Comprehensive Guide to Case IH 900 Planter Parts Diagram

In the realm of modern farming, efficient machinery plays a pivotal role in optimizing crop production. Knowledge of individual elements that comprise these machines is essential for proper maintenance and functionality. By breaking down the various components, farmers and technicians can enhance performance and reduce downtime.

The intricacies of these agricultural tools often require a detailed examination. Each element is designed to serve a specific purpose, contributing to the overall efficiency of the system. Familiarity with these mechanisms not only aids in troubleshooting but also empowers users to make informed decisions about repairs and upgrades.

Ultimately, a comprehensive grasp of these components can lead to improved operational success. By delving into the various sections of the equipment, users gain insights that can enhance productivity and ensure that machinery operates at its best throughout the farming season.

Understanding Case IH 900 Planters

This section explores the intricacies of a specific type of agricultural machinery designed for efficient seed placement. Understanding its components and functionality can enhance operational effectiveness and yield quality. A thorough examination reveals how these machines contribute to modern farming practices.

| Component | Description |

|---|---|

| Frame | The structural base that supports all other elements. |

| Seed Box | Holds the seeds prior to planting and ensures proper distribution. |

| Row Units | Responsible for placing seeds into the soil at the correct depth and spacing. |

| Hopper | Facilitates the loading and storage of seeds for easy access during operation. |

| Wheels | Ensure mobility across various terrains while providing stability. |

Key Features of the Case IH 900

The equipment in question is designed to enhance agricultural productivity through advanced engineering and thoughtful design. Its functionality not only maximizes efficiency but also ensures adaptability to various farming conditions, making it an essential asset for modern agriculture.

Precision Engineering: The machinery is built with high-quality components that ensure durability and reliability. This precision engineering allows for optimal performance, reducing downtime and maintenance costs.

Innovative Technology: Equipped with cutting-edge technology, it facilitates accurate seed placement and uniform spacing, which are critical for achieving higher yields. The integration of smart features provides real-time data, allowing farmers to make informed decisions.

User-Friendly Design: The intuitive interface and ergonomic layout make operation straightforward, minimizing the learning curve for new users. This focus on user experience enhances productivity in the field.

Versatility: This equipment can be customized to suit a variety of crops and soil types, demonstrating its flexibility in diverse agricultural settings. The ability to adjust settings based on specific needs ensures optimal performance.

Effective Resource Management: By improving seed placement and minimizing waste, it promotes efficient use of resources. This not only contributes to cost savings but also supports sustainable farming practices.

Importance of Planting Equipment Maintenance

Proper upkeep of agricultural machinery is essential for optimal performance and longevity. Regular maintenance ensures that equipment operates efficiently, reducing the risk of unexpected breakdowns during critical planting periods. By prioritizing care for these tools, farmers can enhance productivity and ensure a successful growing season.

Routine inspections and servicing can identify wear and tear early, allowing for timely repairs before they escalate into costly issues. Moreover, well-maintained machinery can lead to better seed placement and soil management, which ultimately improves crop yields. Neglecting maintenance not only jeopardizes the functionality of the equipment but can also negatively impact overall farm operations.

Additionally, maintaining equipment can help conserve resources, as efficient machines use fuel and other inputs more effectively. This sustainability aspect is increasingly important in modern farming practices, where environmental considerations play a crucial role. Ultimately, investing time and effort into equipment maintenance fosters a more reliable and productive agricultural system.

