Comprehensive Guide to Cummins M11 Parts Diagram

In the intricate world of machinery, the functionality of an engine relies heavily on the interconnection of various elements. Each component plays a crucial role, contributing to the overall performance and efficiency of the system. To navigate this complex landscape, it’s essential to explore the layout and relationship of these elements.

Grasping the intricacies of engine assemblies allows for better maintenance and troubleshooting. With a detailed exploration, individuals can enhance their understanding, ensuring that each part operates in harmony. A thorough overview can ultimately lead to improved performance and longevity.

Diving deeper into the specifics of these components equips users with the knowledge needed to identify and resolve potential issues effectively. As we examine the structure and functions, we unveil the ultimate connection between each piece, fostering a comprehensive appreciation for the entire system.

Engine Overview

This section provides a comprehensive look at a robust engine known for its reliability and performance in various applications. Designed for heavy-duty use, this power unit is a preferred choice in many industrial settings.

Key characteristics of this engine include:

- High durability and strength

- Efficient fuel consumption

- Advanced technology for improved emissions control

- Versatile applications across different sectors

Typical features include:

- Power output ranging from moderate to high levels

- Multiple configurations for diverse operational needs

- Robust cooling systems to maintain optimal temperatures

- Easy maintenance access for service technicians

This engine is well-regarded for its longevity and performance under demanding conditions, making it a staple in the heavy machinery market.

Key Components of the M11

The functionality and performance of a heavy-duty engine rely heavily on its essential elements. Understanding these crucial components is vital for ensuring optimal operation and maintenance. Each part plays a specific role in the overall system, contributing to efficiency and reliability.

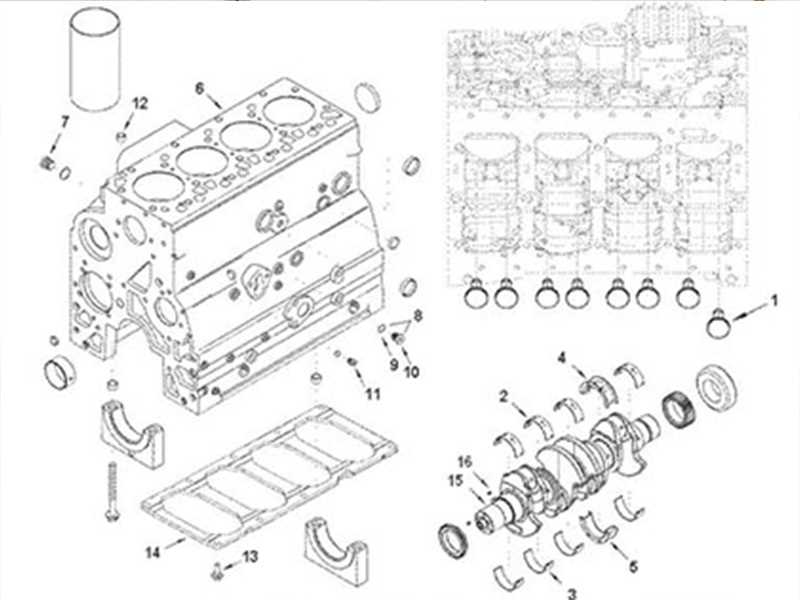

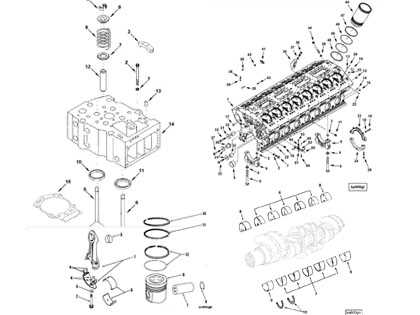

Engine Block and Cylinder Head

The foundation of the engine comprises the block and the cylinder head. The engine block houses the cylinders and supports various components, while the cylinder head contains the combustion chambers and intake/exhaust valves. Together, they facilitate the combustion process and help manage the engine’s thermal dynamics.

