Understanding the Ls Tractor Parts Diagram for Optimal Maintenance

In the realm of agricultural equipment, a thorough comprehension of each individual segment is essential for optimal functionality. This exploration will guide enthusiasts and professionals alike in identifying and utilizing the various elements that contribute to the overall performance of these powerful machines.

By breaking down the intricate assembly of these vehicles, one can gain valuable insights into their operation and maintenance. This knowledge not only enhances efficiency but also extends the lifespan of the equipment, ensuring that it meets the demanding needs of its users.

Ultimately, a detailed examination of these crucial components empowers operators to make informed decisions, streamline repairs, and enhance productivity in their daily tasks. Join us as we delve into this fascinating topic, uncovering the significance of each piece in the larger mechanical puzzle.

Understanding LS Tractor Components

Grasping the intricacies of machinery involves recognizing the essential elements that work in harmony to ensure optimal performance. Each component plays a vital role, contributing to the overall functionality and efficiency of the equipment. By exploring these critical elements, one can appreciate how they interact and support one another.

Engine: The heart of any machine, this unit converts fuel into power, driving all other functions. Regular maintenance ensures longevity and efficiency.

Transmission: This mechanism transmits power from the engine to the wheels, allowing for varied speeds and torque. Understanding its configuration aids in better handling.

Hydraulic System: Vital for lifting and moving heavy loads, this system utilizes fluid to generate force, making tasks easier and more efficient.

Chassis: The framework supports all components, providing stability and strength, essential for durability in various conditions.

By delving into these elements, users can enhance their knowledge and improve their equipment’s performance.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in understanding complex systems. They serve as essential tools for maintenance and repair, ensuring efficiency and reliability.

- Facilitate quick identification of components

- Enhance comprehension of assembly and functionality

- Minimize errors during installation and service

- Support effective training for new technicians

Ultimately, having accurate visuals fosters confidence and expertise, allowing users to delve deeper into their equipment’s inner workings.

Common Parts in LS Tractors

Understanding the essential components of LS machinery is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring efficiency and longevity, enabling operators to achieve their goals effectively.

| Component | Description |

|---|---|

| Engine | The heart of the machine, providing the necessary power for operation. |

