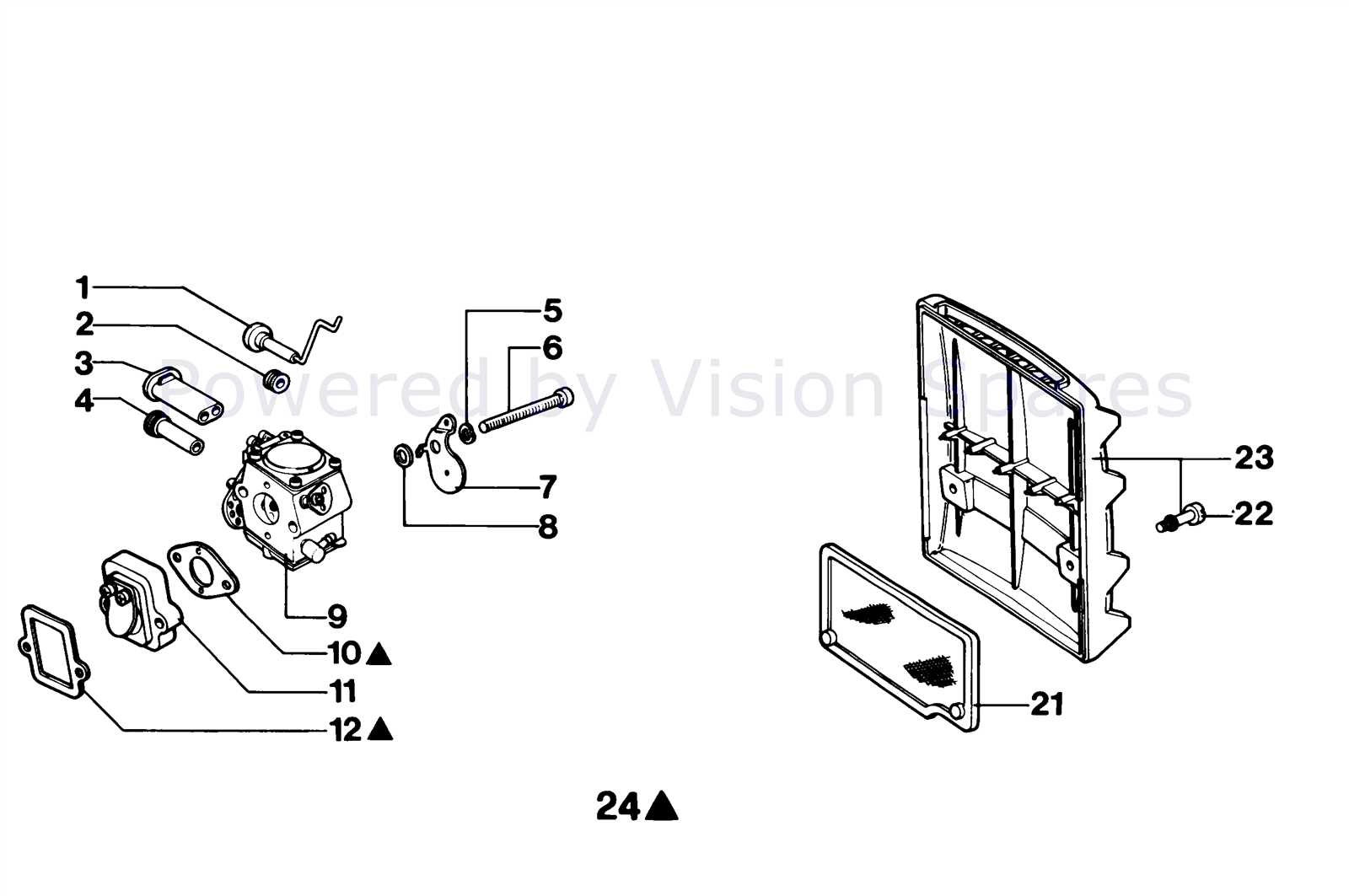

Understanding the layout and components of mechanical devices is crucial for maintenance and repair. Visual representations serve as essential tools, enabling users to identify and locate each element with precision. This clarity helps ensure that everything functions correctly, promoting efficiency and longevity.

Enhanced Maintenance

Visual aids allow for quicker diagnostics and repairs. By knowing where each component fits, users can effectively address issues without unnecessary disassembly, saving both time and effort.