Fuel System and Turbocharger

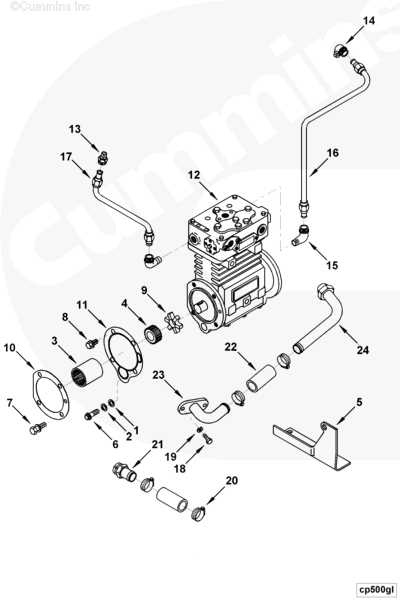

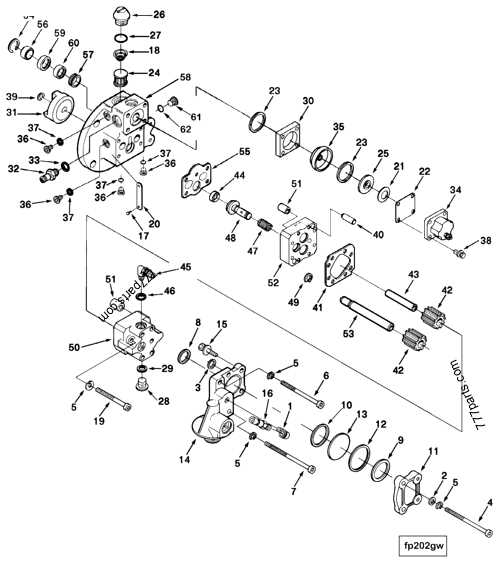

The fuel system is responsible for delivering the necessary fuel for combustion, ensuring optimal performance and efficiency. Meanwhile, the turbocharger increases the intake air pressure, enhancing the engine’s power output. Both systems are integral for achieving high levels of performance and meeting emission standards.

Understanding Parts Diagrams

Comprehending assembly illustrations is crucial for effective maintenance and repair of complex machinery. These visual representations serve as blueprints, showcasing how components fit together and interact within a system. By analyzing these schematics, one can gain insights into the function of each element and identify potential issues more efficiently.

Each segment of the illustration typically highlights specific pieces, often accompanied by reference numbers or labels. This organized approach allows technicians to quickly locate and understand individual elements, facilitating streamlined repairs. Moreover, familiarity with these visual aids enhances troubleshooting skills, enabling users to pinpoint malfunctions and devise appropriate solutions.

In addition, a thorough understanding of assembly visuals fosters better communication among team members. When everyone interprets the same illustration, it reduces the risk of misunderstandings and errors during the repair process. This collective knowledge contributes to more efficient workflows and ultimately leads to improved equipment longevity and performance.

Importance of Maintenance for M11

Regular upkeep of heavy machinery is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to costly repairs and decreased efficiency. By adhering to a routine maintenance schedule, operators can prevent unexpected breakdowns and enhance the overall reliability of their equipment.

Benefits of Preventive Care

Implementing preventive measures can significantly reduce the risk of mechanical failures. Regular inspections and timely replacements of worn components contribute to smooth operation. Moreover, this proactive approach helps in identifying potential issues before they escalate, ultimately saving time and resources.

Cost Efficiency and Performance

Investing in consistent maintenance translates to better fuel efficiency and enhanced performance. Well-maintained machinery operates more effectively, leading to lower operational costs. Additionally, maintaining optimal conditions allows for peak performance, ensuring that the equipment meets the demands of various applications.

In conclusion, prioritizing routine upkeep is essential for maximizing the lifespan and functionality of heavy equipment. A commitment to maintenance not only protects investments but also ensures that machinery remains reliable in the long run.

Common Issues with Cummins M11

Engines of this particular model can experience various challenges that may impact their performance and reliability. Understanding these issues is essential for effective maintenance and longevity.

Frequent Problems

- Oil Leaks

- Overheating

- Fuel System Failures

- Cooling System Issues

- Electrical Failures

Preventative Measures

- Regular Oil Changes

- Consistent Monitoring of Temperature

- Routine Inspection of Fuel Lines

- Thorough Checks of the Cooling System

- Electrical System Diagnostics

By addressing these common concerns proactively, operators can ensure smoother operation and reduce the likelihood of costly repairs.

Replacement Parts for M11 Engines

Maintaining optimal performance in heavy-duty machinery relies heavily on the availability of suitable components. Understanding the various elements that contribute to the efficient functioning of these engines is crucial for any operator or technician. This section explores essential substitutes that ensure longevity and reliability in operation.

Common Components for Replacement

When dealing with high-performance engines, several key elements often require replacement over time. Ensuring you have access to the right substitutes can significantly enhance operational efficiency.

| Component | Description |

|---|---|

| Cylinder Head | Vital for sealing the combustion chamber and optimizing power output. |

| Piston | Crucial for converting combustion energy into mechanical movement. |

| Oil Pump | Ensures adequate lubrication throughout the engine, preventing wear. |

| Fuel Injector | Delivers fuel into the combustion chamber for efficient burning. |

Importance of Quality Substitutes

Choosing high-quality replacements can make a significant difference in engine performance and durability. Investing in reliable components is key to maintaining the ultimate efficiency of your machinery.

Where to Find M11 Diagrams

Locating detailed illustrations and schematics for heavy-duty engines can significantly enhance maintenance and repair efforts. These visual aids provide essential insights into component placement and assembly, ensuring optimal performance and longevity of the machinery.

Online Resources

The internet is a treasure trove of information, offering various platforms where enthusiasts and professionals alike can access comprehensive illustrations. Websites dedicated to engine repair, automotive forums, and manufacturer resources are excellent starting points. Utilizing search engines with specific queries can yield results that include user-uploaded manuals and guides.