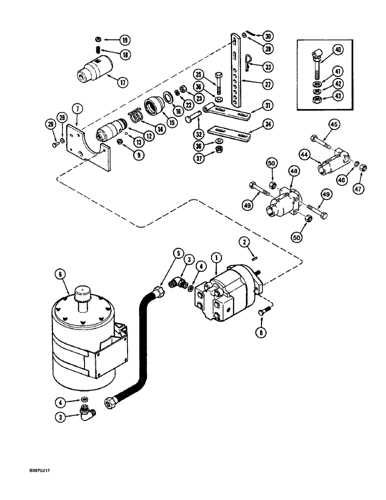

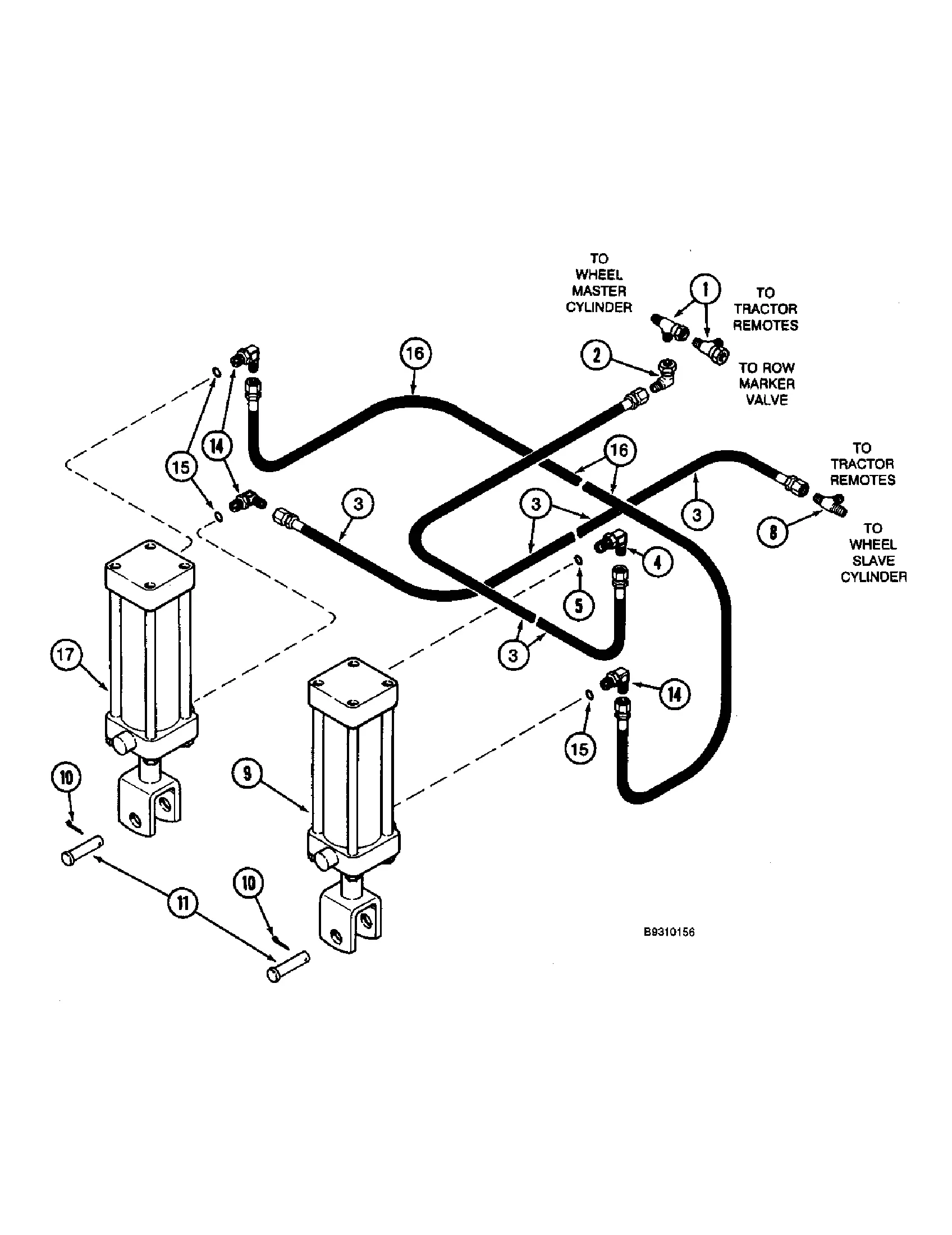

Identifying Components in the Diagram

Understanding the intricate elements within a machinery layout is crucial for effective maintenance and operation. Each component plays a specific role in ensuring optimal functionality, and recognizing these parts can greatly enhance troubleshooting and repair processes.