| Transmission | Facilitates movement by controlling speed and torque. |

| Hydraulic System | Enables lifting and maneuvering of implements with ease. |

| Chassis | Supports all components, ensuring stability and durability. |

| Cooling System | Prevents overheating by regulating engine temperature. |

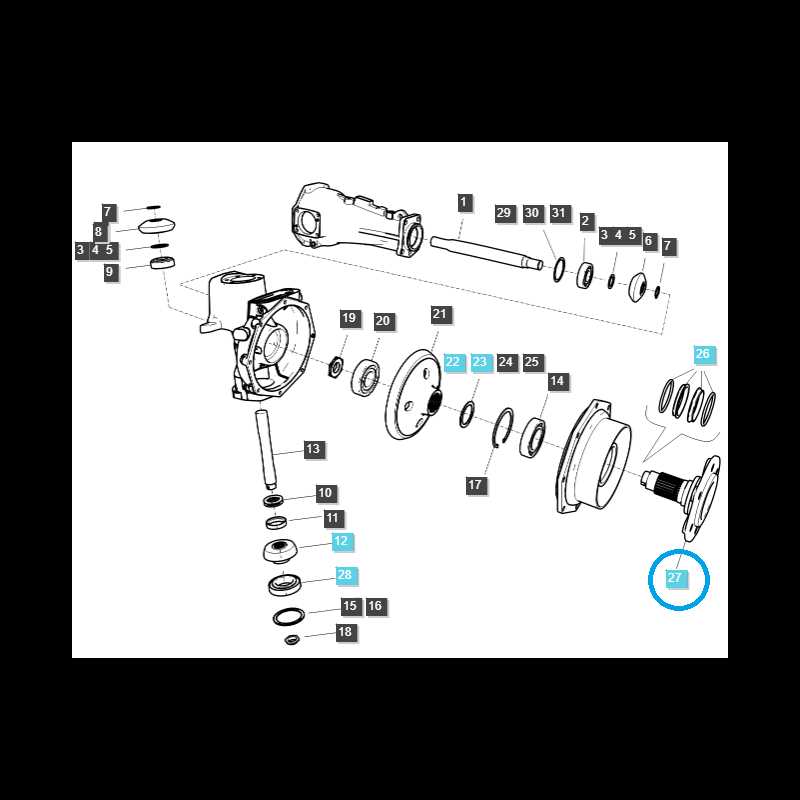

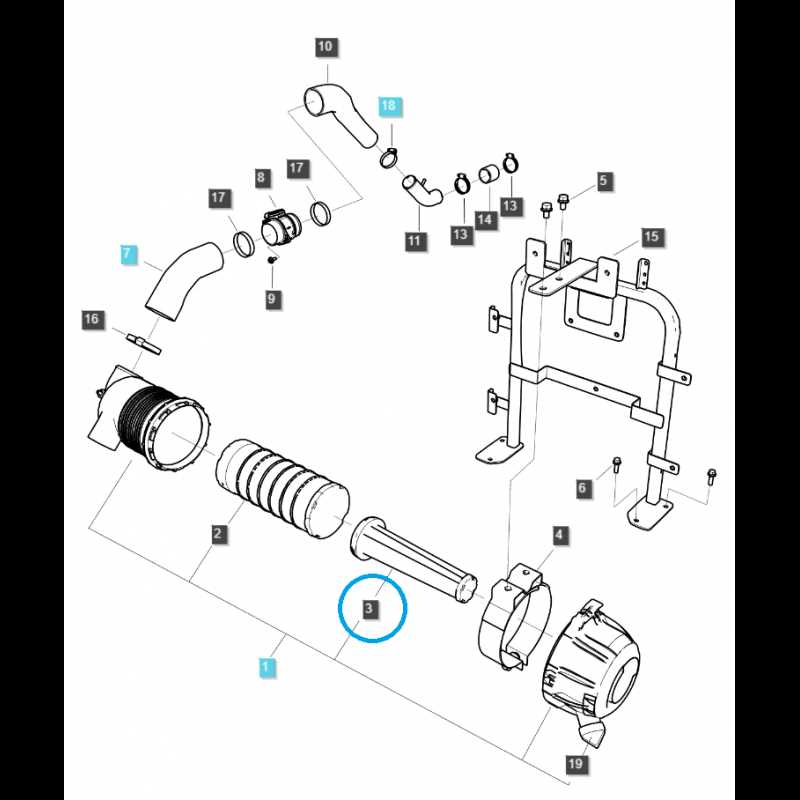

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate such illustrations with ease, ensuring you can identify and utilize each element efficiently.

To begin, familiarize yourself with the layout:

- Key Symbols: Each image features specific icons representing different elements. Knowing these will aid in quick recognition.

- Labeling: Most visuals include labels that correspond to component numbers. Cross-reference these with the accompanying list for clarity.

- Grouping: Components are often grouped by function or location. Understanding these clusters can streamline your approach to repairs.

As you delve deeper, consider the following steps:

- Start with the overview to get a sense of the whole assembly.

- Identify critical components relevant to your task.

- Refer back to the labeled list for specifications or part numbers.

By mastering these techniques, you’ll enhance your ability to interpret visual guides and ensure successful assembly or disassembly. Ultimately, this knowledge will empower you to tackle repairs with confidence.