Local Dealerships and Workshops

Another reliable source for obtaining schematic representations is local dealerships and repair shops. Many professionals maintain extensive libraries of technical documents, which can be invaluable for troubleshooting and repairs. Establishing connections with experienced technicians may also lead to personalized advice and recommendations.

In summary, whether through online platforms or local industry contacts, there are multiple avenues to acquire the necessary schematics for effective engine management and maintenance.

OEM vs. Aftermarket Parts Explained

When it comes to vehicle maintenance and repairs, the choice between original components and alternatives can significantly impact performance and longevity. Understanding the distinctions between these options is essential for making informed decisions that affect both functionality and budget.

Original equipment manufacturers (OEM) produce components that are identical to those used during the initial assembly of the vehicle. These items typically ensure compatibility and reliability, often backed by warranties. On the other hand, alternative options, often referred to as aftermarket items, may offer varying levels of quality and performance. They can be more affordable and sometimes provide enhancements that the original versions do not.

Ultimately, the decision hinges on factors such as cost, quality, and intended use. While OEM components may provide peace of mind, aftermarket choices can offer opportunities for savings and customization. Evaluating these aspects will help in selecting the best solution for specific needs.

Tips for Using Parts Diagrams

Understanding and utilizing visual schematics can greatly enhance your ability to identify and source necessary components for machinery maintenance or repair. These illustrations serve as valuable references, providing clarity on the various elements and their relationships within a system.

1. Familiarize Yourself with the Layout

Before diving into the specifics, take time to comprehend the overall layout of the illustration. Recognizing how different sections are organized will make it easier to locate the components you need.

2. Use Legends and Annotations

Many schematics include legends or annotations that explain symbols and numbering. Pay close attention to these details, as they can help you understand the specific roles of different items.

3. Cross-Reference with Technical Manuals

For a more comprehensive understanding, cross-reference the visual representation with technical manuals. This can provide additional context and specifications for each component.

4. Highlight Key Components

As you analyze the illustration, consider highlighting or marking key components. This will aid in quickly identifying crucial parts when you refer back to the schematic in the future.

5. Keep It Accessible

Store your schematics in an easily accessible location, whether digital or physical. Having them on hand will facilitate quicker troubleshooting and maintenance efforts.

6. Consult with Experts

If you encounter confusion or ambiguity in the illustrations, don’t hesitate to reach out to professionals or forums. Engaging with others can provide insights and clarify any uncertainties you may have.

Assembly and Disassembly Guidelines

This section provides essential protocols for the careful assembly and disassembly of engine components, ensuring optimal performance and longevity. Adhering to these guidelines minimizes the risk of damage and enhances efficiency during maintenance procedures.

Before beginning the process, ensure you have the necessary tools and materials ready:

- Protective gear

- Torque wrench

- Gaskets and seals

- Cleaning solvents

Follow these steps for disassembly:

- Disconnect all power sources.

- Carefully label and remove components in the reverse order of assembly.

- Inspect each part for wear or damage.

For assembly, proceed with the following:

- Clean all components thoroughly.

- Apply lubrication where necessary.

- Follow the manufacturer’s specifications for torque settings.

- Double-check the alignment of each component before finalizing.

By following these guidelines, you can achieve the ultimate success in maintaining engine efficiency.

Cost Considerations for M11 Parts

When assessing the financial aspects of acquiring components for heavy-duty engines, it is essential to evaluate various factors that influence overall expenses. These considerations extend beyond the initial purchase price, incorporating maintenance, durability, and performance metrics. Understanding these elements can lead to informed decisions that enhance both efficiency and longevity.

Replacement components can vary significantly in price, often reflecting the brand’s reputation, quality, and warranty offerings. Investing in higher-quality items may result in lower maintenance costs over time, whereas opting for cheaper alternatives can lead to increased expenditures due to frequent failures. Therefore, it is crucial to analyze the long-term implications of each option.

Additionally, sourcing availability plays a critical role in pricing. Components readily available from multiple suppliers typically offer competitive rates, while those less common may command a premium. Establishing relationships with reliable vendors can provide access to better deals and ensure timely availability, thus reducing downtime.

Lastly, consider the overall value proposition when selecting engine components. The cheapest option may not always provide the best return on investment, especially when factoring in potential repairs and inefficiencies. A thorough evaluation of all financial aspects can guide you toward m

Resources for Cummins M11 Owners

Maintaining a robust engine requires access to reliable information and quality components. This section provides valuable resources for individuals who seek to enhance their understanding and care for their machinery.

Online Communities

Joining online forums and social media groups can offer invaluable insights from fellow enthusiasts and professionals. These platforms allow owners to share experiences, troubleshoot issues, and recommend trusted suppliers.

Repair Manuals

Comprehensive manuals are essential for anyone looking to perform maintenance or repairs. They typically include detailed instructions, specifications, and troubleshooting tips.

| Resource Type | Example | Link |

|---|---|---|

| Online Forums | Engine Forum | engineforum.com |

| Repair Manuals | Service Guide | serviceguides.com |

| Parts Suppliers | Quality Components | partsupplier.com |