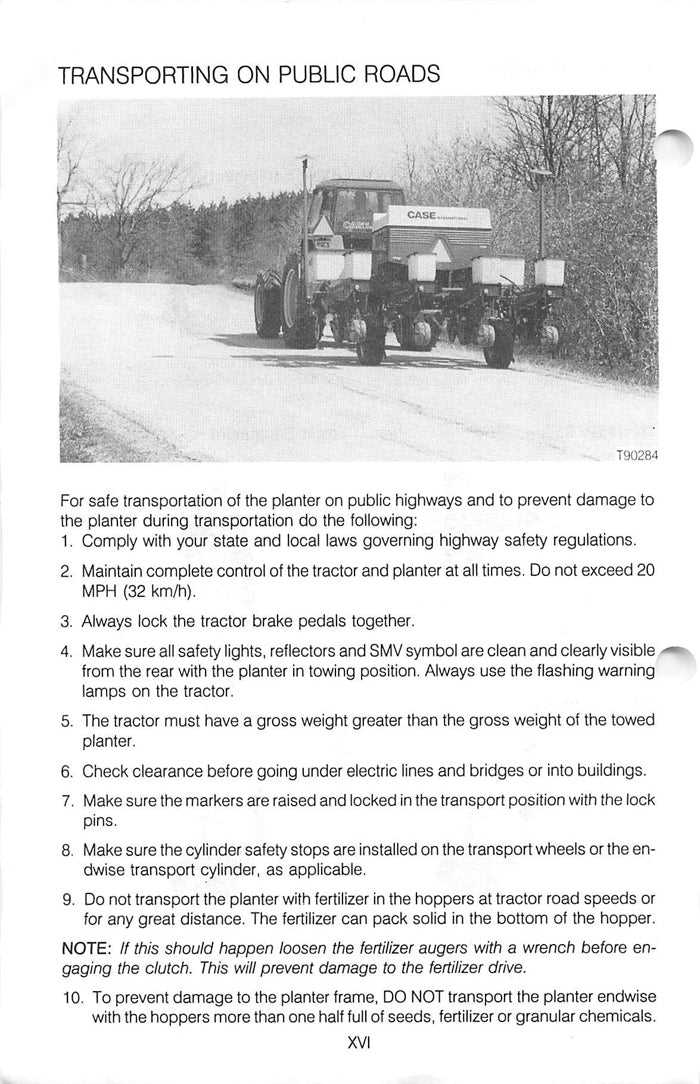

First and foremost, familiarize yourself with the primary structures that support overall performance. These foundational elements include frames, wheels, and attachments, all of which contribute to the device’s mobility and stability.

Next, focus on the operational sections, such as seeding mechanisms and fertilizer distribution systems. Understanding how these interact can help in achieving the desired outcomes during usage.

Lastly, pay attention to the control and monitoring units. These features are essential for adjusting settings and ensuring that everything operates within the intended parameters, leading to the ultimate efficiency of the equipment.