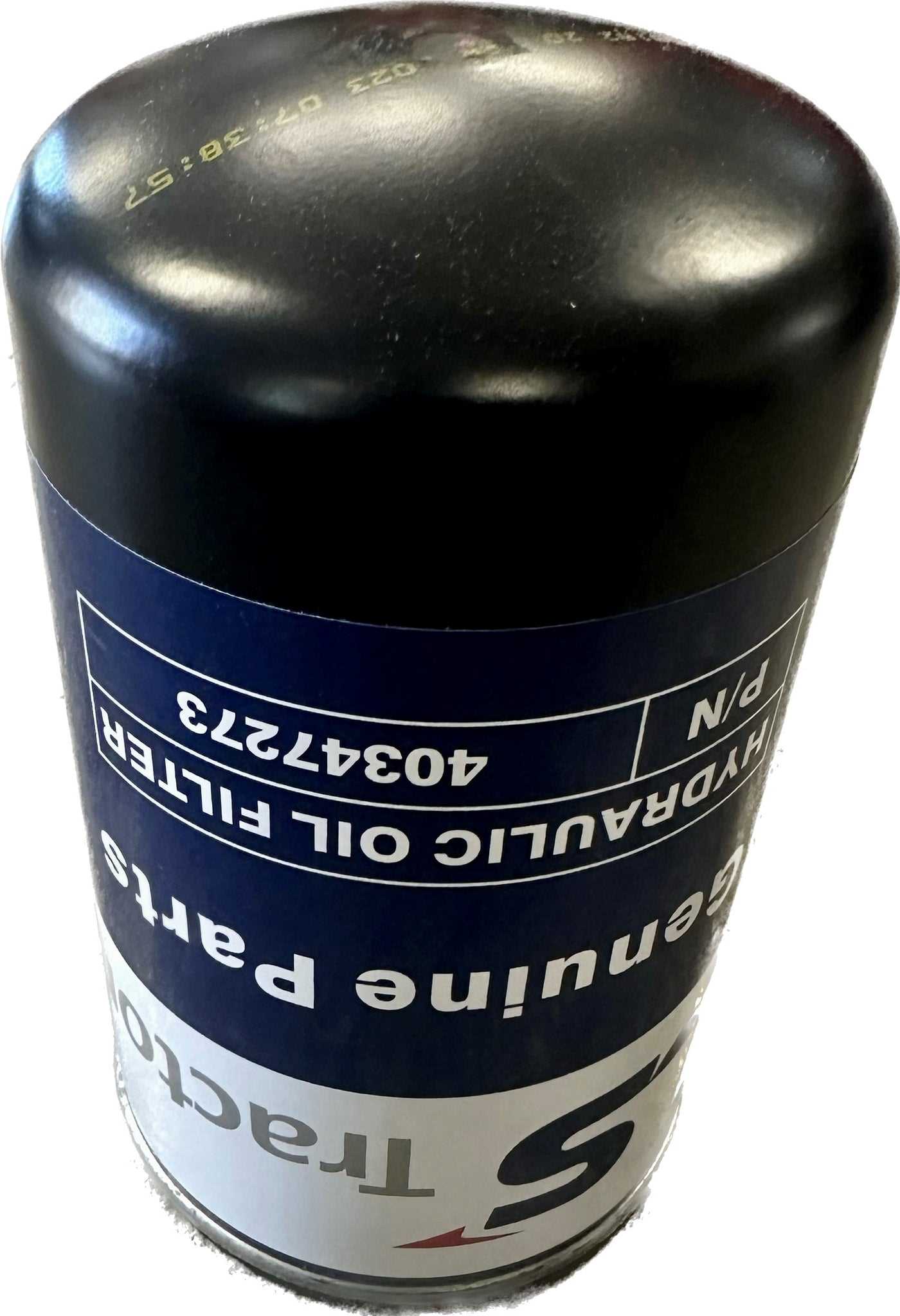

Benefits of Using OEM Parts

Choosing original equipment manufacturer components can greatly enhance the performance and longevity of your machinery. These components are specifically designed to meet the exact specifications required for optimal functioning. Below are some key advantages of utilizing these original products.

- Quality Assurance: OEM items are manufactured to the highest standards, ensuring reliability and durability.

- Perfect Fit: Original components provide a precise fit, reducing the risk of operational issues and minimizing the need for adjustments.

