Toyota Camry Engine Parts Diagram

In the realm of automotive mechanics, comprehending the layout of critical components is essential for maintenance and repair. This overview serves as a guide to help enthusiasts and professionals alike navigate the intricate design of a vehicle’s interior mechanisms. By grasping the arrangement and function of these elements, one can enhance performance and ensure longevity.

Each section of the vehicle’s assembly plays a vital role in its overall functionality. From the ignition system to the cooling apparatus, understanding how these components interact is fundamental. This information not only aids in troubleshooting but also fosters a deeper appreciation for automotive engineering.

Whether you are an experienced mechanic or a novice car owner, familiarizing yourself with the configuration of essential elements can empower you to make informed decisions. By engaging with this knowledge, you can optimize your vehicle’s operation and address potential issues before they escalate.

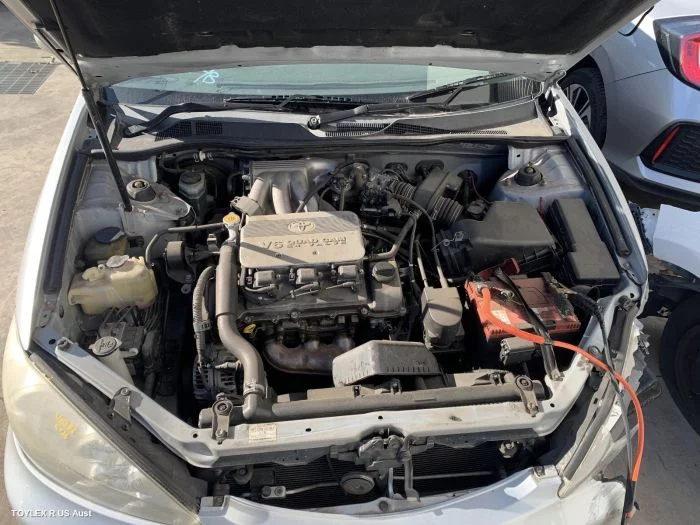

Toyota Camry Engine Overview

This section offers a comprehensive look at the key components that contribute to the performance and functionality of a specific automotive power unit. Understanding these elements is essential for those interested in maintenance or enhancement of vehicle capabilities.

Key Features and Functions

The design and arrangement of the various components play a crucial role in ensuring efficiency and reliability. Each element serves a distinct purpose, contributing to overall operation and longevity.

Maintenance Considerations

Regular upkeep of these crucial components can prevent premature wear and enhance performance. Awareness of potential issues allows for timely interventions, ensuring optimal functionality over time.

Components Ensuring Fuel Efficiency

In modern vehicles, various elements play a crucial role in optimizing fuel consumption. These components work together to enhance performance while minimizing waste, leading to better mileage and lower emissions.

Innovative Fuel Delivery Systems

Advanced systems for fuel delivery ensure precise amounts of fuel reach the combustion chamber. This accuracy maximizes combustion efficiency, ultimately improving energy use. Techniques like direct injection contribute significantly to reducing excess fuel consumption.

Efficient Air Intake Mechanisms

Well-designed air intake systems facilitate optimal airflow, which is vital for effective combustion. By enhancing the mixture of air and fuel, these mechanisms ensure that the engine operates at peak efficiency. The result is not only improved power output but also increased fuel economy.

Main Systems Supporting Engine Cooling

The effective regulation of temperature within a mechanical unit is vital for optimal performance and longevity. Several interconnected systems work collaboratively to ensure that excessive heat is dissipated efficiently.

- Cooling Fluid Circulation: This system circulates coolant through various components to absorb heat and maintain a stable operating temperature.

- Radiator Functionality: A core element that facilitates heat exchange, allowing the heated fluid to cool before recirculating.

- Thermostatic Control: This component regulates the flow of coolant based on temperature, ensuring the system operates within designated parameters.

- Cooling Fan Operation: Fans assist in airflow across the radiator, enhancing the cooling process, particularly during stationary periods or low-speed driving.

Each of these systems plays a critical role in preventing overheating, ultimately contributing to the overall efficiency and reliability of the machinery.

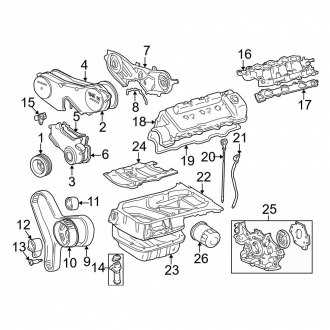

Air Intake and Exhaust Layout

The design of the air intake and exhaust system plays a crucial role in the performance and efficiency of any vehicle. This configuration ensures that the optimal amount of air flows into the combustion chamber while allowing exhaust gases to exit effectively. A well-engineered setup contributes to improved power output and reduced emissions.