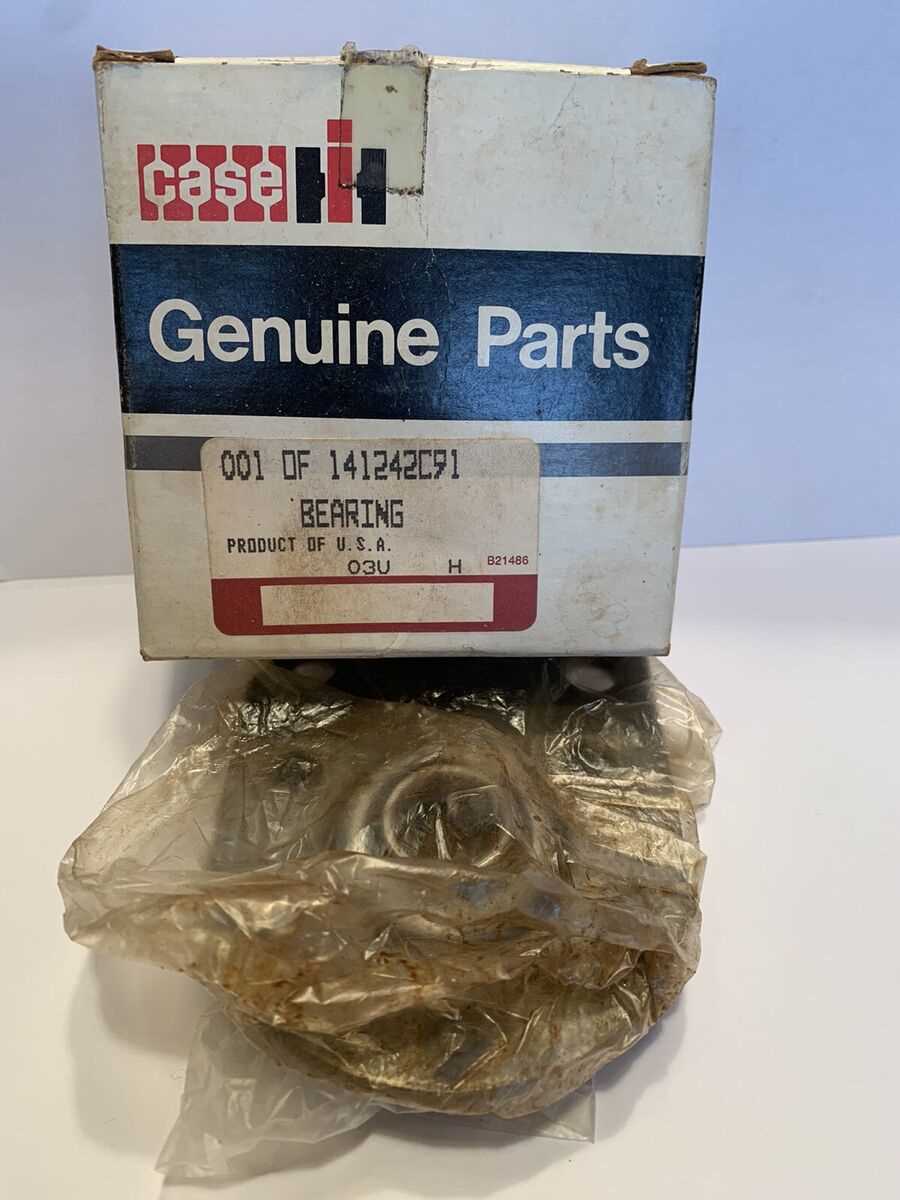

Common Replacement Parts for 900 Planters

Maintaining optimal performance of agricultural equipment often requires replacing worn or damaged components. Understanding the typical elements that may need attention can enhance efficiency and prolong the lifespan of your machinery. Here, we highlight essential components frequently requiring replacement.

- Seed Discs: Critical for accurate seed placement, these discs can wear out over time, affecting planting precision.

- Gauging Wheels: Ensuring proper depth during planting, these wheels may become damaged or lose effectiveness, necessitating replacement.

- Closing Wheels: Vital for soil coverage post-seeding, worn closing wheels can lead to poor seed-to-soil contact.

- Furrow Openers: These elements are essential for creating the planting trench and may dull with use, requiring periodic replacement.

- Spring Assemblies: Springs that assist in maintaining tension can weaken, impacting the overall operation of the unit.

- Frame Components: Structural elements may sustain damage during operation, necessitating replacements to ensure stability and function.

Regular inspections and timely replacements of these key components can significantly improve performance and yield, making it crucial for operators to stay informed about their condition and potential wear.

How to Read Parts Diagrams Effectively

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide crucial information about the various elements of machinery, helping users identify and locate specific items with ease.

Start with a Key: Before delving into the visual, familiarize yourself with any accompanying legends or keys. These often explain symbols and numbers, offering clarity on how to interpret the image.

Identify Major Sections: Break down the illustration into major categories. Recognizing the primary groups of components can streamline the process of finding what you need.

Focus on Labels: Pay attention to labeled parts. These annotations often provide vital information such as part numbers, descriptions, and their relationships to other elements.

Trace Connections: Follow lines or arrows that indicate connections between various components. This can help you understand how different pieces interact and function together.

Use Additional Resources: Don’t hesitate to consult manuals or online resources for further information. Supplementing visual data with text can enhance your overall comprehension.