- Enhanced Performance: Using OEM items can lead to better efficiency and overall performance of the machinery.

- Warranty Protection: Many manufacturers offer warranties on their original components, providing peace of mind and protection against defects.

- Increased Resale Value: Machinery maintained with original components often retains a higher resale value, appealing to potential buyers.

Investing in original equipment manufacturer products is a smart choice for ensuring the longevity and efficiency of your equipment.

Identifying Replacement Components

Understanding the elements that require substitution is crucial for maintaining optimal performance. Recognizing the specific components and their functions can enhance the longevity and efficiency of your equipment.

| Component Name | Description | Signs of Wear |

|---|---|---|

| Engine Block | The main structure housing the engine’s internal parts. | Unusual noises, oil leaks |

| Hydraulic Cylinder | Transmits power through hydraulic fluid. | Loss of pressure, visible damage |

| Drive Belt | Connects the engine to various systems. | Cracks, fraying, slipping |

Maintenance Tips for LS Tractors

Regular upkeep is essential for optimal performance and longevity of your equipment. Adopting a routine maintenance schedule can prevent potential issues and enhance efficiency.

- Check fluid levels regularly to ensure proper operation.

- Inspect filters and replace them as necessary to maintain airflow and fluid cleanliness.

- Keep the exterior clean to prevent rust and corrosion.

- Examine belts and hoses for wear and replace them if needed.

- Monitor tire pressure to ensure stability and traction.

Additionally, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures.

Resources for Parts Lookup

Finding the right components for your machinery can be streamlined with various resources available online and offline. Utilizing these tools will help you efficiently identify what you need for repairs or upgrades.

- Official Manufacturer Websites: Many manufacturers provide extensive catalogs that allow users to search for specific items by model or serial number.

- Online Marketplaces: Platforms like eBay or Amazon often have user-friendly search options for a wide range of components.

- Community Forums: Engaging with forums dedicated to machinery enthusiasts can yield valuable insights and recommendations for sourcing components.

- Local Dealerships: Visiting nearby dealers can provide access to original equipment and knowledgeable staff who can assist with inquiries.

Leveraging these resources ensures that you can quickly locate the necessary items to maintain optimal performance of your equipment.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining equipment, the choice between original components and alternatives can greatly influence performance and longevity. Each option offers unique advantages and potential drawbacks, making it essential for users to understand their differences before making a decision.

Quality and Reliability

Original components are often manufactured to the exact specifications of the original design, ensuring a precise fit and optimal performance. This can lead to increased reliability and fewer issues over time. In contrast, aftermarket options may vary in quality, as they are produced by third-party manufacturers. While some aftermarket items can provide satisfactory performance, others might not meet the same standards, which could result in unexpected complications.

Cost Considerations

Cost is a significant factor in the decision-making process. OEM options tend to be more expensive due to their brand reputation and guaranteed compatibility. However, aftermarket alternatives often come at a lower price point, making them an attractive choice for budget-conscious users. It is crucial to weigh the potential savings against the risk of inferior quality, which could lead to higher maintenance costs in the long run.