Key Components of the System

Understanding the primary components is essential for appreciating how air enters and exits the system. The intake manifold directs air from the filter to the cylinders, while the exhaust manifold channels spent gases away from the combustion area. Both elements work in harmony to optimize airflow and enhance overall performance.

Impact on Performance

A properly designed layout can significantly affect vehicle dynamics. Enhanced airflow leads to better combustion efficiency, resulting in increased horsepower. Additionally, a streamlined exhaust path minimizes back pressure, allowing the engine to operate more smoothly and efficiently. Ultimately, these improvements contribute to a more responsive driving experience.

Critical Sensors for Smooth Performance

The functionality of modern vehicles relies heavily on a variety of vital monitoring devices that ensure optimal operation. These components work together to provide accurate data, facilitating seamless interactions between various systems and enhancing overall efficiency.

Key Monitoring Devices

Understanding the essential devices that contribute to a vehicle’s performance can lead to improved maintenance and timely repairs. These monitoring tools play a crucial role in adjusting various parameters for better handling and fuel economy.

| Device Name | Function |

|---|---|

| Mass Airflow Sensor | Measures air intake for fuel optimization |

| Throttle Position Sensor | Tracks accelerator pedal position for response |

| Cylinder Head Temperature Sensor | Monitors temperature to prevent overheating |

| Oxygen Sensor | Analyzes exhaust gases for emissions control |

Importance of Regular Checks

Regular assessments of these monitoring devices are essential to maintain performance levels. Timely identification of any discrepancies can prevent more significant issues, ensuring a smooth and reliable driving experience.

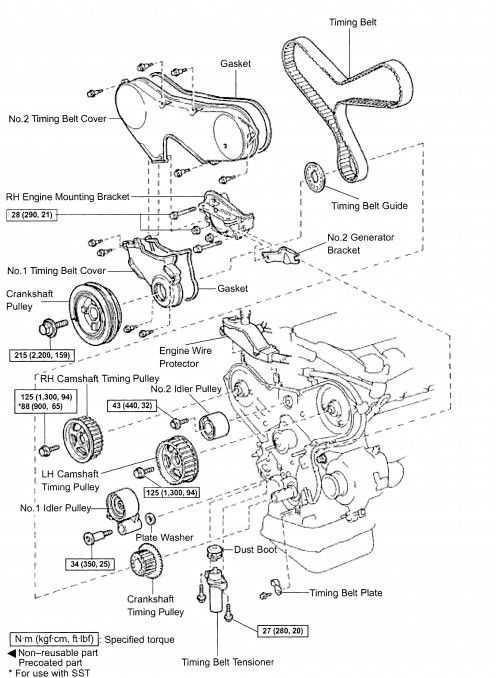

Parts Responsible for Ignition Timing

The components that govern the timing of combustion are crucial for optimal performance and efficiency. These elements work in harmony to ensure that the ignition occurs at precisely the right moment, which is essential for smooth operation.

Key Components Involved

Several key elements play a vital role in managing ignition timing. Each component contributes uniquely to the overall function, affecting power delivery and fuel efficiency.

| Component | Function |

|---|---|

| Distributor | Directs high voltage to the correct cylinder at the right moment. |

| Ignition Coil | Transforms battery voltage to create a spark for combustion. |

| Timing Belt | Synchronizes the rotation of various engine elements for accurate timing. |

| Crankshaft Position Sensor | Monitors crankshaft position to determine timing adjustments. |

Importance of Accurate Timing

Precise ignition timing is crucial for maximizing engine efficiency and minimizing emissions. Any deviation can lead to performance issues, highlighting the importance of these components in maintaining optimal operation.

Understanding the Role of Pistons

Pistons play a crucial part in the functionality of an internal combustion mechanism. They act as the moving components that convert the energy produced during fuel combustion into mechanical force. This transformation is vital for generating the power necessary for the operation of various systems.

Functionality and Movement

The primary task of these components is to move within a cylinder, creating pressure and enabling the combustion of fuel. As the combustion occurs, the force generated pushes the piston downward, initiating a cycle that ultimately leads to the rotation of the crankshaft. This process is essential for maintaining the motion required for performance.