By approaching these illustrations methodically, you can significantly improve your ability to navigate and utilize the information presented, ensuring more effective repairs and maintenance.

Top Suppliers for Case IH Parts

When it comes to maintaining agricultural machinery, sourcing high-quality components is essential for optimal performance and longevity. Numerous suppliers specialize in offering a wide array of items that cater to the needs of farmers and machinery operators. Understanding the best options available can significantly enhance operational efficiency.

Leading Manufacturers

Renowned manufacturers provide an extensive range of items that ensure compatibility and reliability. These brands are often recognized for their commitment to quality and innovation, making them a top choice for those seeking dependable components.

Online Retailers

In today’s digital age, many online platforms specialize in agricultural equipment supplies. These retailers offer convenience, competitive pricing, and often a vast selection, allowing customers to easily find what they need with just a few clicks.

Common Issues with Planting Equipment

Understanding the frequent challenges encountered with agricultural machinery can enhance operational efficiency and crop yields. Regular maintenance and awareness of common faults are essential for any farmer or operator.

Frequent Challenges

- Worn-out components leading to ineffective planting

- Improper calibration resulting in uneven seed distribution

- Blockages caused by debris, affecting performance

Preventive Measures

- Conduct regular inspections to identify wear and tear.

- Calibrate equipment before each planting season.

- Keep the machinery clean to prevent clogs.

Upgrades for Improved Planting Performance

Enhancing agricultural efficiency often hinges on the implementation of advanced technologies and components. By integrating innovative solutions, growers can achieve superior results, ensuring optimal seed placement and overall crop health.

Key Enhancements

- Precision Seed Placement Systems

- Advanced Monitoring Sensors

- Improved Soil Penetration Tools

- Adjustable Row Spacing Mechanisms

Benefits of Upgrading

- Increased Yield Potential

- Reduced Seed Wastage

- Enhanced Soil Health

- Improved Operational Efficiency

Tips for Troubleshooting Planting Problems

Addressing issues during the sowing process can be crucial for ensuring optimal crop yields. Identifying and resolving these challenges early can prevent further complications down the line.

- Check Seed Depth: Ensure seeds are planted at the appropriate depth to promote healthy growth.

- Inspect Equipment: Regularly examine your machinery for wear and tear that could impact performance.

- Monitor Soil Conditions: Assess moisture levels and soil type to ensure compatibility with the chosen seeds.

Utilizing these strategies can help you effectively diagnose and remedy common sowing issues, leading to a more successful planting season.

Comparative Analysis of Planter Models

This section provides an in-depth exploration of various seeding equipment, emphasizing their unique features, benefits, and drawbacks. By examining the distinctions among different models, users can make informed decisions based on their specific agricultural needs.

Key factors to consider include:

- Design and functionality

- Seed placement accuracy

- Ease of operation and maintenance

- Durability and reliability

Below is a comparison of some notable models:

- Model A:

- High precision in seed depth control

- Robust construction for longevity

- Complex operation requiring skilled handling

- Model B:

- User-friendly interface and operation

- Moderate accuracy in seed placement

- Lightweight design for easy maneuverability

- Model C:

- Exceptional durability under tough conditions

- High seed capacity, ideal for large fields

- Requires regular maintenance to ensure optimal performance

By analyzing these models, growers can ultimately identify the best equipment to enhance productivity and efficiency in their operations.

Resources for Technical Support and Manuals

Accessing reliable information and assistance is crucial for maintaining agricultural machinery. Numerous platforms provide detailed guidance, troubleshooting tips, and user manuals to enhance operational efficiency. These resources empower users to effectively manage their equipment and ensure optimal performance.

For comprehensive support, consider visiting the official website of the manufacturer, where you can find downloadable manuals and technical documents. Additionally, forums and online communities dedicated to agricultural equipment offer a wealth of shared knowledge and experiences from fellow users.

Online retailers also frequently stock manuals and provide access to specific documentation, ensuring you can find the necessary information for your machinery. Utilizing these resources can ultimately save time and enhance the longevity of your equipment.

Remember to always verify the source of your information to ensure accuracy and reliability when seeking support.