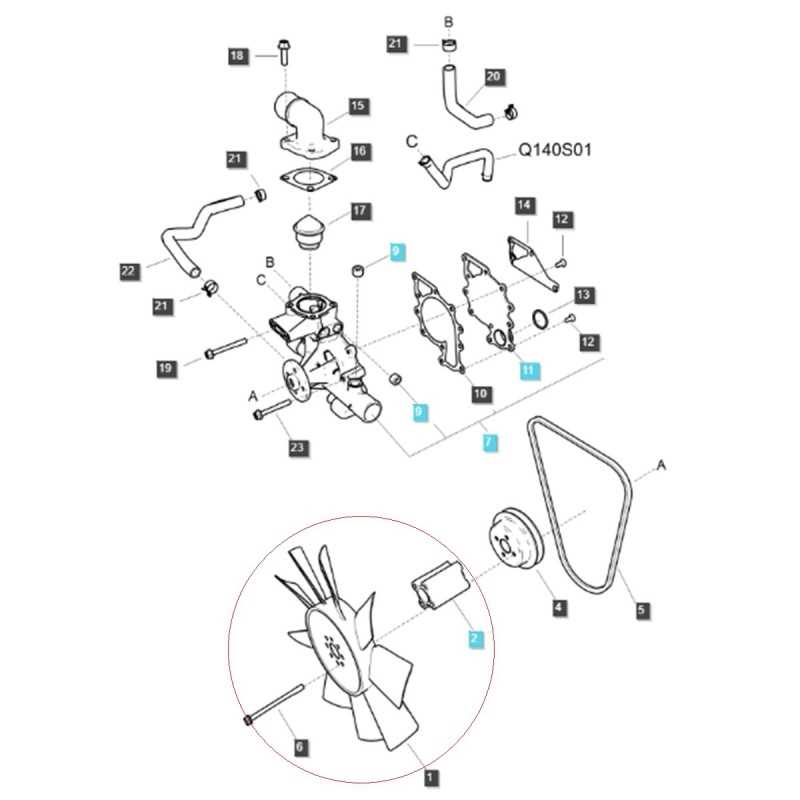

Understanding Hydraulic System Parts

The hydraulic system is a crucial component of many machines, playing a significant role in transferring power and enabling movement. This system operates using fluid to transmit force, allowing for efficient operation of various functions. Understanding its elements is essential for maintenance and troubleshooting, ensuring optimal performance and longevity.

Key components of a hydraulic setup include the following:

| Component | Description |

|---|---|

| Pump | Generates pressure by moving hydraulic fluid through the system. |

| Reservoir | Stores hydraulic fluid and allows for expansion and heat dissipation. |

| Actuator | Converts hydraulic energy into mechanical motion, enabling movement of various components. |

| Valves | Control the flow and direction of the hydraulic fluid, allowing for precise operation. |

| Hoses and Fittings | Transport hydraulic fluid between different components, ensuring a closed system. |

By familiarizing oneself with these critical elements, operators can better understand how to maintain and troubleshoot the hydraulic system effectively, leading to enhanced performance and reliability.