Materials and Design Considerations

Constructed from durable materials, these components must withstand extreme temperatures and pressures. Their design influences not only performance but also efficiency. A well-engineered piston can enhance the overall effectiveness of the entire system.

| Material | Temperature Resistance | Weight |

|---|---|---|

| Aluminum | Up to 300°C | Lightweight |

| Steel | Up to 600°C | Heavier |

| Forged Alloys | Varies | Medium |

Mechanisms Involved in Oil Circulation

The circulation of lubricant fluid within a mechanical assembly is essential for maintaining optimal performance and longevity. This process involves several interconnected components that work together to ensure that the viscous substance reaches critical areas, reducing friction and preventing wear.

Key Components

- Pump: Initiates the movement of the fluid throughout the system.

- Filter: Removes impurities, ensuring clean fluid flows to vital areas.

- Passages: Channels designed to guide the lubricant to various sections.

Operational Process

- The pump draws lubricant from the reservoir.

- The fluid is filtered to eliminate debris and contaminants.

- It then travels through designated pathways to lubricate moving elements.

- After lubrication, it returns to the reservoir for reconditioning.

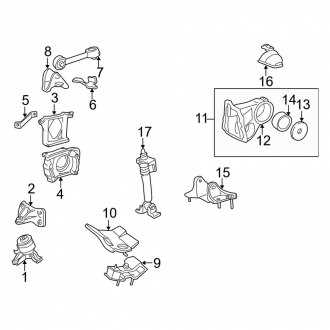

How Belts and Chains Operate

In mechanical systems, flexible loops are essential for transferring motion between various components. These elements ensure that rotational force is effectively conveyed, allowing for synchronized operation of different parts within the assembly.

There are two primary types of these mechanisms: belts and chains. Each type serves a similar purpose but operates under different principles and conditions. Below is a comparison highlighting their characteristics.

| Feature | Belts | Chains |

|---|---|---|

| Material | Rubber or composite | Metal links |

| Flexibility | Highly flexible | Less flexible |

| Noise Level | Quieter operation | Generally noisier |

| Durability | Subject to wear | More durable |

| Maintenance | Requires periodic checks | Needs lubrication |

Understanding the distinctions between these two types enhances insight into their roles in ensuring effective mechanical operation, showcasing how each contributes to the overall functionality of the system.

Electrical Components Within the Engine

The heart of any vehicle’s functionality relies heavily on a variety of electrical systems that ensure smooth operations. These systems are crucial for performance, monitoring, and control, serving as the nervous system for the machinery.

Key Functions of Electrical Systems

Electrical components play vital roles, including power distribution and management of various functionalities. They facilitate communication between critical systems, allowing for effective monitoring of operational status and performance metrics.

Components and Their Importance

Various devices such as sensors and actuators are essential for the overall efficiency of the machinery. Sensors provide real-time data, enabling adjustments to maintain optimal performance, while actuators respond to control signals to regulate different processes.

Diagnosing Common Engine Issues

Identifying typical problems in automotive machinery can be crucial for maintaining optimal performance. Understanding the signs and symptoms is the first step in troubleshooting effectively. This section will outline common indicators that may suggest underlying difficulties.

| Symptom | Possible Cause |

|---|---|

| Unusual Noises | Worn components or loose fittings |

| Decrease in Power | Fuel delivery issues or air intake blockages |

| Excessive Exhaust Smoke | Burning oil or coolant leaks |

| Rough Idling | Faulty spark plugs or air-fuel mixture imbalance |

| Overheating | Cooling system failure or low coolant levels |

By observing these indicators, owners can take proactive steps to address any mechanical concerns before they escalate into more significant issues.

Maintenance Tips for Long Engine Life

To ensure the longevity of your vehicle’s power unit, regular upkeep is essential. Consistent care not only enhances performance but also prevents costly repairs down the line. Adopting a proactive approach can significantly extend the lifespan of crucial components.

One of the most effective ways to maintain optimal functionality is to follow a scheduled oil change regimen. Fresh lubricant minimizes friction and wear, promoting smoother operation. Additionally, regularly checking fluid levels and topping them off when necessary helps maintain the system’s efficiency.

Furthermore, monitoring the state of belts and hoses is vital. Replacing these components at the first sign of wear can avert unexpected breakdowns. It’s also advisable to keep an eye on the cooling system, ensuring that it operates effectively to prevent overheating.

Lastly, adhering to manufacturer-recommended service intervals is crucial. This includes inspections and replacements of filters and spark plugs. Following these guidelines will contribute to a reliable performance and enhance the overall durability of the vehicle’s core mechanisms.