Facilitating Replacement

When it comes to acquiring new components, having a clear visual reference makes the process straightforward. It aids in ensuring compatibility and correctness, ultimately leading to better performance and reliability in the device’s operation.

Common Issues with Efco Chainsaws

Power tools can experience various challenges that hinder their performance and efficiency. Understanding these common problems can help users maintain their equipment and ensure smooth operation. Below is a table highlighting frequent issues encountered and their possible causes.

| Issue | Description | Possible Causes |

|---|---|---|

| Starting difficulties | Inability to start or irregular starting behavior. | Clogged fuel filter, faulty spark plug, or empty fuel tank. |

| Overheating | Excessive heat during operation, leading to performance drop. | Poor lubrication, dirty air filter, or dull cutting tool. |

| Stalling | Sudden shutdown during use. | Fuel starvation, air leaks, or a malfunctioning ignition system. |

| Vibrations | Excessive shaking while in operation. | Loose components, unbalanced tool, or worn parts. |

| Uneven cutting | Inconsistent results when cutting through materials. | Dull blade, incorrect tension, or improper technique. |

Identifying these challenges early can lead to prompt solutions, ensuring the longevity and reliability of the equipment.

Identifying Parts for Repairs

Understanding the various components of your equipment is essential for effective maintenance and timely repairs. By familiarizing yourself with these elements, you can ensure optimal performance and longevity of the machine. This section outlines key strategies for recognizing and locating the necessary components.

Steps to Identify Components

- Refer to the user manual for detailed descriptions of each part.

- Use online resources and forums to compare visuals and get insights from experienced users.

- Label components during disassembly to simplify reassembly.

Common Components to Recognize

- Power unit

- Cutting mechanism

- Guide bar

- Chain tensioning system

- Safety features

By systematically identifying these crucial elements, you can streamline the repair process and enhance the functionality of your equipment.

Overview of Efco Models

This section provides a comprehensive look at various models offered by a well-known manufacturer in the power equipment industry. Each model is designed to cater to specific needs, combining performance, durability, and user-friendly features. Understanding these options helps users select the right tool for their tasks.

Among the available selections, several models stand out for their versatility and reliability. Compact units are ideal for light-duty applications, allowing for ease of handling and maneuverability. In contrast, heavy-duty variants are built to tackle more demanding tasks, offering enhanced power and durability.

Features such as engine capacity, weight, and cutting efficiency are crucial considerations when comparing different models. Additionally, ergonomic designs enhance user comfort, making prolonged usage more manageable. By evaluating these aspects, individuals can make informed decisions that align with their specific requirements.

Tools Needed for Maintenance

Proper upkeep of outdoor power equipment is essential for longevity and optimal performance. A well-equipped toolkit enables users to efficiently address common issues and perform necessary adjustments. Below is a list of essential instruments that facilitate effective maintenance procedures.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening or loosening bolts and nuts. |

| Screwdrivers | To adjust screws on various components. |

| Fuel Can | For storing and mixing fuel and oil. |

| File | To sharpen blades and edges for better performance. |

| Safety Gear | Includes gloves and goggles for personal protection. |

| Cleaning Brush | For removing debris and ensuring cleanliness. |

Step-by-Step Repair Guide

This guide aims to provide a clear and concise approach to troubleshooting and fixing common issues encountered in outdoor power tools. By following these systematic steps, users can effectively identify problems and apply appropriate solutions, ensuring optimal performance and longevity of their equipment.

Preparation and Safety

Before starting any repair work, it is essential to prepare adequately and prioritize safety. Gather the necessary tools and protective gear, and ensure that the equipment is turned off and disconnected from any power source. This will help prevent accidents and injuries during the repair process.

Diagnostic Steps

Begin the repair by performing a thorough examination. Check for visible damage or wear, listen for unusual sounds, and note any irregular behavior during operation. Documenting these observations will assist in pinpointing the root cause of the malfunction.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Tool won’t start | Faulty ignition system | Inspect and replace spark plug |

| Poor performance | Clogged air filter | Clean or replace air filter |

| Excessive vibrations | Loose components | Tighten or replace loose screws |

| Overheating | Insufficient lubrication | Add appropriate oil and check levels |

Following these guidelines will enable users to address common issues effectively, ensuring that their tools remain reliable and efficient in their tasks.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. A variety of resources are available that can help you obtain high-quality replacements, ensuring your machine remains in top working condition.