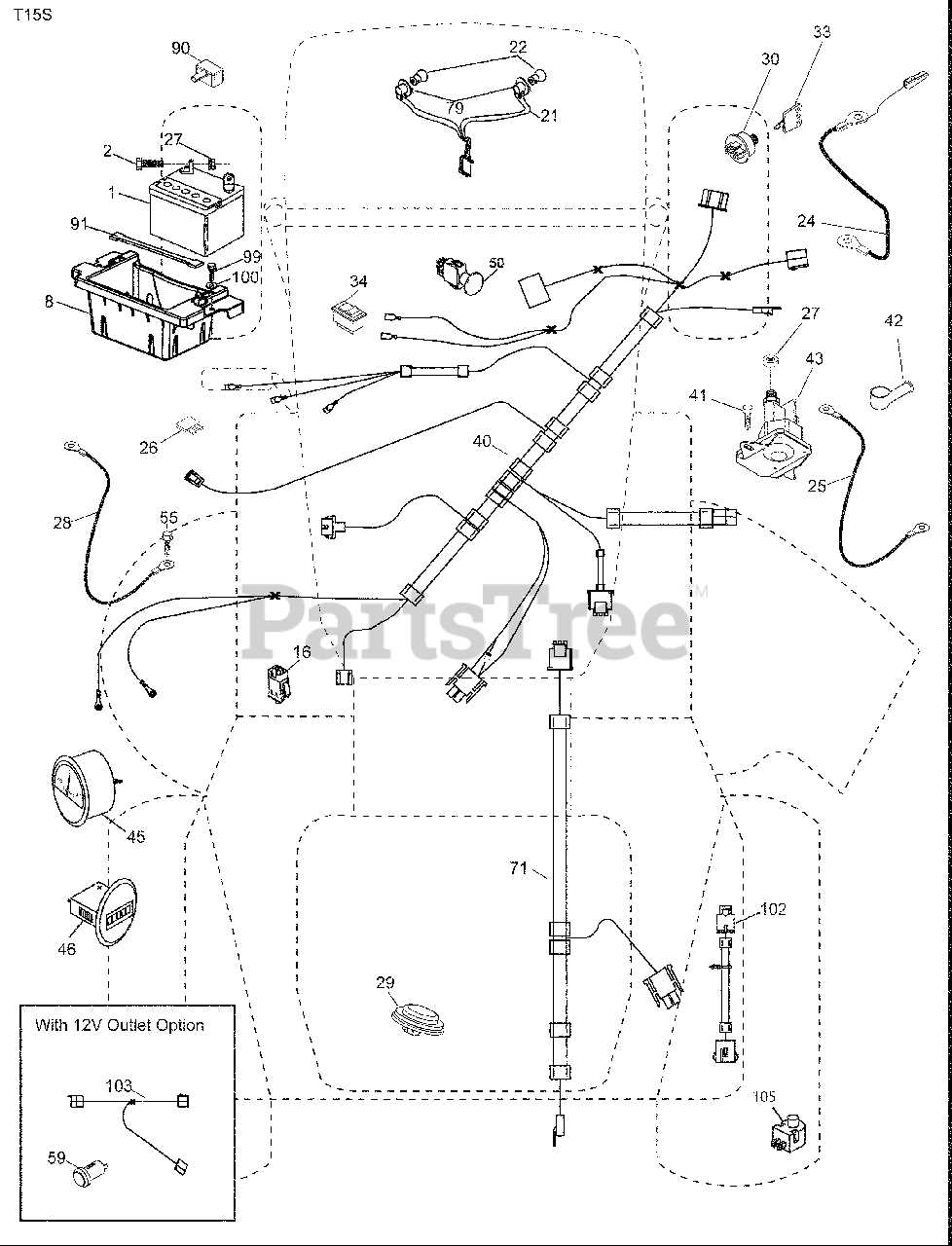

Electrical Components in LS Tractors

The electrical systems in LS machinery are crucial for optimal performance and functionality. These components ensure that various systems operate efficiently, contributing to overall reliability and user experience.

Battery serves as the primary energy source, providing the necessary power for ignition and operation of electrical systems. A well-maintained battery enhances performance and longevity.

Alternator is responsible for charging the battery while the engine is running, ensuring a consistent power supply. Its efficiency directly affects the reliability of electrical functions.

Starter Motor initiates the engine’s operation, converting electrical energy into mechanical energy. A robust starter is essential for quick and reliable starts, especially in challenging conditions.

Wiring Harness connects all electrical components, facilitating the flow of electricity throughout the system. Proper routing and insulation of wires are critical to prevent shorts and ensure safety.

Fuse Box protects the electrical system from overloads and short circuits by breaking the circuit when necessary. Regular inspection and replacement of fuses help maintain system integrity.

Understanding these electrical elements allows users to appreciate the engineering behind LS equipment and highlights the importance of regular maintenance to ensure optimal functionality.

Where to Purchase LS Parts

Finding the right components for your LS machinery can significantly enhance performance and longevity. Various options are available to acquire these essential items, ensuring you have what you need to maintain efficiency.

Authorized Dealers are a reliable source, as they provide genuine items specifically designed for your equipment. You can expect quality and support from these establishments.

Online Retailers also offer a vast selection, often at competitive prices. Websites dedicated to heavy equipment supplies can be particularly useful, providing user reviews and detailed descriptions.

Local equipment supply stores may stock a range of necessary components, allowing for immediate purchases without the wait for shipping.

Lastly, specialty forums and community groups can connect you with sellers offering used or hard-to-find items, often at lower costs. Engaging with fellow enthusiasts can lead to great deals and insights.