Online Retailers

One of the most convenient ways to find the necessary components is through online marketplaces. Many websites specialize in outdoor equipment and accessories. Here are some reliable options:

- Amazon

- eBay

- Specialized equipment sites

- Manufacturer’s official website

Local Suppliers

Visiting local hardware or equipment stores can be beneficial as well. Many establishments carry a selection of components and can provide personalized assistance. Consider checking:

- Neighborhood hardware stores

- Garden centers

- Tool rental shops

Additionally, joining local community forums or social media groups dedicated to outdoor equipment can provide insights and recommendations from other users. This approach may lead to discovering reliable local suppliers or even second-hand options.

Comparing Efco Parts with Competitors

This section explores the nuances of various components from one brand in relation to those from other manufacturers. By examining quality, durability, and performance, we can understand how these offerings stack up against their rivals. Each brand has its unique strengths, and a thorough comparison can help users make informed decisions.

When evaluating components, one must consider material quality and manufacturing processes. Some brands utilize advanced technology, resulting in superior longevity and efficiency. Others might focus on cost-effectiveness, appealing to budget-conscious consumers while sacrificing some performance aspects.

Additionally, compatibility plays a crucial role. A well-designed piece should seamlessly integrate with other systems, enhancing overall functionality. Discrepancies in compatibility can lead to inefficiencies, making it vital for users to research before making a choice.

Lastly, customer feedback and support services cannot be overlooked. Brands that prioritize user experience often foster loyalty, influencing consumer preferences. A brand’s reputation can significantly impact the perceived value of its components compared to those of competitors.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent injuries and damage. Adhering to proper guidelines not only protects the individual performing the work but also extends the longevity of the equipment involved.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards. Ensuring that the work area is free from distractions can also enhance focus and safety.

Work Area Safety

Maintaining a clean and organized workspace is vital. Keep tools and materials within reach to minimize unnecessary movements. Adequate lighting and ventilation are important to reduce risks associated with poor visibility and harmful fumes.

Maintaining Your Chainsaw for Longevity

Ensuring the durability of your cutting tool requires regular attention and care. By implementing effective maintenance practices, you can enhance performance and extend the lifespan of your equipment. Here are essential tips to keep your tool in top condition.

Regular Cleaning

Cleaning your device after each use is crucial. It prevents debris buildup that can hinder performance. Follow these steps:

- Remove any sawdust and dirt from the exterior.

- Check and clean the air filter regularly.

- Inspect the cutting mechanism for any obstructions.

Lubrication and Tensioning

Proper lubrication is key to smooth operation. Additionally, maintaining the correct tension helps avoid wear:

- Use appropriate oil to lubricate moving parts.

- Regularly check and adjust the tension according to the manufacturer’s guidelines.

- Replace any worn or damaged components promptly.

By adhering to these maintenance practices, you can significantly improve the efficiency and longevity of your cutting tool, ensuring it remains a reliable asset for years to come.

Understanding Warranty and Service Options

When investing in outdoor equipment, comprehending the available guarantees and support can significantly enhance your ownership experience. Knowing what is covered under warranty and the service options can provide peace of mind and ensure longevity for your tools.

Warranty Coverage

Most manufacturers offer a warranty that typically includes defects in materials and workmanship. It’s crucial to review the specific terms to understand the duration and limitations of the coverage, as well as the necessary steps for claiming warranty services.

Service Options

In addition to warranties, various service options may be available. Regular maintenance, repairs, and authorized service centers play a vital role in keeping your equipment in optimal condition. Below is a table outlining common service options and their benefits:

| Service Option | Description | Benefits |

|---|---|---|

| Routine Maintenance | Scheduled check-ups to ensure proper functionality. | Prevents issues and extends equipment life. |

| Repairs | Fixing any malfunction or damage. | Restores performance and reliability. |

| Authorized Service Centers | Professional servicing by trained technicians. | Assures quality and adherence to manufacturer standards. |

Customer Reviews on Efco Products

This section provides insights into user experiences with a renowned brand’s offerings. Customers often share their thoughts on quality, performance, and overall satisfaction, helping potential buyers make informed decisions.

Positive Feedback

- Durability and longevity of equipment.

- Ease of use for both beginners and professionals.

- Excellent customer support and service.

Constructive Criticism

- Occasional availability issues for specific components.

- Some users noted a learning curve for advanced features.

- Price points may be higher compared to competitors.